By choosing to make a fence from corrugated sheets with your own hands, the owner of a country or private house protects his territory from outside access and prying eyes, while at the same time saving on the services of master builders. Distinguished by its affordable price, good strength and high durability, the material can be installed without the involvement of third-party specialists - although for this you will have to use special instructions. Carrying out basic and preparatory work requires the performer to have certain experience and time. But their result is a reduction in landscaping costs and the ability to control all stages, making sure of the quality of their implementation.

Which corrugated sheeting is suitable for a fence?

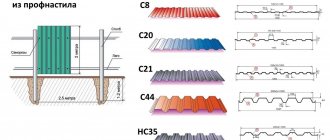

In the marking of profiled flooring you can see different letter designations that indicate its load-bearing capacity and purpose. What types of corrugated sheets exist:

- "N". The load-bearing profiled sheet is one of the strongest, with a groove in the middle of each wave, which increases the rigidity of the material. Purpose – construction of interfloor ceilings.

- "WITH". Wall, made of thin sheet steel, with a small width and height of waves. Purpose – installation of a fence made of corrugated sheets and wall cladding.

- "NS". Load-bearing wall, in comparison with load-bearing, is less rigid and cheaper. Also called roofing. Purpose – installation of roofing. Acts as an alternative to metal tiles.

We advise you to study in more detail: “Is it worth putting metal tiles on the roof: an overview of the material, for which roofs and buildings it is best suited.”

The fence is made of wall corrugated sheets. These can be brands, C10, C20, C21, C44. In some cases, HC35 is also used. The numerical designation after the letter indicates the profile height. It affects the final stiffness of the canvas.

Modifications of corrugated sheets recommended by experts for fencing

Please note: the C20 sheet, contrary to the markings, has a wave height of 18 mm, not 20 mm.

C8 sheets are suitable for the fence , but in regions with strong winds it is better to take sheets from C10.

They can have a thickness of 0.45-0.5 mm. Since the fencing also has a decorative function, it makes sense to buy painted corrugated sheeting. It is more aesthetically pleasing than galvanized and even more durable.

List of tools

Let's look at the requirements for each of them in more detail.

welding equipment

Will be needed to fix the joist to the posts. A 220 W household device operating from the network is suitable. To speed up the process, welding locations are pre-marked.

Photo: welding machine with chameleon mask

After the work is completed, the seams are cleaned, treated with anti-corrosion primer and painted.

If you don’t have the skills to operate the device, it’s better to invite an experienced neighbor or a craftsman.

If fastening is done with bolts and self-tapping screws, welding equipment is not needed.

Grinder (angle grinder)

Required for cutting metal parts and cleaning finished welds. You need to stock up on cutting and grinding wheels of suitable diameter.

Metal scissors

Metal scissors are used to cut corrugated sheets.

It is not recommended to cut sheets with a grinder, since the material overheats and the ends soon begin to rust.

Screwdriver

To fix the sheets to the frame, use a screwdriver with a special attachment for roofing screws - M8. During operation, the magnetic holder prevents the screw from falling.

Building level, plumb line and other tools

Among other things you will need:

- shovel or drill for digging a trench;

- concrete mixer (can be rented);

- tape measure, pencil (for measurements);

- building level;

- plumb line

Photo.

Plumb line - on the left, to measure the vertical position. The building level is on the right, used to measure the horizontal plane. When all the materials and tools are prepared, you can begin installing the structure.

Stage 1. Development of a fence made from corrugated sheets: sketch and drawing

A corrugated fence is an extended structure that includes:

- Pillars (2) installed in a hole in the ground (1), which is concreted and filled with sand and gravel backfill (4).

- Joists (5) connecting the pillars. For a height of up to 1.5 m, 2 joists are sufficient, top and bottom. If the fence is higher than 1.5 m, an additional log in the center is required.

- Profiled sheets (6), which are attached to the transverse joists with self-tapping screws. To hang a gate or wicket, the support posts are equipped with hinges.

What elements does the fence consist of?

To calculate the required number of materials and install a durable fence made of corrugated sheets, you should first develop a sketch of it. This is a preliminary sketch depicting:

- Where will the fence be located, taking into account the entrances, the location of the gate, green spaces on the site, topography, etc.

- Changes in ground heights are noted to determine where shorter or longer sheets will be needed.

- Dimensions of individual straight sections, their height and length.

- Pole installation points: basic and intermediate.

- The length of the sections is for a sectional fence. It is taken as a multiple of 1, 1.5 or 2 sheets of corrugated board.

When installing a fence made of corrugated sheets, it is necessary to take into account that the distance from the ground to the bottom edge of the sheet can be 0-150 mm. With a terrain slope of up to 3%, the difference between the sheets is 150 m. For steeper terrain changes, the height difference is taken individually.

An example of a drawing of a fence made of profiled sheets

Sketch of a fence made of corrugated board

Mounting horizontal joists

The support pillars are installed, the concrete mixture is finally fixed and dried (it is necessary to allow time for the concrete mixture to harden according to the instructions, this will ensure that the fence will not move). Now you can mount the horizontal logs to the frame.

Transverse logs are placed parallel to each other, usually in two tiers. If the fence height is planned to be more than two meters, then you will need to install a third guide, which is attached exactly in the center. The boundaries of the upper and lower tier vary within 25-30 cm from the expected edge of the corrugated sheet.

The strength of the structure directly depends on the chosen method of fastening. The ideal option is to weld the logs to metal poles using a welding machine. This is a fairly reliable method, but it will require certain welding skills.

There is another way - you can attach the logs using bolts and nuts. Perhaps less reliable, but easier to implement. You need to start fastening from the top tier. The most commonly used profile is with a cross section of 25*50 mm. It is worth noting that if the upper veins are aligned evenly, then the process of aligning the lower rows will proceed easily along the entire perimeter of our fence.

It is recommended to clean all surfaces of metal structural elements, prime them well, and then paint them to match the profiled sheet with two layers of enamel.

Stage 2. Preparation of materials

Corrugated sheeting . For fencing, flooring marked “C” is used, sometimes “NS”. It is important that there is no capillary groove on the sheets - it is only needed on the roof.

Corrugated sheeting for building a fence

Support posts (pillars). Can be made of any materials: wood, stone, metal. But the simplest and most affordable are metal racks in the form of pipes with a round or rectangular cross-section. It is more convenient to use special ready-made support pillars. They have a “heel” for support on the sand cushion, holes for fixing the flooring and an upper plug.

Support racks (pillars) with special fastenings for corrugated sheets

Cross joists. The best option is pipes measuring 40x40x2 mm or 40x20x2 mm. Wooden logs are not suitable due to rotting at the attachment point.

Square cross-section joists

Holder plate for decking (bracket). Necessary for assembling the fencing frame using the non-welding method. Used in combination with hardware.

Holder plate for mounting logs on poles

Plugs for pillars (supports). Cover the end of the racks, preventing moisture and precipitation from entering them.

Plastic plugs for poles

Hardware: M6 bolts or screws (20 or 30 mm), self-tapping screws for corrugated sheets or rivets.

Hardware for attaching corrugated sheets to the frame

Decorative end strip. A fence or covering U-shaped strip that is attached to the upper end of the deck. Eliminates injury to people and protects the sheet from rust.

Fence strip to protect the upper end of the corrugated sheet

Paint for corrugated sheets. It can be used to mask defects that may appear during installation and paint over the cut of the sheet.

Additionally you will need:

- cement, sand and gravel (for making a cushion and pouring the foundation);

- screwdriver;

- solution container;

- drill or shovel;

- welding machine;

- primer and anti-corrosion compound;

- level and plumb;

- grinder for cutting sheets.

How to attach a corrugated sheet to a frame

The sheet is secured with self-tapping screws or rivets. Self-tapping screws for corrugated sheets are galvanized and painted. They are selected to match the color of the fence. Tighten with a screwdriver using an attachment.

The installation step depends on the wavelength and height of the fence. The higher the fence, the more often you need to install fasteners. It holds normally if you fasten it through a wave, to increase strength, with two lags you can fasten it in a checkerboard pattern, and not one above the other.

When installing, it is important to align the first sheet vertically. Then everything else will install without problems. When laying sheets, the next one goes onto the one already installed on wave 1. Attach to the bottom of the wave. The self-tapping screw must be installed strictly perpendicularly. Then the hole is blocked with a washer and precipitation will not cause the paint to peel off.

To see how one can attach a corrugated sheet to a fence, watch the video.

Stage 3. Calculation of the amount of materials for a corrugated fence

In order not to overpay for extra materials and not face a shortage, you need to correctly calculate the quantity.

How to determine the number of profiled sheets:

- For a continuous fence, divide the total length of the fence by the usable width of the sheet.

- For a sectional fence, divide the total length of the fence by the entire width of the sheet, if it is equal to the length of the section, or by the useful width of the sheet, if the section is 1.5-2 sheets.

Solid and sectional fences made of corrugated sheets

How to calculate the number of support posts

- For a continuous fence, divide the total length of the fence by the distance (span) between adjacent posts (2-3 m).

- For sectional fence. The distance between the supports is equal to the total (if the section is one sheet) or useful (if the section is 1.5-2 sheets) width of the corrugated sheet.

Racks must be provided:

- at the corners of the fence;

- at the gate installation site;

- at the place where the gate is installed.

The resulting number of racks can be rounded down. The lack of 1-2 pillars is compensated by a slight increase in the span. The height of the rack should be equal to the height of the fence plus another 30% for penetration into the ground. For example, for a fence of 2,000 mm, posts with a height of 2,000 · 1.3 (130%) = 2,600 mm are required. Intermediate posts can be buried 25% into the ground.

How to calculate the number of transverse joists

It is necessary to multiply the total length of the fence by the required number of crossbars. If the fence height is less than 1.5 m, 2 logs are required, more than 1.5 m - 3 logs. For example, for a fence 50 m long you will need 50 · 2 = 100 logs for a fence height of up to 1.5 m and 50 · 3 = 150 logs for a height of more than 1.5 m.

Corrugated fence with two and three joists

How to determine the amount of remaining materials

Holder plate: multiply the number of posts by the number of rows of crossbars (2 or 3).

Plugs: add 2-3 plugs to the number of support posts as a reserve.

Hardware. The corrugated sheet is fastened:

- in 2 extreme waves;

- through 2 waves in the center of the sheet into each of the lags.

For two crossbars per sheet, 6 hardware is required, for three - 9 pieces. Next, 6 or 9 is multiplied by the number of sheets. The resulting value is rounded up by a multiple of the packaging.

Paint: one can or 50 g can is enough.

Decorative end strip: divide the total length of the fence by the working length of the strip itself. Round the resulting number up. Most often, the planks reach 2,000 mm in length. The working length is then 1,850-1,950 mm.

Construction with metal posts

The simplest production is a fence with metal posts dug into the ground. You can use round or square pipes, but it is more convenient to work with square - profiled ones.

The length of the pillars is taken depending on the desired height of the fence, plus 1 to 1.5 meters are added for penetration into the ground. It is necessary to bury it in the ground below the freezing depth of the soil. For each region, the soil freezes to a different depth, but in central Russia it is about 1.2 m. When determining the depth to which you bury pipes, it is better to play it safe and make the holes deeper. Otherwise, the forces of winter heaving will simply push the posts out, and your fence will collapse (see photo).

Insufficient depth of the support posts led to the fence sagging

For pillars, a profiled pipe with a cross section of 60*60 mm and a wall thickness of 3 mm is usually used. The distance between the pillars is from 2 to 3 meters. The greater the thickness of the profiled sheet, the less often you can install pillars. If the soil is difficult to dig, it makes sense to make the distances larger, otherwise you can save on purchasing metal - the thinner, the cheaper and the difference in price is significant.

Logs for a fence made of corrugated sheets are made from a profile pipe 40*20 or 30*20 mm. The second option is wooden blocks 70*40 or so. When using wood, a significant amount is saved, but the wood disappears faster, and besides, it warps from moisture. Most likely in a few years you will have to change the logs, and they will already be metal. But it will work as an economical option for several years.

Fence made of corrugated board on wooden logs

When making a fence from corrugated sheets with your own hands with wooden logs, do not forget to thoroughly treat the wood with an antibacterial compound (for example, Senezh Ultra). It is better to do this in the bathroom - immerse the bars completely in the solution for 20 minutes. This way they will last longer.

The number of logs depends on the height of the fence. Up to 2 meters - two are enough, from 2.2 to 3.0 meters you need 3 guides, even higher - 4.

Read more about choosing and building a foundation for a fence here.

Stage 4. Installation of a fence made of corrugated sheets

Installation of a fence made of corrugated board consists of several stages, including:

- Preparing the site for installation.

- Marking the site according to the sketch.

- Pouring the foundation and installing racks.

- Installation of cross beams.

- Decorative design of racks.

- Fastening the corrugated sheet to the frame.

- Installation of decorative and protective elements.

Preparation

It consists of cleaning the soil surface from anything that could interfere with the independent installation of the fence. Experts also recommend leveling out the most pronounced unevenness in the terrain, which can cause problems with installation.

Marking

To mark the site you need:

- Find the extreme points of the fence. These are the corners of the fence where support posts will definitely be installed.

- Hammer the pegs at the extreme points and stretch the cord between them - it will show the line of the future fence.

- Place pegs in the places where other supports are installed - they are determined again from the sketch.

- Attach a plumb line to a stretched cord at the location where the posts are installed - it will indicate the exact location for drilling a hole for the post.

Construction of the foundation and/or installation of support pillars

A corrugated fence is installed:

- On the foundation. In this case, the main support of the fence is not the pillars, but the foundation on which the posts already rest.

- Only on poles. Under each of them they dig out a hole with a bayonet shovel or drill a hole with a drill. The depth is chosen taking into account the penetration of the columns into the ground plus 100-200 mm for the installation of a sand and gravel cushion. The pillars are installed in dug holes and then concreted. Next, check again how straight the racks are and, if necessary, adjust their position.

Options for installing fence support posts

Which foundation to choose for a fence made of corrugated sheets

A fence made of corrugated board is a lightweight structure that does not require a serious foundation. For such structures, a strip shallow foundation is considered optimal. Its width is selected taking into account the width of the support posts. The depth is about 300-400 mm. But when installing a fence made of corrugated sheets, it is important to take into account a couple of nuances:

- In the place where the base pillars are installed (in the corners, where gates and gates are installed), the depth of the foundation pit should be at least 1/3 of the height of the posts plus 100-150 mm for the sand and gravel bed.

- For intermediate pillars, a pit with a depth of at least 1/4 of the height of the posts plus the height of the cushion is required.

This is an important condition, the observance of which will minimize the impact of groundwater and frost heaving of the soil on the structure.

Construction of a foundation for a fence made of corrugated sheets

The strip foundation for the fence is mounted using the same technology as in the case of a gazebo, bathhouse or house:

- A pit of the required depth and width is dug along the perimeter of the fence.

- According to the fence drawing, base and intermediate posts are installed: at the place of their installation, the soil is removed with a drill, a sand and gravel cushion is poured, and the supports are concreted to a depth of 100-150 mm.

- The foundation formwork is being arranged. It can be temporary or permanent (for example, from simple galvanized corrugated sheeting).

- The trench is reinforced and filled with concrete mixture.

We advise you to study in more detail: “What you need to know about galvanized corrugated sheeting: characteristics, types, advantages, areas of application.”

Installation of logs

After the support pillars are securely concreted, the installation of transverse joists begins. As a rule, you will have to wait at least 5-7 days for the solution to harden. The connection of the lags with the racks can be:

- welded (one-piece, non-separable)

- collapsible, i.e. using fastening elements.

In the latter case, holder plates are used. They are screwed to the support post, and the logs themselves are attached to them. This type of fastening is considered more reliable.

For a welded joint, the fixation area is first cleaned of paint using sandpaper or a grinding machine. To perform welding, you will need the help of another person who will hold the joist in the desired position. Welding is carried out along the entire length of contact between the crossbar and the post.

When the ground slopes on the site, logs and sheets must be mounted with a height offset

In the case of a pronounced relief of the site, the logs are mounted with a slight offset in height. The amount of displacement can be determined from a right triangle in which:

- The vertical leg (VC) is precisely the amount of displacement (height difference).

- Horizontal leg (AC) – the length of one profiled sheet. This is a segment parallel to the horizon, i.e. without a slope with an angle of 0°.

- The acute angle (A) between the horizontal leg and the hypotenuse (AB) is equal to the angle of inclination of the earth's surface, for example, 5°.

The tangent of angle A is equal to: tan A = BC/AC. Hence BC = tan A · AC. The tangent for an angle of 5° is 0.0875. If we take the length of the profiled sheet (AC) as 2,000 mm, then BC will be equal to 2,000 · 0.0875 = 175 mm. It turns out that each subsequent profiled sheet needs to be shifted in height by 175 mm. For this purpose, the logs are fixed 175 mm higher than in the previous span.

Using this scheme, you can find the displacement value (BC) of corrugated sheets, taking into account the slope of the ground surface on the site

Methods for attaching joists to support posts

- Front butt. Suitable for solid fences.

- Behind. Requires the use of a bracket, the optimal method for sectional fences.

- On the side. With this ability to fasten the crossbars, the corrugated sheet can be fixed not only to the joists, but also directly to the posts themselves. In this case, the consumption of self-tapping screws increases, but the structure itself becomes more stable.

Options for attaching the lag to the pole: butt in the front, using a holder in the back, from the side

Decorative design of racks

Installing a fence made of corrugated sheets is not just a dry installation technology. There is room here to show your imagination and sense of style. When choosing a sectional fence, you will have to decorate the support pillars. The most popular design option is to cover metal pillars with brick or stone. It is important to think through this stage at the sketching stage, since finishing reduces the distance between the pillars and, accordingly, the length of the required corrugated sheeting.

You can, of course, decide on such a design already during the installation process, but then you should be prepared for cutting sheets and increasing installation time. Important conditions for laying bricks:

- Use high-quality decorative bricks without chips or efflorescence.

- Maintain uniform seam thickness.

- Reinforce every third row of masonry with masonry mesh.

- Fill the void between the support column and the completed masonry with concrete mortar.

- The top of the post must be covered with a cap to protect it from moisture and precipitation.

We advise you to study in more detail: “Masonry mesh: what it is and what it is used for (+ technology and laying rules).”

We advise you to study in more detail: “A cap on a fence post – decoration or necessity? Varieties of products by shape and materials, advice on selection, installation instructions.”

Installation of corrugated sheets on the frame

To fasten corrugated sheets, rivets or metal screws are used. The most important thing is to install the first sheet correctly:

- Having determined the permissible height of the extension along the upper edge above the vein, the sheet is secured with one self-tapping screw at the top point.

- Then, using a level, set the second edge to the desired position and also grab it with a self-tapping screw.

- After this, you can screw on the remaining hardware.

- Subsequent sheets are mounted in the same way, overlapping the last covering wave of the previous sheet.

How to properly attach a corrugated sheet

In order for a fence made of corrugated sheets to maintain its spatial rigidity, it is necessary to follow the rules for fastening with self-tapping screws:

- The sheet is fixed along the edges to each of the transverse logs: one fastening is in the center of the sheet, the rest - through 2 waves.

- Fastening is carried out only through the lower wave.

- The sheets are fixed to each other through the upper wave.

- The screws are not fully tightened to maintain the integrity of the sealing rubber.

Self-tapping screws should not be tightened too tightly

Installing additional items

Almost the last stage in the construction of a fence made of corrugated sheets is the installation of decorative strips on the upper cut of all sheets. They are fixed with rivets to match the color of the flooring. The width of the strip is selected according to the wave height of the corrugated sheet. For a sheet with a profile height of 8 mm, you need a strip 8 mm wide without rolling or 10 mm including rolling. It is also important not to forget to install caps on the ends of the support posts.

Advantages and disadvantages of such a fence

Profiled sheets, like any building material, have their positive aspects, as well as disadvantages unique to this material. In some situations, when the desire to build a fence with your own hands takes precedence over rationality, miscalculations and design errors gradually begin to appear. This gives reason to remember once again the pros and cons of this material.

Sheet options and sizes

pros

The building materials offered on the market for the construction of fences and barriers today largely act not only as a separate type of component materials, but also as engineering systems developed and brought to perfection. It is precisely this approach in evaluating iron profiled sheets that makes sense to talk about when assessing the positive aspects of the material.

beautiful hedge

The positive aspects include:

- The possibility of using corrugated sheets as a separate building material for construction, or as part of a special system for erecting fences.

- Quick installation of the frame and canvas either by welding or using a special installation system using bolted connections and self-tapping screws.

- Creation of a blind fence up to 6 meters high.

- Low cost of maintenance: profiled sheets with PVC coating and conventional paint coating do not require annual painting.

- Gates and gates can have additional decoration and decoration, while properly done decoration only improves the aesthetic qualities of the estate.

- The building can have either a massive stone or brick foundation or a lightweight, prefabricated frame on screw piles.

- With the right choice of base design and construction method, such a fence can be built on almost any type of soil without restrictions.

Finishing operations

Prices for popular brands of portable welding machines

Portable welding machine

All that remains is to weld the horizontal elements, make a gate and sew up the fence with profiled sheets.

Attaching the top crossbars

Welding horizontal elements

Fence frame and outer gate frame

Wicket door frame made

The so-called horizontal cross members are made from a 25x30 mm pipe; weld them flush with the surface of the intermediate supports, the distance between them is approximately 150 mm. Use a bubble level and test threads. To hold the profiles in the desired position, you can make a device; it is fixed at the end of the column, and special plates hold the pipe in the desired position.

Sheet holding device

Clean metal surfaces from dirt and rust, prime them and cover them with paints for external use. Make a gate and screw the metal profile sheets. Sheets can also be held with a device; the principle of its manufacture is no different from the first, only the height of fixation of the holding shelf changes.

Checking Sheet Position

Marking for fasteners

Fixing sheets after 1 wave

Prices for popular drill models

Drill

The fence is sewn with corrugated sheets

Fence with a gate after covering with corrugated board

Features of installing fencing on a slope

For areas located on slopes in uneven terrain, it is important to develop the project in such a way as to compensate for sudden changes in elevation.

The optimal type of foundation for this would be a strip foundation.

Study in detail the types of tape and the sequence of filling.

The deviation must be uniform. Sections are created with the same lifting and lowering heights.

The fence is mounted in two ways:

- Repeating the slope contour. Performed on steep hills and slopes. The jumpers are fixed not horizontally, but parallel to the slope. Sections may be of different heights, but the same top level is maintained.

- Stepped fence. Suitable for estates with a gradual difference in height. Gives the fence an aesthetic appearance. The pillars are mounted in steps of 2-2.5 m, so that transverse joists can be secured between them. The average drop height per section is the total drop height of the section divided by the number of drops between the pillars.

When the differences in ground level are less than the depth, it will be easier to build a foundation for a fence on a slope. The concrete base of the base is made in the form of steps, the top is parallel to the ground.

Photo gallery of finished fencing

Below are different ways of fastening corrugated sheeting to a fence, the most original combinations with other materials.

To create a reliable fence yourself, corrugated board is a universal material and a good choice. The finished structure will perfectly complement the site, protect the yard from curious neighbors, and the variety of colors will allow you to purchase a material that will definitely suit any owner.