The main task of the metal tile roofing substrate is to prevent direct contact of the structure and its components with condensation vapors, as well as protection from the negative effects of moisture. We are talking about counter-lattice, sheathing, rafter system and, most importantly, reliable insulation. Proper vapor barrier under metal tiles is necessary for the safety of the roofing system as a whole.

Depending on the selected components in the organization of roof construction and roof design, the final protection scheme also depends.

What kind of roofing substrates can there be?

When organizing a roofing pie, it is extremely important to additionally use all kinds of substrates. Their main task is to ensure maximum service life of the structure as a whole and individual elements. We are talking about protection from atmospheric influences, heat loss and moisture.

Vapor barrier under metal tiles is laid as part of the roofing pie

Professional builders distinguish two main types of roofing:

- Heated (warm roof) underlays are usually used to protect attics and attics. Here it is not at all necessary to use roofing felt, since the roofing cake is already thermally insulated with appropriate materials.

- Unheated (cold roof) underlays are used in attic spaces that are not often used. Typically, roofing felt is used in finishing, especially when creating a vapor barrier for metal tiles and other metal elements.

Conclusion

Now you know which waterproofing to choose for metal tiles and how to secure it. If you have any difficulties with choosing or styling, contact me in the comments, and I will be happy to help you with advice.

Did you like the article? Subscribe to our Yandex.Zen channel

December 9, 2021

Waterproofing, Roofing, Metal tiles

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

Vapor barrier under metal tiles for cold roofs

In cold attic spaces with metal roofing, only waterproofing of the roof with membrane materials is performed. The waterproofing is secured to the rafters with counter-battens and taped at the overlaps with special tape. Then after this the main sheathing is carried out, on which the metal tiles are subsequently mounted. It is important to leave a ventilation gap to organize ventilation from the drip to the ridge. Due to this, in simple terms, a layer of air is formed, which is necessary to remove accumulated condensate.

Vapor barrier under metal tiles for warm roofing

As for heated rooms, for example, a warm attic or attic, it is worth understanding that the structure of their roof is somewhat different. It really doesn't matter whether the roof is made of tiles, a metal base or a soft roof. The main task is to make the correct roofing pie, and most importantly the correct vapor barrier to protect the thermal insulation.

Waterproofing and thermal insulation of the roof

In addition to the substrate, the roof is additionally decorated with waterproofing and thermal insulation components. Depending on the climate zone in which the building is located, materials are selected accordingly. Mineral wool is often used for thermal insulation. With its help, it is possible to provide optimal protection for the house, and it itself is very easy to install.

Laying mineral wool

The optimal thickness of such a P-75 insulator for the middle strip is a layer of 200 mm. When using polystyrene foam boards, you must also focus on the density of the material and its thickness.

Creating a ventilation space

Ventilation under the roof is a mandatory element, since it serves several purposes at once:

- removes moisture accumulating under the roof;

- prevents the formation of icy areas and equalizes the temperature over the entire surface in winter;

- prevents the penetration of street heat in hot weather.

A special ventilated roof ridge is designed to remove air, and the air flow occurs through the overhang of the eaves. Without properly installing the ventilation system, you will soon encounter the problem of high humidity, and as a result, the structure will quickly begin to deteriorate.

Metal tiles on roofing felt

A common type of substrate for metal tiles is roofing felt. Such material can be used for an uninsulated attic .

This scheme has a lot of advantages :

- roofing felt is an inexpensive substrate that will significantly save your repair costs;

- installation of the substrate does not require special skills ;

- roofing felt is a popular building material , so it can be bought everywhere.

However, for high-quality installation of metal tiles on roofing felt, you need to follow certain rules :

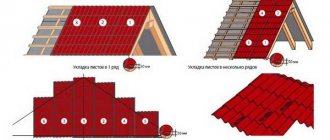

- Under no circumstances should sheets be laid directly on roofing material; this creates favorable conditions for the structure to shift. It is necessary to make the sheathing in two layers: 1 - along the roofing felt, 2 - under the wave of metal tiles;

- as an alternative, you can fill ordinary slats along the installed rafters;

- To prevent fire and simplify ventilation of the room, it is worth constructing ventilation holes.

Roofing installation is best left to professionals. However, if you are determined to carry out all the work yourself, then carry it out in accordance with the established requirements. Only in this case can you obtain a durable and reliable design.

A backing for metal tiles is necessary to create conditions that will provide the rafter system with maximum protection and safety. The influence of the underlayment in a roofing system cannot be underestimated and it is important to know which material to choose and how to use it.

The substrate for metal tiles on the roof is selected depending on the type of roofing device.

Metal tiles are a roofing material that has gained popularity recently due to its durability, quality and relatively low price. There are general standards for the construction of roofs. One of the principles is to ventilate the tiles from both the top and bottom, which will prevent the top layer from collapsing. However, for all these characteristics to correspond to reality, it is necessary to correctly lay the roofing material, as well as select the optimal substrate for the rafter system. Roofing pie is an insulating layer that protects an object from the negative influences of weather: cold, wind and noise.

Many people are interested in the question of what to put under metal tiles. There is no clear answer here. There is a list of criteria:

Structure of a metal tile sheet.

- Underlay material for “cold” roofing.

- Underlay material for “warm” roofing.

- Using roofing felt as a substrate.

- Waterproofing composition.

- Types of insulation and vapor barrier.

- Ventilation and its role in the roofing system.

- Errors during roof installation.

The substrate for metal tiles is selected according to the recommendations of the manufacturer, as well as according to the type of attic space. Here you need to understand whether the attic area is a living space where a “warm roof” is used, or whether it is a “cold roof” for an empty attic.

Types of waterproofing films

All waterproofing roll materials for roofs under metal tiles are divided into two main types:

- waterproofing films;

- diffusion membranes.

The main difference between waterproofing films and diffusion membranes is that the former do not allow both droplet moisture and water vapor to pass through, while the latter retain droplet moisture, but are easily overcome by water vapor.

Waterproofing films are several times cheaper than membranes. Therefore, it is better to use them for moisture protection of a cold roof. This will reduce material costs without losing protective properties.

If the roof is insulated with mineral wool or other heat-insulating material, then it is recommended to use a diffusion membrane, which will release steam that has penetrated from the insulation, but will not allow moisture to penetrate into the insulation.

In addition to vapor permeability, waterproofing film materials also differ in other parameters: base material (polyethylene, polypropylene, etc.), density, strength, UV resistance, service life. Read a detailed review of films here.

The technology of waterproofing depends on the brand of material used and the type of roof - cold or insulated.

Which is better?

Roof insulation must have certain characteristics. The waterproofing material should prevent moisture from entering, while facilitating the removal of vapors. The period of operation should be equal to the service life of the metal tile itself. It is advisable to refuse the choice of roofing material.

This coating is not capable of allowing steam to pass through. In addition, roofing felt is less durable than metal tiles. Another nuance is the fact that when interacting with metal tiles, bitumen can destroy it. Therefore, roofing felt must be laid carefully, otherwise the roof may leak.

The best recommendations apply to film or membrane covering. The price will be a definite plus. But you should be careful when choosing. Since the film is essentially polyethylene (only thickened), it does not allow steam to pass through well enough. This point is not taken into account if the roof is not insulated. If there is insulation, it can quickly deteriorate.

The ideal choice would be membrane film. This is a polymer multilayer coating with specific perforation. Anti-condensation film, which has many advantages, is perfect for waterproofing. It has good durability. There is no risk of damage to the insulation during installation.

The membrane coating perfectly removes steam, while at the same time blocking the access to moisture. It is distinguished by a long service life. Typically, waterproofing replacement is carried out when the roof has already failed. With proper operation, replacement of the material will only be required after a few decades.

It is characterized by a simple installation process, so installation does not require special skills or knowledge. The cost of such material depends on the use of high-tech technologies.

Therefore, when purchasing expensive waterproofing, you should be careful and use the services of trusted manufacturers and sellers.

For a cold roof

A cold roof means there is no insulation in it. When waterproofing it, both a diffusion membrane and a waterproofing film with low vapor permeability - polyethylene or polypropylene - can be used.

| Strength*, N/50mm | Weight, g/sq.m | Note | |

| Yutafol D 110 Standard | 250/240 | 110 | Optimal choice, price-quality |

| Ondutis D (RV) | 650/500 | 85 | Same price as Izospan, but less durable |

| Izospan D | 1068/890 | — | 2-layer, high strength |

| ROCKWOOL | 120/65 | 60 | Very thin, can be torn |

* Strength - maximum tensile force in the longitudinal and transverse directions.

The film is laid directly on the rafters with a slight (about 20 mm) sagging. Laying is done in strips starting from the eaves upwards with the bottom layer overlapping the top layer by 50-100 mm. The joint between the sheets is sealed with adhesive tape.

If a “breathable” film is used, you need to pay attention to which side it is laid up, its correct operation depends on this. This information can be found in the instructions for the material, usually the side with the logo should face up.

There should be a ventilation gap above the waterproofing film. To install it, counter batten strips 50 mm thick are nailed onto the rafters on top of the film, and the sheathing is already attached to them.

Instructions for use of isospan

What you need to purchase for installation:

- For fastening - screws or nails, stapler, wooden slats;

- Isopan vapor barrier tape – glue adjacent strips together;

- Scissors - cut material.

Calculation of the material itself: roof area + 15 centimeters for overlaps for each strip.

- On roofs, the membrane is used on the inside of the pie. Those. the film is attached to the rafters, then the insulation boards are installed.

- Vapor barrier isospan - which side to lay? Isospan B film for roofing is two-layer. It is smooth on the inside and rough on the outside. The rough side is the abductor side. Since we need to protect the insulation from getting wet, we place the film with the smooth side facing the slabs.

- The film is rolled out along the long side of the roof, starting from the eaves. The next strip is placed on the previous one with an overlap of 15 centimeters. The material should not be placed in tension; a slight sag is needed (so that later the insulation boards can be placed between the rafters by surprise).

- The membranes are secured to the rafter system with a stapler and glued together with construction tape. Fixing the flooring layer can also be done with wooden slats. They are nailed every 30 centimeters.

To install waterproofing and install roofing pie, please contact us. Our experience in roofing work is more than 15 years. We will waterproof your roof with isospan quickly, conscientiously, inexpensively and provide you with a guarantee for our services.

For roofs with insulation

Waterproofing an insulated roof is more difficult and expensive. There are two options for waterproofing depending on the type of material used.

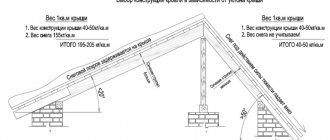

Waterproofing with two gaps

If a film with low vapor permeability is used, it is necessary to create two ventilation gaps - between the insulation and the film and between the film and the sheathing.

Typically, insulation is laid between the rafters flush with their top surface. Therefore, to create the first gap, you need to nail the counter-lattice strips to the rafters and lay the film on them without sagging. Then, strips are placed on top of the film to the counter-lattice, providing a second gap, and to them the lathing for the metal tiles.

Price

I suggest you familiarize yourself with the cost of all the coatings described above. Prices shown are valid for fall/winter 2021.

| Brand | Cost in rubles |

| Folinet, polyethylene reinforced, m2 | 34 |

| Novopolymer, m2 | 38 |

| Yutakon 130, anti-condensation, polypropylene, roll | 4200 |

| FineTek, polypropylene, 40m2 | 700 |

| Nanoizol SM, 70m2, diffuse | 2300 |

| Izospan-A, diffuse, 70m2 | 1880 |

Is it possible to use roofing felt?

Our usual roofing material, which several decades ago was almost the only waterproofing material, is inferior in every way (except perhaps price) to new products for waterproofing.

Its service life is significantly inferior to that of modern waterproofing films; it burns well and emits a strong, unpleasant odor when heated. Experts do not recommend using it for waterproofing under metal tiles.

When planning your home design, you always want it to be warm and cozy.

To do this, you should follow the instructions when carrying out construction work.

It is also necessary to pay enough attention to the insulation of the roof, in particular to the competent provision of all types of insulation.

How to choose a vapor barrier for a roof and not make a mistake? First, let's get acquainted with the types of vapor barrier materials.

Some points when installing waterproofing

The logs on which the film will be installed should not have a pitch greater than 1.2 meters. If the surface on which the film is installed is flat, it is necessary to install a lag system that will allow you to obtain the required ventilation system and the degree of sagging of the material.

If there are attic windows, then waterproofing under the metal tiles should be done in such a way as to completely eliminate the appearance of so-called blind, unventilated areas. The film is attached to the joists using stainless steel staples. Please note that there is no need to save money when carrying out this stage of work. Use only high-quality staples that are reliable and highly resistant to corrosion

.

If the roof structure is complex, the overlap must be at least 2 cm. In places where there are passages for ventilation or pipes, the waterproofing film must have an overlap of at least 5 cm. The overlap can additionally be covered with another layer of film in order to increase its reliability .

What is a vapor barrier?

In residential premises there is always water vapor that circulates inside it. And according to the laws of physics, it rises with the warm air. Over time, it will penetrate into the under-roof space, where the insulation will begin to absorb .

To avoid these consequences, it is necessary to install a vapor barrier, which must be present in any roofing pie . Some believe that finishing the attic with cladding, which prevents moisture from entering, eliminates negative consequences. But it is recommended to always use a special coating that is placed between the ceiling and the insulation.

Let's sum it up

Films on the roof are needed to protect the insulation from moisture from the inside and outside. Without them, the thermal insulation layer will retain heat worse, and fungus and mold will begin to develop inside the roofing pie.

Which film to choose for the roof:

- For vapor barrier, polyethylene film with a thickness of more than 200 microns is best suited. The budget option is reinforced polypropylene, the optimal option is a foil vapor barrier.

- For waterproofing an attic, reinforced film is used; for a residential building, diffusion and superdiffusion membranes are used.

Which vapor barrier to choose for the roof?

There are the following types of vapor barriers for roofs:

Painting room

It is used more often for high-rise buildings, soft roofs made of roofing felt, iron roofing sheets, where insulation is not used. This vapor barrier is well suited for flat roofs. The main difficulty in using mixtures of this kind is preparing the surface before application. For this type of insulation, the following compositions are used:

- hot bitumen;

- bitumen-kukersol mastic;

- varnish based on chlorinated rubber or polyvinyl chloride.

Pasting (membrane)

This type is more popular, especially in individual construction . Materials for this type of insulation are produced in rolls and this provides some advantages:

- simplification of installation;

- ensuring a tight connection when overlapping;

- reduction in the number of seams.

Types of adhesive vapor barrier materials

- Waterproofing . Prevents steam from penetrating into the insulation. They have special perforation , which allows vapors to penetrate outside. It is mounted with some clearance from the roof covering, which promotes air circulation between the outer and under-roof space. Has unidirectional vapor permeability, keeps the insulation dry. You can read about waterproofing materials here.

- Anti-condensation . They are equipped with a special fleecy layer , which is located on their inner surface. It retains moisture and prevents contact with thermal insulation. Moisture quickly disappears due to air circulation in the gap. This type of insulation must be laid with an adsorbent layer to the inside of the room. Attached using a counter-lattice.

- Vapor-tight . They provide impenetrable protection to the inside of the roof insulation. Sometimes they have a layer of aluminum foil , which is capable of reflecting part of the radiant energy back inside. It is laid with a ventilation gap to the insulation. Provides good protection from moisture while retaining heat.

- Membranes . They are modern vapor barrier materials that can prevent moisture from escaping while allowing air to pass through . When using membranes, providing an air gap is often not necessary. This material for roof vapor barrier has gained great popularity these days.

Installation features

Laying waterproofing under metal tiles is carried out after preparing the rafter system. The work is carried out in the following order:

- A cornice strip is attached to the bottom of the rafters.

- Waterproofing material is rolled out along the outer surface of the rafters. The bottom edge of the strip should be 15–20 cm above the edge of the cornice batten.

- Strips of waterproofing material are connected to each other using construction tape.

- The counter-lattice is placed in the film laying area. These are 50x50 mm wooden blocks that are attached along each rafter, pressing the membrane against it. The counter grille is needed to create a ventilation gap. A sheathing is placed on it, to which the metal tile itself is attached.

- After installing the roofing, insulation from the inside begins (if planned).

It must be taken into account that when using any material other than diffusion membranes, a ventilation gap must also be arranged at the bottom of the waterproofing. This is due to the fact that condensation may form on the surface, which will be removed by air circulating in the gap. Laying the heat insulator close to the film in such cases is unacceptable.

Metal roofs are a practical and attractive solution for a private townhouse, country cottage or small apartment building. However, every roofer will confirm that the use of this material without proper waterproofing will lead to a decrease in the service life of the structure, problems with the rafter frame and the roofing itself. To protect the rafters from atmospheric moisture and condensation, waterproofing is installed under the metal tiles. In this article we will tell you what waterproofing materials exist, how to choose and apply them correctly.

Do you need a vapor barrier for a cold roof?

The special design of such roofs does not require laying two layers: thermal insulation and vapor barrier. This saves money and construction resources. Water vapor that passes through the film ends up between the waterproofing and the corrugated sheet, from where it is removed by an air flow.

Therefore, the main task when installing a cold roof is to ensure good ventilation , which is ensured by creating a gap using a counter-lattice.

Cold roof installation

Do you need a vapor barrier under the corrugated roof of a cold roof? No, it’s not necessary, the main thing is to take care of good ventilation.

Preparing for work

Laying a layer of waterproofing requires preparatory work. They include the creation of a rafter system designed according to preliminary calculations, installation of cornice and end boards. Only after this the waterproofing is laid.

Certain tools will be useful for installing waterproofing. These are a tape measure, scissors, a hammer, a marker, a construction stapler, and a screwdriver. You will also need to purchase bars and screws.

Tools for installing metal tiles

Vapor barrier for attic roof

The most commonly used materials are glassine, roofing felt and foil insulation. Also quite effective are modern membranes , which have proven themselves in this sector and are excellent for vapor barrier of soft roofs.

First of all, it is necessary to seal and insulate the various structural elements. The vapor barrier is laid on the insulation and secured using a method that corresponds to the surface material. You can read about insulating an attic roof here.

Fastening to concrete, brick and metal surfaces is carried out using double-sided adhesive tape, laid with a 10 cm overlap . And it is attached to the tree with nails or staples.

The foil film is installed as a reflective layer inside the room so that thermal energy remains inside the building. A gap is provided between the thermal insulation and vapor barrier parts for ventilation, as well as to create a warm air barrier.

Detailed diagram of the roofing pie of the attic roof

The joints of the film are taped with tape made of a material with a similar coefficient of thermal expansion. It is better to press the junctions of the foil to the wall with strips with sealant applied under them.

Installation technology

Waterproofing material is used to protect rafters and roof insulation from contact with condensation or atmospheric moisture. Installation of waterproofing is carried out after assembling the rafter frame, but before laying the roof covering. The technology for laying waterproofing material is as follows:

- The film or membrane is cut into strips, the length of which corresponds to the length of the slope plus 10-15%.

- Waterproofing under metal tiles is carried out with sagging, so that in the event of a leak, water pressure does not lead to rupture of the film or membrane.

- The film or membrane is laid in strips perpendicular to the roof rafters with an overlap of 10-15 cm.

- The waterproofing film or membrane is secured along the roof rafters using a construction stapler with high-quality stainless staples.

- Roofing felt is nailed to the rafters with regular or galvanized nails.

- The joints between the strips can be sealed using moisture-resistant sealant, construction tape, or left as is.

- After laying the film or membrane along the rafters, counter-lattice slats are installed, creating a ventilation gap.

Please note that without properly organized waterproofing, the service life of a roof covered with metal tiles is significantly reduced. This simple, inexpensive measure allows you to preserve the performance qualities of the roofing and insulation longer, which will save a lot of money usually spent on repairs.

Vapor barrier under corrugated sheets or metal tiles

Metal tiles are a thermally conductive coating, so with the onset of cold weather, condensation causes irreparable damage to them. To solve this problem, it is necessary to provide the roof with proper vapor barrier and waterproofing. Before choosing, you should decide what is more important: price or efficiency ? Let's look at which vapor barrier is better for metal roofing:

Cheap option - glassine and polyethylene

Glassine can last a long time, while it has sufficient flexibility and low cost . However, its large mass, unpleasant odor when heated and difficulties during installation make it not the best option.

Polyethylene retains steam well and protects the thermal insulation layer from moisture . It is cheap, but polyethylene is very easy to damage. It is difficult to install it yourself. Due to its significant mass, it is difficult to install the film to the corrugated sheet using the standard method. Therefore, installation occurs to the inside of the cladding using a stapler. The film is mounted in two layers.

Reinforced film, foil, membranes

In terms of price, it is also an acceptable option. Reinforced film consists of several layers with a reinforcing fabric mesh that adds strength. Light weight and rigidity allow you to install such insulation yourself. Attached with self-adhesive tapes . A significant drawback is the lack of an anti-condensation layer, which can negatively affect the insulation.

Which vapor barrier to choose for a roof under metal tiles? One of the best options is foil . It has low thermal permeability, which allows you to retain heat in the room, is lightweight and has sufficient strength. The big disadvantage of this material is its tendency to corrosion.

Functions

Metal tiles are a roofing material based on galvanized steel, coated with paint or polymer with a wavy relief. It has high thermal conductivity, therefore, due to the temperature difference inside and outside the house, it becomes covered with condensation, which significantly reduces the service life of the roof. If you do not install the waterproofing film, the following unpleasant consequences arise for the roof:

- Dampening of the rafter frame. If condensation gets on the rafters, the wood absorbs excess moisture, which leads to the spread of mold, mildew and rotting of frame elements. Ultimately, this ends in irreversible deformation of the roof structure.

- Moisture on the thermal insulation material. If the insulation is not protected by a waterproofing film or membrane, it becomes damp over time, which reduces its effectiveness by half. It is necessary to take into account that the properties of the thermal insulation material are not restored even after complete drying.

- Corrosion of roofing material. If waterproofing is not installed, condensation accumulates on the inner surface of the metal tile roof, contact with which causes the metal coating to begin to rust. The most vulnerable areas to corrosion are the places where roofing material is attached to wooden rafters. Rust, gradually corroding the metal tiles, significantly reduces the durability and reliability of the roof of the house.

Important! Waterproofing under metal tiles is a prerequisite for the durability, reliability and quality of a roof made of this material. If a waterproofing film or membrane is not used to protect the rafters and insulation, the service life of the roofing is reduced by more than half.

The modern construction market offers a wide range of materials for waterproofing, which differ in price, properties and application. The choice depends on the type of roofing pie at home and the financial capabilities of the buyer. To protect the rafters, insulation and roof covering from condensation, install:

- Ruberoid. Underlay roofing felt is the most accessible and inexpensive material for waterproofing under metal tiles. It has high water resistance, mechanical strength and an inexpensive price. However, it is used if the roofing pie of the roof of the house is of the cold type, since roofing material does not allow steam to pass through. Experienced craftsmen recommend installing roofing felt under metal tiles only in extreme cases, when there are no other options.

Note! If the roof structure is of a warm type, then only vapor-permeable materials can be used as waterproofing. In addition, the installation of the waterproofing film is carried out so that there is a ventilation gap between it and the roofing material. Waterproofing under metal tiles should not come into contact with either the roofing covering or the insulation.