The emergence of new types of coatings and finishes in the world of building materials has always been received with interest. For example, one of the new products, quartzvinyl, is already in good demand. Reviews of quartz-vinyl laminate indicate that the natural coating has a very serious competitor with decent characteristics and high consumer qualities.

The surface quality of quartz vinyl is higher than that of parquet

Features of quartz-vinyl laminate

In appearance, the new material is practically indistinguishable from the classic version of cellulose lamella with a traditional wood pattern. Once you take quartz vinyl laminate in your hands, it immediately becomes clear that it is just plastic, even if it is of good quality. The use of vinyl backing and quartz provides sufficient rigidity and hardness so that the flooring will not be crushed under the weight of furniture or occupants.

Before choosing a new product, it would be right to learn more about the main features of this unusual floor covering:

- High flexibility, strength and abrasion resistance. The main mechanical characteristics of quartz vinyl laminate allow you not to worry about its integrity when laying the material;

- The outer surface of the laminate is made of melamine or polyurethane film with the addition of quartz, aluminum oxide and stabilizers that prevent premature aging of the material under the influence of heat and ultraviolet radiation;

- The middle part of the lamella consists of PVC with a high content of finely ground quartz. Thanks to this insert, the laminate retains its quality even when laid on an unprepared surface;

- The base of the supporting part consists of fiberglass reinforced vinyl plastic;

- Huge selection of textures and colors;

- Due to the new structure, the technology for laying quartz vinyl laminate is somewhat different from traditional methods of installing cellulose panels.

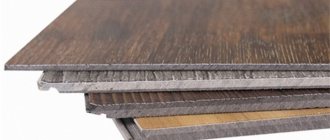

Balanced structure of quartz - vinyl base

The result is a fairly durable and very abrasion-resistant facing material. Moreover, in addition to the traditional elongated plank or laminate panel, quartz-vinyl coating is available in the form of rectangular and square tiles, which are much simpler and easier to install than regular laminate.

Composition and structure

The main criterion for the strength of this material is vinyl, which is used to treat the base in order to increase wear resistance.

The laminate plank consists of two layers : protective and bottom.

The top protective layer is usually made of polyurethane or aluminum oxide. This layer gives the surface an aesthetic appearance like stone, wood or parquet; it can also imitate the appearance of leather, sand in three-dimensional quality.

The bottom layer, also known as the base , is made of vinyl, which is the key to the strength of this type of floor. The thickness of the vinyl layer is about 0.5 mm.

Between these layers there is a middle in the form of stone chips , and vinyl backing

Advantages and disadvantages of quartz-vinyl laminate

The emergence of a new type of laminate flooring did not happen out of the blue. Developers have long tried to complement and modify the classic version made of pressed cellulose fiber so that it can be made not only with an imitation of boards, parquet or mosaic flooring, but also given more interesting textures and reliefs.

Good thermal insulation

Positive aspects of using quartz vinyl

If we evaluate all the pros and cons of quartz vinyl laminate, first of all we should note the two most important:

- High decorative qualities of the coating. Quartz - vinyl laminate today remains the champion among all floor coverings in the number of various imitations of stone, mahogany wood, all kinds of textures, including leather and mosaics. Moreover, all this is in three-dimensional relief design;

- "Indestructibility" of the material. Of course, any coating can be damaged, but the former fear of breaking locks, splitting or damaging the pressed chip lamella during installation is no longer there.

Clearly, this does not mean that quartz-vinyl material can be handled in a completely arbitrary manner. Polyvinyl chloride does not tolerate high temperatures and prolonged heating, and has a high coefficient of thermal expansion. With constant overheating, it turns into a brittle glassy mass.

Cons of vinyl laminate

Of the shortcomings, only two of the most important can be noted. Firstly, PVC material remains plastic, which, unlike wood, releases huge amounts of organochlorine volatile compounds during thermal decomposition. Secondly, it is high cost. If you choose quartz-vinyl laminate or regular laminate, then the first one will at least cost 1.5-2 times more than the second one.

Despite the obvious disadvantages, pros and cons, quartz-vinyl laminate is only growing in popularity. Most customers choose it primarily because of its high decorative qualities, and only then evaluate how convenient and safe it is in everyday use.

Can even be laid on old linoleum

The best manufacturers

Every year the number of companies presenting their products on the Russian market is growing. Just 5 years ago their number barely exceeded one dozen. Today their number is approaching a hundred. It is difficult even for specialists to choose the best among them. Therefore, here are two ratings:

- by popularity among consumers;

- according to quality characteristics and decorative properties according to analysts of construction industry products, published in the public domain.

By popularity among buyers

According to customers, the best manufacturers of quartz vinyl tiles operate in Russia (Tarkett and Holzplast), Belgium (Vinilam, Flexo and Moduleo), Germany (Grunde), and the USA (Allure).

Tarkett. The joint Russian-German company Tarkett has two factories in Russia, which allowed:

- become the largest manufacturer in the domestic market;

- to ensure a low price level for products (inexpensive products “Fiesta” and “Holiday” are produced especially for the Russian consumer).

The PVC laminate line includes high quality products with a variety of designs, which allows you to satisfy almost all customer requests. Available in the form of planks and slabs of various sizes.

Holzplast. Another Russian-German enterprise, Holzekstroplast, produces vinyl floors under the Holzplast brand with a Viniklick lock. Products with 100% moisture resistance, easy to care for and durable, find their application in any room of the apartment (bathroom, kitchen), as well as in shops, cafes and other public places with large crowds of people.

Vinyl. A Belgian company with a short history (just over 10 years) produces high quality products (class 43), a variety of designs in texture and shade (imitates natural wood) and 100% moisture resistance. This allowed the company to enter the top three manufacturers in Europe.

Flexo. Another Belgian brand whose products have proven themselves in residential and public places:

- does not absorb moisture and odors;

- retains its original appearance for a long time;

- easy to install;

- does not require a perfectly flat base surface;

- The locking mechanism allows you to disassemble the floor covering if necessary.

The products produced have a variety of designs and sizes with an affordable price (Flexo Premium Click laminate model).

Moduleo. Belgian-made vinyl laminate “Moduleo” attracts consumers with a variety of designs, reasonable prices, and most importantly, a convenient locking connection.

Grunde. German has a good price/quality ratio. However, this only applies to products manufactured in Germany, where the concept of quality is sacred to the manufacturer. This laminate does not always meet the high standards of the German company, but at the same time it has a lower price. It is up to the consumer to decide what to buy from this brand.

Allure. The American product (USA) is one of the most controversial types of flooring. There are practically no neutral assessments on the forums - they are all sharply opposite. Some argue that the high price does not correspond to the quality (it is easily damaged even when the chair moves), while others, on the contrary, cannot get enough of their floor. But despite all this (a really high price and problems with strength), American laminate is in demand.

The best brands according to experts

The rating of the best brands according to experts is as follows:

- Quick Step.

- Grunde.

- IVC International (Moduleo).

- Natura.

- Vinyl.

- Haro.

- Tarkett.

The top 3 for different specialists is unchanged, but the places in the top three for companies may change depending on the priorities set.

Quick Step. The specialized production of the Quick Step brand (produces only vinyl flooring) is located in Belgium. The company's products are of the highest quality with fairly high prices. But here is the case when the quality matches the price.

To reduce the financial burden when purchasing laminate flooring, the manufacturer constantly runs promotional offers that allow you to save money on repairs. But even with this approach to PVC floor sales, the consumer does not consider the brand popular among the general population.

Attention: experts highly rate Natura brand products. However, in Russia this manufacturer has a cheap Chinese counterpart, the products of which do not stand up to criticism - the packages contain a large number of defective strips (cracks). It is very difficult to find out from the seller the place of production. Therefore, the editors advise you to be extremely careful when buying PVC laminate flooring of this brand - you can buy flooring for a real cost of 900 rubles. per 1 m2 at a price of 4.0-5.0 thousand rubles. for 1 m2.

Haro. Vinyl laminate "Haro" from Hamberger Flooring (Germany) has a very high price. But this is justified by its long service life, beautiful design that imitates natural wood, increased abrasion resistance and environmental friendliness.

Types of quartz-vinyl laminate

There are two options for quartz-vinyl coating on the building materials market:

- Glue-on or lockless laminate. Placed on a concrete base using glue or a self-adhesive base applied to the back of the lamella;

- Locking types of laminate. In this case, the material is assembled according to the classical scheme using metal clips and locks.

Stick-on tiles typically come in the form of elongated strips and rectangles, while interlocking lamellas come in the form of square or rectangular tiles. There are no serious differences between the two types of coatings. The only thing is that glued coatings are considered to be highly resistant to moisture, so in most cases quartz vinyl laminate in the bathroom is laid with glue. Interlocking or prefabricated quartz vinyl tiles have good thermal insulation, dampen noise and sounds well, which is why they are most often used in corridors and kitchens.

Both vinyl coating options are highly wear-resistant. Most models of quartz vinyl laminate are class 43 in terms of resistance to wear and static load. That is, you can realistically hope for a service life of at least two to three decades.

For your information! According to manufacturers, glued-on quartz-vinyl slats can last 40-50 years, while panels assembled with locks last 20-25 years at best.

Covering on locks

What are quartz vinyl tiles?

Quartz vinyl tiles also have a multilayer structure - PVC is used as the base, and quartz or chalk are the binding components. Polyvinyl chloride provides stability and ductility, while quartz is responsible for strength and durability. Polyurethane is used as a protective layer.

The difference between quartzvinyl is its moisture resistance, so it is recommended to inject it in rooms with high levels of humidity or where there is a risk of spilling something.

The coating also has other advantages:

- elasticity, which allows you to relieve tension when walking;

- resistance to ultraviolet radiation and dyes;

- high wear resistance;

- ease of care;

- When heavy objects fall from a great height, there are no traces of chips and cracks left on the surface of the dies, as on laminate.

Thickness of quartz vinyl laminate

Most vinyl flooring models have a thickness ranging from 2 to 9 mm. The thinnest lamellas are glued ones, even though the structure is multilayer materials, necessarily with a compacted base and fiberglass reinforcement. Thicker ones, 6-9 mm, belong to the locking models of quartz vinyl laminate. They are more rigid and difficult to bend when cold.

Due to their small thickness, vinyl slats are widely used as a covering for underfloor heating. Of all types of flooring, quartz vinyl laminate is best suited for underfloor heating. Firstly, the high quartz content in the structure of the vinyl sublayer provides both thermal inertia and high thermal conductivity. Secondly, PVC with quartz does not “float” under heating conditions, like regular vinyl tiles or linoleum.

Cons of vinyl laminate

Among the disadvantages, the main disadvantage is the price. She is very tall. Among other weaknesses of the material, it should be noted:

- release of harmful substances during a fire, which requires immediate evacuation of people from the fire site;

- there is a high probability of PVC containing cheap, but very harmful lead and cadmium in most Chinese-made products, which is excluded from manufacturers in other countries - they simply will not pass certification;

- fear of hot objects - the protective film is damaged;

- remaining traces of black rubber (shoes or rugs), which are difficult to remove;

- the need to carefully level the base of the floor (for lamellas with locks, the requirements are the same as for classic laminate).

Do I need a backing for quartz-vinyl laminate?

The lining material under traditional wooden slats appeared only to soften and absorb the load on the floor surface caused by walking. A classic cellulose panel turns out to be quite hard and even brittle, so without a backing, the locks on the joints would fail after just a few days of use.

The main thing is that the floor is level

For glued quartz vinyl laminate, no backing is used; natural flexibility and elasticity are sufficient to ensure that the adhesive seam does not collapse under load. Another thing is the interlocking types of laminate tiles. The material is quite rigid and durable, so a lining layer is needed to install and improve thermal insulation, otherwise the metal clips soldered into the lamella easily become loose and fail.

What kind of substrate is best to use under it?

In materials for flooring made of polyvinyl chloride, it will not be possible to find an answer based on the type of substrate under it, since the concept of “vinyl laminate” currently includes several completely different materials:

- PVC floor tiles (regular covering);

- self-adhesive panels (Contesse);

- vinyl laminate with a locking connection method (quartz vinyl).

There is no point in laying the backing under the tiles and lamellas on glue - there should be no intermediate link (layer) between the base of the floor and the glue. A number of interlocking laminate manufacturers also believe that an underlay is not needed. The inscription on the packaging will help you figure out when it is necessary to lay a substrate, where this point is necessarily specified: “needed, not needed.”

If laying the underlay according to the flooring installation technology is necessary, you can buy:

- cork backing. This is the most effective material that allows you to compensate for unevenness of the base, retain heat well and absorb sound waves. Considering the small thickness of the lamella board and its flexibility, the optimal thickness of the backing is 2 mm (on the forums, visitors note that with a thicker backing, the floor begins to sag under the weight of an adult);

- "Izolon" is the cheapest material. It is necessary to lay foamed polyethylene with a thickness of 3 mm. Under the weight of the floor covering, it will shrink to 2 mm, which will compensate for unevenness of the base;

- "Tuplex" . This underlay perfectly compensates for unevenness on the floor base and is a good heat and sound insulating material. Here, too, the optimal thickness is 2 mm;

- coniferous substrate - guarantees compensation for minor irregularities and good sound insulation. One of the best options when installing a “warm floor” is to ensure uniform distribution of heat over the surface of the laminate.

How to choose quartz-vinyl laminate

In order not to make a mistake with your choice, it is best to see with your own eyes a specific type of coating in real conditions. You can come to an office or construction salon that sells quartz vinyl coatings. In any case, you can pick up a sample, touch it and understand how suitable it is for an apartment or house. Quartz vinyl laminate looks quite impressive in the interior.

Living room with light quartz under sandstone

Typically, models and types of quartz vinyl coating are chosen based on the decorative qualities of color and surface texture. For the living room and corridor, light shades with the texture of sandstone or crushed stone are used.

Not afraid of moisture

For the kitchen it can be a laminate with a pattern of marble, jasper stone or malachite. For the kitchen, as well as for the bathroom or toilet, it is important that the surface is smooth, but not slippery.

“Marble” floor based on quartz-vinyl coating

In the hallway you can use quartz - a vinyl laminate with a rough-sandy surface; this not only masks sand and dust brought from the street, but also reduces wear from the soles of shoes.

For the office, imitation parquet and mosaic sets are most often used. In the bedroom and children's room, light and multi-colored coatings are traditionally laid.

Classic walnut structure

Reviews

“We recently installed regular laminate flooring in our home. I really regret that I didn’t find out about vinyl laminate earlier, as I definitely would have preferred it. All the benefits of vinyl make it so different from ordinary vinyl. Moreover, I have now set a goal to replace the floors in a couple of years and install vinyl laminate.” Olga, Krasnodar.

“On the advice of a friend, I installed vinyl laminate. I was surprised that it is absolutely no different from parquet. The top covering is designed to look like parquet, and at a much lower price than the real thing. Nowadays, you can believe the advertising: why pay more for parquet if you have vinyl laminate?” Vladimir, Saransk.

“I laid the floor myself. At first, I chose any laminate in the store, but settled on vinyl. I didn’t know about its advantages, I relied on the ease of installation, consulted with the sellers and they suggested vinyl laminate as the easiest for these purposes. The boards are light, it’s clear how and where they are attached, for each square meter I spent only 500 rubles. This is the best choice for the price." Vitaly, Voronezh.

“We chose the gender as a family. The renovation budget was minimal. The qualities of vinyl flooring are ideal: environmentally friendly, durable and, according to specialists, should last a very long time. But still, the choice of vinyl laminate hit our wallet. We paid 1,800 rubles per square meter. We hope it pays off." Julia, St. Petersburg.

We have a child at home, he is still six months old. That's why I took a long time to choose the floor. Based on reviews and characteristics, vinyl laminate flooring was suitable. I decided what would be the safest for the child, and I was not mistaken in my choice. Plus the floor is very practical. All the time some kind of moisture gets on the surface, which is a common occurrence with a child, I have never noticed any damage.” Lana, Moscow.

How to lay quartz-vinyl laminate

Vinyl coating can be laid without problems on any base, regardless of its characteristics and structure. The main thing is that the surface is relatively flat, without bumps, depressions and sharp edges. The material can be laid on concrete, old linoleum, parquet, it is important that the base is rigid and solid.

In this case, it is desirable that the air temperature in the room should not be lower than 16-17°C; quartz-vinyl laminate, like all PVC-based materials, have a fairly high dependence on the level of heating and cooling, so it is advisable to lay the lamellas at the operating temperature of the material.

Self-adhesive material

Self-adhesive types of quartz-vinyl laminate are pre-measured according to the width of the room, just as in the case of cellulose panels. The only difference is that the lamellas must be laid with overlapping edges. If tile adhesive is used to install vinyl material on concrete or a substrate, then you additionally have to grind the adhesive mass, and after installation, you also have to level the surface to the building level.

Quartz vinyl lock models are most often laid diagonally across the room. Like most cellulose lamellas, tiles with metal interlocks can have problems if the seam line between the tiles matches the joint on the backing material. In order to connect two slats, it is enough to tilt one of them at an angle of 45 degrees and engage the second one with the lock, and then click the connection. You can learn more about laying quartz vinyl laminate in the video:

Laying

Installing vinyl laminate flooring is essentially no different from installing regular laminate flooring. The main feature is lightness and simplicity.

Vinyl flooring can be installed on any old ceramic, concrete or linoleum surface. The process is divided into stages

- The base for installation is carefully leveled and putty is applied.

- The surface is cleaned of moisture, dust and dirt. The material itself is cleaned using the same system and kept indoors for about two days.

- Before installation begins, the room temperature is checked. It should be no lower than +18 degrees.

- Section of the planks. The laminate planks are separated using a hacksaw or scissors. After separating the boards, special glue is applied to them.

- Laying begins from the corner of the room; the planks should be connected at an angle of 45 degrees.

Very fast installation. Just a few hours.

It is also important not to forget about the deviation of the planks from the wall by 4-5 mm. Everything is carefully checked for possible cracks and uneven joints.

The same applies to laying interlocking laminate. First, the panels are joined at the specified angle, then lightly pressing downwards are snapped into place.

At the end of the work, the floor is once again checked for unevenness and the strength of the connection of the planks. To do this, it is best to use a special rolling roller.

Rating of quartz-vinyl laminate manufacturers

The main production of vinyl materials is concentrated in the European Union countries - Germany and Belgium; some of the highest quality materials are produced in Japan and South Korea.

Belgian Quartz - Vinyl Laminate Flooring

The first places in the quality rating can be given to the two most famous brands - AquaFloor and FineFloor. In fact, the developments of the leading IVC manufacturer set the tone for fashion, technical and design solutions in the polymer laminate market.

Quartz - the vinyl base of the laminate undergoes strict environmental control, therefore, in addition to an extremely high service life of 45-50 years, the company guarantees complete safety of the coating.

Belgian quartz vinyl is considered the best in the world

Japanese and Korean quartz - vinyl laminates

Two well-known brands, the Korean Decoria and the Japanese Art Tile, are practically not inferior to the Belgian models in terms of quality and technical characteristics, perhaps only differing in a more concise and simple design.

The advantages of Korean and Japanese coatings include extremely simplified installation technology. If necessary, laying quartz-vinyl material can be done with your own hands, even with minimal experience in performing this type of work.

New brands

Among the models that have just appeared on the market, we can note the Russian-German development of Tarkertt Art Vinil and the new product of Belgian origin DumaFloor from the Dumaplast company.

Both brands are characterized by a huge range of textures and patterns, primarily imitation of natural stone and valuable wood species. It is believed that Tarkertt Art Vinil is one of the most suitable quartz vinyl laminates for underfloor heating. In terms of performance characteristics, laminates are second only to market leaders.

Comparison of materials by quality characteristics

Before choosing quartz vinyl or laminate, it is necessary to compare the properties and technical indicators, which play an important role in further operation. Here is a comparison of quartz vinyl and laminate according to the main characteristics, which will allow you to select products for the type of room and the requirements of the property owner.

Moisture resistance

PVC tiles are impervious to moisture, temperature changes, and ultraviolet radiation. In addition, the coating is designed to be in the same room with aggressive substances, which expands the scope of its use - kitchen, loggia, warehouse and garage premises, office and commercial premises. The risk of leakage is dangerous when laying tiles with an interlocking joint. Water can seep through the lock onto the subfloor, which can result in the formation of mold and mildew, and such consequences can only be eliminated by dismantling the floor. If adhesive quartz vinyl is used for installation, such risks are eliminated.

Laminate is considered a moisture-resistant coating. This means that it can withstand wet cleaning, but if water gets on the surface, it must be removed immediately. Otherwise, the edges of the boards may swell and rise like a house. But there is a laminate labeled “waterproof”; it can withstand water spilled on the surface for 2 to 24 hours (depending on the manufacturer) without causing damage. For production, a special impregnation is used that repels moisture. It processes HDF boards and interlocking joints. This property still will not save you from leaks or excessive ingress of water, although there is a chance to avoid consequences.

Environmental friendliness

Both quartz vinyl and laminate belong to the same emission class - E1. Despite this definition, we should not forget that laminate is made from wood chips, and vinyl is based on plasticizers. If you choose tiles of low quality, with a cheap price or of an unknown brand, then the risk increases that during operation the plasticizer will begin to harden and release harmful substances. You should not trust and buy products of dubious quality; it is better to overpay and opt for products from European brands.

Compatibility with heated floors

Both coating options are suitable for installation on a heated floor system, provided that the surface is heated to a temperature of no more than 27 °C. Previously, it was not recommended to lay the coating on an infrared heated floor, because... it required a backing to be used, and PVC tiles were not allowed to be placed on a regular backing. But with the advent of a special substrate on the market, this problem was solved.

Durability

According to this parameter, both materials, quartz vinyl and laminate, are designed for a long service life. Depending on the conditions of use, manufacturers guarantee the safety of products for 10-35 years, and coatings installed in living rooms with low traffic may not require replacement at all.

Resistant to wear and scratches

Laminate and quartz vinyl floors demonstrate good resistance to stress. There are practically no traces of heavy furniture, heels, or animal claws left on the surface of the coatings. In turn, laminate is still better in terms of scratch resistance, since it is easier to leave a scratch on PVC tiles, which is due to the characteristics of the protective layer. Also, PVC tiles can be damaged by a sharp object, such as a knife. But if the same knife falls from a height, then a chip may remain on the laminate, while a slight “cut” will remain on the vinyl, not very noticeable.

Decors

Both coatings are presented in a variety of designs, mostly imitating natural materials: wood or stone.

The surface treatment and texture itself are more interesting with laminate. There are more options for different designs of chamfer - the joint between the boards. More collections with matte or glossy surfaces are presented.

Quartz vinyl does not lag behind in decors; not everyone will understand that there is an artificial floor on the floor. In some collections you can see models with register embossing and a brushed effect. But PVC tiles have an advantage due to the adhesive installation method. It lies in the variety of styling patterns. In addition to the standard spread, you can install it in the form of a herringbone, squares, braid, etc.

Laminate and interlocking vinyl are laid in staggered patterns, and there are also herringbone-shaped collections (there are not very many of them).

Linoleum

I sorted it out and forgot about it. We replaced it with a more economical option - linoleum. It feels good. Modern linoleum has an almost imperceptible smell (and even then at first), a wide range of colors, and a variety of textures.

And installation is simple: just cut the slit and that’s it. It doesn’t crack, doesn’t crumble, doesn’t crack, doesn’t warp, but... it tears well. Our Labrador Bucks proved it. One day, returning from work, we discovered a hole in the lid and a happy dog's face.

The hole was repaired and a bedside table was placed in place of the injury. The dog grew up and stopped chewing everything, but could still run. Thus, running in circles at the sound of the refrigerator opening and stopping at his plate in the kitchen, Bex's sharp claws caused yet another injury to our "under the laminate" linoleum.

Doesn't slip

Most owners of this flooring report the “anti-slip” nature of quartz vinyl. However, in rare reviews, the opposite information also slipped through (it was clarified that we were talking about tiles with a smooth surface).

Textured quartz vinyl still does not slip. Therefore, many people choose this tile for the bathroom. The risk of falling with such coverage is reduced.

From the forums

“It doesn’t slip. Even non-slip ceramic tiles are more slippery than this.”

The nuances of laying vinyl laminate flooring

When working with quartz vinyl panels, it is necessary, in addition to following the classical technology of laying laminate (see the work “How to lay laminate on a concrete floor?”), to take into account some nuances associated with the different composition of the components of the floor covering.

- Before installation, it is necessary to soak the floor for 48 hours in the room where it will be installed so that it takes on geometric shapes at a specific temperature.

- All holes for the passage of heating pipes must be cut according to the pattern.

- The best way to cut vinyl is with a utility knife.

- Since the floor practically does not expand under the influence of different temperatures and humidity, there is no need to leave technological gaps.

- Due to the fact that water that gets under the floor covering practically does not dry out when flooded, it is advisable to seal the joint between the wall and the vinyl laminate with silicone sealant (this also applies to obstacles) - water can only get under the covering near the walls and heating pipes.

Installation of quartz vinyl laminate.

Doesn't creak

Even interlocking quartz-vinyl tiles do not begin to creak, crunch and click over time the way laminate and parquet boards can do. After all, quartz vinyl is not at all so hard and hard.

From the forums

“We also have quartz vinyl and laminate. Quartz vinyl is softer and warmer than laminate. Moreover, the laminate (after 5 years) began to creak, swelling of the edges appears here and there, but the tiles don’t care. When we do the renovations, I’ll cover everything with it.”

Quartz vinyl in the hallway

Can absorb dyes

One of the most famous manufacturers of quartz vinyl in our country convincingly states: stains are not characteristic of their floor covering. After all, quartz vinyl is supposedly characterized by the highest resistance to staining. This is explained, first of all, by the absence of pores.

In addition, quartz vinyl can easily withstand the effects of special means: if you are unable to wipe off the stain with a wet rag, you can try to remove it with alcohol, alkali solutions, acids, etc.

Everything is fine in words, but what in reality? One of the most frequently mentioned disadvantages is the high risk of permanent stains. They didn’t wipe the juice from the berries in time, the child drew with gouache, they put a wet colored box on the floor - anything can stain the floor. And attempts to eliminate these traces are often unsuccessful.

From the forums

“The only negative is that we took a light one, but it absorbs different dyes like a sponge. That is, the dark carpet, the child’s markers, etc. - this was a problem. Nothing else bothered me."

******************************************************************************************

“I placed a wet bag of construction mixture on class 43 quartz-vinyl (well, what will happen to it?). And he was painted with red inscriptions on the bag. Well, I think: now I’ll get the alcohol and, as usual, wipe it off. Nothing like this! I rubbed it with water, household products, solvents... I solved the problem by rearranging a couple of tiles. This also turned out to be not so easy... It turns out that dyes (probably household dyes - for example, watermelon, beets, etc.) eat into the top layer. If it’s too ingrained, goodbye tiles.”

*******************************************************************************************

“Almost two years. They put it in the nursery. The seams are fine, but there are still barely noticeable colored spots from plasticine, felt-tip pens or pencils. They can’t be removed even with a melamine sponge.”

Quartz-vinyl flooring in the nursery

Comparison table of materials

The table shows the difference in performance characteristics of floor coverings.

| Options | PVC tiles | Quartz vinyl |

| Durability | Limited to 10 years | Minimum 25 years |

| Ability to withstand mechanical stress | Average | High |

| Soundproofing properties | Mid: Reduces loud sounds to conversation level | High: extraneous noise is heard as a whisper |

| Thermal conductivity | Average | Bad: it conducts cold slowly, a heated one takes a long time to cool down |

| Wear resistance | Average | Maximum |

| Can be used as a finishing coating for heated floors | Selected species | Applicable |

| Antistatic qualities | Average | Virtually no dust attraction |

In other respects, these flooring materials have no differences.

They are characterized by high slip resistance, resistance to fading in the sun, and ease of installation. When we compare PVC and quartz vinyl coatings, the material with a sand filler has clear advantages.

Doesn't make noise

Like linoleum, quartz vinyl dampens impact noise due to its multi-layer nature and relative softness. This advantage is especially important for offices and various public institutions where people wear shoes. But this quality is also important for a home, especially if small children live in it.

From the forums

“One of the advantages of the floor is that in the nursery, even though an elephant can jump, there is no sound.”

Quartz-vinyl flooring in the nursery

Reason 3: tactile comfort

It’s pleasant to walk barefoot on warm quartz vinyl

Ceramic tiles have a high thermal conductivity coefficient. The property of the material to absorb heat will be noticeable even in a warm room. That is why in southern countries tiles are used in rooms for thermoregulation.

In our latitudes, the tactile sensation of cold from the tiles is rather its disadvantage. Stand on the tile floor in your kitchen while you prepare food and within 20 minutes your feet will feel cold.

Due to the quartz layer, the thermal conductivity coefficient of Fine Floor tiles is similar to wood. This means that the coating is heated to room temperature.

Types of raw materials for PVC tiles

Raw materials can be primary or secondary by origin. The latter is used mainly in factories in Asian countries. For manufacturers, processed raw materials cost 2 times less than primary ones, and for consumers, purchasing products made from them results in troubles:

- unpleasant odors are felt for a long time;

- product dimensions change;

- the material crumbles.

Primary raw materials are used mainly in European factories. The products are more expensive, but of better quality and environmentally friendly. For these reasons, when choosing a floor covering, pay attention to the manufacturer. It’s better to pay more, but be sure of health safety and quality.

Time for new solutions

IVC Moduleo

IVC Moduleo is a well-known Belgian manufacturer of vinyl flooring materials. The main task that the company sets for itself in the production of PVC coatings is complete external resemblance to the imitated materials.

High-quality Moduleo textures allow you not only to see the smallest nuances of wood patterns, but also to feel the relief of natural wood.

And the 0.55mm thick protective layer provides unmatched wear resistance, which is backed by a 20-year warranty. IVC Moduleo vinyl laminate collections include wood and stone designs.

NATURA

The Belgian manufacturer offers innovative products - engineered vinyl plank (IVD) NATURA.

The product consists of five layers:

- An ultraviolet protective coating protects the IVD from short-wave solar radiation, preventing the pattern from fading. The same coating has an antistatic effect. Dust and dirt do not stick to it, which makes cleaning easy and quick.

- The protective layer of transparent polyurethane provides high wear resistance and impact resistance.

- Decorative film with applied texture realistically imitates wood.

- The PVC layer ensures the stability of the linear dimensions of the board during fluctuations in temperature and humidity.

- The bottom layer of the IVD is a rigid composite base.

The coating has a wear resistance class of 43 and is absolutely waterproof.

Pergo

Pergo vinyl comes with a 25-year warranty, is 100% waterproof and 100% phthalate-free. The manufacturer produces two types of vinyl dies. One uses a rigid fiberglass-reinforced composite base.

Elastic vinyl is pressed on top of the rigid layer, which provides a combination of the hardness of the composite and the elasticity of PVC. In the flexible version, the two vinyl layers are separated by a fiberglass spacer.

In addition to high-quality vinyl flooring, Pergo also offers a wide range of installation accessories.

These are the installation tools:

- professional vinyl cutting knife with 10 blades;

- mounting tool for precise cutting.

And also accessories:

- baseboards;

- substrates;

- profiles;

- care products.

Progress

Like most modern vinyl coverings, the products of the Swiss company Progress are positioned as environmentally friendly. Other benefits include:

- One hundred percent waterproof: moisture does not penetrate even through the joints, says the manufacturer.

- In terms of wear resistance, Progress floors belong to the highest resistance class of 43. The coating can withstand loads of up to 100 kg per square centimeter of surface.

- Progress vinyl is an excellent sound insulator, absorbing up to 24 decibels of noise.

- The material is extremely resistant to chemicals, even aggressive ones such as hydrochloric acid.

Other advantages of the floor from the Swiss manufacturer include an antibacterial effect, ease of installation and maintenance.

Resistant to moisture

Not a single layer of quartz-vinyl tile is afraid of moisture. Even if water gets deep, nothing will probably happen to the tiles.

Craftsmen from the construction forum described their own tests, carried out out of curiosity. Quartz vinyl was poured, soaked, damaged and soaked again - no change.

Thanks to this quality, quartz vinyl is perfect for the kitchen, bathroom, balcony, and hallway. Ceramic and porcelain tiles look, of course, much more solid and last, as a rule, longer, but quartz-vinyl is not a bad alternative with a lower cost and much easier installation.

From the forums

“We are very happy, considering that we have already been drowned a couple of times. Laminate would swell, but quartz-vinyl tile would not.”

Quartz-vinyl tiles in the kitchen