Before you make a foundation from blocks for a private cottage, you need to take into account that the construction budget will hardly change compared to pouring into formwork, but the work time will be reduced by three times. The industrial method of producing FBS guarantees maximum design life.

A foundation can be made from FBS blocks only if there is lifting equipment (manipulator, crane). For a project with a basement, it is necessary to dig a pit; if the building does not have a basement, trenches around the perimeter are sufficient.

Advantages, disadvantages and features of the device

A shallow foundation is a not too deep foundation for a building. The average depth is about 0.2-0.5 m. The need to use this type of house foundation is due to the fact that construction is planned on heaving soils. The advantage of a shallow foundation is obvious, since with a buried foundation, the tangential heaving forces acting along the side surface of the reinforced concrete structure of the foundation for construction significantly exceed the load created by light houses. And in the case when a shallow foundation is used on heaving soils, this problem is eliminated.

In addition to everything, this version of the foundation for construction allows you to do the construction yourself. Firstly, when laying this type of foundation, it is enough to use half the amount of materials that would be needed if a buried foundation were being built. Secondly, a shallow foundation with your own hands does not require much effort to prepare a very deep trench, since sometimes you can get by with a depth of 20 cm.

However, there is also a drawback to this type of foundation for construction. So, the degree of soil heaving plays a role. In case of increased heaving, it is necessary to use reinforcing mesh, and weak heaving soils allow you to make do with a concrete base. There is also another variety - a shallow columnar foundation. Its use is quite limited due to the small loads it can withstand, which is explained by the small supporting area. And this parameter, in turn, characterizes the bearing capacity of the foundation for construction. But a shallow columnar foundation with your own hands is also much easier to create and much more economical.

If you do not have qualifications or basic skills in construction, you can choose an alternative option. Considering that for any foundation for construction it is necessary to prepare a concrete mixture, make formwork, and, if necessary, strengthen it with reinforcement, a lot of time and effort is required. But there is a simplified option - a shallow foundation made of FBS blocks (foundation building blocks).

What is this material? These are ready-made blocks, which will cost approximately the same amount as completing the foundation for construction completely independently. However, their strength is high enough to withstand even multi-story buildings. Therefore, a shallow foundation for a brick house can be made from such material.

Work quality control

| Parameter | Parameter value, cm | Control (method, volume, type of registration) |

| Deviation of the actual dimensions and position of on-site (and prefabricated) foundations and grillages from the design ones, see: | ±5 (±2) | Acceptance (measurements with theodolite, tape and ruler) |

| dimensions in terms of | +2; -0,5 | Same |

| protective layer thickness | (+1; -0,5) | Same |

| height position of the top (edge) of the foundation or grillage | ±2 (±1) | Same |

| plan positions relative to alignment axes | 2,5 (1) | Same |

| Note - The values given in the table in brackets refer to prefabricated foundations and grillages. |

Download series 2.110-1 “Details of foundations of residential buildings” issue 1 Download series 2.110-1 “Details of foundations of residential buildings” issue 4

How to calculate the amount of material

To find out the required amount of building material that is supposed to be used, it is necessary to calculate the depth of the foundation for the building. The main parameter that is taken into account is the depth of soil freezing. The calculation of a shallow foundation is also influenced by the degree of soil heaving, as well as the height of the groundwater.

For example, if the freezing level of slightly heaving soil is 1 m, a foundation depth for construction of 0.5 m will be sufficient. In addition to these parameters, the load level should also be taken into account. Thus, a shallow foundation for a frame house, due to its lightness, can be made with a shallower depth at the same level of soil freezing. Next you need to calculate the total volume of the concrete mixture. Why is the value of the perimeter of the future house and the length of all internal walls summed up? The volume of the trenches is then calculated.

To calculate the mass of the concrete mixture, you need to multiply the resulting figure by 2,500 kg/cubic meter. m. It is quite possible to calculate the amount of cement if you divide the volume of the concrete mixture into five parts, which are cement, sand and water.

Step-by-step instructions for performing construction work

The construction of shallow foundations is a combination of basic materials: a concrete slab and a sand cushion. If the first of them takes on the load transmitted by the building, then sand is an excellent way to maximally smooth out the uneven distribution of base deformations. A shallow foundation for a wooden house also needs a sand cushion, despite the lightweight type of construction. The thickness of the sand layer under the base is determined by the level of load transmitted by the object.

After the site has been marked, trenches can be dug. It is important to first perform the necessary calculations to determine the sufficient depth of the foundation for construction. At one stage of construction, a blind area for a shallow foundation is constructed. If in any other case this is done in order to avoid the negative impact of wastewater on the concrete foundation of the house, that is, the blind area plays the role of waterproofing, then with a shallow foundation it additionally helps to negate the effect of soil heaving in frosty times.

Returning to the step-by-step execution of the work, it should be noted that after sand has been laid at the bottom of the trench as a cushion, you need to take care of waterproofing. For this purpose, bitumen-polymer roll materials are used. Then the formwork is built, if necessary, the reinforcement frame is fixed and concrete is poured. At the next stage, the shallow foundation is insulated with polystyrene foam. This is done on the outside of the foundation for the building in order to protect the basement floor, if there is one, or the residential building itself from cooling.

Insulation of a shallow foundation can be carried out not only on the outside of the concrete foundation of the house. In areas of more severe climates, a different insulation scheme is used, in which the heat-insulating material is laid horizontally directly under the base of the foundation. This is done before pouring the concrete mixture. There is another insulation scheme, which is a combined version of the two methods described. That is, the thermal insulation is located both in the vertical and horizontal planes, maximally protecting the foundation from the effects of low temperatures.

Technology for constructing aerated concrete columnar foundations

It depends on the type of building materials used, as well as the size of the house, but the basic technology remains the same. It consists of the following stages:

- Calculation of pillars and selection of building materials. For structures that are small in size and weight, aerated concrete, foam blocks and wooden beams are suitable. Accordingly, the calculation is carried out individually for each material, taking into account the bearing capacity of the products and the characteristics of the soil itself.

- Digging a trench for installing pillars. If a wooden beam is used, then the diameter should be at least twice the diameter of the beam. This is necessary for installing waterproofing layers. You can use asbestos pipes or plastic as waterproofing, but the financial component is taken into account here.

- In some cases, it is recommended to make the base structure in the form of a shoe. Here, a wide sole and a small diameter base are made in order to increase the load-bearing capacity of the columnar base. It is practiced when constructing combined foundations, where the base is made of aerated concrete, and the pillar itself is made of wooden beams. It is recommended to use the shoe in soils with low heaving. A sand cushion is poured onto the sole and compacted thoroughly.

- Installation of waterproofing. An asbestos or plastic hollow pipe is installed into the finished well. You can also use roofing material connected in layers.

- Wooden piles are mounted inside the waterproofing layer or aerated concrete blocks are laid in layers. The beams are connected to each other by transverse reinforcement, and a vertical beam for the grillage is also provided. Aerated concrete blocks are connected in horizontal and vertical belts with concrete and reinforcement and are erected sequentially to the entire height of the column.

- If you use aerated concrete, you need to wait until the pillars settle down and dry and only then build the grillage.

- Construction of the grillage. A strip reinforced concrete structure is suitable here, but private developers use a prefabricated structure made of aerated concrete or wooden beams. Used in the construction of country houses, it is characterized by low weight and high strength.

- Grillage reinforcement. Reinforcement is mounted between the beams or blocks, connected to the reinforcement of the pillars; I do not use welding here due to possible deformation of the metal.

- Installation of waterproofing of pillars. It should be used if high horizons of soil layers are possible and vertical movements are capable of raising the existing insulation.

As a rule, a columnar foundation made of aerated concrete with the correct construction technology can withstand heavy loads. But you should not practice constructing massive high-rise buildings with concrete, because the base material is fragile.

Accordingly, taking into account the cost of the material and its characteristics, it is better to immediately use it for wooden country houses, bathhouses or small residential houses of low height and built with lightweight building materials.

Foundation for a house made of FBS blocks

A house made of FBS blocks is a very popular type of construction. This material is used to create load-bearing elements of buildings that can be used at temperatures from -70 to +50 degrees. Their most relevant use is for the construction of basement and basement surfaces and laying strip foundations. It is worth noting that such blocks are perfectly combined with all types of soil and climatic conditions. In our article we will find out how to build a building from FBS correctly and independently.

Work on supports

Crushed stone is poured at the bottom of each hole, which will serve as a drainage layer. This is especially important during seasonal temperature changes. Once the preparation is completed, you can make a cushion of mortar on which the first blocks are installed. The next two need to be laid on top, positioned perpendicularly. The smaller you make the seam between the stones, the more reliable the base will be.

The pillars should be raised so that they rise 30 cm or more above the ground. It is important to ensure that the surface of such supports is horizontal. After laying all the pillars, they must be protected with a layer of waterproofing. This will protect the base from moisture, which can wash the mortar out of the masonry and destroy the blocks under the influence of low temperatures.

Pros and cons of the material

Before choosing blocks for installation work, you need to familiarize yourself with the advantages and disadvantages of the FBS material. Namely these:

- Good strength;

- Durability;

- Resistance to mechanical and biological influences;

- High level of thermal insulation;

- Environmental Safety;

- Wide range of block models.

Such advantages expand the range of applications of FBS products, allowing them to be used in the most uncomfortable conditions. Construction specialists strongly recommend using such material for laying basements, as this will reduce the time it takes to build a house. Of course, such blocks have a huge number of advantages, but we must also consider the disadvantages of these products:

- It is worth noting that the blocks have a high cost, but it is lower than that of a monolith;

- In addition, in most cases it is not possible to obtain maximum sealing at the joints. If you install a self-leveling foundation and a plinth, you can get a more reliable structure. This design is especially relevant in difficult climatic conditions.

- For construction work on the construction of the plinth, it is necessary to use the services of special machines.

Attention! FBS products are more expensive than other materials, and require additional waterproofing treatment of the base or basement.

Aerated concrete and gas silicate

Types of gas silicate blocks

Construction time, cost of materials and work, and operational characteristics of the house largely depend on the choice of wall type. The most popular products when constructing the walls of a low-rise individual house, garage, gazebo and cottage are wall materials made of cellular/porous concrete. Their frequent use is largely due to technical characteristics and economic benefits for the developer.

Selecting blocks for installation

When choosing a building material for a house, namely FBS blocks, first of all, you need to check the product documentation and the availability of a passport. The official product certification must contain the following information:

- Contact information of the manufacturer;

- Serial code and lot number;

- Dimensions, brand, weight;

- Indicator of strength during compression;

- Resistance to frost and moisture;

- Basic operating rules.

We make the foundation from blocks with our own hands

The construction process using FBS products is no different, but the work must be performed in strict accordance with the instructions. So, the first thing you need is to calculate all the values. Let's talk about this in more detail.

Calculation of the quantity of materials

Before you go shopping. We need to know how much material we need to complete the construction. The volume of load-bearing masonry is calculated using the following formula:

V= l by a by h, that is, length multiplied by thickness and height. Next, the resulting value is divided into indicators of one block. If the building has the shape of a parallelepiped, then the calculation is complete, the resulting amount will be the amount of material needed.

Attention! Here it is very important not to forget that FBS elements have a lot of weight, so you should use the services of specialized equipment to carry out the work. Based on this fact, professionals recommend performing calculations for middle blocks, since they will be easier to install.

Today, manufacturers produce several standard parameters for block products. Such values simplify construction work. Usually the block has a height of 58 cm, but for calculations you need to use the number 60. The side walls may be slightly convex, but this is not a mandatory norm, so most blocks are even. Design features are based on the financial capabilities of the owner.

Attention! Of the main requirements, we must not forget that construction should begin by creating a sand and gravel cushion for the foundation. All work is done easily, the main thing is to do everything accurately and correctly.

Tools and materials for performing work

As we have already found out, installation of the foundation for the house is carried out without any particular difficulties. The duration of the process depends on the characteristics of the soil on the site and the total weight of the building. But, you should not forget that the blocks need to be mounted on a prepared surface, which takes most of the time. To perform installation you need the following tools:

- Level of construction purpose;

- A special level, a clamp and a long rope;

- Compact excavator or shovel. The choice of this tool depends on the dimensions of the house.

- Sand and crushed stone;

- Vibrating mechanism for compaction;

- FBS blocks;

- Wooden board for creating formwork;

- Concrete solution.

The materials for creating a prefabricated base are FBS blocks, with a length from 120 to 240 cm, and a height of 40 and 60 cm. These values are standard, but nowadays experts use other options.

Attention! Before you buy blocks you must decide for yourself. Which blocks will be more profitable for you to install?

Preliminary construction stage

When you need to lay blocks, you must not forget about the most important work - preparatory work. This stage includes the following sequential actions:

- We prepare the area for work. To do this, you need to level the soil, remove large grass and bulges in the area. Next, we determine the type of soil by deep shunting. The type of finish will depend on this factor.

- If the construction is carried out on clay soil. For such conditions it is necessary to dig a ditch of a certain depth. Sand and gravel 30 cm wide need to be laid at the bottom. Such a layer can be created in several ways, which are selected according to the availability of materials for construction. The compaction of the pillow should be done with a special vibrating tool.

- After completing the layer of sand and gravel, trapezoidal slabs should be laid on the cushion. FBS products are used to increase the area of load on the soil. This process increases the overall strength and stability of the building. It is recommended to lay the blocks one at a time, in the form of a chessboard.

- If the site has sandy soil, the process is slightly different. To perform installation, it is recommended to use a different method. First. What needs to be done is to prepare a trench. It is worth noting that for such soil there is no need to make a sand cushion. We compact the bottom, install the slab and fill it with a thickness of 10 cm.

Attention! For a sandy type of site, it is cheaper to install a strip base.

The main stage of the construction process

This stage is called the main stage, since it is now that the blocks are being laid. There are some rules for performing this task. FSB products should be laid from corner to corner and diagonally. We begin work by completing the first layer of construction. The blocks must be installed on a prepared concrete layer, which must be durable and free of gravel and crushed stone. It is worth noting that this principle is reminiscent of brickwork.

Installation of block elements must be carried out with bandaging in the corners of the building. In this case, there should be no seams between adjacent blocks. Each layer of the structure must be protected from water and moisture. Suitable materials for waterproofing include rubber, liquid resin and roofing felt.

The position of the structure plays an equally important role in the quality of construction. It is worth noting that it can be performed vertically and horizontally. The second method is characterized by checking using special beacons, a rope and a building level. Deviation from the norm of the angle can be the following values: horizontally - 2 degrees, vertically - 3.

Attention! It is impossible to create voids when installing block devices, as they can quickly deform or lead to the destruction of the building.

The final stage of construction

When creating a building on any type of soil, with the exception of the sandy type, the last stage consists of performing the following mandatory work:

- Waterproof the material. This task can be accomplished using roofing felt, liquid rubber, and bitumen.

- When the waterproofing agent has dried, it is necessary to fill the area near the walls with sand from the inside and outside. It is worth noting. That all layers need to be compacted with a vibrating block.

Attention! A prerequisite for such a construction is the need to install a drainage system and a concrete blind area.

So we got acquainted with all the nuances and features of installing houses from FBS blocks with our own hands. Now you can build the desired building yourself.

Types and weight of wall blocks

Its weight also depends on the structure of the block.

Wall blocks are a modern material that is used for the construction of load-bearing walls and partitions in buildings for various purposes. They come in different shapes, sizes, and are made from concrete and additives and fillers.

Depending on the composition they are:

- expanded clay concrete;

- foam concrete;

- aerated concrete;

- arbolite;

- polystyrene concrete, etc.

Concrete products

Laying of small-sized products

Large-sized wall structures are used for the construction of load-bearing walls; their large mass requires the use of special equipment for transportation and installation.

Construction from large products

Compared to brickwork, the use of blocks saves time, which means construction costs are reduced. They are easier to work with, they have good heat and sound insulation properties, and do not require cladding.

Hollow block wallExpanded clay concrete blocks

They are made from expanded clay, water and cement. This material is porous, frost-resistant, with high sound and heat insulation, and fire-resistant. Expanded clay concrete is used for the construction of walls, partitions, foundations, chimneys, and fireplaces.

Expanded clay concrete

The strength and weight of expanded clay concrete depend on the ratio of the components. The volumetric weight of this material is 700–1200 kg/m3.

Concrete block weight

The weight of expanded clay concrete depends on several factors, the main ones being the density and grade of concrete. The higher the density, the greater the weight of the structure. Below is a table of the weight of blocks 200x200x400 mm by concrete grade.

Weight concrete blocks 20x20x40 Table

Solid expanded clay concrete wall

When purchasing expanded clay concrete, the deciding factor should not be price, but quality. It is important to purchase materials from trusted manufacturers and require certificates of conformity

Foam concrete blocks

Foam concrete is produced from a mixture of cement with sand and a special whipped foaming agent. Both compositions are first prepared separately, then mixed into a single mass, poured into molds and dried under natural conditions.

Foam blocks

Foam concrete is used for laying internal and external walls, constructing load-bearing elements in low-rise construction, roofs, ceilings, floors, and outbuildings as insulation.

Foam concrete in section

Foam concrete structures are durable, have low thermal conductivity and high noise insulation, fire resistance and fire safety, and are easy to process.

House made of foam blocks

By purpose they are:

- structural (the strongest D up to 1200 kg/m3);

- structural and insulating (D = 600–800 kg/m3);

- thermal insulation (D = 400–500 kg/m3).

Weight and other characteristics of foam concrete depending on density

Construction from foam blocks

Foam concrete products of various weights, volumes, and sizes are used for construction. Depending on the brand of foam concrete, the weight of blocks of the same size will be different.

Foam concrete weight

The versatility of use, ease of installation and cost-effectiveness make foam concrete a popular building material. When erecting buildings with your own hands, use the manufacturer’s instructions, which indicate the sequence of actions and the necessary auxiliary tools and materials. The relatively light weight of the blocks allows you to save on transportation and quickly complete the necessary work.

Installation instructions for foundations made of FBS blocks

FBS building blocks are rectangular concrete blanks used for the rapid construction of walls, foundations, and basement sections. They are easy to install due to their simple geometric shape; compared to pouring mortar, the labor intensity of the process is minimal; an additional advantage is the independence of installation from the time of year. The strength and reliability of reinforced blocks make it possible to create a durable base that is resistant to mechanical loads.

The use of FBS is a proven construction technology; thanks to factory quality tests, the workpieces have no defects and are not subject to temperature changes. Disadvantages include the need to rent lifting equipment, high requirements for waterproofing and the risk of subsidence of sections of the structure (minimal if construction standards are observed). The work does not require special skills, but it is advisable to study video instructions on the topic: how to correctly lay blocks with your own hands and carry out calculations.

Calculation of masonry parameters

The depth of the structure depends on the characteristics of the soil and the expected load. On average, to build a base, 2 to 5 rows of FBS are laid (up to 2.5 m). The use of a shallow strip foundation (1 block) is allowed only during the construction of utility rooms, garages or bathhouses.

In this case, the masonry is the protruding part of the base. Calculating the required number of blocks is easy to do, thanks to their standard dimensions (the length and width are different, in contrast to the height - 58 cm). After calculating the volume of the masonry, the resulting value is divided by the parameters of one workpiece and their required number is obtained.

Features of the material

Today they are very popular due to some features of the material. They are most relevant for building houses with your own hands - working with the material does not require special equipment, special tools, any knowledge and skills, or a large number of workers.

The following blocks are most often used in construction today: aerated concrete, solid and hollow, foam concrete, expanded clay concrete, polystyrene concrete. All of them differ in certain advantages and disadvantages and operational properties.

Hollow concrete blocks

Typically, such blocks are used in the construction of low-rise buildings. The size of concrete blocks for walls with a hollow structure is usually 20x20x40 centimeters. Their main advantages: affordable cost, low weight, low level of flammability, vapor permeability, good sound insulation and heat insulation properties.

This concrete wall block is not afraid of moisture due to the closed pore structure, which is why water does not get inside the block. The products are made of reinforced concrete and concrete; walls are built from them by pouring polymer foam insulation or cellular heat-insulating concrete into the channels. Blocks are often used to construct permanent formwork, when reinforcement is poured into the voids and installed, creating a monolithic prefabricated structure.

Aerated concrete

Concrete is used most often in modern private construction. The material has good thermal insulation properties, but is susceptible to moisture and therefore requires protection. This type of concrete wall block is made from Portland cement, lime, quartz sand, water and aluminum powder. When the reaction occurs with aluminum powder, bubbles appear, which harden in the material during heat treatment.

Aerated concrete is characterized by precise geometric dimensions, low weight, and high density. Autoclave material is considered the highest quality. Products may differ in size, shape, and the presence on the surface of the blocks of certain auxiliary recesses and recesses that facilitate the installation process.

Foam concrete

Production is carried out from cement, sand, water and special foaming agents. All components are mixed, the foamed raw materials are sent into collapsible molds or formwork structures for a certain period of time (4-12 hours), then taken out and allowed to gain strength under natural conditions. Large masses are cut into smaller concrete blocks for walls.

Foam concrete differs from aerated concrete in the shape of its pores, geometric parameters in terms of edge accuracy, and strength. Typically, blocks of this type are used in low-rise construction when installing walls; in frame construction, such blocks fill the openings between load-bearing structural elements.

Polystyrene concrete

These products include polystyrene granules, which act as insulation.

The main advantages of polystyrene concrete:

- Simple and quick installation

- Thin seams made of adhesive composition

- High-quality adhesion to any finishing materials

- Excellent workmanship in terms of geometry and dimensional accuracy

- Strength – the ability to use blocks even in seismically active zones

- Resistance to large temperature changes and various environmental factors

- Resistant to deformation, mold and mildew

- Excellent thermal insulation and sound insulation characteristics

- Good level of vapor permeability

Expanded clay concrete

produced using the technology of vibration casting into molds. The blocks must contain the same volume of cement and expanded clay. Typically, such concrete wall blocks (sizes may vary) are used for the construction of partitions and walls.

The material demonstrates good thermal insulation and strength, since there are cavities inside it that act as stiffeners. Due to the peculiarities of the structure, it is possible to significantly save on the solution. Expanded clay concrete blocks are heavier compared to gas and foam concrete, but you can still build with them without the use of special equipment.

Not only residential buildings are built from expanded clay concrete, but also retaining walls, fences, various partitions, fences, and utility buildings.

Main stages

Standard step-by-step instructions for laying a strip foundation include:

- Preparatory work: marking, digging a trench.

- Laying and compacting the sand cushion.

- Arrangement of the base: installation of wide FBS slabs or monolithic concrete screed.

- Laying foundation blocks.

- Waterproofing and, if necessary, insulation.

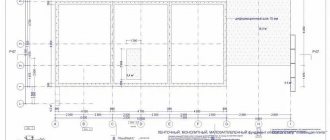

The construction of a columnar foundation from FBS is almost no different, with the exception of pouring bitumen mastic under piles or pedestals instead of a concrete monolith. Conventionally, all work can be divided into two stages: preparatory and direct laying of the blocks. It is important to make the placement scheme in advance; filling the cracks with brick or concrete is allowed, but this leads to a decrease in the strength of the structure. After determining and marking the main axes, rigid reinforcement is driven into the required points, which is checked as the trench is dug for vertical deviation with plumb lines.

The base cushion is standard: at least 10 cm of crushed stone and 5 cm of sand (for clay soils it is three-layer, up to 60 cm, coarse filler is poured as the middle layer). A prerequisite for proper preparation of the pillow is abundant moistening and compaction. The walls of trenches dug in loose soils need protection from collapse. Next, a thin layer of concrete (2–3 cm) is poured onto the compacted sand, and a certain period of time is waited until the minimum strength is achieved. As an alternative to cement screed, masonry mesh can be used under foundation building blocks. Laying the first row is allowed only after the cushion and concrete layer have dried.

First, the base is formed: wider slabs (specially purchased flat or simply inverted) are placed. Laying FBS begins from the corner and the axes marked with reinforcement. For fastening, a high-quality cement-sand mortar of medium thickness or construction glue is used (the latter option is preferable, but will be more expensive). All cracks and contact points, including vertical seams, are coated without exception, and the horizontal level is checked. Free space (if any remains) is filled with brick or concrete. The exception is the gaps for pipes and communications; it is advisable to think through their placement scheme without damaging the wall foundation blocks.

Each subsequent row must be laid offset, according to the principle of brickwork. That is, the vertical seam of the upper block is located strictly in the middle of the lower one; for corner elements, the overlap method is used. The thickness of the cement mortar between the rows is 1.5 cm; if the dressing is insufficient, reinforcement is carried out with mesh or rods.

It is also recommended to reinforce the foundation of blocks with metal when building on heaving soil. By analogy with the first row, each subsequent row is checked for level deviation horizontally and vertically, all voids are filled with solution (the latter is the most important nuance of the technology).

In some cases, the construction of an intermittent foundation is permitted (subject to suitable soil conditions, lightweight masonry and the absence of a basement). But the maximum permissible gap between FBS should not exceed 70 cm. This option allows you to save up to 20% of building materials, but it cannot be used when constructing a building with more than 2 floors.

Ideally, choose long blocks that match the foundation layout. After the solution has hardened, they begin waterproofing work, in this case coating, the top row is covered with roofing felt. In case of intense freezing of the soil, additional insulation of the base is required, most often with polystyrene foam or extruded polystyrene foam; it is allowed to start building walls after 1 month.

How to properly lay a single-row structure?

For light buildings, a simple shallow foundation made of FBS is sufficient, but if there is a risk of displacement (in heaving soil conditions), it should be strengthened. For this purpose, the trench is deepened by 40 cm, and a 30 cm cushion of crushed hard rock and sand is poured onto the bottom. Then a concrete screed, at least 10 cm thick, with reinforcement is poured.

Laying foundation blocks is allowed only after the mortar has hardened; they are coated with bitumen on the sides, and another concrete monolith with a reinforcing frame is installed on top. A prerequisite for the construction of a single-row foundation is the insulation of the blind area.

- Purchasing from an unverified manufacturer.

- Lack of coating waterproofing.

- Construction of discontinuous foundations in buildings with basements.

- Construction of a structure without taking into account future communications.

Tips and tricks

The main advantage of FBS is associated with the high speed of foundation construction; the use of the longest blocks is considered optimal (up to 2.38 m). In this case, the structure becomes more monolithic and the time required to use expensive lifting equipment is reduced.

The foundation should be compacted in stages; river sand is well suited for backfilling; each layer is recommended to be wetted and compacted. On heaving soils, it is not advisable to deepen the structure, but its thermal insulation properties are strengthened in every possible way (by reinforcement, insulation of the base and blind area).

Waterproofing

For high-quality waterproofing of a building, it is necessary to have a proper drainage system around the foundation.

Waterproofing the foundation itself is needed for two purposes: preventing moisture from penetrating into the structure of the house from the foundation (done on the horizontal surface of the foundation) and preventing moisture from penetrating into the foundation from the soil and the environment, so that the concrete does not collapse when this moisture freezes. Let's talk about the second one.

It is done in many ways:

- coating - bitumen, polymer and epoxy mastics are used for this;

During coating waterproofing, molten bitumen is applied with a brush to concrete foundation elements - spraying liquid plastic mass (polyurethane) is the most expensive, but also very effective method;

Spraying polyurethane is the most expensive, but also very effective method. - plastering - special plaster mixtures with plasticizing additives are used for this;

Plastering the foundation is the most labor-intensive method - pasting - films (with polymer glue) and membranes and glass insulation (they are self-adhesive).

The foundation is covered with waterproofing in an overlapping manner

Pasting, as a rule, is combined with coating with mastic before and after pasting. If the pasting is multilayer, a mesh is laid between its layers, which is used for conventional plastering.

The placement of layers when pasting should only be vertical; the vertical overlap should not be less than 10 centimeters, the horizontal overlap should not be less than 30, and pasting should be done from below.

Strip foundation made of FBS concrete blocks for a bathhouse

It is faster to install a strip foundation under main walls using FBS blocks

In construction, the design of a prefabricated strip foundation made from FBS brand blocks is very common.

The foundation design of FBS blocks was previously used everywhere in the construction of multi-storey residential buildings. Convenient, fast. Therefore, the industry for the production of such blocks in Soviet times very quickly occupied its niche.

During the construction of multi-storey buildings on a construction site, construction equipment was necessarily used and construction cranes were assigned to this construction site for the period of construction of the facility. Unlike the modern construction organization, now not all contracting organizations have construction equipment and often the necessary construction machines are rented on an hourly basis.

Why is the issue of the cost of construction machines so acute when building a foundation made of blocks? Because FBS blocks, although they have several standard sizes, all of them require the use of equipment during their installation. And the cost of renting a crane per hour of work is not small.

Expert advice

If you need to build a bathhouse, garage or utility building, and the project is limited both in terms of implementation time and financial capabilities, then a columnar foundation will be the best solution. It is suitable for any other small building, in addition, construction can be completed in the shortest possible time. You can use not only blocks, but also bricks, wooden poles and asbestos-cement pipes. Such bases have high load-bearing capacity and durability. You can use FBS, which are presented on the market as factory-produced reinforced concrete or expanded clay concrete products. They are made by vibration pressing and are excellent for this purpose.

Concrete blocks for foundation

For some reason, concrete blocks for foundations of the FBS brand are always called concrete, although little reinforcement is used in their manufacture.

The abbreviation FBS stands for foundation wall blocks. They are intended for basement walls, because often such a foundation is laid to the depth of soil freezing or immediately for the purpose of constructing a basement under the building. Therefore, walls made of FBS blocks are also the foundation and walls of the basement of a residential building or building for any other purpose.

What are there (sizes)

Based on the name, the main purpose of FBS is to make the base and walls of a house. Regulates the sizes of fbs blocks GOST 13579-78. According to this regulatory document, the dimensions of foundation blocks can be:

- height h– 0.3, 0.6 mm;

- width B – 0.3, 0.4, 0.5 and 0.6 m;

- length L – 0.6, 0.8, 0.9, 1.2 and 2.4 meters.

FBS block, photo

| Brand | Dimensions, mm | Weight, t | Concrete class | Consumption of materials | |||

| L | B | H | Concrete, m3 | Steel, kg | |||

| FBS24.3.6 | 2380 | 300 | 580 | 0.97 | B7.5 | 0.406 | 1.46 |

| FBS24.4.6 | 2380 | 400 | 480 | 1.3 | B7.5 | 0.543 | 1.46 |

| FBS24.5.6 | 2380 | 500 | 580 | 1.63 | B7.5 | 0.679 | 2.36 |

| FBS24.6.6 | 2380 | 600 | 580 | 1.96 | B7.5 | 0.815 | 2.36 |

| FBS12.2.6 | 1180 | 200 | 580 | 0.32 | B7.5 | 0.133 | 0.76 |

| FBS12.3.6 | 1180 | 300 | 580 | 0.485 | B7.5 | 0.203 | 0.76 |

| FBS12.4.6 | 1180 | 400 | 580 | 0.64 | B7.5 | 0.265 | 1.46 |

| FBS12.5.6 | 1180 | 500 | 580 | 0.79 | B7.5 | 0.331 | 1.46 |

| FBS12.6.6 | 1180 | 600 | 580 | 0.96 | B7.5 | 0.398 | 1.46 |

| FBS12.2.3 | 1180 | 200 | 280 | 0.16 | B7.5 | 0.066 | 0.38 |

| FBS12.3.3 | 1180 | 300 | 280 | 0.24 | B7.5 | 0.1 | 0.38 |

| FBS12.4.3 | 1180 | 400 | 280 | 0.31 | B7.5 | 0.127 | 0.74 |

| FBS12.5.3 | 1180 | 500 | 280 | 0.38 | B7.5 | 0.159 | 0.74 |

| FBS12.6.3 | 1180 | 600 | 280 | 0.46 | B7.5 | 0.191 | 0.74 |

| FBS9.2.6 | 880 | 200 | 580 | 0.235 | 0.36 | ||

| FBS9.3.6 | 880 | 300 | 580 | 0.35 | B7.5 | 0.146 | 0.76 |

| FBS9.4.6 | 880 | 400 | 580 | 0.47 | B7.5 | 0.195 | 0.76 |

| FBS9.5.6 | 880 | 500 | 580 | 0.59 | B7.5 | 0.244 | 0.76 |

| FBS9.6.6 | 880 | 600 | 580 | 0.7 | B7.5 | 0.293 | 1.46 |

Advice: if upon purchase you find that the dimensions of the FBS block differ from those presented above, then you should think twice before buying such material. It is probably homemade and its quality is suspect.

Strip foundation made of blocks

A strip foundation made of blocks in private construction is arranged:

- for a low-rise building with solid walls (brick, gas block) with the base of the foundation laid to the depth of soil freezing

- for a low-rise wooden house or bathhouse with or without a basement, with the base of the foundation laid to the depth of soil freezing

- for any one-story building (house, bathhouse, garage) without a basement, like a shallow foundation

When building any foundation structure, it is necessary to build on the soil.

A strip foundation from FBS blocks can be made for any type of soil, it will only be necessary to apply appropriate structural measures depending on the type of soil and groundwater level.

For example, you want to build a wooden house with a bathhouse, and even a basement. This is a fairly large building.

If you have sandy or rocky (with crushed stone, gravel) soils and the groundwater level is below -3m, then no problem, the design of a strip foundation made of blocks is your most optimal solution.

These soils are not heaving, so under such soil conditions it is possible to construct a full-fledged basement from FBS blocks, which will always be dry.

If you have clayey or loamy soils and a high groundwater level, for example, at 1 m below ground level, then you need to think very carefully before making foundations from FBS, since the basement will have to be waterproofed against groundwater seepage. And clayey soils are heaving and therefore you will have to do:

- monolithic belts along the base of the foundation and along the top of the foundation to strengthen the FBS masonry located in the middle between the monolithic belts.

- fill all foundation cavities around the perimeter of the building with medium-grained sand, which is a non-heaving soil

- coat the side surface of the foundation in contact with the ground with bitumen, thereby reducing lateral buckling forces

- in modern construction, another design solution is used to reduce soil freezing by installing an insulated blind area around the perimeter of the structure

Characteristics of wall blocks

Retaining walls in the local area

When choosing wall blocks made using one technology or another, their technical properties and upcoming operating conditions are taken into account.

Concrete blocks for retaining walls with a decorative facing layer

All products are characterized by the following indicators:

- In terms of strength;

- In terms of environmental friendliness;

- On fire safety;

- According to frost resistance;

- According to thermal conductivity and the required degree of insulation;

- By vapor and air permeability;

- By shrinkage;

- If necessary, reinforce the masonry;

- According to the requirements for the type and capacity of the foundation;

- According to the requirements for the installation of reinforced belts and types of floors;

- According to the cost of products;

- At the cost of the work performed.

At construction sites, products of various sizes are used, each of which performs its own function.

The instructions for working with this material are simple, and the video in this article will tell you how to properly use concrete blocks for retaining walls.

Foundation for a bathhouse made of blocks

- sand and gravel pad 300mm thick

- preparation for 100mm thick blocks of monolithic concrete with reinforcement

- laying concrete blocks on a layer of cement mortar and filling the vertical joints between the blocks with mortar

- monolithic reinforced belt on top of a row of blocks 100-200mm high

- Coating the sides with bitumen

- filling the foundation cavities with sand 100-300mm wide

- insulated blind area

- Less likelihood of deformation under the influence of soil heaving forces

- Greater structural rigidity of the foundation

How to lay blocks?

The building material must be covered with bitumen - it will serve as waterproofing. As soon as the concrete in the holes has completely hardened, we begin laying.

The blocks must be placed on glue or cement-sand mortar. To increase strength, experts usually use reinforcing mesh. You need to make a mark on the first pillar - in the future, the height of all other supports will be determined from it.

Finally, backfilling must be done. It is also necessary to equip a grillage - this is the framework for the foundation. The size of materials in each case must be selected individually.

Construction of foundations from FBS blocks

FBS concrete blocks are laid with ligation of vertical seams

To construct foundations from FBS blocks, it is best to hire professionals who have construction equipment.

The technology for constructing foundations from FBS blocks is as follows:

- digging a pit to the depth of soil freezing or to the depth of the basement height with the addition of the height of the basement floor structure. The width of the pit should be larger than the dimensions of the foundation so that the blocks can be comfortably mounted.

- cleaning the bottom of a pit or cleaning the bottom of trenches for foundation blocks with horizontal leveling and measuring the design elevation of the foundation base.

- foundation preparation device: sandy or monolithic, depending on the type of soil, its bearing capacity and groundwater level.

- laying foundation slabs (FL pads) under FBS, which increase the base area of the foundation. They can be laid as a continuous strip or intermittently, depending on the overhead load on the foundation. For low-rise construction, foundation slabs can be replaced with a monolithic slab with reinforcement. It is possible for low-rise construction to construct a foundation from FBS blocks without widening the base, that is, without the use of foundation slabs. Everything is determined by calculations and ground conditions.

- Installation of FBS foundation blocks according to drawings and layout diagrams with ligation of vertical seams (in the middle of the blocks). The blocks are laid using cement mortar and filling the vertical joints.

- Construction of monolithic sections between blocks according to the drawings and laying sleeves for communications.

- Installation of roofing felt waterproofing on the horizontal surface of the top row blocks

- Coating with bitumen 2 times all the side surfaces of the foundation, which will later be backfilled and come into contact with the ground

- Backfilling of foundation cavities with local soil or sand, depending on the heaving of the soil and design decisions.

Prefabricated foundation reinforcement

To increase strength, reinforcement can be laid in the horizontal joints of the masonry in the foundation walls of any blocks.

Reinforcing mesh of 2 - 3 longitudinal rods of working reinforcement with a diameter of 10 - 12 mm is placed in monolithic belts and foundation soles.

Scheme of reinforcement of monolithic sections of the foundation. a - reinforcing mesh with two working reinforcement bars; b - the same, but with three rods. 1 - longitudinal rods of working reinforcement A-III, with a diameter of 10-12 mm; 2 — auxiliary fittings Вр-I, 4 mm in diameter.

In monolithic foundation strips, the distance between adjacent working reinforcement rods should not be more than 300 mm. If necessary, the number of rods is increased.

In the mesh of the monolithic tape with an increased width of the sole, additional rods of working reinforcement are installed transversely in increments of 600 mm . Vertical working rods with the same pitch are placed between the lower and upper meshes.

The protective layer of concrete between the soil and reinforcement in foundations must be at least 50-70 mm.

Scheme of reinforcement of a monolithic belt of a prefabricated foundation

Longitudinal and transverse reinforcement are fastened with knitting wire.

Don't leave your foundation unprotected over the winter

Protection from water and winter insulation of a prefabricated strip foundation made of concrete blocks. 1 - from top to bottom: loading layer of soil, film, insulation (foam plastic, bags of straw, sawdust), waterproofing of the soil and foundation tapes; 2 - waterproofing and insulation of the foundation according to the project; 3 - backfilling of the sinuses and embankment of the foundation strip with soil.

Shallow foundations should not be left unloaded for the winter if the walls and roof have not been built.

This is especially true for foundations on heaving and waterproof soils.

The lateral surface of foundations buried in the ground is affected by the tangential forces of frost heaving of the soil, which will push the unloaded foundation upward.

Under an unprotected foundation strip, the soil will freeze to a greater depth, significantly increasing its volume. In the spring, when it begins to thaw, the soil will sag unevenly and the foundation will not be able to return to its original place. All these processes often lead to cracking of the foundation.

If such a foundation is left unloaded for the winter—the house is not built—then the foundation and the soil near the foundation must be protected from water and freezing . The foundation and soil are insulated and covered with heat-insulating material - polystyrene foam, sawdust, straw, etc.

It is safer and more profitable to entrust the choice of a specific foundation design for a house to specialists. Doing it yourself will most likely lead to excessive cost increases.

construction as a result of reinsurance, or to a weak design, which will cost even more.

It is convenient to lay out the walls of the basement at the same time as the foundation using small-format concrete blocks. Find out everything about the size, waterproofing and insulation of the basement of the house.

Blocks. FBS. Concrete. Expanded clay concrete. PGS. Insulation boards. Foundation. Profiled geomembrane. Waterproofing. Fittings. Drainage. House. Tools

Next article:

Calculation of the dimensions of thermal insulation of a shallow foundation for a house

Previous article: