To grill delicious shish kebab, you need a good grill

If the weather permits, we love to barbecue outdoors with friends. However, if the weather doesn’t allow it, we also… fry it. But in any weather, barbecue without a grill is not a serious matter. If you have a private house or cottage, you can make a permanent, solid installation that combines a barbecue grill and a barbecue grill. They are usually made partly from brick or natural stone, partly from metal. If you don’t want to build something serious, you can weld a metal brazier and place it nearby - in the backyard under a canopy, in the garage, in a storage room, etc. If you are a lover of outdoor recreation in any form, you cannot do without a portable barbecue. And one that will be convenient to carry/transport. This is how to make a barbecue out of metal with your own hands and will be discussed further.

We grill kebabs both when the weather permits and when it doesn’t... that’s why we need a grill at any time of the year

Brazier and its characteristics

Its dimensions should allow the skewers to be placed with sufficient space between them. The width of the grill should be equal to the length of the skewers minus 12-18 cm. The length of the grill should be calculated on the basis that each skewer will have about 8-10 cm. The height above the coals should not be more than 10 cm, and the depth should be about 20-25 cm.

And, of course, for ease of cooking, it is necessary to have slots for skewers along its entire length. The wall thickness should be thick enough.

Also, there is no need to completely clean off the soot from the inside of the walls - after all, this gives a special taste to the meat. It is necessary to make holes in the side walls closer to the bottom to facilitate air flow.

Important works

To ensure that the design meets all expectations , make holes closer to the bottom - this way air will enter the area where the coals are located. Temperature maintenance depends on this. The diameter of the holes should be from 5 to 11 mm.

Make a grate over the bottom of the grill, which will serve as a grate. This will increase the life of the bottom and also create additional air flow. Watch a video on this topic

You can make both a removable and non-removable grate.

Making a barbecue

Where should you start when making a barbecue? You first need to decide on the type of barbecue you want to make. The sizes of barbecues vary depending on the needs, as a result of which they are divided into stationary and portable.

Depending on your needs, you need to choose the material for making your own barbecue. Next we will look at all types of barbecues from simple to the most complex.

Finished models, photo gallery

Below you can see beautiful photos of barbecues. Here you can find interesting ideas for creating your own barbecue area.

How do you like the article?

Alexey Petrovich

Ask a Question

Metal brazier

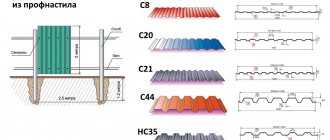

The most popular type is a barbecue made of sheet steel. The advantages of this type are low cost, ease of assembly and minimal labor costs.

To make it, you can use pieces of sheet metal, a steel cylinder or barrel in combination with scraps of pipes and corners. And since there is a high probability that this material may simply be lying around at your dacha in the form of unnecessary rubbish, the barbecue will not require any financial expenses from you at all.

The second advantage is ease of assembly. Every person who knows how to use welding at least a little can easily design and assemble a barbecue from metal of virtually any complexity. Yes, when using corners, you can do without welding at all, and use special holes, bolts and nuts for connections.

Also, these barbecues are very mobile. And most importantly, you can approach the creation of a barbecue creatively, and this whole pile of junk will become your creative masterpiece, which you can be proud of.

The disadvantages of such barbecues may be that the walls are not thick enough, due to their ability to quickly burn out. As a result, rust will appear on the walls and will definitely damage your structure when exposed to strong heat.

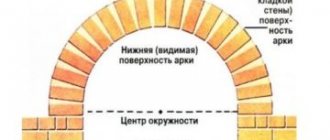

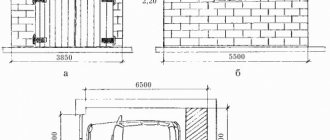

Blueprints

And finally, a few drawings.

Change the sizes at your discretion, there is no crime in this. Drawing of an iron barbecue with high legs

Drawing of a barbecue-suitcase made of metal

Drawing of a collapsible barbecue

Features of making a barbecue

First of all, you need to completely get rid of the gas in the cylinder using a valve. To control the gas output, it is necessary to moisten the open valve with a soap solution. While the soap solution is bubbling, the gas pressure inside the cylinder is not yet sufficient to proceed with further actions.

After you make sure that the pressure is equal to atmospheric pressure, you need to turn the cylinder over, pour out the remaining condensate, and fill the edges with water for 2-3 days. It is advisable to pour water away from residential buildings, due to the fact that methane has a pungent odor.

The assembly stages are similar to creating it from sheet material with minor differences.

For production we will need:

- adjustable wrench;

- welding machine;

- Bulgarian;

- 2-4 loops;

- gloves;

- hammer;

- rivets with a rivet gun;

- screwdriver;

- chisel;

- drill with drills from 10 to 14 mm;

- metal pipes for legs and chimney;

- 4 squares with an area of about 100 cm2 for the legs.

Step-by-step instructions on how to make a grill from a gas cylinder:

- Bedroom design with 3D wallpaper: expert advice

Projects of houses with luxury kitchens

Decorating a fireplace in the interior with 90 photos and videos - ideas 2022

Sawing. Perhaps this is the most important stage, because the aesthetic appearance of the future product depends on it. You need to completely unscrew the valve using an adjustable wrench and cut it off with a grinder. It is recommended that all work with the grinder be carried out with direct watering to prevent the combustion of methane residues.

We attach the handles and the lid by welding. We recommend using hinges whose connections are based on rivets. And then weld the hinges to the cylinder. The need to weld hinges is associated with the influence of high temperatures, because if this is not done, then over time the rivets will disappear.

Installing the legs. We saw them off to a length convenient for you and weld them to the bottom of the cylinder at an equal distance from the center. Don’t forget to attach metal plates to the bottom of the legs to ensure stability on soft ground.

There is also another base option. The process of creating it will be more labor-intensive and consists of the following. A couple of strips of metal are taken, bent in an arc that follows the shape of the cylinder, and the legs are welded to its ends. Next, the legs are connected from below by a transverse bar. And to complete the creation of the racks, we connect them together.

To avoid deformation during cooking of meat, we weld two corners inside it to add greater rigidity.

We drill about 14-18 holes with a diameter of about 12-18 mm in the lower part at the back to supply oxygen, which is so necessary for combustion. We also make cuts along the edges using a grinder.

In place of the large hole where the valve was removed, we mount a chimney pipe and weld it.

In this article we paid special attention to barbecues made of metal, but many people make their own special stationary barbecues from brick. You can find more information about the manufacture of such barbecues on the Internet. As an example, we provide below a photo of finished brick barbecues.

Photos of interesting designs for a summer residence

Forged barbecues with a roof, photo

The advantage of forged barbecues with a roof is their relatively low weight - they can be transported. Thanks to their diversity, forging elements make it possible to give even a simple product an individual character. Such barbecues, of course, are more expensive, but they are worth it.

The forged barbecue will plunge you into the Middle Ages. It will give not only delicious dishes, but also unforgettable emotions.

The “Carriage” grill with a roof is designed like a real carriage for Cinderella. This interesting brazier will decorate any country cottage and add romance to it. Cast iron and high-strength stainless steel are used for manufacturing. The roof is sloping and round in shape.

The “Spider” grill with a roof is made by hand using hot forging.

The top consists of three sections arranged with gaps through which smoke escapes. The roof, pillars and main structure are united by an openwork structure in the form of a web.

Compact, versatile design includes:

- roasting pan, spit;

- stove for a cauldron;

- small cutting table;

- shelf, woodcutter;

- roof with pillars;

- supports.

At the end of the kebab maker there are hooks for a scoop and poker.

A grill with a stove under a cauldron allows you to prepare pilaf in a cauldron while frying shish kebab. The oven for the cauldron can be built over the brazier or made as a separate structure with a door for removing ash.

The barbecue with a smokehouse to remove the smoke generated during smoking is equipped with an exhaust system with a pipe in the roof.

Collapsible option

A grill with a collapsible roof is in demand among lovers of outdoor recreation. As a rule, it has minimal equipment: a roasting pan, folding legs, a removable canopy, and holders.

Useful tips

The durability of the barbecue depends on the type of metal you choose. Therefore, experts recommend using heat-resistant steel. Cast iron meets all requirements in terms of durability, reliability, and ability to retain heat, but working with it requires professional skills. There is no clear opinion regarding galvanized steel. Some believe that it is dangerous, since at high temperatures it can release harmful substances. Others believe that it is impossible to heat a brazier with wood to such an extent. Everyone agrees that stainless steel is the best material. A brazier made from it will last for several decades.

You need to remove dry grass, branches and other flammable debris from the place where the grill is installed, and place a box of sand nearby. If wooden parts are used in the design, they must be located at a distance of at least 20 cm from the body. To prevent smoke from interfering with your rest, it is recommended to install a hood with a short pipe. It is equal in area to the barbecue and is attached to its body.

When caring for the grill, you must follow the following rules:

- Do not fill the coals with water, as this will lead to deformation of the metal,

- grease drips are removed with a rag and sand,

- To protect against adverse weather influences, the grill should be regularly lubricated with vegetable oil.

To make a metal barbecue, the highest qualifications and scarce materials are not required. It is possible that the first copy will turn out lopsided, but don’t give up. The next grill will turn out no worse than the factory one.