The foundation for a house is a foundation that will last for many years. Its quality determines how warm the rooms will be, whether communications will be protected from freezing, and much more. Therefore, the choice of foundation must be approached with all seriousness. If the differences between a strip foundation and a monolithic one are roughly clear to everyone, then with a foundation on piles everything is not so simple. Therefore, we will consider the pros and cons of this design and compare it with the tape one.

Features of foundations on piles

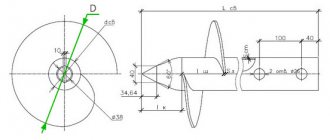

In this case, screw piles are used as supports, each of which is equipped with a kind of blades, which in turn fit tightly into the ground to a selected depth. Such structures are becoming increasingly popular due to their high load-bearing capacity. In addition, modern elements of this type are produced even more durable.

The thickness of the metal wall of a typical pile is 4-6.5 mm. This means that such a foundation can be built on problematic soil. It is in such areas that they are given the greatest preference.

Pros and cons of such a foundation

If we talk about the advantages, it is worth highlighting:

- Speed of installation.

- No need to use heavy construction equipment. The piles are driven in by hand.

- Possibility of building a house on swampy or loose terrain. This is the best option for unstable soils. Piles are also suitable for areas with large differences in ground height.

- Long service life.

- There is no need to carry out numerous preparatory work (digging trenches, etc.).

- Possibility of installing piles at any time of the year.

But no one is perfect, so such designs also have disadvantages:

- The risk of purchasing material of poor quality. In fact, there is a similar drawback when building a concrete foundation. If you purchase not steel piles treated with a protective compound, but made from other metals, the structure will be susceptible to corrosion.

Healthy! When selecting piles, be sure to check all welds. They must be neat and of high quality. The reliability of the entire structure will depend on this.

- Piles are very difficult to install on rocky soils. Since these products are equipped with blades, it is they that are damaged during the installation process. Because of this danger, it becomes impossible to install the structure to the required depth. As a result, the finished foundation turns out to be extremely unstable.

Also, the lack of a basement is often considered a disadvantage. But if desired, it can be organized without problems by sewing up the structure.

Of course, piles have fewer disadvantages than advantages, but the usual strip-type concrete structures also have them.

Delivery and installation process

Reinforced concrete piles are installed using a mini-pile driving machine. That's what they're called - driven ones. The crawler-mounted machine moves independently around the site, operates at high and low temperatures, and installs supports quite quickly. But delivering it to the site requires special equipment. However, in one shift it is possible to install about 40 reinforced concrete piles, that is, the foundation for a house.

Mini-pile driving machine drives reinforced concrete piles Source kkzm.ru

Screw piles are installed manually, electromechanically or, if absolutely necessary, using a hole drill. The best option is electromechanical installation. Today, any serious company offers it. How does this happen? Screw piles are installed using manual hydraulic machines. That is, the mounting hole is inserted into the gearbox, which creates torque. Compared to the manual method, the electromechanical method has advantages in terms of penetration and installation speed.

If the area where it is necessary to install the foundation is difficult to access for one reason or another, the only possible way is manual installation of screw piles.

Features of strip foundation

In this case, we are talking about a continuous closed structure, which is made only from the highest quality concrete mixtures. During the installation of such a foundation, reinforcement is required. The base itself is installed around the entire perimeter of the house.

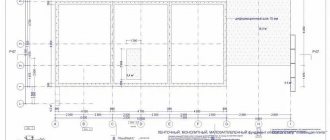

Strip foundations are suitable for both wooden buildings and more massive monolithic houses. During the construction process, trenches, a layer of waterproofing, etc. are prepared. At the next stage, formwork is assembled from plywood and boards, into which a metal frame is installed to strengthen the entire base. Then concrete is poured, the structure is covered and dries for 28 days.

Pros and cons of the foundation

Let's start, as usual, with the advantages:

- Such a foundation allows you to immediately begin arranging the basement during the construction process. You can lay out communications and think about the finishing.

- Simplicity of the device. You can build such a foundation yourself. The main thing is to purchase all the necessary materials of the best quality and familiarize yourself in detail with the features of laying the “tape”. Trenches are dug by hand, the same goes for reinforcement and concrete pouring.

- Concrete has high strength characteristics.

- If everything is done correctly, then groundwater will not have any effect on the foundation.

- A concrete foundation can also be installed on rocky soil.

Despite the apparent simplicity and relevance of such a foundation, it also has quite a few disadvantages. For example,:

- A lot of preparatory work will be required. Again, you need to dig trenches around the entire perimeter, install formwork, reinforcement, pour concrete, and dry.

- Long construction process. The point here is not even 28 days, but the fact that if you install such a foundation alone, then it will take you months just for the preparatory procedures.

- It is not recommended to pour a concrete foundation during the cold season. This means that all work will have to be clearly planned in order to be completed on time (a month before the onset of frost). Otherwise, the strength of the finished structure will be significantly lower.

- The concrete is poured immediately. You can't stretch out the pleasure over several days. Otherwise, joining seams will form, and this is again a minus in strength.

- This base is not suitable for peat soil and problematic soils.

Now let's go through the main parameters. Some people believe that concrete is 100% better than piles. Let's look at why this might not be the case.

Advantages and disadvantages

So, we are closer to the main goal. This is the number one question homeowners ask. After all, it is the advantages and disadvantages that characterize this or that type of foundation. The main advantage of a strip foundation is that you can build a garage or basement under the house. Monolithic structures can last more than 200 years due to their strength and reliability. What are the advantages of a screw foundation for a house? There are even more of them than you think. Let's look at everything in detail point by point.

Advantages

- Speed of foundation construction. You might be surprised, but with all the labor involved, you can build a screw foundation in just two days! Can you imagine, two days! If you take the same strip foundation, then you can spend two days, or even more, just digging a trench on your own. Is it worth talking about concrete work and hardening of the solution? You will be able to fully construct the building only after 30 days after pouring the foundation. Only during this time will the concrete dry completely.

- Excellent ability to withstand heavy loads. The fact is that a pile-screw foundation can be immersed even 8–12 m into the ground. Can you imagine how much material would be required for such a concrete foundation? With screw piles this is not a problem. It is enough to immerse them below the freezing point of the soil and groundwater deposits to ensure reliable fixation. The lower layers of soil are much denser. And thanks to the fact that the piles are screwed in, the soil does not loosen when digging, but is even more compacted.

- All work can be easily done on your own, without the use of special equipment. This is precisely why private developers value the screw type of pile foundation so much. After all, the driving option will require special equipment that will press the pile into the ground. And with a screw design, you just need to screw the support into the soil in a circular motion.

- It is also important that work on installing a screw foundation can be carried out regardless of the time of year. Summer, autumn, spring, winter - in any of these periods we can start work. If there is snow on the site, simply remove it.

- Since there is no need to transport sand, crushed stone and concrete to the construction site by truck, there is no need to take care of the access road to the construction site.

- Structures that stand on such a foundation can easily be expanded by adding a new room. And most importantly, you can make a screw foundation for an old house, reviving the old one. Watch a special report on this topic.

- One of the main criteria that speaks in favor of such a foundation is the possibility of constructing a building on almost any type of soil. If you are faced with the most difficult soil (heaving, marshy, quicksand, etc.), then a screw foundation is the right solution. For him, these types of soil are not a problem. The only exception is stony and rocky soil.

- The piles can be reused to build a new structure (terrace, veranda, garage).

- And finally - low cost. By choosing this type of foundation, you can save as much as 30 or even 40% of your budget. This is truly impressive. A strip foundation will cost three times more.

Note!

Despite the cheapness of construction, quality is not lost in any way. You get a reliable and durable base that can withstand high loads. Despite all its positive aspects, the foundation also has some disadvantages. Without them, as you know, you can’t go anywhere.

Disadvantages of a screw foundation

- In order for the foundation to serve you for a long and reliable service, it is important to perform the calculations efficiently. When you do not take into account the level of soil freezing or poorly calculate the load on each support, the foundation may sag.

- In addition, the foundation can be deformed due to poor-quality installation: unevenness of screwed-in piles, installation of screw supports in ready-made drills, poor piping.

- Unlike a strip foundation, it will not be possible to create an additional room.

- To save heat, the lower part needs to be sheathed and insulated.

- It is impossible to use a pile foundation in production. Therefore, those who want to build a large-scale structure should not think about a pile foundation.

- It is important to purchase high-quality material so that the piles meet the declared quality. Otherwise, they won't last long. And given the fact that this type of base is gaining more and more popularity, low-quality manufacturers are emerging who just want to sell you a bad product.

In fact, most grounds have such disadvantages. After all, if you use low-quality materials and do not adhere to installation technology when building a traditional foundation, then you cannot expect it to last long.

Floor warmth

There is an opinion that a concrete foundation will allow you to forget about cold floors, and the screw piles will be constantly ventilated. This is not true, and here's why:

- Concrete has high thermal conductivity, so it also quickly loses all accumulated heat.

- Since its thermal conductivity is higher than that of the soil, it will freeze faster, which means it will cool the floor in the house.

- If you do not prepare a layer of waterproofing when laying the foundation, the concrete structure will also constantly get wet. This means the floor will be even colder.

Thus, the concrete foundation becomes only a barrier to the wind. But it will not make the floor warmer in any way. The same results can be achieved by sewing up the piles. In addition, screw piles allow you to set up a simpler ventilation system. This means the ground will be drier and the floor warmer.

Departments

Accounting

The accounting department has all the necessary information about the receipt of payments from Clients for services provided by GlavFundament (sale of screw piles, construction of foundations on screw piles, express geology, design of foundations on screw piles, civil and industrial facilities). Each Client has the opportunity to promptly receive information about the receipt of his payment to the organization’s account. The department's tasks also include issuing invoices and documents closing the reporting period.

Vasiliev Denis Alexandrovich

Corporate department

The Corporate Department is responsible for fulfilling contractual obligations to Partners for the supply of screw piles to the GlavFundament company (quantity, nomenclature, assortment, timing and other terms of delivery). The department provides assistance in working with other departments and separate divisions of the company, providing the Partner with marketing, technical and logistics support, and promptly compiles financial estimates and other documents.

Head of Corporate Department

Kopev Evgeniy Sergeevich

Human Resources Department

The HR department of the GlavFundament company occupies a responsible position in the development of the organization's plans in terms of providing it with labor resources, carrying out selection, admission, official employment, adaptation, accounting and dismissal of employees.

The tasks of the department include carrying out work on the formation and preparation of a reserve of personnel for appointment to appropriate positions, advising senior management and heads of departments on personnel policy issues in the development of projects, the production of screw piles, and construction. The department evaluates the performance of each employee of the organization.

Base insulation

And again, fans of concrete insist that there will be fewer problems with a concrete foundation. Alas, no. The requirements for insulation and insulation of communications are the same for all types of foundations. Therefore, you should not hope that with a concrete base there will be less headaches.

You can’t do without finishing materials. Either concrete or sewn-in piles will have to be covered with siding, natural stones or panels made of fiber-reinforced concrete or other material. Accordingly, there is no winner in this matter at all. Perhaps there will be a striking difference in cost.

Which piles are better - reinforced concrete piles or screw analogues when building a house from SIP panels?

A house made from SIP panels is relatively lightweight, so for small one-story projects, metal screw piles or columnar foundations poured on site are also suitable. For two-story buildings with an attic, it is better to give preference to reinforced concrete.

When choosing reinforced concrete piles or screw analogues, the customer first of all determines the bearing capacity of the foundation. The type of soil should also be taken into account - engineers make a sample at an early stage of design. The house will not “walk” on concrete or a strong wooden grillage.

Price issue

Let's say we decide to build a small 8x10 wooden house. To organize a structure made of screw piles, we will need to spend money on the delivery of materials, installation, geological examinations and on the piles themselves. As a result, the foundation of screw piles will cost approximately 70,000 rubles. The most impressive cost columns will be for 16 piles (each approximately 2,250 rubles) and for their installation (approximately 38,000).

Well, if we go to build a strip foundation, then we will have to double the list of everything needed. If engineering and geological surveys for piles cost 2,500 rubles, then to calculate the strip foundation you will have to pay 55,000 rubles. Added:

- Reinforcement (about 7,000). And the fittings for our house itself will cost about 40,000.

- Pouring concrete (another 33,000 rubles). And of course you need the solution itself. It will cost another 50,000 rubles.

- Waterproofing (you can’t live without it, so you’ll have to spend at least 12,000).

- Plywood and burs (that's at least another 15,000).

The list can be continued longer. Ultimately, such a foundation will cost not just a pretty penny, but 270,000 rubles or more.

And that is not all. Can you determine the quality of concrete by eye? How to catch the moment when the reinforcement begins to be laid? Contractors almost always use cheaper materials. Therefore, such a concrete foundation will be too expensive. Piles are much easier to check. And their installation is usually carried out without problems in front of the customer.

Concreting technology

The first step is to make level marks, along which all sections are subsequently trimmed. The sand-concrete mixture is poured slightly below the edges. The mixture is prepared in a ratio of 1 to 3 cement and sand, respectively. Dry ingredients are mixed with water to form thick sour cream. The solution is poured into the sealed pipe manually using a rod. It sags in the pipe, so after a short period of time the top of the pile is again filled with cement or powdered concrete, which helps eliminate residual excess moisture, level the mixture and ensure high-quality pouring.

The mixture is poured dry, because over time it will become saturated with moisture, turning into stone. The pile filled with concrete solution is tied with a channel or a steel cap is placed on it for further fastening of the structure of the structure. The grillage connects the base elements, combining with the piles, adding them to its thickness. This relative arrangement of parts is used to construct the foundation of structures from any type of material. The base with a grillage does not need to be monolithic, because it is welded and secured to the heads of the elements.

As the solution settles, the pipe is topped up with it.

Heads are fixed on top of the structures.

At temperatures above 0ºC, the mixture can be diluted with water, but at sub-zero temperatures, an additive must be added to prevent the solution from freezing, since the pile can break due to the pressure difference when water expands in the mixture. Table salt serves as a budget additive, preventing water from changing to another state until the cement sets.

If the air temperature is quite low (-5ºC or more), then anti-frost liquids should be used to prevent the pile from collapsing and the poured solution from leaking out.

Necessary materials and tools for installation

To carry out the work you need to have heads at hand.

Materials for installing this type of foundation include:

- screw type piles;

- heads;

- wooden sticks for marking the territory;

- fine sand;

- cement and mixing tank;

- water;

- anti-corrosion agents for treating joints and seams.

List of necessary tools to complete the work:

- measuring tape 20 m;

- a marker that is applied to a metal surface;

- water building level and magnetic;

- discs for grinders that can handle metal;

- welding equipment;

- backup power supply;

- earth drill with removable cutters of suitable diameter.

Trimming piles

For such work it is necessary to wear personal protective equipment.

It is better to apply cutting marks with a permanent silver felt-tip pen, because this color is well reflected by the laser beams. The line along which the cutting is carried out is wrapped with a clamp for the correct cut. Next, a grinder with a thin disk performs the cutting process. This is a long and labor-intensive process; in 1 working day, a professional master can cut only 20 piles. It is imperative to wear headphones, glasses and thick gloves when performing work.

Reinforcement

The cutting of rods is carried out in accordance with the reinforcement diagram of the project. The reinforcement is assembled into a frame of a given shape, to which clamps are attached and fixed at their intersections. The grillage structure itself, if provided, is assembled according to the following principle:

The grillage also needs to be properly reinforced.

- The clamps are laid out every 400 mm.

- Longitudinal reinforcement is threaded inside.

- The crossing points are tied together with knitting wire.

- L-shaped rods are tied to the grille for fastening to the grillage.

Pouring concrete

Roofing material and a reinforced frame are inserted into the prepared recesses. The pile is filled with sand-cement mortar. This is necessary to block the flow of oxygen and water into the pile and to provide additional resistance to horizontal loads. The process of filling a well is carried out layer by layer. Each layer is 200 mm. The volume of the poured mixture is compacted with a hand vibrator or improvised means. All that remains is to weld the heads, channel or something similar as the base of the crowns.

Deepening

Some people naively believe that if we are talking about a modest wooden house, then there is no need to deepen the foundation. Like, what will a small shed do to him? Alas, the foundation of the house must always be below the freezing depth. Otherwise, the foundation will move, float and completely deform in a few years.

Therefore, you won’t be able to save money here either. Either make a full-fledged concrete foundation, or choose piles.

Strip-pile foundation

This structure makes it possible to reduce the cost of construction work and increase the strength of the building.

A pile foundation with strips is a type of monolith that is ideal for soils such as heaving and weak ones. A distinctive feature is that the walls press on a solid strip base, and the strength of contact with the hard rocks of the earth is created by piles that are mounted at depth.

This structure makes it possible to reduce construction costs and increase the strength of the building.

Technical description

In this design, the tape is responsible for dividing the load evenly, which protects the building from deformation.

In this design, the tape is responsible for dividing the load evenly, which protects the building from deformation. Piles stabilize the tenacity of the building to solid soils, which protects the building from subsidence and distortions during seasonal soil shifts.

This combination of elements at the base makes it possible, even on a moving plot of land, to erect a stable and durable building that is not afraid of the climatic conditions of the soil. The most common use of such a foundation is observed in areas of marshy soils, which are characterized by a humid climate and high groundwater.

Variety

It is the features of this combination that contribute to high strength and protection from soil shifts

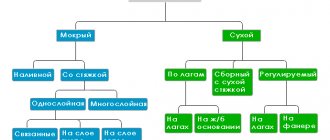

There are three types of such foundation:

- Having a pile screw. In this case, metal piles are used, which have blades of certain sizes. They are installed in the ground with your own hands or with specialized equipment. To extend their service life, it is recommended to treat them with a primer or special paint for protection.

- Bored piles. They are installed on the construction site, so their price is much lower. The first thing these parts require is a well of a certain size not below the soil freezing level. The principle of construction is a reinforced water intake, which is filled with a concrete solution.

- Pile foundation made of pressed elements. It differs in its design. Its design consists of a monolithic reinforced concrete strip on which all piles are installed.

The advantages of basing such a combination

Pile strip foundation has the following advantages in its functionality:

Construction speed. This foundation is erected in a matter of time. This is due to the shallow penetration of the tape and the ease of installation of piles.

- Low cost. This base does not require special costs, for example, like a deep tape base. It is worth noting that the result of the work is practically no different.

- No need for correction if calculated correctly. And in this case, repairs will not be useful for ten years, because the device is not influenced by water, flowability and antinodes of the soil.

Disadvantages of a pile strip foundation

Buildings that are based on such foundations have a number of disadvantages. So, the disadvantages of the designs:

- Impossibility of constructing a basement or basement. For such purposes, the tape part should be immersed lower in the ground.

- There is an additional need to insulate the floor covering, since the soil can freeze.

Durability

If we talk about concrete, then according to the unchanged GOST 27751-2014, if everything is done in accordance with the technology, then such a foundation will last at least 50 years. In this case, it is necessary to take into account operating conditions, quality of materials, negative environmental influences, waterproofing and much more. Only with an ideal balance of all characteristics will the concrete foundation last the stated period.

At the same time, 1 mm of steel (St20), which is usually used to make piles, will last at least 40 years without any coating, even if it is located in loam. But piles are made with a wall thickness of up to 6.5 mm. But you need to take into account loads and other parameters. But in any case, piles certainly cannot last less than concrete. Even if the piles are installed in the so-called aggressive soil (where there is slag, ash, etc.), the structure will still fully meet the requirements of GOST.

Healthy! Galvanized piles should not be installed. Even in the best conditions, they last no more than 15-20 years.

What is better - reinforced concrete piles or screw piles made of reinforced concrete?

Screw-type concrete products are a relatively uncommon phenomenon. More often, a person chooses between load-bearing elements made of concrete with a square cross-section or made of metal. It is up to the owner to decide whether to choose rectangular reinforced concrete piles or screw piles for building a house, and engineers will advise on choosing the most effective technology for a specific project. In most cases, it is recommended to pour the columnar foundation in situ. This is economically feasible; the load-bearing capacity of such a foundation is quite sufficient for houses made of SIP panels. When wondering which piles are better - reinforced concrete or screw, remember that concrete products have a load-bearing capacity that is at least twice as high.

You can use the services of construction of houses from SIP panels on a turnkey basis in Moscow and the Moscow region. We use only high-quality materials and technologies, have implemented hundreds of projects, and organize the delivery of panels or house kits throughout Russia.

Reliability

Although concrete looks much more reliable than piles, this does not in any way indicate its real characteristics. Firstly, the concrete still needs to be laid correctly so that it hardens evenly. And this takes up to 28 days. Of course, you yourself will have to monitor the concrete base for almost a month. If you violate precautions, then all the work will be in vain. But even if the builders themselves made a mistake, how can you then prove that it was not you who walked on the unfrozen foundation, and their hands were completely off their shoulders?

With screw piles everything is simpler. They did the work, looked at it, accepted it. All the defects are immediately visible and can be asked to be corrected on the spot. You don't have to wait weeks to appreciate the build quality at all. And you don’t have to hide them from sunlight. Thus, with the greatest probability, they will build you the wrong “ribbon”, which means that its reliability will be at a low level.

Pouring concrete for screw piles

If the question of whether screw piles need to be filled with concrete is not raised and the master understands the feasibility of this stage of work, it is necessary to begin studying the technology. A standard screw pile is a metal pillar, which is equipped with a screw blade on one side and a special technical hole on the other. This element allows you to securely fasten the foundation under the building, making it stable and durable.

Why is concreting necessary?

Concreting makes piles more resistant to different types of loads, extends their service life, and significantly increases functionality. A properly concreted pile will last many times longer than one reinforced with zinc. Also, pouring concrete into the pile is necessary in order to protect it from corrosion, which is done by displacing air from the pipe. Concrete significantly increases strength and saves money.

Brands of concrete used

For concreting, it is best to use low-fraction concrete of grades M200 or M300. The M200 brand is best suited for the construction of one-story buildings or two-story buildings with light floors. The brand is used in the creation of reinforced concrete products and is considered structural in strength. M300 is suitable for building a foundation for a building up to 5 floors.

Technology

Before pouring concrete into screw piles, you need to prepare everything: find a watering can for pouring the mixture, cut and insert reinforcement into size, a concrete mixer or a container for mixing concrete.

All rods must be precisely adjusted in height. If installation holes remain after pouring, they can be sealed with paper tape, which is removed after the concrete has hardened.

The main stages of pouring concrete into piles:

- Preparation of tools and materials

– you need to decide in advance on the type of piles, the method of creating them, the type of immersion, and location. Depending on these factors, the tools are selected: usually a drill, shovels, a level, twine, pegs, a tape measure, a special tool for working with reinforcement, a construction vibrator. Materials: the piles themselves, a mixture of sand and gravel, everything for preparing a concrete solution.

- Trimming piles

– the supports must be installed perfectly level, so they use a special tool: an excavator attachment is attached to a kind of boom, inside with a powerful cutting tool that levels the supports.

- Inserting steel bars

.

- Pouring concrete

– directly into the trunk, layer by layer, with a tamper. It is imperative to ensure that no voids appear in the area where the pile adjoins the concrete.

Process Benefits

Screw piles help create a durable foundation, protect reinforcement from corrosion, and are used for construction on all types of soil. When installing supports, it is not necessary to carry out excavation work, since the soil under the piles almost does not freeze and does not show heaving. On such a structure you can build a reliable and durable brick house.