Cylinders are universal equipment for storing and transporting gaseous substances for domestic and industrial purposes. The shut-off valves in them do not last forever, so over time the valve on the gas cylinder needs to be replaced. You can do it yourself, following a number of safety rules.

We will tell you how to choose the right valve for equipping a gas cylinder. For independent craftsmen, we provide detailed instructions on how to change a worn-out device. Here you will learn what safety measures must be observed when installing a shut-off device on a gas tank.

Components of a gas cylinder

Requirements for production processes and technical characteristics of gas cylinders are regulated by rather old GOSTs 949-73 and 15860-84.

The maximum operating pressure in the devices ranges from 1.6 MPa to 19.6 MPa, and the wall thickness can vary from 1.5 to 8.9 mm.

A standard gas cylinder assembly consists of the following elements:

- Cylinder body.

- Valve with shut-off valves.

- Valve closing cap.

- Backing rings for fixation and transportation.

- Support shoe.

An important element of the cylinder is also the technical information stamped on it.

The bottom of the cylinders is shaped like a hemisphere for uniform distribution of internal pressure. For better stability of the body, a shoe is welded on the outside, on the lower edges of which there are often holes for attaching the cylinder to horizontal surfaces.

You will learn about the types of gas cylinders and the features of their markings in this article, which we recommend viewing and reading.

VALVE DESIGN

In the standard version, propane gas cylinders with a volume of up to 27 liters are equipped with KB-2 valves or VB-2 valves. The second option is considered more reliable. The gearbox is connected to the valve using a fitting thread and a union nut. The degree of tightness of the connection is adjusted with an open-end wrench. A disposable gasket is installed for sealing.

The connections to the valve are not always tight and often lead to gas leaks.

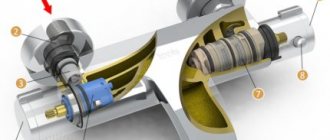

Structurally, the valve consists of the following elements:

- steel body in the form of a tee with thread;

- locking part;

- flywheel;

- seals.

The type of valve must match the characteristics of the contents of the container and the cylinder itself.

The color of the cylinder indicates what kind of gas is there:

- red color – propane-butane;

- black – nitrogen;

- blue color – oxygen;

- green – hydrogen;

- white color – acetylene.

Types and design of valves

The threads of valves for gas cylinders are standardized, but they themselves can have a variety of designs. The choice of valve model is influenced by the type of chemical substance being stored, production features of operation and the amount of money.

Before purchasing new equipment, you should familiarize yourself with the design options and the internal structure of the valves.

Classification of shut-off valves for cylinders

The design features of gas cylinder valves are determined not by the whims of engineers, but by safety considerations.

Depending on the material used, shut-off valves are divided into brass and steel . The choice of metal for the manufacture of the valve body is determined by the type of gases contained in the cylinder.

There are the following types of shut-off valves, depending on the type of chemicals stored:

- Acetylene. The body of such cylinders is painted white. Special valves are used in cylinders containing acetylene, chlorine, ammonia and other aggressive substances.

- Oxygen . The cylinders are painted blue and are intended for storing oxygen, argon, hydrogen, nitrogen, carbon dioxide and other inert gases.

- Propane-butane . They are painted red and are intended for storing substances corresponding to the name and other gaseous hydrocarbons. The most common valve type model for such a cylinder is VB-2.

Valves for acetylene cylinders are not made of brass because the substances they contain may react chemically with copper. Typically, carbon or alloy steel is used to manufacture shut-off valves of this type.

Gas valve device

A standard gas valve has the form of a tee, each fitting of which has an external thread. More advanced models may have an additional protrusion - a safety valve. Its purpose is to relieve excess pressure in the event of a full cylinder heating up or in case of incorrect filling.

The lower fitting of the valve is used to connect to the gas cylinder, the upper one is used to attach the flywheel, and the side one is used to connect communications for gas outlet and injection. The arrangement of the gas cylinder tap is quite simple.

Shut-off valves usually consist of the following general elements:

- Brass or steel body.

- A stuffing box valve or flywheel connected to the body with a union nut.

- Internal locking mechanism with valve and stem.

- Sealing gaskets.

- Plug for the outlet.

You can examine in detail the design of valves on gas cylinders of each type in the presented images.

Worn valves can leak small amounts of gas, which can lead to unpredictable consequences in enclosed spaces. To prevent such situations, a plug is used on the side fitting, which serves for additional sealing of the cylinder during transportation and long-term storage.

The direction of the threads on the outlet holes depends on the chemicals contained in the cylinders: the right is used for non-flammable gases (oxygen, nitrogen, argon, etc.), and the left is used for flammable gases (hydrogen, acetylene, propane, etc.)

The principle of operation of the assembled gas valve is unremarkable. To supply gas and shut it off, simply slowly turn the flywheel in the appropriate direction.

Indications for replacement

In order to send the cylinder in time for repair work and performance testing, perform an external inspection and pay attention to the following:

- Is the shut-off valve flywheel spinning?

- on the body and valve of the cylinder, whether mechanical deformation is visible in the form of abrasions, cracks and traces of corrosion damage;

- validity of technical inspection data;

- feeling the smell of the gas-air environment next to the cylinder;

- skewed or damaged shoe at the base;

- absence of a plug on the fitting.

Before replacing the valve of a gas cylinder with your own hands, the user needs to be able to not only externally determine the malfunction of the cylinders, but also identify counterfeit products. All cylinders that are permitted for use in Russia must be produced in a certified production facility and comply with GOST requirements. This can be easily determined by examining a metal plate on which the main text is located on 2/3 of its area, and all letters must be the same height, equal to 6 mm.

Data on the cylinder:

- Permissible pressure in MPa;

- test pressure in MPa; volume in liters;

- factory number;

- date of issue “MM.YY.AA”, where M is the month, G is the year of manufacture, A is the year of the next inspection;

- empty tank weight in kg;

- mass of container with gas in kg;

- the next check is in the “R-AA” format, where “R” is the stamp of the state verifier, A is the year of validity of the certification.

To replace the valve you need a gas wrench

Mandatory Precautions

Before replacing the gas cylinder valve, precautions must be taken. Work must be carried out in such a way as to protect people from potential hazards and keep the equipment in working condition.

The following precautions are used when preparing to replace a gas valve:

- The remaining contents of the cylinder can only be vented in an open space. An exception can be made only for nitrogen, air and argon.

- The work area should be well ventilated, although it is advisable to carry out work outside.

- There should only be one closed gas cylinder within the workplace.

- The flywheel must be unscrewed slowly to prevent electrification.

- You can begin replacing the valve only after the pressure in the cylinder and outside has been completely equalized.

When screwing the valve into the cylinder, fum tape or special lubricants are used, which provide increased tightness and strength of the connection. When replacing a faucet, such seals greatly complicate the process of dismantling it. To solve this problem, you can heat the valve with a hairdryer.

You can heat the shut-off valves only after bleeding the gas from the cylinder and closing the tap. In this case, the procedure is safe and will not lead to unpredictable situations.

An alternative to a hairdryer is to wrap a cloth around the valve and then pour boiling water over it. With this heating method, any suitable plug should be screwed onto the outlet fitting to prevent water from entering there.

After taking all precautions and warming up the shut-off valves, you can begin to unscrew the valve, which can be a difficult task at home.

If, in addition to replacing the cylinder shut-off device, you also need to replace the valve installed on the gas pipeline, we advise you to study the procedure and rules for performing this work.

Safety rules when working with valves

If you have never worked on unscrewing a tap, then it would be a good idea to familiarize yourself with the safety rules before starting such work.

The operation of the valve is regulated by documents such as PB 12-368-00 “Safety Rules in the Gas Industry”, Resolution No. 91 of June 11, 2003 “Rules for the Construction and Safe Operation of Pressure Vessels” and GOST 12.2.008-75.

Disassembly, repair and replacement of the valve should only be carried out by persons authorized to repair gas equipment. Repairing a device under pressure is strictly prohibited. Therefore, if you notice that the valve is leaking or faulty, then the right decision would be to contact a gas service representative, rather than carry out repairs at your own peril and risk.

If you want to disassemble an old cylinder in order to make a useful homemade product from it, such as a potbelly stove, smokehouse or gas grill, then it is worth remembering that these actions cannot be called safe. And you will have to bear the consequences.

Home craftsmen are rich in ideas for constructing interesting and functional homemade products from old gas cylinders. Thus, a home grill will become not only a useful device, but also a very stylish addition to the interior of the gazebo.

All actions to unwind the cylinder should be carried out outdoors or in a well-ventilated garage or other room. But this is strictly forbidden to do in an apartment - such an experience could end in an explosion.

Next, let's look at the basic safety rules that are important to follow:

- To release the remaining gas, you should smoothly and slowly unscrew the valve flywheel.

- Do not disassemble or cut a pressure cylinder under any circumstances.

- There should be no other cylinders near the vessel being disassembled.

If you are just about to unscrew the valve and have not had time to do anything yet, and the smell of gas is clearly audible in the garage where the cylinder was located, you should ensure that this room is ventilated as much as possible. Why open the gates, windows, doors (if any), and immediately leave.

Guide to unscrewing the valve

An additional supply of tightness is never superfluous, but when replacing shut-off valves on a gas cylinder, the strength of its fastening can become a big problem. The difficulty lies in fixing the cylinder body so that it does not rotate when the valve is unscrewed with a key.

It is with this problem in mind that further step-by-step actions for replacing shut-off valves will be considered. There are many ways to secure the body of a gas cylinder; let’s look at some of them.

Method 1: Attaching the limit bar

You will need the following tools and materials: a pipe wrench, two bolts at least 20 mm long with two nuts and a metal corner profile at least a meter long. Instead of a corner, you can use any other product in which you don’t mind drilling two small holes.

Next, you need to measure the distance between the two nearest holes on the cylinder shoe and drill the corresponding holes from one edge of the metal profile. After this, screw the iron bar to the cylinder body using bolts and lay it on its side. This design will not allow the cylinder to rotate.

Then you need to place your foot on the metal profile, and using your hand, using a key, carefully unscrew the valve.

Step-by-step photo instructions for the process are presented below.

Method 2: welding the cylinder to a metal base

This method is quite dangerous and should only be used by a professional welder with extreme caution. The shoe is grabbed in two places so that after unscrewing the valve, you can easily tear the cylinder off the base.

After welding the body, the fittings are carefully unscrewed using a pipe wrench. Then the internal thread of the cylinder should be cleaned of any remaining sealant.

Methods for fixing a gas cylinder are not limited to the described options. Many alternative methods can be used to secure it. Liquid water condensation sometimes accumulates at the bottom of the container, so after removing the valve, be sure to turn the container over so that water can flow out of it.

INDEPENDENT REPLACEMENT OF FITTINGS

According to the rules of safe operation, independent installation of valves on gas cylinders is strictly prohibited. If the situation is hopeless, you can very carefully try to replace the device yourself. Technically, the work itself is not difficult, but breaking the seal of the cylinder is always fraught with risk.

To begin with, it is worth considering the process of replacing the valve by a technician at a specialized enterprise. Removal of the fittings is carried out using a cylinder valve wrench. A dynamic key is used for installation. The tightening force should not exceed 250 N for brass fittings and 480 N for steel fittings. Before delivery of the gas cylinder, the threads are sealed with paint.

In handicraft conditions, you can try to remove and install the valve manually. To increase the tightness, use FUM tape.

The replacement process will look like this:

- the cylinder is completely emptied of gas away from residential premises;

- carefully unscrew the valve;

- smoothly remove the device without damaging the case;

- gas condensate is poured out;

- install a new valve;

- check the tightness of the device.

Important information for consumers! The valve on the cylinder should only be changed by specialists. There is an unspoken ban on such activities by non-professionals. However, there are times when there is simply no other option but to do the job yourself. This video shows how to unscrew the valve (valve) on a cylinder using improvised means in a country house or garage.

Gas cylinders are a universal device designed for storing and transporting liquefied gas for domestic and industrial purposes. They are very reliable and can last a long time, even longer than the stated service life. The most common failure in them is a malfunction of the shut-off valves, so users of liquefied gas need to know the basic requirements and rules for replacing the valve on a gas cylinder (GB). It is necessary to make a reservation right away that any work on repairing a gas cylinder is carried out by personnel of specialized organizations that have been trained, certified and have permission to carry out work, therefore the information below is presented for informational purposes only.

Screwing in new shut-off valves

Before tightening the valve, all connected parts must be degreased to prevent clogging of the locking mechanism. To do this, you can use a cloth with regular detergent or moistened with white alcohol. After this, rinse the surfaces with plain water and allow them to dry.

A new valve is never screwed to a cylinder with bare threads. It is imperative to use a sealant: special thread compound or fluoroplastic fum tape. They are applied to the lower fitting and only after that the valve is tightened.

The thickness of the gas fum tape is greater than sanitary tape and is 0.1 - 0.25 mm, and its reel should be yellow. The tape is wound with tension in 3-4 layers. It is better to twist it once again when it breaks than to make the seal loose.

It is advisable to tighten the valve with a torque wrench. Steel shut-off valves are screwed with a maximum force of 480 Nm, and brass valves - 250 Nm. After clamping the valve, you can proceed to subsequent steps to test the tightness of the resulting connection.

Conclusion

As you can see, composite cylinders do not require any special conditions either during storage or during operation. And service maintenance comes down to periodic checks once every decade. Whereas, with intended use and compliance with the manufacturer’s recommendations, their service life is practically unlimited, even if passed on by inheritance.

More answers from a specialist on composite gas cylinders can be found in the previous thematic material. You can ask your question and receive a real-time answer from the manufacturer in the profile thread on the forum. The video includes a review of electric, charcoal and gas grills, as well as a test drive in difficult weather conditions.

Subscribe to our Telegram channelExclusive posts every week

Checking tightness and completing work

When checking the tightness of the valve connection, you will need to pump gas under pressure into the gas cylinder.

This can be done in two ways:

- Pump gas using compressor equipment or a car pump.

- Connect two cylinders with a hose, the first of which is empty (tested), and the second is filled with gas.

First, under the control of a pressure gauge, you need to fill the test cylinder with gas with a pressure of 1.5-2 atmospheres. After this, soap foam is applied to the connection and the tap is opened slightly.

If soap bubbles are not inflated anywhere, then the connection is sealed. But if even slight swelling of foam appears, you will have to re-tighten the valve.

If the cylinder is small, then you can immerse its valve in a small bowl of water and see for bubbles.

After replacing the shut-off valves, the corresponding mark must be placed in the gas cylinder passport.

It should be remembered that the methods described above for replacing a used valve are applicable only to metal tanks. If you have a composite gas storage cylinder, you cannot act this way because of the possibility of damaging the flask and breaking its seal.

Safety precautions

Even if you are sure that the cylinder is empty, there may be residual liquefied gas at the bottom. Therefore, in order not to take risks, you need to get rid of it. To do this, leave the structure open for 12 hours. In this case, it is necessary to make sure that there are no sources of ignition nearby.

After this time, it is necessary to rinse the inside of the cylinder with clean water, which will remove any remaining gas. In addition, it is allowed to use lime with water or chlorine to clean the structure. True, after such manipulations an unpleasant odor may remain, which quickly disappears.

Conclusions and useful video on the topic

The presented video materials allow you to see with your own eyes all the details and difficulties when replacing valves on gas cylinders.

Video #1. Unscrewing the valve from the gas cylinder:

Video #2. Screwing in a new valve with an original method of fixing a gas cylinder:

Video #3. How to replace the valve on a gas cylinder:

When performing work to replace a gas valve, you need to take your time and think about each subsequent action and its consequences.

Even if all precautions are taken, the described manipulations with gas equipment are quite dangerous for a beginner. It is best to entrust this work to professionals who will carry it out at a specialized stand.

If you have any questions while reading the article, you can ask them in the block below. Here you can leave comments and share useful information. Please comment on the material, we are interested in your opinion.

It is unlikely that at least one modern person can imagine his life without a stove. But there are situations when gasification of a home is impractical or impossible. The reasons are different, but the result is the same: people have to use liquefied propane in cylinders. When equipping a point yourself, many questions may arise, from choosing a location for the device to connecting to an energy source. Mistakes and errors made during the installation and connection of the gas stove to the cylinder can lead to irreversible tragic consequences.

p, blockquote 2,0,0,0,0 –>

p, blockquote 3,0,0,0,0 –>

Important! Gas equipment that will be used for cooking must be in good condition.

How to identify a defective or faulty product

Modern certified cylinder manufacturers produce effective designs that meet GOST requirements. If you have a counterfeit product in front of you, it is very easy to identify. You just need to know the basic standards.

The main text on the label should occupy 2/3 of its area. Moreover, all letters must be the same height, equal to 6 cm. The inscription must contain information about the weight of the empty and capacity of the full cylinder, the date of production and technical inspection, the manufacturer’s trademark, as well as other information must be indicated.

The following facts indicate a malfunction of the cylinder:

- The flywheel on the valve itself does not rotate

- Mechanical deformations are visible to the naked eye on the surface of the container or valve: scratches, abrasions, cracks, dents, traces of corrosion.

- the inscription on the label states that the technical inspection date was overdue;

- there is a smell of gas in the air;

- the cylinder shoe is installed incorrectly or damaged;

- the fitting does not have a plug.

Important information for consumers. The pressure in the cylinder must always remain! The container must not be completely emptied!

Materials and tools required for work

When connecting a gas cylinder to the stove you will need:

- 2 clamps;

- a fitting with a spout to attach a hose and internal thread (must be included with the gas appliance);

- the stove is new or old, but in good condition;

- reducer with inlet pressure 30 mbar;

- gas cylinder made of metal-composite, polymer-composite or other special materials with a capacity of 5–50 liters;

- rubber or rubber-polymer connecting hose, which can maintain room temperature and does not heat above 30 degrees;

- sealing tape;

- special gas key.

Where to buy a propane tank

Our company provides you with the opportunity to buy propane at a competitive price.

Our region has a wide network of certified companies selling and refilling cylinders. The most common are tanks with a capacity of 27 and 50 liters, but upon pre-order, you will be supplied with products of 5 or 12 liters in the shortest possible time.

When refueling, of course, it’s faster to exchange your cylinder for an already filled one. However, many people prefer to wait a little to get theirs back. After all, it definitely does not allow gas to pass through and passed the necessary tests on time. The operator himself ensures that the amount of liquid propane does not exceed 85% of the geometric capacity of the vessel. This is necessary so that when heated, the internal pressure does not exceed the permissible threshold. If there are residual contents at the bottom (so-called condensate), the refiller must drain it into a special container.

Gas is a high-quality and inexpensive source of energy that people have been using for a very long time. There are several types of such substances that can be used either separately or in mixed form.

One of the ways to use gas is to refill household cylinders, which can be connected to the stove. You can learn more about such products on the website https://safegas.com.ua/.

Jets for bottled gas

One important point must be taken into account: the stoves, originally designed to operate on mains natural gas, have jets (nozzles) that are not suitable for operation on bottled propane.

p, blockquote 8,0,0,0,0 –>

The jet is like a bolt with a hole in the top through which fuel flows to the burner. Bottled gas injectors have a smaller hole diameter because the pressure of liquefied propane is higher than that of natural fuel. Consequently, to connect such a stove to a liquefied gas cylinder, you will need to purchase and replace the entire set of nozzles.

p, blockquote 9,0,0,0,0 –>

A new set will cost an average of 200 rubles. (the cost depends on the brand of the stove), it can be bought at a gas equipment spare parts store or ordered from the manufacturer.

p, blockquote 10,0,0,0,0 –>

p, blockquote 11,0,0,0,0 –>

If the jets need to be replaced, do the following:

- The burners and the burner table cover are removed.

- Using a hex wrench, the old injectors are removed and the new ones are screwed in.

p, blockquote 12,0,0,0,0 –>

You can understand all the nuances of the process of replacing jets by watching the video.

p, blockquote 13,1,0,0,0 –>

p, blockquote 14,0,0,0,0 –>

Independent work

What to do if the gas cylinder is leaking gas? The following manipulations will be required (only suitable for VK-94 models).

Take a 2.7 cm wrench. Tighten the nut (marked in the image). The motion vector is clockwise (CW).

When the flywheel opens and the valve of the propane tank is released, unscrew the flywheel in the opposite direction to the very limit.

If these options do not produce an effect, then you must:

- Unscrew the nut located under the flywheel. The movement is against the emergency. It is then removed from the tank.

- Using a wrench, unscrew the nut at the top of the flywheel by 1 cm.

- The rod is removed from it. There is a sealing gasket there.

If the tank has been in use for a long time, it will be worn out. It needs to be replaced. PTFE is good for these purposes.

It should have two holes:

- internal - maximum 8.5 mm.

- external – identical to the internal parameter of the nut (diameter).

After installing a new product, the rod should be placed very tightly. He will need to be hammered. You can do this with a hammer or the flat side of a key. After which the flywheel returns to its position and is screwed with a nut. It should not be screwed all the way. There is no need to clamp the spring here. It should be taut. Otherwise, the flywheel will not rotate.

Such measures often become a solution to a dilemma - what to do if a gas cylinder leaks? It is important at the end of the operation to put the assembly back on the cylinder and screw it with a nut. Vector - according to emergencies. You need a 2.7 cm key. Force: 5-7 kg. Don't screw it all the way.

If you have a VKB faucet, you cannot disassemble it yourself. If there is still gas in the container and even a small percentage of residual pressure, opening the nut is life-threatening! After all, only it holds back the pressure in this unit. It can only be repaired in a devastated state.

There is a small hole at the back of this valve. If the diaphragms are breached, gas escapes.

When there is no such leakage when installing the gearbox and the valve is open, it means that the valve has no problems.

The VKB modification is usually mounted on a helium tank. For other gases use VK-94.

Features of equipment selection

Several recommendations for choosing gas equipment:

- Plate. If you are using an old unit, before connecting it is necessary to check that the fastenings and burners are not damaged and are working.

- Gas reducer. The main part when connecting bottled gas. It regulates the propane pressure at the outlet and lowers it to the required level. Must be equipped with threaded connections with brass nuts. For a cylinder with a valve, model RDSG 1-1.2 is used, for a container with a valve RDSG 2-1.2 is suitable.

p, blockquote 16,0,0,0,0 –>

- Hose for connecting the plate and cylinder. Purchased at specialized sales points, it must be intended specifically for gas. Its length must exceed the distance between the connected equipment by 150 cm, since it is prohibited to use it in a tense state.

p, blockquote 17,0,0,0,0 –>

Important! Do not use old hoses, as the integrity of their internal surface may be damaged.

The following details should alert you when purchasing a cylinder

- Valve malfunction - the flywheel does not turn or there are other problems;

- Corrosion, dents or other damage on the body of the cylinder and valve part;

- The inspection date has expired;

- You can feel the gas in the air;

- A crooked or damaged cylinder shoe;

- There is no plug on the fitting.

Important! Under no circumstances should the contents of the gas cylinder be completely used. During cessation of operation, the residual pressure inside should remain at 0.5 kgf/cm2.

Choosing a place to install the cylinder

Before connecting the gas stove to the cylinder, you need to choose the place where the devices will be installed, since the distance between them must be at least 100 cm. Safety instructions require that there be a window in the room with connected gas equipment.

p, blockquote 19,0,0,1,0 –>

When using a shielded cylinder, the distance between it and the stove can be reduced to 50 cm.

- If the gas container will be in the same room as the kitchen appliance, it is advisable to place it in a metal cabinet or make a wooden mount.

- The cylinder may be located in the pantry located behind the kitchen wall. In this case, you will need to make a hole for the hose.

- The best option in terms of safety is to install the cylinder in a special metal box located outside and locked with a padlock.

p, blockquote 20,0,0,0,0 –>

p, blockquote 21,0,0,0,0 –>

Important! You can place a cylinder in an apartment only if the building has no more than 2 floors.

Cabinet design

Install cabinets on the shady side of a residential building. There are several requirements for them in accordance with the laws of the Russian Federation:

- All elements are made of non-combustible material;

- The cabinet must have a locking device;

- Openings for ventilation of the internal space are required;

- There should be a warning on the door: “Flammable.” Gas".

The non-flammable materials used in the production of storage facilities do not smolder or burn and serve as protection from fire. Locks prevent unauthorized access to cylinders.