A three-way tap (tee) is a special device that regulates the temperature of the water flow. It is used to redistribute the hot flow in the heating system. With its help, the operation of the entire mechanism is optimized, and water hammer is prevented and prevented.

Tee is applied:

- in hot water supply systems;

- in heating circuits;

- in water supply systems.

As a rule, a device of this type is used for heating structures with several units and circuits in order to stabilize the temperature in all radiators. The use of such a product allows you to control the flow of hot water, distribute it to different areas (for example, a house, summer kitchen, garage) and regulate the temperature of each radiator located in any room.

What is it and what is it for?

A three-way valve is a “tee” with a locking mechanism. His task:

- Mix flows of different media transported through a pipeline - coolant in a heating circuit, water in a hot water supply system, gases or other substances in industrial lines, etc. To simplify, such three-way taps can be compared to typical kitchen faucets, with the only difference being that they remove the mixed medium not into the usual sink, but into one of the main branches.

- Divide the flow of the transported medium and divert it along different circuits.

Hence the fundamental division of three-way valves into mixing and separating.

Purpose and scope of three-way valves

The main task of a three-way valve is mixing or separating main flows. But where might these functions be needed and, most importantly, why?

- The thermostatic mixer is an important part of a modern and, most importantly, energy-efficient heating system. Its installation on the supply circuit and simultaneous connection to the return circuit allows you to regulate the degree of heating of the coolant. This prevents the batteries from overheating, ensuring a comfortable room temperature. That is, the “tee” is a kind of thermal power regulator.

- Three-way taps are indispensable in underfloor heating systems, where the heating temperature of the coolant is strictly regulated. In addition, they are used in complex heating circuits, where their installation makes it possible to stabilize the heating temperature in all radiators in the network.

- Also, “tees” are installed in hot water supply systems equipped with a boiler.

- Three-way valves are a mandatory safety element for gas pipelines and fountain systems, equipped with a pressure gauge, in front of which they are, in fact, installed.

Three-way mixers are widely used in the industrial and agricultural sectors. They are used to equip a variety of equipment, from the familiar washing machines and cars to complex engineering systems in ships and locomotives.

Three-way taps are also used in medicine. They are used to equip infusion lines - a necessary part of complex medical equipment.

Technical and operational characteristics of three-way valves

Key technical parameters of three-way valves:

- The standard size, or more precisely, the nominal diameter of the pipes.

- Throughput directly related to the cross-sectional size of the pipes.

- Operating pressure.

- Maximum permissible temperature.

- Tightness class.

- Service life, which determines the estimated number of revolutions (cycles).

- Type of main connection - threaded, flanged, union-end, coupling, pin or welded.

All these characteristics for shut-off valves are strictly regulated by GOST standards. The difference between them depends on the model of the product and the materials from which it is made.

How many positions does a three-way valve have?

The number of operating positions of three-way valves is determined by the shape of the channel in the valve and its purpose. The diagram is shown in the photo below:

- Three-way T-shaped mixers have 4 operating positions.

- Three-way L-shaped valves with a rotation angle of 90 or 180° have only 2 operating positions.

- “Tees” working in tandem with a pressure gauge, regardless of the shape of the channel in the valve, operate in 4 positions. The fifth is considered a neutral (non-working) mode.

On a note! Three-way valves are not designed to completely shut off flow in all directions. They only redirect the transported medium from one branch to another or mix them, temporarily blocking one of the pipes.

What materials are three-way valves made of?

The strength of shut-off valves and its operational capabilities are determined by the material from which it is made.

For the body, stem and shut-off element of three-way valves, the following is most often used:

- Plumbing brass. The excellent characteristics and relatively light weight of such models explain why they are most often found in domestic heating and water supply systems. For additional protection, parts can be plated with nickel or chrome.

- Bronze. Bronze products are also of excellent quality, but due to their cost they are less in demand.

- Carbon steel. In fact, it is a cheaper analogue of brass. However, the choice of shut-off valves made of carbon steel should be approached responsibly, because low-quality alloys significantly reduce the service life of the locking mechanism.

- Cast iron. Such “tees” are used only in utility systems and on industrial highways. Having good anti-corrosion properties, cast iron products wear out extremely quickly, and their high weight significantly reduces demand.

In the agro-industrial complex and in medicine, three-way valves made of polymers are often used.

The locking element of some models can be made of ceramic. It is reliable and wear-resistant. However, ceramics are extremely sensitive to the composition of the transported medium. If the media is not clean enough, such a mechanism will very quickly fail. Therefore, three-way valves with a ceramic cartridge are most often installed in water supply systems or heating circuits running on purified antifreeze.

The sealing parts of the “tee” (gaskets, oil seal, seat rings) can be made of Teflon. Its use increases the operating temperature of a three-way mixer to 150 °C. The rings can also be coated with fluoroplastic.

Classification by type of mechanism control

The three-way valve is controlled either manually or electronically. In the latter case, additional equipment is used - sensors or thermostats.

| Manual control mode | A cheap device that looks like a standard ball valve. Mixes the flows in approximately equal proportions. The main disadvantage is the unevenness and duration of heating of heating batteries remote from the boiler. |

| Automation | Allows you to regulate the heating of the coolant automatically and does not require human intervention. It is characterized by a more effective action and ensures uniform heating of all areas. Control is carried out via a servo drive, pneumatic or hydrodynamic thermostat. |

Design and principle of operation of a three-way valve

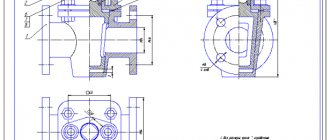

The design of a three-way mixer includes the following elements:

- Sealed housing with three T-shaped pipes.

- Valve with internal T- or L-shaped channels. Most often, the bolt mechanism has the shape of a ball, less often a cone or cylinder.

- Stuffing box.

- A rod that transmits movement to the bolt mechanism.

- Control unit - handle (butterfly or lever) or drive.

The operating principle of a three-way valve is based on the rotation of the valve inside the body. An L- or T-shaped stroke drilled into the valve serves to pass flows. By turning, the shutter either opens all the holes in the pipes or closes one of them.

Let's consider the principle of its operation using the example of a heating circuit. A three-way valve is installed in the circuit so that one of its pipes is connected to the pipeline coming from the boiler.

The pipe located in the middle is connected through a bypass connection to the “return”, where the coolant has a lower temperature. The third pipe connects to the pipeline going to the radiators.

On a note! The installation diagram is indicated by the manufacturer in the form of markings on the “tee” itself.

The shutter position is set by turning the handle:

- In the first position, transported flows are mixed, simultaneously coming from the circuit supplied from the heat generator and from the “return” circuit.

- In the second position, only hot coolant from the boiler is supplied to the heating circuit.

- In the third position, the flow of hot coolant is blocked, only cooled water from the return circuit is supplied to the system.

Diagram of operation of a valve with a seat mechanism:

With fifth wheel actuator

The cone (3) fixed to the rod (4) overlaps the seat (5).

Valves differing in their actuators can be of two types: separating and mixing.

The mixing valve (SV) has two inputs for one output. The main application is for heated floors. Different temperature streams arrive at the inputs, which, when mixed, equalize the temperature to the specified level.

A separating valve (VV) has the opposite situation: there are two outputs per inlet. The flow is divided by the valve into two different directions.

The differences are related to the number of balls: one in the SK, two in the RK. They are built into the outlet pipes. There are as many outputs as there are ball valves. The movement of water is indicated by arrows.

SCs are used more in heating lines. Separating – for DHW. One divided stream will have a constant thermal regime (the quality of the liquid is important here), in the second stream the regime can change (only the quantity is important).

Adjusting the rod allows you to achieve the required temperature in a constant circuit. A variable circuit can completely overlap.

Pros and cons of three-way valves

| Advantages | Flaws |

| Compact and ergonomic | Limited functionality |

| Convenient controls. Soft smooth shutter movement when switching modes | |

| Possibility of use in polluted environments. An exception is three-way mixers with a ceramic shutter | Not intended for adjusting flow intensity and installing the shutter in intermediate positions |

| When installed in a heating circuit, they act as a thermostatic device, which allows optimizing the energy efficiency of the system | |

| High seal tightness | |

| Low level of hydraulic resistance | Rapid wear and frequent jamming when operating in adjustment mode |

| The “tee” design prevents accumulation and stagnation of the transported medium | |

| Simple, clear design and operating principle | |

| Ease of installation | Limited temperature: maximum 200 °C |

| Ease of use. Reduced requirements for regularity of performance checks | |

| Long service life |

Why do you need to make adjustments?

Setting the optimal temperature of the heating radiators allows you to create the most comfortable living conditions indoors. In addition, adjustment allows:

- Remove the effect of air in the batteries, allow the coolant to move freely through the pipeline of the heating system, effectively transferring its heat to the interior of the room.

- Reduce heat consumption costs by up to 25%.

- Do not keep windows constantly open if the air in the room is excessively overheated.

It is advisable to set up heating and adjust batteries before the start of the heating season. This is necessary so that later you do not experience discomfort in the apartment and do not adjust the heating temperature of the batteries in emergency mode. Before setting up and adjusting the radiators, initially in the summer you need to thermally insulate all windows. In addition, you need to take into account the specific location of the apartment:

- In the middle or corner of the house.

- Lower or upper floor.

After analyzing the situation, it is advisable to use energy-saving technologies to maximize heat conservation inside the apartment:

- Insulate walls, corners, floors.

- Carry out hydro and thermal insulation of the seams between the concrete joints of the panel house.

Without this work, it will be useless to regulate the temperature of the radiators, since the lion's share of the heat will heat the street.

The difference between a three-way tap and a gate valve, valve and valve

The faucet, gate valve, valve and thermal valve belong to the class of shut-off and control valves. However, the shape of the bolt mechanism and the principle of operation are different. For greater clarity, I have summarized the comparative characteristics of the devices in a table:

| Tap | Valve | Gate valve | Valve | |

| Shutter function | + | + | + | + |

| Adjustment function | Not recommended | + | + | + |

| Gate shape | Ball, plug | Wedge | Disc, wedge | Books |

| The principle of movement of the bolt mechanism | Around its own axis | Parallel to the flow | Perpendicular to flow | Parallel to the flow |

| Control handle | Lever arm | Flywheel | Flywheel | Lever, flywheel |

| Possibility of installing an electric drive | + | + | + | + |

| Possibility of installing a thermostat | External only (for automatic models) | + | — | + |

| Compactness | + | — | — | + |

From the table data it is clear that the tap is less functional. However, this is precisely why it is more reliable and lasts much longer than its counterparts.

Types of three-way valves

Design features suggest dividing three-way mixers into several types:

| Options | Types of three-way valves |

| Bolt mechanism type | Ball, cork (cylindrical, conical) |

| Gate bore diameter | Full bore, reduced (the diameter of the channel in the shutter mechanism is somewhat narrowed) |

| Shape of the channel in the bolt mechanism | T-shaped, L-shaped |

| Control method | Manual (lever, butterfly), with electric drive, with pneumatic drive |

| Connection method | Threaded (coupling, fitting, pin), welded, flanged |

Using the drive in combination with a remote temperature sensor, controller or manual switch allows you to automate the control process. Pneumatically driven models are safer than their electric servo-driven counterparts.

Features of choice

To ensure maximum benefit from a three-way heating valve, it is necessary to select it correctly. To do this, you should follow some recommendations:

- The diameter of the tap must correspond to the diameter of the pipelines. In this case, the throughput of the circuit will not suffer, and installation will be carried out without the use of adapters;

- The connection type must match the existing one. For example, a fitting connection will not be compatible with the flange connectors of the faucet;

- It is necessary to decide in advance whether a servo drive will be mounted on the crane;

- Do not buy household three-way taps for systems with high coolant pressure. There are special fittings for such systems. The same restrictions are recommended to be observed if the diameter of the pipeline exceeds 4 cm.

Service life of three way valve

The period of trouble-free operation of the device is determined by:

- Design features.

- The material from which it is made.

- Compliance of its technical characteristics with real operating conditions.

Manufacturers give a guarantee of 5-7 years for steel “tees”, but with moderate intensity they can easily last 50 years. The service life of plastic models, as a rule, does not exceed 2 years.

How to choose a three-way valve

Before purchasing a three-way mixer, you need to resolve the following issues:

- Scope of use.

- Maximum heating temperature of the transported medium.

- The diameter of the pipe to which the “tee” will be connected. If a suitable size is not available, an adapter is installed first.

- System operating pressure.

- Control method. For “warm floors” it is better to take models with a drive.

The main technical characteristics of a three-way valve can be seen on the body.

Popular manufacturers of three-way valves

The modern range of shut-off valves can confuse the average person. But not all meet quality standards. Among those who have long established themselves in the plumbing market, I would highlight:

- German brand Danfoss.

- Swedish manufacturer ESBE.

- Austrian company HERZ.

- Russian-Italian brand Valtec.

Approximate prices for three-way valves

The cost of shut-off and control valves depends on:

- Dimensions

- The material from which it is made.

- Technical parameters.

Manually controlled devices are 2-3 times cheaper than electric and pneumatic ones.

Blitz tips

- Before starting the heating system, you need to check the serviceability and condition of the three-way valve and the entire heating system.

- The tap should not be installed on pipes with a diameter greater than 40 mm.

- In a hot environment, the tap must be opened very carefully to avoid failure of the hydraulic valve.

- It is important that the rod, together with the adjusting device or the rotation handle, extends towards free access to them.

- It is better to buy a faucet made of brass. It will last slightly longer than other materials.

- The best option is a crane with pneumatic control of operation.

- To avoid mistakes , consult a specialist first.

Rules for installing a three-way valve

- The installation site must be freely accessible.

- The “tee” is installed with the lever up or sideways (outward). The control lever should move freely in the desired direction.

- Markings in the form of arrows on the device body will tell you how to correctly connect it to the system. The arrows indicate in which direction the flow will move.

- If the quality of the coolant is low, it is advisable to install a filter in front of the three-way mixer.

- In the heating circuit, a “tee” is installed in front of the circulation pump.

- The threaded connection must be sealed with flax fiber and treated with a sealant.

- When connecting for welding, it is necessary to avoid the formation of scale inside the line.

Connection diagram of a three-way valve to the heating circuit

Connection diagram of a three-way faucet to a water supply system with a water heater

Simplified mixing elements with temperature lock

An autonomous three-way valve of a simplified type can be installed in simple heating systems of country houses, where heat is obtained from a TT boiler. To function, it does not require a thermal head with a temperature sensor, and there is no rod there.

The thermostatic element, which is installed inside the housing, is adjusted to a certain temperature of the coolant at the outlet, for example. 50 or 60 °C (must be marked on the body).

The mixing valve of this sample always maintains the set temperature of the coolant at the outlet; this setting does not change. This gives rise to positive and negative aspects when using such fittings:

- advantage - cheaper, unlike a unit with a thermal head. The difference is about 30%;

- disadvantage - there is no possibility of adjusting the heating of the exiting coolant. If the factory settings are set to 55°C, then it will constantly supply water at this temperature ±2°C;

- Before purchasing a valve of a simplified design, carefully study the documentation for the solid fuel boiler; it usually indicates the minimum return temperature.

A thermostatic three-way valve is a rather useful thing in the heating system of a private home, which makes it possible to efficiently use the heated liquid, and thereby save fuel. Moreover, this part allows you to increase the service life of solid fuel boilers, and also plays the role of a safety element. On the other hand, you should not sculpt the valve just anywhere; it is always better to consult with a specialist who is well versed in this.

Rules for operating a three-way valve

The “tee” installed in the system requires periodic inspection for wear and leaks. If a leak is detected, you can try tightening the threaded connection. If the leak cannot be eliminated, the mixer will have to be disassembled. Very often it is the O-rings that wear out. Replacing them and cleaning the elements from scale extends the life of the device.

To reduce the wear of the device, it must be periodically lubricated with a special plumbing product.

Common mistakes and problems when installing a three-way valve

Errors made when installing a “tee” not only shorten its service life, but also negatively affect the operation of the entire pipeline:

- Incorrect connection of pipes increases hydraulic resistance.

- The use of models with fluoroplastic seals in systems with operating temperatures above 150 °C will require replacing the three-way mixer after 2-3 months.

- Installation in a hard-to-reach location will complicate preventive maintenance procedures.

Expert advice

- During installation, the brass body is easily damaged. To prevent this, it is better to place a thick fabric gasket under the wrench.

- To install a three-way valve on plastic pipes, special adapters are needed.

- Instead of a “tee”, you can use 2 conventional two-way valves. They must work according to a reverse pattern: when one opens, the other closes.