Wood has always been valued in the interior. Cabinets, tables, chairs, doors and frames are made from it. With the development of power tools, more opportunities have emerged for creating wooden objects of various shapes, and productivity has also increased significantly. One of these indispensable assistants is an electric planer. A similar tool is available in every professional workshop and in the garage of amateurs. At the dacha, with its help it is possible to make the necessary furniture and fixtures in the yard. Such construction equipment contains many options for choosing, understanding which it will be possible to purchase a tool that justifies the hopes placed on it for the implementation of tasks.

Device, purpose, principle of operation, pros and cons

In essence, an electric plane is an analogue of the long-existing manual version of the tool. It performs the same basic range of tasks, only on a larger scale, with less physical effort, much faster, more accurately and with better quality. However, there are also differences – primarily in the wider list of operations carried out with its help:

- Planing is the removal of the top layer of a given thickness.

- Sampling quarter.

- Chamfering.

- Tongueing.

- Performing the function of a jointer (with stationary fastening).

- Edge beveling.

- Grinding.

- Adjustment of surfaces.

- Giving the workpiece a strictly rectangular shape.

All these functions are widely used in carpentry in the manufacture and finishing of wooden elements of building structures, furniture, interior design and decoration.

The use of an electric planer in the manufacture of household structures Source oboiman.ru

Device

To choose the right electric planer for your home, you need to understand how it is designed and what technical parameters its main components are equipped with. The standard tool model includes the following main elements:

- Electric motor.

- Knife drum.

- Belt drive with protective cover.

- Housing equipped with a handle and a start button.

- Sole.

- Additional side handle.

- Processing depth regulator.

- Side pipe for removal of chips, dust and sawdust.

- Ruler and limiter.

Each modern model of electric planer is equipped with two keys - the main start button and an additional one that protects against unintentional start of the drive.

Operating principle

The main operating unit of an electric planer is a knife drum rotating at high frequency. It is driven by a toothed belt drive from an asynchronous motor powered from a 220 V network, the power of which, depending on the model, can range from 0.5 to 2.2 kW. In this case, the number of drum revolutions varies from 10 to 18 thousand rpm.

Electric planer design Source calameoassets.com

When they come into contact with the material being processed, the knives cut into the surface and remove chips. The sampling depth is determined by the difference in the heights of the two parts of the support sole. As a rule, the rear part is stationary, and the front part is changed by the depth regulator and fixed in a given position, determining the thickness of the chips being removed.

Advantages and disadvantages

Another important criterion that allows you to evaluate and choose the right electric planer for your dacha is the main advantages and disadvantages of this type of tool in general.

Pros:

- Great performance.

- Minimal physical effort required.

- High quality of all operations.

- Savings – finished construction materials cost at least 2 times more than untreated ones.

- Possibility of using the plane as a planer and surface planer as a stationary machine.

Minuses:

- Not accessible for floor treatment.

- Strict adherence to safety precautions is required.

- Not intended for processing ends and corners.

Using an electric planer as a jointer Source blogspot.com

On a note! Instead of removable knives, special shaped cutters can be installed in the tool drum. When processed with their help, the surface will acquire wavy, jagged and other forms of decorative patterns.

What are there

Planers come in different types. Their differences can be traced in the design, shape of the blades, parameters and purpose.

Medvedka. The instrument is characterized by a long sole, making pair work possible. Used for leveling large pieces of wood and performing large volumes of work.

Jointer. Equipped with double cutter. Its purpose is finishing surface treatment. The length of the sole exceeds the sherhebel, which allows you to plan a larger volume of workpieces in the same time.

Half jointer. This is a shortened version of the jointer. The design also has a double blade. Used for finishing wood.

Additional. The design of the sole consists of three full planes. The distance between the front and the knife is minimal. The purpose of a plane is to trim sharp corners on the edges of wood pieces.

Rip-off. The purpose of the tool is rough planing of wood, as well as cutting edges on sheets of drywall to obtain an even, sloping cut.

Sander. The plane provides high-quality finishing of the wood surface. Used in the area of knots, near the ends and in other areas of the workpiece after rough planing.

folding

tongue and groove

Zenzubel

Types of planes for figured cutting | |

| Federgubel | Thanks to the unique shape of the blade, it is possible to create protrusions at the ends of the edge. |

| Zenzubel | Planing of quarters and perpendicular surfaces. The design is equipped with a double blade resembling a spatula. |

| Staffgobel | The knife has a rounded tip. A tool is used to process concave workpieces. |

| Falsebel | The sole has a ribbed surface. This form allows you to strip the quarters. Knives in the design are straight and oblique |

| tongue and groove | The tool consists of two blocks, which are connected by clamping screws. It is used to create longitudinal grooves along the edge of the workpiece. |

| Gruntubel | The design is a block on which a cutter is installed on the side. The plane makes grooves along the grain of the wood. |

| Mold | Provides a figured cut used for decorating cornices, frames for doorways, baguettes. |

| Gorbach | It is distinguished by a block that has a curved shape. Suitable for surface treatment of outer and inner diameters of workpieces. |

Varieties

The main parameter for distinguishing electric planers by which they are selected for home or professional use is the motor power and the cost dependent on it. The higher the first indicator, the higher the second. On this basis, power tools are divided into two categories:

- Household.

Equipped with a drive with a power of 0.5-1 kW. This is quite enough to perform small-scale and rare procedures for processing wooden surfaces. In this case, there is a direct relationship between the power of the motor and the main characteristics of the device. Household models are not capable of rotating the knife drum above 10-12 thousand rpm. The processing depth does not exceed 2.5-4 mm.

Main advantages:

- Low cost.

- Sufficient power.

- Fine adjustment.

- Light weight – 2.5-4 kg.

- Ergonomic handles.

Compact lightweight household electric planer Source protechniky.ru

Disadvantages are associated with the insufficient power of household models for processing hard wood, as well as the shortage of some additional accessories when it is necessary to expand the capabilities of application.

- Professional.

Tools in this category have a stronger drive – up to 2.2 kW. With their help, you can process workpieces from any type of wood, including oak and ash, for several hours a day. The maximum cutting depth adjustment is from 4 to 18 mm, the minimum step adjustment is from 0.25 mm, which allows you to plan the surface of the product as accurately as possible. The number of drum revolutions is highest.

Advantages:

- Great power.

- High resource.

- Additional accessories.

- Maximum speed.

- Considerable depth.

- High quality planed surface.

- Wide processing area.

However, when reviewing the best professional electric planers, obvious shortcomings are also revealed. First of all, this is a fairly high price, and a large weight - 9-10 kg or more.

Professional electric plane Source gvozditut.ru

In addition, the instruments of this type are divided into energy-dependent and autonomous. The former operate from a 220 V network, the latter from a built-in battery. At the same time, modern models are not inferior in power to network analogues.

Classification of knives for electric planers

Electric planer knives are divided into two main categories:

- disposable;

- reusable.

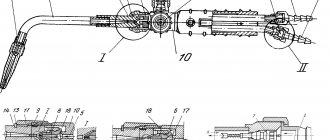

Diagram of the electric planer.

The disposable knives shown are made from carbide steel. The picture shows that these are small plates. They are not sharpened and are used twice each. The fact is that they are double-sided. When the cutting edge is worn out, they must be installed on the other side and work can continue. When the second edge is worn out, the knife can be thrown away. Disposability is not the only drawback in this case. Such a tool can only be used for work that does not require high quality and precision. At the same time, they are simple and convenient to work with, and there is no need for fine tuning and balancing.

Disposable knives, in turn, are divided into:

- straight;

- straight with rounded ends;

- wavy.

The first has a straight cutting edge and is convenient for processing material with a width less than the length of the knife. The rounded edges of the second do not leave steps on the surface being processed, so this edge is good for planing large-width products. The third is intended for specially rough processing of wood.

The pair of reusable knives on the right are noticeably different from the disposable ones in size and shape. They are made from high-quality tool steel, which ensures appropriate processing quality and ease of operation. With such knives, a good craftsman will achieve a level of smoothness at which polishing will no longer be necessary. Blades, which are usually marked with the letters HSS (High-Speed Steel), are usually called professional. They require highly precise adjustment and balancing, as well as careful sharpening at a high level. Tool steel blades can be made very sharp.

There are electric planers that cannot be equipped with disposable knives. But there are relatively few of them; the design of the rest is universal, and they should be given preference when purchasing.

Criterias of choice

In order for the purchased electric planer to perform the necessary range of wood processing tasks, meet operating conditions and be simply convenient and safe to use, the following set of criteria must be taken into account:

- Appearance.

- Specifications.

- Additional options and elements.

Let's look at them in more detail.

Appearance

The way an electric planer looks largely indicates its following main characteristics:

- Color – every well-known brand paints its products in a certain shade. In addition, individual brands have their own gradation. For example, Bosch household models have a green body, professional models have a blue body. Knowing this feature helps you choose an original electric planer, avoiding counterfeit ones.

Branded blue electric planer Source art-liga.rf

- Ergonomics. A responsible manufacturer strives to make its product as easy to use as possible. This is primarily design, compactness, streamlined shape, comfortable handles, etc.

- Durability of the plastic case. High-quality plastic always has a glossy sheen. The device itself should not have thin or fragile elements, and should withstand being dropped onto a concrete floor from the workplace.

In addition, a good sign of a high-quality tool is its good packaging - a case, additional accessories and spare parts.

See also: https://m-strana.ru/services/otdelochnye-materialy/

Specifications

The most important technical parameters of the electric planer include:

- Motor power. For domestic use, models with a power of up to 1 kW, rarely up to 1.5 kW, are sufficient; more powerful units are for professional activities.

- Cutting width. The higher the value of this parameter, the higher the processing speed in each specific case. In domestic conditions, models with a planing width of 80-110 mm are used; for production needs, specimens with drums up to 350 mm are produced.

The cutting width of an electric planer is set by the parameters of the knife drum Source protechniky.ru

- Planing depth. At the household level, there is no need to select more than 2-3 mm of material in one pass. Production is another matter - here it may be necessary to remove 3-4 times more chips than this. In this case, the higher quality the surface is required, the more discrete the value of the adjustment step should be. Also, a large value of this parameter is necessary to level the surface of the unedged material with the bark.

- Rotation frequency. To solve everyday woodworking problems, the user only needs 10-12 thousand rpm. In the professional field, a much higher value will be required - up to 17-19 thousand rpm. At the same time, advanced models are able to automatically select the shaft rotation speed depending on the load level.

- Weight. The optimal weight of the device is 2-3 kg. Professional models weigh up to 10 kg. At the same time, light models often do not have the capabilities that heavy ones have. However, only physically strong people can be advised to choose a heavy electric planer for home, cottage or professional work, since they will have to hold it in their own hands the entire time the material is processed - or, alternatively, use it as a permanently fixed machine.

A lightweight electric planer is convenient for use in the home Source stroyka.ru

Advice! When choosing a modern electric planer, you need to be guided by what types of wood will be processed with it. For example, soft woods are used in construction - pine, aspen, spruce - they do not require much power. On the contrary, in the manufacture of furniture and interior items, hard types are used - oak, maple, ash - they require maximum power.

Additional options and elements

There are several design features in the design of an electric planer that you should pay attention to - these are:

- Gradual acceleration of the engine. The engine reaches operating speeds not chaotically, but slowly and incrementally - within 3-4 seconds. This significantly reduces the stress on interacting parts and electronics, and helps extend tool life.

Large volumes of work require a powerful plane with motor protection Source ytimg.com

- Forced braking. A shaft accelerated to a high number of revolutions does not immediately slow down after turning off the drive. The operator has to waste time waiting, and if the device is placed on the surface until it stops completely, the knives will receive a defect from contact and will ultimately last less than their intended life. A special electrodynamic brake system comes to the rescue.

- RPM support. When choosing an electric planer, you need to check whether the model you are purchasing has support for speed at variable loads. Special constant electronics do not allow the shaft to slow down and overheat when the density of the processed medium increases, and deteriorate the quality of the planed surface.

- Ergonomic handle. The tool must be held comfortably and firmly by the user during operation. This is ensured by a specially shaped rubber-coated holder, which in addition also provides electrical insulation.

Model of an electric planer with an ergonomic handle Source castorama.ru

- Chip drain pipe. To prevent shavings, sawdust and dust from flying in all directions during planing, including towards the operator, the machine is equipped with a special waste disposal system through a side pipe. Some models are additionally equipped with the ability to connect a hose from a vacuum cleaner.

Note! An electric planer has an open blade drum rotating at high speeds. When working with it, you should always remember this and follow safety rules.

Planers - main technical characteristics

The most important characteristic of the tool is power. Professional models boast power from 850 to 1100 W, amateur models – from 450 to 600 W. The higher the power, the easier it will be to work with hard wood. Regardless of the engine power, the rotation speed of the drum with cutting knives can differ significantly by almost two times - this depends on the type of tool. If we have a sprinter in our hands with speeds up to 19,000, we need to work quickly and superficially, but if we have a stayer (about 10,000 rpm), the tool will plan deeper, but slower.

Rating

The TOP 10 rating of modern electric planers for the home with a work surface width of up to 110 mm and above includes the following models from the best manufacturers:

- Interskol R-82/650.

The best inexpensive planer model with a 650 W motor powerful enough for domestic conditions, a cutting width and depth of 82 and 2 mm, respectively, for short-term work.

Pros:

- Molded sole.

- Low price.

- Ejection of chips on both sides through nozzles.

- High quality processing.

- A complete set of durable knives.

- Rotation speed 16 thousand rpm.

Household electric planer Interskol R-82/650 Source cdnmedia.220-volt.ru

The disadvantages are associated with a short cable - you will need to use an extension cord, and the need to initially fix the knives and set up the platform.

- Whirlwind R-82/1100.

A budget category tool with a 1.1 kW motor and a processing width of 82 mm. Equipped with overload protection. The main functionality is limited to setting the cutting depth and cutting out the quarter.

Pros:

- Great power.

- Safety system.

- Light weight.

- Parallel type stop.

- High build quality.

The disadvantages are caused by its limited functionality and the inability to use the device for long-term work.

- Makita KP0800.

A mid-price manual electric planer with planing width and depth parameters of 82 mm and 2.5 mm, respectively. Equipped with a 0.8 kW motor with a rotation speed of 17 thousand rpm. There is a groove for chamfering.

Assembling the plane and adjusting the position of the frog

Before you begin assembling the planer parts, you need to inspect the metal elements. It is recommended to treat unpainted areas with oil to prevent rust formation.

Design and setup of a hand plane

Build process:

- Move to the side the screw stop plate responsible for the longitudinal adjustment. This will allow the frog to take its place in the center of the body.

- Lightly tighten the frog clamping screws. Thanks to this, it will move back and forth using the adjustment screw.

- To determine the correct position of the frog, you need to install the blade and adjust it for thin, uniform chips. Stretch the wooden piece along the sole, directing it across the blade. The edge of the knife should run parallel to the leading edge of the mouth. If asymmetry is observed, you need to slightly move the frog without touching the knife skew lever. Thus, parallelism is achieved.

- For beginning craftsmen, the gap is set within 0.4-0.5 mm. Experienced carpenters will be able to adjust the gap to 0.15 mm.

- After setting the parallelism and gap, remove the knife without touching the frog. Tighten the clamping screws without using excessive force. Otherwise, the thin section of the sole in the mouth area may crack. Tightening is necessary only to fix the position of the frog.

- Before work, all screws are tightened and the knife is installed. Unfair preparation of the tool will provoke deformation of the sole under the influence of the lever-clamping insert.

- Lastly, the screw of the lever-clamping insert is adjusted. He takes a position so that under the force of his thumb a clear fixation of the lever is felt. A loose fit in the threaded hole provokes the formation of backlash. To seal the element, it is recommended to unscrew the screw, degrease it, drop a liquid fixative into the threaded hole, return the screw to its original place, making the same number of turns as it took to unscrew.

Video description

Video review about choosing an electric planer:

Advantages:

- Affordable price.

- Lightweight and compact.

- Sampling quarters up to 9 mm deep.

- Drive overload protection.

The disadvantage is due to the insufficient length of the power cable.

- Hammer RNK600.

This electric plane was included in the rating as the best option for a home workshop. The tool is designed to work with already treated wood. However, it is capable of planing even hard wood.

Pros:

- Economical.

- The functionality includes quarter cutting and chamfering.

- Professional platform made of die-cast aluminum.

- Optimal cost.

- Soft start system and drive protection.

Cons - 1.5-meter power cord and small planing depth - 2 mm.

- Bison ZR-950-82.

The 0.95 kW-strong tool is powerful enough for home use and long-term work. Copes with wood of any species.

Positive properties:

- Compact with a weight of 3 kg.

- Overload protection.

- Possibility to make quarters up to 15 mm deep.

- Good equipment.

Negative qualities are associated with clogging of the discharge system with chips.

Video description

Video example of how to work with an electric planer:

- Makita 1911.

A simple plane with a small set of functions. In addition to high-quality assembly and stability in operation, it is characterized by the following advantages:

- 4 meter power cable.

- Continuous work without overload.

- High accuracy.

Although the machine does not overheat during prolonged operation, it is not suitable for processing hard wood.

- DeWALT D26500K.

A universal tool with a rich set of accessories. Copes equally well with jewelry work and rough processing.

Pros:

- High efficiency.

- Light weight.

- Ergonomic handles.

- Expanded equipment.

- Extended cast aluminum platform.

Disadvantages are the small width of the knives and the lack of smooth starting.

Recommendation! Craftsmen in the manufacture of furniture, windows and various household utensils need to choose from the rating a manual wood planer with an electric drive that allows you to chamfer. The sole of such a model must have at least one V-shaped groove.

Electric planers - how not to get confused in the variety?

The popularity of this tool is also evidenced by the fact that in any construction equipment store you will find planes from a good dozen different companies, and they, in turn, offer dozens of models. And you have to judge it only by appearance and the attached instructions!

When buying an electric hand plane, ask whether it is possible to make a small machine based on it - many manufacturers even offer special fasteners and adapt the planes to work in an inverted position.

There seem to be no special changes in the design, but the number of functions is noticeably increasing. In an inverted position with a plane, you can not only plan boards, but also bevel the edges, adjust them to size and even select grooves. And with the help of additional attachments, the electric planer can surprise you with the number of functions it performs. It would be a shame if, having spent money on this tool, you end up unknowingly not getting the full list of the tool’s capabilities.

Briefly about the main thing

An electric planer performs almost all the same functions as a manual planer, but faster, more productive and with less effort. In addition, it allows you to perform some previously unavailable tasks, such as a stationary jointer. The standard model consists of the following main parts:

- Electric drive.

- Drum with knives.

- Belt-gear transmission.

- Housings with handle and start button.

- Soles.

- Additional side handle.

- Depth regulator.

- Side outlet pipe.

- Rulers and limiters.

The operating principle of the tool is based on the interaction of the drum knives driven by a motor with the material being processed. Devices are classified according to power and capabilities - into household and professional. The former are on average equipped with a drive up to 1 kW, the latter up to 2.2 kW. When choosing, appearance, technical characteristics and additional functions are taken into account. The TOP of the best electric planers included such specimens as Interskol R-82/650, Vikhr R-82/1100, Makita KP0800, Hammer RNK600, Zubr ZR-950-82, Makita 1806B, Bosch PHO 1500, Rebit IE-5708C, Makita 1911 and DeWALT D26500K.

Ratings 0

The best manufacturers of electric planers - which company to choose

High-quality construction tools traditionally have German or Japanese roots.

If you are too lazy to delve into all the features of electric planers, you can purchase the company’s products from the list below:

- Makita;

- DeWalt;

- Skil;

- Bosch;

- Hitachi.

But each of the presented companies has such a wide variety of models in terms of characteristics and capabilities that it’s worth looking into the rating of the best electric planers.

The key features of the power tool and its purpose for different tasks are described below.

Recommendations: 15 best angle grinders (angle grinders)

16 best electric planers

18 Best Drilling Machines