Organization of electrical safety is one of the main requirements when commissioning residential premises, private houses or detached outbuildings. A lightning strike or short circuit can lead not only to material losses, but also lead to more tragic consequences. Such cases can be prevented by constructing a reliable grounding loop. Among the many options for its design, some professional builders recommend using screw piles as grounding electrodes. However, experts working in the electrical industry question the advisability of such use of products, so there is no consensus on this matter.

Advantages and disadvantages of grounding devices with screw piles

The advantages of using screw piles are due, first of all, to the ease of installation of the grounding structure being constructed.

Screwing in the support eliminates a significant amount of excavation work. The thickness of the pile wall, ranging from 3 to 5 mm, guarantees long service life, and the large surface area guarantees reliable grounding. However, some experts point out that the presence of welds is unacceptable for structural elements used for grounding objects. Welding areas are primarily subject to electrolytic corrosion. The presence of an electrical substation, railway tracks or cell towers near a grounded building, where there is a high probability of electricity leaks into the ground, leads to a significant reduction in service life and destruction of the screw pile.

Before carrying out work on installing the grounding structure of a private house, it is recommended to seek advice from employees from the power supply network organization serving the area. They will help you make calculations for high-quality grounding, advise which materials are best to use, and, if necessary, draw up design documentation.

An important part of construction and installation work during the construction of any structure is the organization of electrical safety. Protective grounding with screw piles is a simple and affordable option for constructing a circuit.

The selection of the length of piles for grounding is carried out based on data on the depth of soil freezing in the construction region: if the piles are not immersed 0.1 m below the average value of soil freezing over 10 years, they will not perform the protective function assigned to them. The trunk diameter may not exceed 57 mm.

What kind of concrete is used for filling?

According to the documentation, work can be performed with M350 grade solution.

The design documentation regulates the grade of concrete for piles M350 or low-grade M200. The characteristics of the mixture make it possible to use it for the production of products and structures that carry extremely high loads. Strength characteristics belong to class B 25, where a pressure of 25 MPa per 1 m2, which creates a high level of wear resistance.

Insulation of pile-screw foundations

Insulation scheme for pile-screw foundations

The technology for insulating pile-screw foundations is practically no different from insulating strip grillages, because they are present everywhere. But there is one feature here - the possibility of insulation only at the level of the grillage, because it is technically practically impossible to insulate piles. In such cases, a strip plinth made of concrete blocks or bricks is erected around the perimeter of the base, and the internal space is filled with expanded clay or soil. The technology itself is not complicated, but it is quite labor-intensive and requires appropriate knowledge.

Is it possible to make grounding on screw piles

Question:

Asks Vladimir from the Sverdlovsk region. "Good afternoon! I'm interested in the following question: is it possible to use screw piles for grounding? And if so, is it possible to install grounding on the pile foundation itself or is it necessary to make a separate structure?”

Answer:

Good afternoon, Vladimir!

According to the PUE standards, any massive rolled metal can be used as vertical grounding electrodes. Since these elements need to be buried to a depth of 2 - 3 m, this is much easier to do when choosing screw piles.

Screw piles can be used as a grounding loop with proper piping, only when coated with zinc. If polymer anti-corrosion paints are used, the efficiency of the pile as an electrical conductor tends to zero.

If you want to make a grounding device from screw piles

The charger circuit consists of conductors placed vertically deep in the soil, tied with a horizontal circuit (usually in a triangular configuration), and a bus that approaches the house. The main difficulty when installing vertical electrodes is their length, since 2-3 m rods are inconvenient to drive into the ground at the initial stage.

A grounding loop made of screw piles, which serve as vertical conductors in it.

This inconvenience can be completely eliminated if you buy a screw pile that does not need to be driven. Products of SHS or other modifications are screwed in alone with an electric drill with a multiplier (torque amplifier) or manually (you will need crowbars and two assistants).

Important! Before making grounding, you should calculate and then measure the loop resistance. The housing of the electrical installation (your household electrical network) will not receive damage only if the charger resistance is minimal

The potential dangerous for electrical appliances must be distributed completely into the ground.

When constructing grounding on your own, you should take into account the recommended cross-sections of vertical conductors depending on the rolled metal used:

- strip – minimum 12 x 4 mm

- rod – 3.6 mm

- corner – 40 x 40 mm

- pipe – wall thickness minimum 3.5 mm

Manufacturers usually make screw piles from thick-walled pipe with a minimum of 4 mm wall. Therefore, there are no problems; you can buy SHS of the minimum diameter from the available assortment with a length of 2-3 m.

Important! All manufacturers of screw piles use anti-corrosion coating. Therefore, when purchasing, you need to choose the option of hot or cold galvanizing

If the assortment only offers SHS with a polymer coating, such piles should be abandoned or the reason explained and the products purchased completely without coating.

Protective grounding device with screw piles

The structure being constructed for grounding a house is usually a metal closed loop in the shape of an equilateral triangle. At the tops of its corners there are screw piles used as grounding electrodes. They are buried below the soil freezing level, a value that is taken on the basis of average values for a particular region over the past few years.

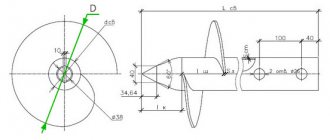

Based on the standard range of standard sizes produced by the industry, the use of screw supports with a diameter of 57 mm is quite suitable for installing a grounding loop. With a standard length of 2-2.5 meters, the products can be used in most regions with temperate climates. The work is performed in the following sequence.

- For the construction of the grounding loop, a suitable site is selected at a distance of at least 1 meter from the foundation of the house and markings are made for the location of screw-in screw piles. It must be taken into account that the distance between the planned points should not be less than the length of the support itself.

- The designated points of the vertices of the triangle are connected to each other by a trench dug along its perimeter, the depth of which should be at least half a meter.

- Screw piles are screwed into the tops of the corners.

- The structural elements are connected to each other in a closed loop by welding. In this case, you can use various rolled metal products, the section thickness of which is at least 4 mm. The welded areas are treated with anti-corrosion compounds.

- From one of the corners of the structure being constructed, another trench is dug in the direction of the electrical distribution panel. The connecting conductor is placed in it.

- The conductor is fastened using a conventional nut connection to a bolt pre-welded to the harness. The second end is connected to the main ground bus of the power distribution panel.

After completing installation, it is necessary to check the resistance of the ground loop. According to the PUE, its value for a 220 V electrical network should not be more than 30 Ohms. Measurements are made in dry weather (at maximum resistance of the soil itself). If the measurements taken satisfy the technical operating standards, you can begin backfilling the trench.

How much does a foundation like this cost?

Let's consider the cost of a screw foundation for a small house 6:6 m. The optimal layout of a pile field consists of 9 piles.

Then the owner of the site will be required to pay for the installation of 9 pieces (cost from 650 to 1100 rubles / piece) and the price of the piles themselves.

It depends on the length and diameter - for example, VS-57 (diameter 57 mm) 3 meters long costs 1100 rubles with installation or 1200 without installation.

If you decide to use VS-108, then the price without installation (for a 3-meter trunk) will be 1150 rubles with installation and 1350 without installation. The difference in purchase price with and without installation is intended to encourage ordering installation from this company.

As a result, the cost of the foundation will be about 20,000 rubles. But this amount does not include delivery and other overhead costs, so it is necessary to have some reserve.

Prices at other companies may differ; this must be clarified directly on site..

Is it possible to use screw piles as grounding - requirements for the device

Organization of electrical safety is one of the main requirements when commissioning residential premises, private houses or detached outbuildings. A lightning strike or short circuit can lead not only to material losses, but also lead to more tragic consequences.

Such cases can be prevented by constructing a reliable grounding loop. Among the many options for its design, some professional builders recommend using screw piles as grounding electrodes.

However, experts working in the electrical industry question the advisability of such use of products, so there is no consensus on this matter.

Screw pile foundation and grounding

Among the objective advantages of using screw piles in low-rise construction, it is worth highlighting, first of all, the absence of a large volume of excavation work, the relatively low cost of construction and a sufficient degree of strength of the foundation of the future building. At the same time, many private developers are wondering whether it is possible to use the very foundation of the pile-screw structure being built as grounding and how this may affect its operational characteristics.

It would seem that significant deepening of the supports of the base of the building provides an exceptional opportunity for high-quality grounding of the home electrical network. However, it is worth remembering that screw piles are treated with various anti-corrosion paint and varnish compounds to increase the service life of the foundation. Made, as a rule, on the basis of polyurethane resins, such coatings make the support unsuitable for use as grounding, since they are a good dielectric.

Answer

Leave your tips and comments below. Subscribe to our newsletter. Good luck to you and good luck to your family!

- Question: Can a water well casing be used as a ground electrode?

- What is and how to do zeroing

- Question: We need a staircase to the second floor, there is not enough space

- What kind of foundation for a garage should be made from FBS blocks?

- How to insulate a bath

- What is the minimum slope of a gable roof for normal snow melting?

- How to make, build a fence from corrugated sheets with your own hands

- How to build a 10x20 m garage from a met sandwich. frame?

- Question: Which roof design is best for an extension?

- Question: There is no ventilation in the apartment, how can I do it?

- Load on the septic tank lid from cars passing over it

- Question: How to repair and insulate a roof

- How to navigate by the stars and moon

- Question: About waterproofing and flooring in a cellar on the river bank

- Vegetable storage in the basement (raise and insulate the walls, arrange ventilation)

- Siding frame for a house made of foam blocks

This can lead to accelerated wear of the piles due to increased corrosion, especially if there are current leaks to the ground. It is better to arrange a separate grounding.

Thickness and grade of metal

Screw piles can be made from pipes with different wall thicknesses. They are divided into:

- thin-walled, made from pipes with a wall thickness of up to 3.5 mm;

- medium thickness - from 3.5 to 6 mm;

- thick-walled piles - 6 or more millimeters.

The choice of piles according to this criterion will directly depend on the composition of the soil at the site of their installation, as well as on the expected load. This parameter of the piles is determined when drawing up the project, and the choice is made in accordance with the data obtained during studies of the corrosion activity of soil layers.

Using the same data, the thickness of the metal for the blades of the pile is selected, but it must be remembered that if the blades are made of steel up to 5 mm thick, they are suitable only for light buildings. If a large massive building is being erected, then the thickness of the blades should not be less than 6 mm.

Based on the soil studies, the steel grade of the products is selected:

Reasons for choosing a pile foundation

- Low bearing capacity of the soil. If strong layers of soil are below the surface, significant swampiness, humidity (closely approaching groundwater), the soil is loamy, clay, sandy, with a lot of humus or excessively dense.

- For deep freezing (over 2 m). In permafrost conditions and areas where the soil freezes heavily.

- With heavy load on the ground. During the construction of multi-storey buildings or bridges with a structural weight of more than 350 tons.

- Small area. When the size of the foundation is limited by the small size of the construction site.

- We need to save money. On average, a foundation on piles is 2 times cheaper and is built faster than any foundation with deepening. Little concrete and reinforcement are used for construction work.

Pile foundation: examples

Construction of pile foundations

A pile foundation consists of piles, as well as a foundation connecting them. Piles can be ready-made (factory-made) or manufactured on site.

The following are used as the basis for pile foundations:

- grillages;

- strip and column foundations;

- cross strips and slabs of different sizes.

Piles + slabs together create a pile-slab foundation. It is actively used to reduce the overall and uneven settlement of houses

Installation of a pile foundation with grounding

The grounding loop for a building is made in the form of a closed system, most often shaped like an equilateral triangle. At the tops of the corners there are screw supports used as electrodes (grounding devices). The piles are screwed in so that they are below the freezing level of the soil. The exact depth of depth is established based on the standards adopted for a particular region. Before starting work, a soil sample is taken.

The work is performed in the following order:

- To create a grounding system, select a site that is at least 1 meter away from the foundation of the building.

- The area is marked for further installation of screw piles. The distance between the marked points must be equal to the length of the support or exceed this figure.

- The designated points at the vertices of the triangle are united by a trench dug along the perimeter of the geometric figure. The recommended trench depth is at least 50 centimeters.

- The supports are screwed at the tops of the corners.

- Once the connections are made (by welding or, more preferably, bolting), the structure becomes a closed loop. Any metal products (tape, pipes, etc.) are used as connectors. The thickness of the metal tape should not be less than 4 millimeters. The connections are treated with an anti-corrosion compound.

- From one of the corners of the ground loop, another trench is dug, directed towards the switchboard. A connecting conductor is placed in the trench.

- The conductor is fastened with a nut with a bolt pre-welded to the harness. The remaining end of the conductor is connected to the main grounding bus of the switchboard.

To reduce the resistance of the ground electrode, it is recommended to connect it to natural grounding objects.

These include:

- water pipelines and other metal pipe communications located in the ground (except for pipes with flammable compounds);

- reinforced concrete and metal structures of buildings in direct contact with the soil;

- well casing pipes.

Brief and general installation diagram

Procedure:

- Marking the pile field.

- Screwing piles.

- Filling the pipe cavities with concrete, trimming the tops to obtain a flat surface.

- Installation of headers.

- Installation of grillage.

It is recommended to carry out installation using special machines. This makes it possible to ensure verticality and the absence of rocking of the pile when screwing, which promotes maximum close contact with the ground . Welding areas and those damaged during the process are tinted with a protective anti-corrosion compound.

Types of piles used for foundations

Today, there are several types of piles that can be used to construct a pile foundation. Among them:

- Driven piles.

- Screw piles.

- Bored piles.

Let's consider each of these types in more detail.

Driven piles

This type of pile gives the foundation the greatest stability. The thing is that during the design of a future structure, designers calculate the future weight of the building and divide it between all the piles. During their installation, each pile is subject to a force that it will then have to withstand. When the pile stops going into the ground, this may mean that it has reached the ground on which the structure can already stand.

The soil compacted around it gives additional stability to the pile. Driving this kind of piles can only be done using a special pneumatic hammer, which is very expensive to use in private housing construction. That is why this type of pile is not recommended for self-construction of such a foundation.

Screw piles

This type of pile is an ordinary steel pipe, at the end of which elements that resemble threads are welded. In fact, this type of pile can be compared to a self-tapping screw, that is, they are screwed into the ground according to the same principle as a self-tapping screw. Thanks to its blades at the ends, the support area increases, which in turn increases the strength and reliability of the structure. If the soil at the construction site is not dense enough and even unstable, then piles can be used on which blades are welded along their entire length.

This type of piles can be used for both private and industrial construction. Piles can be screwed in either manually or using special equipment. If you screw in the pile yourself, this will require several strong people

As a rule, at the other end of the pile, there are two holes that allow you to connect them to the screwing technique, and it is very important that when screwing the pile, it is positioned strictly vertically. When the pile is completely screwed in to the required level, concrete is poured into the pile pipe and the head is welded, onto which a grillage is subsequently installed

Some disadvantages of such piles should be noted:

- A screw foundation requires an accurate calculation of the depth of solid soil, otherwise the pile will not be stable, especially during soil heaving.

- Piles must have high-quality welds, otherwise during the process of screwing the pile, the blades may come off or be damaged. This may lead to loss of load-bearing capacity.

- Piles must be covered with a high-quality layer of factory paint, otherwise poor-quality coating can lead to corrosion.

Bored piles

This type of piles is quite often used in private housing construction. In order to carry them out, it is necessary to make holes for the piles with a hand drill, after which formwork is performed in case of loose soil that crumbles.

Such piles are waterproofed using roofing felt or any other insulating material (asbestos-cement pipes can be used), reinforced, after which concrete is poured directly into the well. Piles are installed along the entire perimeter of the future foundation, that is, in the corners, along the external and internal walls. The number of piles depends on the total weight of the future structure.

Among the disadvantages of these piles is the inability to accurately determine whether the pile has reached solid ground or not.

Concreting technology

The first step is to make level marks, along which all sections are subsequently trimmed. The sand-concrete mixture is poured slightly below the edges. The mixture is prepared in a ratio of 1 to 3 cement and sand, respectively. Dry ingredients are mixed with water to form thick sour cream. The solution is poured into the sealed pipe manually using a rod. It sags in the pipe, so after a short period of time the top of the pile is again filled with cement or powdered concrete, which helps eliminate residual excess moisture, level the mixture and ensure high-quality pouring.

The mixture is poured dry, because over time it will become saturated with moisture, turning into stone. The pile filled with concrete solution is tied with a channel or a steel cap is placed on it for further fastening of the structure of the structure. The grillage connects the base elements, combining with the piles, adding them to its thickness. This relative arrangement of parts is used to construct the foundation of structures from any type of material. The base with a grillage does not need to be monolithic, because it is welded and secured to the heads of the elements.

At temperatures above 0ºC, the mixture can be diluted with water, but at sub-zero temperatures, an additive must be added to prevent the solution from freezing, since the pile can break due to the pressure difference when water expands in the mixture. Table salt serves as a budget additive, preventing water from changing to another state until the cement sets.

If the air temperature is quite low (-5ºC or more), then anti-frost liquids should be used to prevent the pile from collapsing and the poured solution from leaking out.

Necessary materials and tools for installation

Materials for installing this type of foundation include:

- screw type piles;

- heads;

- wooden sticks for marking the territory;

- fine sand;

- cement and mixing tank;

- water;

- anti-corrosion agents for treating joints and seams.

List of necessary tools to complete the work:

- measuring tape 20 m;

- a marker that is applied to a metal surface;

- water building level and magnetic;

- discs for grinders that can handle metal;

- welding equipment;

- backup power supply;

- earth drill with removable cutters of suitable diameter.

Trimming piles

It is better to apply cutting marks with a permanent silver felt-tip pen, because this color is well reflected by the laser beams. The line along which the cutting is carried out is wrapped with a clamp for the correct cut. Next, a grinder with a thin disk performs the cutting process. This is a long and labor-intensive process; in 1 working day, a professional master can cut only 20 piles. It is imperative to wear headphones, glasses and thick gloves when performing work.

Reinforcement

The cutting of rods is carried out in accordance with the reinforcement diagram of the project. The reinforcement is assembled into a frame of a given shape, to which clamps are attached and fixed at their intersections. The grillage structure itself, if provided, is assembled according to the following principle:

The grillage also needs to be properly reinforced.

- The clamps are laid out every 400 mm.

- Longitudinal reinforcement is threaded inside.

- The crossing points are tied together with knitting wire.

- L-shaped rods are tied to the grille for fastening to the grillage.

Pouring concrete

Roofing material and a reinforced frame are inserted into the prepared recesses. The pile is filled with sand-cement mortar. This is necessary to block the flow of oxygen and water into the pile and to provide additional resistance to horizontal loads. The process of filling a well is carried out layer by layer. Each layer is 200 mm. The volume of the poured mixture is compacted with a hand vibrator or improvised means. All that remains is to weld the heads, channel or something similar as the base of the crowns.

Sources:

https://svaigermes.ru/news/nuzhno-li-betonirovat-vintovye-svai-iznutri/ https://glavfundament.ru/articles/obosnovanie_neobkhodimosti_betonirovaniya_stvola_vintovoy_svai/ https://svaisad.ru/articles/stoit-li-zalivat- vintovye-svai-betonom/ https://radosvai.ru/o-kompanii/stati/betonirovanie-vintovye-svai/ https://znaybeton.ru/rabota-s-betonom/zalivka/betonirovanie-vintovyh-svay.html

Which grillage is better to choose?

Experts recognize that a pile-grillage foundation is an ideal option for structures made of frames, bricks or blocks that will be built on sand, loam, and sandy loam. In this case, the ratio of the following indicators is also ideal - cost, quality characteristics and reliability.

For the construction of a small and relatively light structure, it will be enough to use up to 100 piles, the diameter of which will be no more than 200 mm, but in the case when greater load-bearing capacity is required, the following move is used - the base of the piles is increased to a value of 400 mm. It is also worth noting that there are only two options for constructing a grillage - monolithic and hanging, which have their own advantages and disadvantages.

Hanging

The design of a hanging-type pile-grillage foundation is a foundation in which there is a small gap directly between the grillage and the soil itself (it is this that prevents the soil from affecting the foundation if it swells). This type of grillage is considered very economical, because in this case the walls of the well act as formwork.

To prevent the cement laitance from leaking out, a cover is made from roofing felt (sometimes polyethylene foam is also used), which covers the inside of the well. Since such a foundation can only be built on sufficiently strong soils, this option is rarely used. In order to determine how practical the foundation is, the pros and cons of a grillage foundation on piles need to be considered in more detail.

Monolithic

In this case, the formwork is pipes made of various materials (metal, cardboard or asbestos cement), and their diameters are different. To ensure a strong structure, reinforcement cages become an indispensable component of the grillage device under consideration.

Wooden houses on screw piles

Is it possible to use a foundation on screw piles as grounding?

The safety of your building is one of those characteristics that determines the degree of readiness of the facility for commissioning. One of the key parameters of electrical safety during the construction of your home is properly organized grounding on the pile foundation. Most experts recommend using foundation screw piles as a conductor when creating grounding.

Many clients ask the question: is it possible to use screw piles in Mozhaisk to organize reliable grounding? On the one hand, the deep location of the pile foundation is a circumstance that points in favor of creating a reliable grounding system. Meanwhile, as a rule, before installing them in the ground, piles are treated with paints and varnishes containing polyurethane resins. The peculiarity of these paints is that they are excellent dielectrics. Although such surfaces are characterized by increased resistance to corrosion (which extends the service life of the metal), they cannot be used in a grounding loop (according to PUE 1.7.82, screw piles must be combined with the building’s grounding system). Thus, grounding a pile foundation is a valid option only in the absence of dielectric coatings, and to protect piles from corrosion, special conductive paints or galvanized coating must be used. To create grounding on a pile foundation, experts recommend using galvanized supports.

The grounding loop for a building is made in the form of a closed system, most often shaped like an equilateral triangle. At the tops of the corners there are screw supports used as electrodes. The piles are screwed in so that they are below the freezing level of the soil. The exact depth of depth is established based on the standards adopted for a particular region. The industry produces certain standard sizes of screw supports for grounding a private house; piles with a diameter of 57 millimeters and a length of 2 to 2.5 meters are most suitable. Such supports are applicable to the conditions of the Mozhaisk region, that is, with a temperate climate.

The work is performed as follows:

- A site is selected that is at least 1 meter away from the foundation of the building.

- The area is being marked for further installation of screw piles. The distance between the marked points must be equal to the length of the support or exceed this figure.

- The vertices of the resulting triangle are united by a trench dug along the perimeter of the geometric figure. The recommended trench depth is at least 50 centimeters. Screw piles are screwed into the tops of the corners.

- After making connections by welding, the structure turns into a closed loop. Any metal products (tape, pipes, etc.) are used as connectors. The thickness of the metal tape/strip should not be less than 4 millimeters.

- The finished connections are treated with an anti-corrosion compound.

- From one corner of the resulting ground loop, another trench is dug, directed towards the building's distribution board. A connecting conductor (tape/strip) is placed in the trench. The conductor is fastened with a nut with a bolt pre-welded to the harness. The remaining end of the conductor is connected to the main grounding bus of the distribution board.

Grounding check

After completing the installation, be sure to check the resistance of the ground loop. In accordance with the rules for electrical installations, the resistance indicator for an electrical network with a voltage of 220 Volts should not exceed 30 Ohms. Measurements are carried out in dry weather (during such periods the greatest soil resistance is observed). If the measurement results are within the normal range, the trench with the grounding loop is covered with earth, after which the grounding is ready for operation.

Before proceeding with grounding a pile foundation, it is necessary to consult with specialists. Experts will give recommendations regarding the correct installation and operation of screw piles in Mozhaisk and the Mozhaisk region.

Grounding in a country house

Greetings! This may be a moronic question, but I’ll still risk asking; I'm not familiar with the theory.

Is it possible to ground the foundation of a house using screw piles? Piles (15 pieces, pipe diameter 108mm, house 6x9) with a depth of 3 to 4 meters, welded together with a profiled pipe.

Thanks in advance for an adequate answer.

Can. It's interesting to measure the resistance.

worex Greetings! This may be a moronic question, but I’ll still risk asking; I'm not familiar with the theory.

Is it possible to ground the foundation of a house using screw piles? Piles (15 pieces, pipe diameter 108mm, house 6x9) with a depth of 3 to 4 meters, welded together with a profiled pipe.

Thanks in advance for an adequate answer.

Of course you can. First of all, you need to use natural grounding electrodes.

I've already wondered about this question. Having talked with the installers who install such foundations, it turned out that they are all treated with an anti-corrosion compound, something like tar only that is “stronger” is very difficult to even pick off. And therefore, they CANNOT be used as vertical grounding conductors.

I also asked the installers what the pile would look like if it was unscrewed, but it turned out that when screwed in, this miracle coating erases perfectly. And the pile is perfectly polished with primer. Especially if you screw it into the sand. Don't believe marketing fairy tales. No coating will hold up and will be erased during screwing. But not many will tell you this.

Thanks for the answer! How to take measurements correctly? Is it possible on your own with available equipment?

Thanks for the answer! What is meant by natural grounding? Or do you mean preference for soil over other methods?

This is when to unscrew. What does she look like when she was just closed? In your case, all that remains is to experiment. Tie all the piles and take measurements as the Master wrote above. Tell me later how it all turned out.

This is exactly what your piles are meant to be.

Why do the piping with a strip if the piles are already welded together with a profiled pipe? In our work we use screw piles as a vertical grounding conductor. They have different external coatings, including galvanization. They measured it at one of the objects - it is possible to ground the power lines.

In addition to the existing profiled pipe piping? Pipe being welded. In principle, the strip can be screwed through the holes in the pile heads. Can the connecting wire be inserted directly into the panel onto the terminal? Or is there a connection/connection feature?

How and with what to take measurements? I'm not an electrician))

The PUE strictly prohibits the use of “control” in work)))

If you are talking about the elements of a concrete foundation, this is a common misconception. Relic. A good foundation must have perfect waterproofing.

If it's correct, then no. The service costs from 3 tr. + transport.

A non-waterproofed concrete foundation with reinforcement sticking out in all directions, water supply in iron pipes buried in the ground and other remnants. Functionally, your piles can be compared to a natural grounding system. The main thing is that they are buried significantly below the freezing level, i.e. as a ground electrode they will work all year round.

“Natural grounding is a third-party conductive part that is in electrical contact with the ground directly or through an intermediate conducting medium, used for grounding purposes.”

Since the metal parts of the foundation are impregnated with an anti-corrosion compound, they cannot be used as a ground loop. It is necessary to make (separately) a grounding loop and connect the metal parts of the building (foundation) to it.

Therefore, if you focus on a shoddy coating, then you can use piles as a grounding conductor.

I agree, but this is only if the coating is high quality and expensive. It is unlikely that this will be used for a country house.

Master Therefore, if you focus on the shoddy coating, then you can use piles as a ground electrode.

I agree, but this is only if the coating is high quality and expensive. It is unlikely that this will be used for a country house.

But to avoid any doubts, it is necessary to measure the resistance to spreading on a given object.

Well, this coating is definitely not some kind of monolithic; there are cuttings of piles; from them one can draw such a conclusion.

Thanks everyone for your opinions. I'll try to take measurements in the near future, and I'll be sure to let you know the results.

Master, as far as I understand, I can contact you with this question, right?

Advantages and disadvantages of screw supports

Screw piles are characterized by a number of obvious advantages:

- There is no need for large-scale excavation work, since the piles are installed by screwing into the ground.

- Financial costs for the construction of the facility are reduced.

- The base has sufficient strength.

- The service life of the piles is extended, which is due to the sufficient thickness of their walls.

- The installation of the ground loop is simplified.

- High-quality grounding is ensured thanks to extensive metal surfaces.

At the same time, screw supports also have disadvantages:

- Welds are not the best solution for creating connections when arranging grounding. Such areas are the first to corrode.

- The service life of screw piles is significantly reduced if there are nearby sources of current leakage into the ground - a grounded electrical substation, railway or cellular transmitters.

Life time

Under ideal conditions (soil that does not have a destructive effect on the material, no corrosion, etc.), the support can last up to 300 years , and if there is a galvanized layer, up to 800 years.

This is what manufacturers and marketers say, although they have no basis for this. Not even 299 years have passed since the invention, so such statements cannot be taken seriously. Ideal conditions do not exist, and impacts and normal metal fatigue have not gone away .

Therefore, the real service life of such a foundation should be considered 50-75 years, although deviations in one direction or another are possible.

NOTE!

Some of the structures that were first built on screw piles by their inventor, Mitchell, are still standing and in use today.

Pile foundation pros and cons

When choosing a foundation of this type for a house, you need to know the pros and cons of a pile foundation

This is important both at the construction stage and during operation. First, let's look at the advantages of a pile foundation

Advantages of a pile foundation for a house

- possibility of construction on complex, weak and unstable soils;

- the use of piles to construct a foundation allows construction to be carried out on complex surface topography, for example, on a mountain slope;

- the ability to install the structure in any weather and climatic conditions;

- settlement of a building on stilts is minimal, in some cases reduced to zero;

- relatively low construction costs;

- reduction of construction time;

- does not require extensive preliminary preparation and does not require the construction of an additional supporting structure;

- the ability to easily build an extension to an existing structure;

- the average service life of a pile foundation is up to 100 years;

- subject to competent engineering calculations and strict compliance with the design during the construction process, the structure is as reliable as possible.

Disadvantages of a pile foundation

The disadvantages of a pile foundation are few, but they must be taken into account, starting with the development of the project and during the operation of the building:

- to build a reliable and durable foundation for a house, it is necessary to conduct a thorough geodetic study of the soil of the site and a clear engineering calculation;

- a pile-screw foundation is often subject to severe shrinkage, which can cause the house to warp;

- in some cases, it is necessary to construct a grillage or connecting reinforced concrete, wooden or metal beams;

- It is better to use only high quality materials.

Pile foundation pros and cons video

You can see the advantages and disadvantages of a pile foundation, as well as the specifics of its arrangement, in this video.

Epoxy resins

This type of protection is widely practiced by manufacturers of finished piles. It has proven its effectiveness over many years of practice: its service life usually exceeds 50 years, which is quite enough for this type of foundation. This coating will not be scratched even by careless transportation or screwing (which, of course, should be avoided). Many people are interested in the question, what is the service life of such a product? If you improve the design by filling the “insides” of the pipe with concrete, then it can serve faithfully for over 100 years.