Individual developers are increasingly installing houses, outbuildings, gates and fences on a pile-screw foundation. Manufacturers of houses made of profiled timber are guided by such foundations; it is possible to assemble a turnkey house on pile supports in 1-2 days. A foundation made of screw piles may be the only possible solution for construction in urban areas or in conditions of compact arrangement of neighboring buildings.

In almost every region there are companies providing services for survey work and installation of screw piles. Contracting companies have modern equipment and qualified specialists. For some developers, due to economic and other circumstances, these services are not available; ordering the installation of 6-8 supports under the foundation of a bathhouse from a specialized company is simply impractical. For small buildings, it is cheaper and easier to make screw piles with your own hands; to make supports, you can use accessible tools and inexpensive materials.

Screw piles for foundations can be purchased on the market; for the mass consumer, buying ready-made supports is not always profitable. The cost of delivering several supports for a utility block or for a gate may exceed their cost. In this case, independent production of a small batch of screw piles becomes economically feasible.

Selection of pile design

The design of screw piles is not standardized; each manufacturer produces products according to its own specifications, drawings of the piles are available. When making supports with your own hands, it is advisable to be guided by the dimensions indicated in these drawings. For any design decisions, the main elements of screw piles are:

- Tubular body;

- Cast or welded cone-shaped tip;

- Blade of various designs;

- Head for installing a grillage.

When choosing a support design, it is necessary to take into account the weight of the structure and external loads; the choice of pipe size depends on this indicator. You can estimate the weight of the house yourself; determine the required diameter and wall thickness of the pipe using reference books. The weight of an industrial house kit is determined by the manufacturer; the requirements for the foundation are specified in the building documents.

Advantages of a columnar foundation.

The columnar base is characterized by simplicity and speed of work. Installation of load-bearing pillars does not require the use of heavy equipment to dig a pit or trench. Concrete for filling the formwork can be prepared on site in a small mixer and poured yourself.

Do-it-yourself foundation made of metal pipes.

A pipe foundation is a type of columnar foundation and is laid according to the general rules for installing load-bearing supports. This method ensures precise geometry of the pillars, which guarantees uniform distribution of internal loads. The smooth outer surface of permanent formwork helps to resist the forces that arise during winter heaving of the soil.

The pillars are formed from pipes that are driven tightly into the ground and filled with concrete. To distribute permanent and temporary loads evenly across all pillars, they are connected with a grillage. The reliable grillage design reduces the risk of the building overturning due to soil heaving.

How to calculate the load of a timber structure on screw piles

For calculations it is accepted: one square meter of the surface of the log house and load-bearing partitions from the most common building timber 200x150 weighs 70-100 kg. One square of attic flooring with insulation weighs from 100 to 150 kg, the specific weight of a roof made of roofing felt or slate is 50 kg, and that of tiles is 80 kg. A linear meter of double tying of screw piles with timber weighs up to 50 kg. When using rolled metal as a grillage, the weight is determined from reference books. It is necessary to take into account the weight of the screw piles; one meter of a support filled with cement mortar with a diameter of 108 mm weighs 100 kg.

When calculating the weight of snow cover, the following data is used:

- Southern regions - 50 kg per square meter of roof;

- Middle strip – 100 kg;

- Northern regions - 190 kg.

The given data is relevant for flat roofs with a slope angle of less than 35 degrees; for gabled roofs, a coefficient of 0.5 is used.

The weight of home equipment, finishing materials and furniture is determined by the developer independently.

For more accurate collection of loads, it is better to use SP 20.1330.2016 “Loads and impacts”.

Features of laying pipe supports.

The limitation for a columnar base is the significant weight of the building. The use of metal pipes allows you to increase the bearing capacity of the foundation. The metal casing protects the concrete pillar from moisture penetration and destruction. Such pillars do not require additional reinforcement.

Pile foundation of metal pipes.

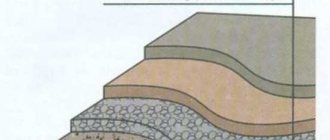

Depending on the weight of the building, climate zone, composition and soil moisture at the construction site, there are two ways to install metal supports as a columnar foundation. shallow and recessed.

On dry, non-heaving soils, the laying depth does not exceed 0.8 m. The supports are pressed into holes of smaller diameter, filled with concrete and tied with a metal channel or wooden beam at a distance of 30–40 cm from the ground.

Foundation made of metal pipes for the veranda.

Important! On sites with high occurrence of aquifers and unstable soil such as fine sand, sandy loam (a mixture of sand and clay), loam, clay, load-bearing pillars must be buried below the soil freezing mark. In the middle zone this mark is 1.2–1.5 m.

The wells are drilled to a depth of 1.8 m in diameter, which exceeds the size of the permanent formwork. Coarse sand is poured into the bottom of the hole and a metal pipe is inserted and filled with concrete. The concrete permeates the sand cushion, forming a stable base.

Making pile supports for timber with your own hands

The thickness of the pipe wall must be more than 3.5 mm, the length of the pipe is determined by the depth of dense layers of soil. This work can be done using a simple screw probe. Most often, the length of foundation piles does not exceed 3-3.5 meters. Sections of steel pipes of this length can be purchased from construction companies and utility companies; the sections are sold as surplus goods at the price of scrap metal. Used pipes are not recommended.

It is necessary to take into account that pipes can be seamless, made by rolling on rolling mills, or welded. The use of welded pipes for the foundation is undesirable; regardless of the quality of the welded joints, the seam is more susceptible to corrosion.

Stages of performing the required work

Due to the fact that quite a lot of piles are required to build a foundation, it would be impractical to mark each of them using a compass. It is prudent to spend some time making the required templates.

You need to create 2 templates:

- A large circle that will have a diameter equal to the outer diameter of the screw;

- A small circle with a diameter equal to the outer diameter of the pipe.

It is advisable to mark the central axes on the templates. This will make it easier for you to orient them on the steel strip during the marking process.

After completing the templates, you can proceed to the next stage.

Making tips

The optimal length of the tip of a homemade screw pile is twice the diameter of the pipe. Tips are made of four types:

- From the pipe body;

- From individual segments;

- All-metal;

- Cross-shaped.

In the first two cases, the tip is formed by 4-6 triangular segments, cut with a grinder from sheet metal 4-5 mm thick or cut in the form of a crown at the bottom of the pipe. From these segments it is necessary to form cones in the form of an isosceles pyramid; the operation is performed by tack welding.

All-metal tips are machined from a metal circle with a diameter equal to the diameter of the pipe; such tips are used when installing pile supports on dense soils and soils containing stones and rhizomes.

For light soils, you can make a cross-shaped peak: weld a cross-shaped pyramid from triangular blanks. The structure is welded to the bottom of the pipe onto a plug.

The most budget option is a pile without a tip; the lower part of the pipe is cut with a grinder at an angle of 45 degrees, and a plug is installed on the hole. This option is used for fencing, when the screw pile is installed not on a dense layer of soil, but is buried to 1.5-1.7 meters.

Beginning of work

Before you begin the process of making manual screw piles, you need to make a drawing. It can be made in the form of the simplest and most uncomplicated sketch. However, it must indicate:

- Diameter of the required trunk;

- Required length of the pile (including the cone);

- The height of the cone, as well as its angle;

- The distance between the bottom edge of the blade as well as the top of the cone.

If you need to make and install a screw pile with your own hands, you must also pay attention to the stiffeners and the head.

The most difficult part may be determining the required length of the pile. To do this, you need to accurately and competently find out at what depth of the construction site the dense soil is located.

The most seemingly correct, and at the same time, expensive way to clarify this important parameter is to order the necessary geological studies. Based on their results, the calculation of screw piles for the foundation is carried out.

But, since we have decided that no major buildings are erected on self-made stilts, such costs will not be entirely feasible.

In the case of a do-it-yourself approach, most homeowners seek the necessary information from experienced practitioners who have a proper understanding of the composition of the soil in the field of construction.

In general, the length of the pile should be 300-500 mm greater than the depth of the load-bearing layer. This is exactly the amount it should protrude above ground level.

How to make a blade for a screw pile

The most complex element of screw piles are the blades; this part of the pile structure performs the following functions:

- Provides forward movement when twisting;

- Reduces tip pressure on the ground;

- Fixes the support in a vertical plane;

- Prevents extrusion during frost heaving.

The blade is installed at the bottom of the support, general design requirements: optimal thickness - up to 5 mm, outer diameter up to 300 mm, screw pitch 0.2-0.4 from the outer diameter. Screw piles are made with single- or double-start blades.

The single-throw design is the simplest and represents a screw with one revolution. A workpiece in the form of a circle with an internal mounting hole is cut out of sheet metal using a plasma cutter, and a routing is made on the workpiece - a one-sided diametrical cut. Using a bench tool, the workpiece is stretched to

propeller pitch width. In a two-lead design, two identical blades are welded at a distance of 250-300 mm, the lower blade is mounted 20-30 mm above the tip.

The lower part is the cutting edge, the blades are sharpened at 45 degrees, the sharp edges of the cut are rounded. The blade is mounted perpendicular to the support body and welded with a double seam. The reliability and quality of the welded joint ensures the durability of the support; when welding, it is recommended to monitor the quality of the weld.

Cut the stripes

With the help of competent design of steel strip cutting, the amount of waste can be significantly reduced.

The width and length of the strip must be a multiple of the outer diameter of the blade blank:

- It is necessary to lay a large template along the width without any allowances. For example, in the case where we have a diameter of 200 mm, the strip width should be 200 mm;

- The strip must correspond in length to the diameter of the template multiplied by the number of blanks (and without any allowances for the gaps between the blanks).

In order for all the blades to be the same size, it is necessary to correctly draw the strip: for this you need to draw the horizontal axis along its length, and the vertical axis, in turn, with a step that will be equal to the diameter of the blade. Moreover, the first vertical must be marked from the short side of the strip at a distance that will be half the diameter of the workpiece.

Using templates, circles are marked. Moreover, these operations can be performed in any order - first large (external), then small (internal) or vice versa.

In the event that you decide not to apply axes to the strip, you need to start marking from the outer contour of the workpiece.

Recommendations for installing screw piles with your own hands

- To enhance the waterproofing of supports, it is advisable to use a two-component anti-corrosion coating based on polyurethane resins.

- Installing the head on the top of the piles is important when tying the foundation with timber. An all-metal grillage can be welded directly to the top of the support, in which case a cap is not required.

- To prevent frost heaving, the blades of the pile-screw foundation should be located below the freezing depth of the soil.

- Until now, the galvanic effect that destroys metal in induced electric fields has been little studied. It is better to refrain from installing metal foundations near the supports of high-voltage power lines and transformer substations.

Advantages and disadvantages

A foundation made from PVC sewer pipes has its pros and cons.

FCT differs from other types of foundations in a number of advantages:

- Lightweight pipes do not cause difficulties during transportation and storage.

- Plastic CTs can be processed. Pipes can be easily cut with a hacksaw and an electric miter saw.

- Installation of the pile foundation is carried out manually, without requiring the use of heavy construction equipment.

- The above-ground height of the piles promotes constant ventilation of the underground space, which does not create conditions for the accumulation of moisture, the formation of mold and fungal colonies, and does not provide shelter for harmful insects, mice and rats.

Along with the above-mentioned advantages, a number of disadvantages should be noted:

- Foundations of this type are erected only for light buildings and structures.

- Pouring concrete into pipes can only be done in the warm season. In winter, it is impossible to build such a foundation, since the process of solidification of the solution occurs at a positive ambient temperature.

- The design of the pile foundation of the house excludes the construction of basements and the ground floor.

Calculations

The purpose of the calculations is to determine the optimal number of piles that would ensure a stable position of the house relative to the soil foundation.

Knowing the diameter of the sewer plastic pipes (in this case 160 mm), you can determine the supporting area of one pile: S = πR2 = 3.14 x 802 = 0.02 m2.

Calculation of a pile foundation from CT consists of several stages:

- determining the optimal weight of the house;

- calculation of the required support area;

- determining the characteristics of the soil base;

- number and layout of piles;

- calculation of CT length.

Determining the optimal weight at home

Load collection includes the weight of all building structures, snow load on the roof, the weight of the future environment, technological equipment (air conditioning, heating systems, electrical devices, etc.).

The maximum number of people who can be in the house at the same time is also taken into account. To insure against miscalculations, the obtained result is multiplied by the reliability coefficient (k = 1.1) .

Required support area

The sum of the loads is divided by the area of the house, obtaining the conditional specific load (kg/cm2). It should be 10 - 15% less than the resistance of a solid soil foundation.

The area of the house is divided by the cross-section of the sewer pipe (0.02 m2) , thereby obtaining the required number of point supports.

Soil characteristics

Pile foundations are installed in places where the upper layer of the earth has a weak structure (clayey, heaving and swampy soils). Therefore, it is important to support the pipes on the lower hard layer of soil.

By experimental drilling of a construction site, the depth of the hard layers of the loamy, rocky or rocky foundation is determined. A cube of soil (1 cm3) is pressure tested to determine its resistance (kg/cm2).

Soil resistance can be found out from a vertical survey with reference to the construction site . The document is stored in the department of architecture and land management of the local administration.

Scope of application

If the soil meets the requirements, and the piles have sufficient wall thickness and are galvanized, they can be used to build a residential building. If construction technology is followed, such a foundation has a chance to last more than 100 years. However, most piles produced in Russia do not have a thickness sufficient for a residential building.

There are several areas where the use of such a foundation is rational :

- Construction of light buildings : bathhouses, gazebos, frame country houses, corrugated fences.

- Arrangement of temporary housing . The foundation will be built quickly; large-scale excavation work will not be required.

- Construction in areas with a pronounced slope, uneven terrain , and the possibility of landslides . Any areas where a lot of money would have to be spent on leveling or constructing a plinth dug into the slope.

- Areas with high groundwater rise .

The soil must meet the requirements of ICC FC358 : it should not be rich in rocky inclusions, be too soft and loose, contain a lot of sulfates or be prone to corrosive processes. This is especially true for the construction of a residential building.

Possible mistakes and tips on how to avoid them

The use of low-grade cement can cause destruction of piles . To prepare concrete, you need to use cement M 400–500.

Deviation from the vertical wells is a consequence of drilling “by eye”. When drilling wells, you must always use a plumb bob or laser level.

The foundation is not poured when the air temperature is below freezing - this leads to the destruction of the monolith. The piles are concreted with minimal air heating of 5–10 C.

Important and useful information about the pipes used to make piles for the construction of a pile foundation is in this section.