For your information!

- You can place an order for the manufacture of a structure or purchase a finished product at any forge presented in our catalog.

- A photo gallery of fences made of different materials, as well as combined structures, is presented on the corresponding page.

- In addition, our site offers cooperation to professional blacksmiths and commercial companies. You have the opportunity to send photographs of your work to us by email. The site administrator will post them and indicate the author when you provide all the information.

What is cold forging

Any forged products, including fences, can be produced with or without preheating the metal, using hot or cold processing technology. The first category of products is created manually using a forge and anvil. The complexity of the process determines the high cost of finished projects. An alternative is cold forging, performed using manual and automated equipment. Other interesting and useful information is presented on a separate page.

Advantages and disadvantages

Compared to manual hot forging

Cold forging for fences in comparison with hot metal has the following advantages :

- affordable price;

- efficiency of creating a large number of parts.

Flaws:

- mass production ensures a standard design, i.e. there is no exclusivity;

- to make products at home you will need a wide range of equipment;

- the possibility of defects in widespread production.

Compared to welded structures

Advantages of structures created by cold forging in comparison with welded fences :

- grace of shapes and lines;

- automation of the process of manufacturing elements for the fence ensures the efficiency of work.

Sketch of a welded fence of a simple configuration from the company “World of Forge”

Flaws:

- independent production requires a certain list of equipment;

- higher cost.

How they are created

Fences are made (assembled) from forged elements; the parts are fastened to each other by welding. Decorative details can be made manually or using special equipment . Do-it-yourselfers usually create small parts using homemade mechanisms or special molds .

Enterprises specializing in the mass production of elements have at their disposal a wide range of modern and automated equipment .

The use of special tools, machines and machines guarantees a variety of shapes and sizes of finished parts. Stamped items have a standard design, but a fence with cold forged elements can have an original design. To do this, the performer needs to create and weld an exclusive composition from the parts.

Manufacturing options

Forged products are distinguished by high functionality, reliability and attractive appearance. A wide range of advantages, coupled with the ability of forging to be harmoniously combined with many materials, make it popular with customers. Next we will look at various combinations of forging with other materials, as well as the classic version of the fence.

Transparent, forged only

The classic version of a wrought iron fence is made entirely of stamped elements. Transparent, functional, elegant and durable design performs protective and decorative functions. Ease of use, interesting design and durability are also important advantages.

Photo “Integral-T”

What to combine with

Combined fence models are also in high demand. The combination of two materials, different in characteristics and shape, attracts attention and causes admiration. Such designs have an attractive appearance and design. In addition, additional parts made of another material can add advantages to the fence, for example, corrugated sheeting makes the structure “blind”.

With brick and stone

Brick is one of the main materials in the construction of fences. This is due to a whole list of its advantages: strength, reliability, wide selection of colors, various masonry methods. There are several types of fences made of brick and forging, which differ from each other in the quantitative ratio of the two materials:

- wrought-iron fence with brick pillars and a plinth; designs without a plinth are also common;

- brick fence with forged elements used as decoration;

- brick fence with forged elements located in the upper part of the “blind” structure.

Regardless of the type of construction, this combination is optimal in terms of reliability and durability. Forged and brick fences look harmonious in the countryside landscape and the city.

Stone has similar benefits to brick. A wide range of natural stones are suitable for the construction of fences: dolomite, gravel, boulders, limestone, sandstone. In addition, modern production offers artificial stone, which has a more affordable price. A fence made of stone and forging will make your home stand out from the crowd of buildings. The variety of colors, textures and shapes allows the design to organically fit into any exterior.

With concrete strip

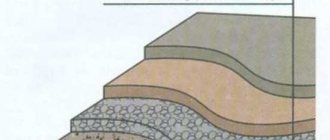

The best basis for a wrought iron fence is a monolithic strip foundation . Such a support guarantees stability and reliability for structures that are characterized by significant mass.

A strip foundation is a solid concrete strip , inside of which reinforcement is located. The depth of the foundation depends on the severity of the spans and the depth of soil freezing (the foundation should be located below), which depends on the region. A small part of the foundation (about 30 cm) rises above ground level. Thus, the base is part of the fence design. The monolithic support gives the structure not only visual, but also actual reliability.

Wrought iron fence on a strip foundation complemented by brick pillars and a plinth

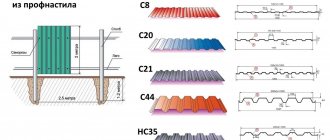

With corrugated sheets or sheet metal

A popular combination is the combination of forging and painted sheet metal. The most popular form is wall corrugated sheeting. The special coating of the canvas is resistant to weather factors. A variety of colors provides a wide choice for customers. The combination of forging and metal sheet allows you to get a reliable “blind” structure with a beautiful design. The stamped elements look especially advantageous against the background of a light profiled sheet. An important advantage is the affordable prices for sheet metal. Read more about this species here.

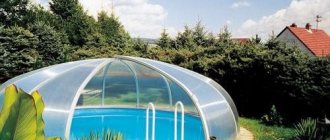

With polycarbonate

Polycarbonate has good impact resistance, thermal and noise insulation characteristics. The polymer is sold at relatively reasonable prices, which is an important advantage of polycarbonate over brick or stone. Forged and polycarbonate fences are gaining particular popularity. This is due not only to the advantages of the materials themselves, but to the ease of assembly, installation and operation of the structure.

Forged elements provide a strong and durable base. Polycarbonate plays the role of a light barrier, as it has a translucent structure. In addition, the polymer is flexible and pliable, so forged patterns can be “sheathed” with polycarbonate.

Photo “Tekhinkov”

With a tree

Forging and wood are one of the most popular and harmonious combinations. The heterogeneity of the wood looks impressive with a forged frame. In addition, metal strengthens wooden spans, which extends the service life of the product. The original lines and patterns of stamped elements harmoniously complement the wood. There are two types of forged wood structures:

- a metal frame with sparsely spaced transverse lines and elements is filled with wooden boards;

- sections of the wrought iron fence are covered with boards on the inside.

In the first case, wood is the main material, in the second - forging.

The photo on the right shows a forged fence with wooden inserts and brick pillars from the Russian Forging company.

With gabions

A gabion is a box made of galvanized mesh filled with stone. Gabions are suitable for installation on difficult terrain, do not require a foundation, have high strength, and it is possible to create a structure of any shape. Forging is perfectly integrated into fences made in accordance with this technology. In addition, niches for forged garden furniture can be easily created in gabion boxes.

With mesh

Chain-link mesh is low cost and easy to install, is resistant to corrosion, and provides access to sunlight. A chain-link fence with a standard and undistinguished design can be effectively complemented with forged elements. This combination of materials will attract attention.

Where is it used?

Forging is widely used both in the exterior decoration of buildings and in interior design. Most often they decorate with forging parts:

- stairs;

- gazebos;

- fences, gates, gates;

- verandas, terraces;

- awnings;

- window and door openings;

- balconies;

- railings;

- fireplaces;

- chandeliers;

- dishes, vases, candlesticks;

- arches;

- barbecues;

- swings and more.

Photo: forging samples

Elements in the form of tips and peaks are used to decorate the top of fences to give them a finished look. Monograms, currency, and balusters are used to decorate stair railings, fireplace grates, and gates. Metal plants will beautifully complement a summer gazebo or balcony lattice.

Wrought iron goes well with wood, polycarbonate, corrugated sheets, and steel, so many owners try to combine several types of materials when building fences.

Thematic material:

- Metal picket fence

- Wrought iron fence with polycarbonate

Elements

Enterprises offer customers a wide range of forged elements. Stamped parts perform decorative and protective functions. Customers have the opportunity to purchase ready-made elements at affordable prices. A variety of shapes, sizes and styles will satisfy the needs of any customer.

Those who like to make things with their own hands can make small parts themselves, at home. To do this, you will need equipment for processing workpieces: a bender; snail; flashlight; wave; twister The operations performed by this equipment will be presented below in conjunction with other mechanisms.

Home craftsmen quite often assemble tools from improvised materials, resulting in homemade analogues. Independent production of elements will take some time and require significant effort from the performer. However, the result of the work will be exactly the products that you had in mind.

Pillars

Pillars made of various materials can act as supports for cold forged fences:

Metal

The most common are profile pipes , which can withstand significant weight, are affordable, easy to transport and install, do not require additional processing, and look harmonious in a single composition with forging. Square and round profiles are used as pillars.

Twisted pipes are strong, durable, easy to install, and affordable, so they will be an excellent support option.

Forged poles can have a classic design or have fancy shapes. Customers have a wide choice of configurations.

poles made of metal rods are popular with customers because they have high strength and stability, a long service life, and are easy to install.

Screw piles have cutting blades at the bottom, which greatly facilitates their installation. The structure has a solid base and a secure foundation.

Brick supports are perfect for tall and heavy structures. Inside the brick pillars there must be a metal base of round or square shape. Reinforcement is welded to this support, which serves to fasten the fence sections and increase the reliability of the entire structure as a whole. Then the brick laying is carried out.

Natural stone is the best option when constructing supports for fences. Large pebbles, sandstone, dolomite, and rubble stone are suitable for construction.

Important! The stones should have a smooth surface and an approximate size of 100-200 mm. This will help to form high-quality and reliable masonry.

To create a stone support, the performer will need 30x30 wooden formwork. The first layer of stones is laid out tightly to the formwork and filled with concrete mortar. A similar procedure is performed with all pillars. After the solution has hardened and dried, you can begin laying the second layer and so on.

Concrete pillars are durable, reliable, resistant to natural influences, and go well with forged elements. The only drawback of such supports is the limitation in the height of the sections. The height of the fence should not exceed one and a half meters, otherwise over time the concrete foundations will collapse under the weight of the spans.

The choice of material from which the pillars will be made depends on several factors :

- financial capabilities and wishes of the customer;

- landscape;

- dimensions of the future structure, the most important is the height.

Sections

Sections for a wrought iron fence can also be purchased ready-made from the manufacturer or made independently. Companies offer a wide selection of spans of various heights and widths, a variety of colors and shades. Customers are provided with sections of different price segments. In addition, purchasing a finished product will save a significant amount of time and effort. That is why this option is most common among connoisseurs of forged products.

Small elements

Small-sized elements can give the design an original and interesting look. Below are the most popular cold forging patterns for fences; the photo is included for clarity.

- tips are solid parts used to decorate fence posts and spans;

- stripes are used to decorate protective structures and give them rigidity;

- clamps perform a decorative function and serve to fasten parts into a single structure;

- balusters are used as support and fencing for fences, gates, balconies and railings;

- curls are intended for artistic decoration of various metal structures.

The full range of elements is presented on the pages of our element catalog.

Types of structures

There are:

- Fences mounted as separate spans and supported on brick or stone supports. The pillars are connected by a ribbon-shaped plinth 15–100 cm high. An option without it is possible.

- Solid fence fabric. The racks are steel pipes. With the correct diameter, the structure has a holistic appearance.

- Fences with a fixed screen, on which forged parts stand out. Thin iron sheets, cellular polycarbonate, and corrugated sheets are used as a shielding surface. Often this is how a wicket or gate is designed to shade the yard and provide reliable protection from strangers.

Photo: stylish fencing of the local area

To make the estate closed and not visible from the street side, you should choose a screened fence.

Let's look at the design of other options for wrought metal fences.

Decorative (low)

They are used to decorate the area, not to protect it. Have artistic elements. They protect flower beds, garden areas, and the area behind the house. They are made low - up to 1 m. They look elegant. They are painted in different colors. Made to order.

Photo: combination of stone and metal in the fencing of the site

Protective (functional)

Factory imitation of artistic forging, obtained by stamping. Implemented in sections. Popular types of pillars are brick and metal. This type of fence is used to enclose private properties, cottages, dachas, and parks. They often have a minimum of decorative elements. Very durable, they serve as reliable protection for the area. The price is affordable.

Combined

This structure combines elements of the first two types. The welded fence is complemented by simple forged parts. A screen made of polycarbonate and corrugated sheets is installed in the background. Standard parts are produced in the factory by stamping. This type of fence is reliable, has average prices, and has an attractive appearance.

Photo: the wrought-iron fence is complemented with profile sheets hiding the garden area from prying eyes

In the private sector, a wicket or gate for a wrought iron fence is often designed using a combination of materials.

Equipment used

Manual rolling machine.

To manufacture elements in accordance with cold forging technology, the following equipment will be required:

- The bender is designed for bending workpieces at various angles;

- the cochlea creates spiral configurations, allows the production of curls and volutes of various configurations;

- the flashlight ensures weaving the rod into complex shapes, used to create baskets and cones;

- wave allows you to make wave-shaped patterns;

- twister (twist) is used for torsion;

- rollers are used to make a houndstooth pattern;

- A globe is a tool that resembles a protractor; it can be used to produce three-dimensional products with a large bending radius.

In addition, the contractor will need tools for assembling parts and processing the finished structure:

- welding machine;

- angle grinder;

- electric drill or hammer drill.

A set of technological devices will also be needed:

- the template is used to obtain parts of a certain shape;

- volumetric is needed to create a specific pattern.

Homemade

Truly high-quality and reliable equipment for cold forging can be obtained in the factory. However, for those who like to make instruments on their own, as well as for those who want to save money, useful information will be presented below.

The manufacture of the machine is carried out in accordance with the drawing, which can be taken from the Internet or, if you understand the operation of the mechanism, you can develop it yourself.

The following are videos where home craftsmen make and assemble some types of equipment for cold forging with their own hands.

Video where a master independently makes and assembles a “snail” machine.

Video containing step-by-step instructions for making a torsion machine.

A visual demonstration for self-production of a “gnutik” machine

Step-by-step instructions for the production and assembly of all types of machines will be presented in the “Do It Yourself” section.

Industrial

To save time and effort, it is recommended to purchase a factory-made machine. Next we will look at the most popular models.

PROMA Gnutik 0005

- The birthplace of the PRPMA brand is the Czech Republic.

- Country of manufacture: Russia or China.

- Hand tools are used to create various workpieces and elements.

- The machine does not require special maintenance; you just need to keep it clean and lubricate the rubbing parts.

- Compact dimensions allow the machine to be installed almost anywhere.

- The maximum section of the strip is 40x5 mm.

- The maximum cross-section of the rod is 12 mm.

- The size of the square bar is 12x12 mm.

- Weight – 19 kg.

- Dimensions: 370x120x230 mm.

Snail Stalex SBG-30

- The homeland of the brand is Russia.

- Country of origin: China.

- Professional curl bending machine.

- The equipment is designed for processing workpieces made of low-carbon steel and non-ferrous metals.

- The maximum strip cross-section is 30x10 mm.

- The maximum cross-section of the rod is 10 mm.

- The size of the square bar is 10x10 mm.

- Weight – 27 kg.

- Dimensions: 550x300x220 mm.

Twister Blacksmith M3-TR

- The tool is designed for longitudinal twisting of rods.

- The machine is an excellent choice for creating forged elements at home or in small workshops.

- Mechanical components are made of high-strength and high-quality materials.

- The maximum section of the strip is 30x5 mm.

- The size of the square bar is 14x14 mm.

- Weight – 17 kg.

How they do it

The production of a forged fence is carried out by professionals of several specialties and includes the following stages:

- The wizard creates a project and sketch with the necessary numerical data.

- With the help of equipment, the required number of parts of the required size and shape is produced.

- Then the frame is welded, it is placed on a flat surface and the location of the elements is marked on it.

- The master welds all the parts using tacks, checks the correct location of the parts, makes the final welding, the joints are cleaned with a wire brush, the surface is degreased, and a primer is applied.

- Then you should dig a trench for a strip foundation or drill holes for a columnar foundation. Or you can do both actions and get a strip-column base.

- Place the pillars, fill the hole with cement, wait until the solution dries.

- Weld fence sections to the posts and paint.

The structure is ready for use.

Difficulties and pitfalls

Making and assembling a wrought iron fence yourself can lead to some difficulties. To avoid this, important nuances :

- The production of forged fence parts should be carried out after careful measurements so that adjustments do not have to be made.

- When welding all the parts into a single composition, deformation and distortion may occur. To avoid such problems, it is worth making welding tacks. Then you should check the geometry of the product and make the final connection.

- Welding joints must be thoroughly cleaned. Failure to comply with this requirement will lead to rust, the paintwork will deteriorate, and the product will lose its presentable appearance.

- Processing of the structure must be carried out carefully and carefully. High quality coatings should be used. Otherwise, corrosion will appear over time.

Conclusion! To obtain a reliable and durable product, it is recommended to contact specialists.

Professionals in their field implement the project with high quality. A wrought iron fence will please the owner for many years.

Fence installation

Post spacing and height

To secure the finished sections, you need to return to the site. The foundation is built along the drawn lines or pegs with a cord. Let's explain how to do this:

- Holes are dug for supports. The depth should correspond to ¼ of the length of the post. The maximum distance from pillar to pillar should not exceed 3 m.

- The filling mixture includes the following components: water, sand, cement and crushed stone. The resulting concrete is well mixed.

- One by one, fill the holes with prepared concrete and immerse the pillar. It is important to maintain verticality; a building level is used to check. For more reliable fixation of the supports, spacers are additionally used. As a result, all posts must be of equal height, and also be equipped with upper and lower cross plates.

- To protect the metal from atmospheric influences, each pillar is covered with plugs on top. They will add decorative value and also extend the service life of the supports.

Once the concrete pour has completely dried, you can remove the spacers and attach the sections to the supports. To accurately represent the future picture, use special fasteners for fixation. Holes are drilled in the thickness of the pillars with a drill. To prevent the fasteners from unraveling during operation, after installation work the nuts are welded to the bolts using a welding machine.

Installation of forged gates and wickets

Note!

Support pillars can be either round or square. Depending on your wishes.

Forging care

Forged products do not require special care. Periodically, the fence should be inspected for signs of rust . Corrosion should be removed using vinegar or citric acid . Another effective way is to heat the area where rust begins to appear. Exposure to temperature will cause oxides to shed at the slightest touch. Then the metal should be coated with primer and paint.

Dirt must be removed using a soap solution . DO NOT use hard brushes or abrasives as this will damage the finish.

Moving structural elements must be lubricated periodically.

What is the price formed from?

The final cost of a wrought iron fence depends on the following factors:

- Construction design.

- Type, thickness, quality of metal used.

- Types and quantities of forged elements used.

- The cost of a specialist’s work depends on the complexity of the project and the duration of its implementation.

- Type of paintwork.

A company employee will always tell the client the exact price for a particular product.

Set for work

- Welding machine with a set of electrodes.

- Grinder with grinding and cutting discs.

- Equipment for the production of decorative elements. There are several types of machines that allow you to give metal rods different shapes. You will learn more about the main units below.

- Vise. A flimsy student setup won't do. You need a powerful locksmith unit. Additionally, prepare patterned yews to give the rods a spiral shape.

- Pliers.

- Roulette.

- Hammer.

- Building level.

- Corner.

- A spray bottle or several brushes of different sizes.

- Steel rods with a diameter of 12-14 mm.

- Sheet steel 2 mm thick. We will use it to make peak tips. We buy the material if peaks are present in the selected fencing design.

Elements of a wrought iron fence

Photos of artistic forging

How to make it yourself

The production of fence elements and their assembly is a rather complex process that requires a certain range of equipment and skills.

- Work should begin with the development of a project and sketch . The contractor has the opportunity to take a ready-made drawing and create a product in accordance with it. Having certain skills and wishes will allow you to make changes to the existing drawing.

- Making a trench or holes for the foundation, positioning the pillars, filling the hole with cement mortar.

- Welding the frame, placing it on a flat surface, marking.

- Assembling all elements, creating welding tacks, carefully and carefully checking the geometry of the structure, performing final welding.

- The finished sections are welded to the posts.

- The structure is treated with primer, varnish or paint.

Detailed information with step-by-step instructions will be presented in a separate article.

Our website provides a wide range of information articles that allow you to master forging techniques yourself.

Many educational institutions offer vocational training in the field of artistic metalworking.

Master classes from experienced forging practitioners will allow everyone to enjoy the process of creating unique masterpieces.

Popular manufacturers of forged fencing

There are a number of manufacturing companies on the domestic construction market that have won trust with good quality and reasonable prices. Let us highlight the main ones.

Kovart

Experience in the field of creating forged products – 17 years. The skills of designers and craftsmen allow the use of artistic techniques that were used by blacksmiths in tsarist times.

The company provides the following services:

- creation of drawing projects to order;

- shot blasting of metal;

- 3D modeling;

- laser cutting;

- artistic patination - application of silver, copper, gold;

- chrome plating;

- coating of forged products with gold by electroplating.

Photo: elite product made

The list of products includes elements of interior decoration of premises and details for the exterior design of buildings and fences.

KovArt also puts into practice designs proposed by clients.

First Forging Factory

A Moscow enterprise that makes jewelry and metal products using artistic or stamped methods. The warranty for all products is 5 years.

Located 15 km from the Moscow Ring Road on the Minsk Highway.

Rowand forging

The domestic company was founded in 1997. Manufactures welded and forged structures of varying complexity and sizes:

- gates,

- railings,

- visors,

- ritual fences,

- furniture,

- fence sections and more.

Takes on any volume of work ordered.

Kreitmet

Russian plant. Mainly produces plastic, metal-plastic, forged products.

The technical capacity of Kreitmet allows us to produce up to 200 tons of metal structures per month.

Among the products:

- fences made of square and round profiles;

- swing and sliding forged and welded gates;

- forged, welded grilles for windows;

- railings;

- flower stands, stands;

- visors;

- chandeliers, sconces

In addition to producing custom goods, a team of craftsmen also performs installation work.

Insight

The plant is engaged in artistic forging. It has production workshops in Moscow, Voronezh, and St. Petersburg. Produces decorative elements, fences, furniture, lanterns and more. Designers will help you develop a design sketch based on the client’s idea or an individual project.