Device, principle of operation, purpose

Pumping equipment for pumping heated water through a closed pipeline loop in a private house is small in size and consists of the following main elements:

- Housing made of stainless steel, cast iron or bronze and brass.

- A stator that can withstand heating of the pumped medium up to 60-700C.

- A rotor shaft with an impeller, the rotation of the blades of which ensures the injection of water into the pipeline.

- Thermoplastic impeller.

- Squirrel cage steel rotor.

At the same time, the pump is able to exhibit the characteristics laid down in it by the manufacturer, provided that the pumped liquid is technically clean - with a viscosity characteristic of water without the inclusion of mechanical impurities. The device is installed quite simply - without removal from the system, but by inserting it into a pipeline section. Therefore, the use of a bypass is not necessarily necessary.

The principle of operation of a recirculation pump for domestic hot water or heating boils down to the following mechanism:

- Water from the pipeline enters the device into the central part of the impeller.

- An electric drive rotates the blades.

Design of a circulation pump for hot water Source eurosantehnik.ru

- As a result, the resulting centrifugal force pushes water to the outlet pipe, giving the flow a given pressure.

- In this case, an increased injection of incoming water occurs at the entrance to the pump - due to the vacuum created on the back side of the blades.

The use of such equipment is not necessary for the operation of an autonomous water heating system, but it can significantly increase the efficiency and cost-effectiveness of energy consumption. If under normal conditions it takes time for hot water to come out of the tap when opening (since with a slow flow it cools quickly), then when using a pump it flows almost instantly.

This is especially true when the consumer is located at a relatively large distance from the water heater. Another useful function for which this type of recirculator is intended is the return of unused heated water to the heater via the return line. In addition, with a gravity-flow system, the farther the consumer is located, the more noticeable the initial pressure drops.

Option for placing a circulation pump in a heating and hot water system for a private home Source s-proms.ru

The use of a recirculation pump allows you to get rid of this significant drawback. This ensures constant water temperature and pressure at any point in the heating system or DHW circuit - regardless of the distance to the unit.

Important! Only a specially designed pump can be installed in a domestic hot water or heating system. A conventional centrifugal model for pumping water is not suitable, since it is not designed to work in an environment with elevated temperatures and will quickly deteriorate.

Natural and forced circulation - what's the difference?

Natural is built on the physical process of heated water rising upward. The density of hot water is less than that of cold water, so warm layers are displaced by less heated layers. This phenomenon occurs without human participation, you just need to create the conditions to start the process.

However, natural circulation is unstable, without the necessary pressure. The speed of movement of layers of water is low; it cannot push the flow through the pipeline. In addition, it is almost impossible to regulate the natural process, just start or stop it.

Forced is the movement of water using special pumping equipment. The process occurs evenly, it can be adjusted, flow parameters changed or stopped as needed. The pump creates pressure that allows water to move through a branched, extended system.

The natural process is used where slow, ineffective mixing of layers of water at different temperatures is sufficient. As a rule, it is used in small water supply systems of a private home, when only a small exchange of layers is needed.

For apartment buildings, only forced circulation is suitable, allowing the water flow to be raised to the upper floors and effectively replacing cooled water.

Control options

Hot water in a private house is used periodically - for washing, washing, cleaning, showering, etc. There is no need to constantly maintain it in the DHW circuit. In addition, such an approach would lead to extremely wasteful consumption of energy resources and equipment.

Circulation pump with temperature sensor Source prom.st

See also: Catalog of companies that specialize in water supply, sewerage and related work

Therefore, in order for the heated water to reach the tap at the right time, 2 special pump control options are used - these are:

- Thermal sensor.

The principle of operation is based on maintaining a given water temperature in the circuit and boils down to the following algorithm:

- The temperature-sensitive element is immersed inside the pipe and is in direct contact with the water.

- As soon as the temperature inside drops below the set value, the sensor instantly sends a signal to the control module.

- The recirculation pump starts and begins to supply hot water to the DHW circuit.

- As soon as the heating level reaches the required value, the pump turns off.

To reduce energy consumption and equipment resources, the pipeline is specially thermally insulated.

- Timer.

Timer operation differs from the above option in that hot water is pumped into the pipes according to a specific schedule. This approach is convenient when it is known exactly during what specific period of time the hot water supply will be used. For example, on weekdays these are the morning and evening hours, when household members get ready for work and come back from it.

Circulation pump with timer Source cok.ru

Modern smart timer models allow you to set up a schedule several days in advance, as well as independently monitor the water consumption schedule and then automatically set the operation of the equipment. In addition, they are able to take into account the parameters of the hot water circuit - the length of the pipes, their capacity, the percentage of heat loss, the cooling time of the water - and, based on this, adjust the time the device is turned on/off.

When is it necessary?

The need for circulation arises in long lines with a large number of subscribers, for example, in apartment buildings or public buildings. In a dead-end pipeline, the water will quickly cool down.

This phenomenon is pronounced at night, when water intake practically stops and the water loses thermal energy.

Starting circulation allows you to:

- constantly update the flow in the pipes,

- heat cooled water to ensure standard values.

In small water supply systems of one-story private houses, circulation is rarely used. The distance from the water heater to the water collection points is relatively small, so it is not advisable to spend money on purchasing or installing a pump, assembling a loop, and starting the process.

It’s easier to let a little water through, which has had time to cool down, to get a normal hot stream.

In two-story houses or cottages, a circulation system becomes a necessity.

Varieties

Hot water recirculation pumps are classified according to several criteria. First of all, they are divided according to their purpose in a closed loop circuit into 2 types:

- The servers. Mounted on a direct line for supplying water from the heater.

- Reverse. Installed on the return branch to return cooled water to the heating circuit.

Based on the type of design, pumps are divided into 2 types:

- With wet rotor.

The working part of the device is located directly in the pumped medium. Therefore, both cooling and lubrication of the device is carried out by the pumped liquid, in this case water.

Recirculation pump with a wet rotor Source teploufa.ru

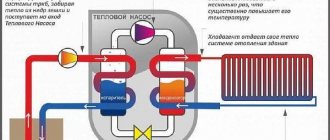

What it is?

It is impossible to organize continuous heating of water using conventional methods, so a simple and effective method is used - the hot water supply line is looped and the circulation process is started.

The flow leaves the boiler, passes in a circle and returns to the heating container.

All that remains is to adjust the speed of movement to ensure the supply of water at the standard temperature for all subscribers of the line.

Circulation pumps are used for movement, although natural circulation is possible in small systems.

Selection rules

In order to choose the right circulation pump for domestic hot water, it is necessary to take into account the following number of criteria:

- Performance. The value is determined by the amount of water pumped per unit of time. For example, for a private house with an area of 100 m2, a model of 80-110 liters/min is optimal.

- Pressure The indicator depends on the location of the water heating installation and the height of the consumer relative to it. So, if the boiler is located in the basement, then a tap on the 2nd floor will require a value of this characteristic of 6-8 m.

- Power consumption. The stronger the motor, the more productive the device will be, but also the more expensive it will cost to operate.

- Control method. By timer or temperature sensor.

- Manufacturer's brand.

- Price.

A circulation pump for a home is selected based on several parameters at once Source byreniepro.ru

Important! Pump selection should be carried out by an experienced designer based on specific application conditions. This takes into account the number of intake points, the minimum and maximum volume of water used, the supply height, and the length of the pipeline.

Gas boilers

In houses with central heating or apartments, it is beneficial to install gas boilers. Under these conditions, they provide savings at the same level of performance. Gas boilers come in two types - with an open combustion chamber and with a closed one. This allows you to use them in an apartment without the use of additional communications, since the power is comparable to the power of a gas stove. And it does not require an additional smoke exhaust device.

Just like in a gas boiler, gas ignition is ensured by a duty wick, which burns all the time and burns gas uselessly, by electronic ignition using batteries, or by hydrodynamic ignition. It is triggered when the cold water tap is opened. The current rotates a small turbine, which ignites the gas in the burner.

Video description

Video review of what a DHW recirculation system is and the rules for choosing a pump for it:

In this case, the standard installation procedure in the DHW circuit of a private house is carried out according to the following algorithm:

- Assembling the device in accordance with the technical documentation.

- Determining the installation location in the circuit.

- Shutting off the feed.

- Cutting out part of the pipeline at the installation site.

- Connecting the device.

- Sealing and checking joints for leaks.

- Turning on the water supply, connecting equipment.

- Configuration and performance testing.

Advice! To facilitate equipment maintenance and maintain maximum system functionality, it is best to install the device in a so-called pocket. This is a special outlet separated from the pipeline by shut-off valves. If necessary, the pump can be quickly turned off and dismantled, replaced with a new one or repaired - without stopping the coolant.

Useful tips

When constructing a new building, it makes sense to immediately install a storage boiler with a capacity of over 100 liters. It will provide comfortable living without the need for alterations in the future.

If the house is used infrequently, for example a summer house, then there is no point in installing a storage system; a flow-through heater is sufficient. At the same time, the compact arrangement of flow points in such buildings will ensure convenience during operation.

If you have a large family, you can install additional capacity in the storage water supply system. A 30-liter tank with additional electric heating, which serves to compensate for heat loss, will allow you to compensate for changes in water consumption with a large number of household members.

When purchasing a gas boiler, preference should be given to ready-made boiler-boiler kits. Their parameters have already been selected for each other, such a combination will optimally consume heat.

When heating a house with solid fuel, it makes sense to use a heat storage tank to create a secondary hot water supply circuit. This will significantly reduce energy costs.

At temperatures of 55 degrees and above, salts begin to actively precipitate from the water. They clog the pipes and impair the flow of water. This is especially important for flow-through heaters that heat large volumes over a short length of pipe. If the water contains more than 140 mg of impurities per liter of water, then instantaneous water heaters cannot be used - they break down too quickly and stop heating the water.

Briefly about the main thing

A hot water circulation pump consists of a housing, a rotor, a shaft with blades, a stator and an impeller. The principle of its operation is that water flows through the inlet pipe to an impeller rotated by a drive. As a result of the resulting centrifugal force, the flow is injected and exits with a given pressure into the system. Thanks to the pump, the water does not have time to cool down in the pipeline and does not lose pressure, regardless of the distance of the tap from the water heater.

Such a pump can be controlled in two ways - by a temperature sensor and by a timer. In the first case, the supply is resumed when the water in the circuit cools, in the second - according to a schedule. Pumping equipment is classified according to several criteria:

- Installation location in the diagram - supply and return.

- Design type - with wet and dry rotor.

- Number of drive speeds.

When choosing a pump, you need to take into account performance, pressure, power consumption, control option, brand, cost. Installation into the pipeline diagram is carried out depending on the purpose and strictly according to a given algorithm.

Ratings 0

System with storage boiler

A system with a storage tank is currently becoming increasingly popular. It is an additional tank that serves as hot water storage and contains a heating element inside. In addition, it is usually additionally connected to the heating system as a second heating circuit and receives additional heat from there. This allows you to save on direct water heating costs and reduce heat loss. Such a system is called an indirect heating boiler.

Water is drawn from the top of the boiler and replaced by new water coming from the water supply. Since the density of cold water is higher, it is located at the bottom of the container, which is connected to the heat exchanger. Getting into it, cold water heats up and reduces its density. Due to this, it rises and flows into the upper part of the boiler, and is replaced by a new portion of cold water. This natural circulation eliminates the need for additional pumps.

In addition, there are various water supply systems that use a storage tank as the main element.

Problems

Circulation in a water supply system is a process that is quite easy to disrupt. In the next section of the article, we will analyze typical problems that can lead to a stop in circulation and the associated cooling of hot water risers and heated towel rails in an apartment building.

Airlock

- Symptoms: after turning off the hot water, one riser or a group of risers has cooled down. The neighbors' pipes are still heated.

- Reason: air lock in the ring jumper. A pressure drop of 0.2 atmospheres is not enough to force it into bottling.

- Solution: expel air through the vent at the top of the jumper. If this is not possible (for example, due to the absence of residents on the upper floor), you can pass the riser through the basement or water fittings in the apartments.

To do this you need:

- Shut off one of the problematic hot water risers with a tap or valve in the basement;

- If there is a vent on this riser, open it and wait for the air to escape;

The hot water riser is equipped with a vent that allows it to be bypassed from the basement

- If there is not a waste pipe on the riser, but a plug, you can open hot water to capacity on one or two mixers in any apartment located along the same riser;

Air can be expelled from the riser through any mixer connected to it

- After bleeding the air, open the valve or tap at the base of the riser.

Closed valve

- Symptoms: when drawing water, the riser heats up from above due to the hot water supply being inserted into it. It is obvious that water flows to the liner through the ring jumper.

- Reasons: after turning off the riser, the faucet or valve remained completely or partially closed.

- Solution: go down to the basement and open the shut-off valves on yours and the adjacent DHW risers all the way to failure.

With an open ball valve, the handle is always directed parallel to the axis of the body

Valve valve separation

Symptoms: water enters the line through the ring jumper from above. A screw valve is installed at the base of the DHW supply riser in the basement. The arrow on the valve body is directed towards the hot water supply.

The arrow on the screw valve body indicates the only possible direction of water flow

- Causes: valve valve separation from the stem. This happens if you try to open an incorrectly installed shut-off valve of this type, overcoming the water pressure on the valve.

- Solution: replacing the valve with a ball valve (on a steel riser, in this case, you have to change the flow to a longer one), installing a new screw valve in the correct position (with an arrow in the direction of flow).

The riser valve in the photo has been replaced by an assembly with a ball valve

No difference in the heating main

In houses with open heating, the hot water circulation system often stops immediately after the end of the heating season. Symptoms: Cold heated towel rails throughout the house. The reason is that local Heating Networks completely eliminate the difference between the threads of the heating main.

Why is this being done?

The fact is that the heating season begins when the temperature outside is +8 °C or higher for at least five days in a row. Even if after stopping the heating there is a new frost, the heating will not be turned on, since on a city scale, restarting it is associated with colossal costs.

However, residents of a separate house may well, having access to a heating point, turn the heating back on. To do this, you just need to open a couple of so-called house valves (after the water jet elevator) or taps. But in the absence of a difference, this will not lead to the resumption of circulation in the heating system, and, therefore, to unpaid heat consumption.

At the end of the heating season, the DHW circulation may stop for some time.

Unfortunately, there is no reasonable solution for this scenario. All you can do is wait a couple of weeks. As soon as truly spring weather sets in, the circulation-providing difference will return.

Malfunctions

What problems in the operation of the water supply system can the apartment owner eliminate on his own? Here are some of the most typical situations.

Valves leaking

Description: leakage along the stem of screw valves.

A typical leak location is shown by an arrow.

- Reason: partial wear of the oil seal or wear of the rubber O-ring.

- Solution: open the valve knob all the way. In this case, the thread on the rod will tighten the seal from below, and the leak will stop.

Crane noise

Description: when you open a hot or (less often) cold water tap, you hear a loud noise and feel the vibration of the mixer. Alternatively, your neighbors faucet could be the source of the noise.

A noisy neighbor's faucet can become a source of a lot of negative emotions.

Cause: a deformed and crushed gasket on the screw valve in the half-open position causes a continuous series of water hammers. Its valve closes the seat in the mixer body at intervals of a fraction of a second. In hot water, the pressure is usually noticeably higher, so the effect is more pronounced.

Solution:

- Shut off the water to the apartment;

- Turn out the problematic valve housing;

- Replace the gasket with a new one;

- Use scissors to remove the chamfer from the new gasket. The removed chamfer will prevent the valve from beating in a turbulent stream of water in the future.

Replacing the gasket on the screw valve

The photo shows a ceramic crane box

Cold heated towel rail

- Description: The heated towel rail in your bathroom has cooled down and is not heating up.

- Reason: if the water supply scheme of a residential apartment building uses continuous circulation of hot water, the air remaining in the jumper between the risers after water is discharged (for example, for inspection and repair of shut-off valves) is to blame.

- Solution: go up to the top floor and ask your neighbors to bleed the air from the jumper between the DHW risers and heated towel rails.

If for some reason this cannot be done, the problem can be solved from the basement:

- Shut off the DHW riser passing through your apartment, to which your connections are connected;

- Go up to the apartment and open the hot water taps all the way;

- After all the air has come out of the riser through them, close the taps and open the tap on the riser.

If a vent is installed on the riser, it can be diverted directly from the basement

Immediately after the end of the heating season, the difference between the lines of the route may be zero

All-season operation of heated towel rails.

In order for heated towel rails to be constantly hot, they must be included in the recirculation system. Consistently, one after another. This will not lead to a significant increase in the hydraulic resistance of the route or any noticeable cooling of hot water at consumers. Simplified, it looks like this: Since there are a great variety of heated towel rails, I will not describe how to connect a heated towel rail. I can suggest that while they are not installed, before finishing, you can install jumpers made of pipes instead of them. The connection diagram for heated towel rails shown in the figure allows you not to worry about the accumulation of air in the upper part of them. Air will be expelled through the hot water taps when any of them are opened.