Not all painting guns allow you to apply paint materials perfectly evenly and obtain a high-quality coating without drips or streaks. To achieve good results, it is recommended to use a pneumatic spray gun. The principle of its operation is to supply compressed air to the spray gun, which breaks the paint into many small drops. To achieve ideal application of the substance, it is important to choose the right compressor for the spray gun.

Choosing the right compressor for your spray gun is of great importance for successful operation

Design and principle of operation

The name of the mechanism in question determines that it works based on the supply of compressed air, which is mixed with a dye. That is why such a device also has a compressor with a receiver. When choosing a compressor for a spray gun, you should pay attention to the following points:

- The spray gun itself is represented by a spray nozzle, which is designed in the form of a pistol. At the top or bottom of the structure there is a place to install a tank for storing the dye.

- The receiver is connected to the sprayer using a special rubber hose. It has fairly high strength, is flexible, and is designed to supply air under a certain pressure from the generator to the actuator.

- In the sprayer, air is directly mixed with the dye, which is broken into small particles. This results in a high-quality coating.

- The shape of the mechanism is created in such a way that the air flow spreads like a torch, diverging at a certain angle in all directions.

Particular attention is paid to the fact that devices must be manufactured using high-quality materials.

How long they will last depends on this moment.

The sprayer has a rather complex design. It consists of the following elements:

- Pendant.

- Channel for supplying substance.

- Nozzle.

- Channels designed for air supply.

- Air type head.

- Tank for storing dye.

- A regulator that allows you to change the parameters of the resulting torch.

- A regulator responsible for the direct supply of paint.

- Air supply regulator.

- Lever.

- Connection for direct hose connection.

A fairly simple principle of operation determines that the mechanism can last for a long period.

Equipment options for various fields of activity

You can get lost in the numerous variations and sets of components for building an effective air supply system. Therefore, it is worth giving a few simple recommendations and templates for average solutions.

- For domestic use in periodic mode, a piston oil compressor is perfect. Today there are many options for ready-made stations on sale that supply air with a pressure of up to 8 bar. Such kits are equipped with a receiver with a volume of 6 to 100 liters (it is recommended to choose at least 50 liters), and are capable of operating for 20 minutes every hour.

- Semi-professional class compressor stations are built on oil piston compressors with coaxial or belt drive and are equipped with a receiver with a volume of at least 50 liters. They also cannot be operated continuously, but the effective operating time is up to 40 minutes every hour. The average maximum pressure is up to 16 bar.

- Industrial (professional) equipment does not have a clear gradation of parameters. As a typical feature, we can note the huge volumes of receivers - up to 1 cubic meter. Such stations can operate continuously, and you can purchase equipment with characteristics that satisfy any need.

For purely one-time garage work, you can assemble a compressor station with your own hands. To do this, you will need to purchase moisture and oil traps, a reducer, a pressure switch and find an empty gas cylinder in good condition. The main supercharger in a homemade station is a compressor from a refrigerator. This device belongs to the piston oil class.

After dismantling the refrigerator, the old oil is drained from the unit and modern synthetics are filled in. After this, the output tube is connected to the receiver, and the power system is switched through a thermal relay. A mini compressor of this class is capable of satisfying minimal garage needs.

Compressor Features

Today, the equipment in question has become very widespread in a wide variety of industries. Among the features of such a device, we note the following points:

- To create pressure, a motor is required, which is powered by an electrical network. The compressor engine for a spray gun is characterized by power consumption, design and many other features. As the power of such an element increases, so does the productivity, as well as the amount of electricity consumed.

- The design of the compressor for the spray gun itself may differ in a fairly large number of ways. An example is that air is pumped when the screw rotates or the piston moves.

- Attention is paid to what type of materials are used in the manufacture of the main parts. The most commonly used is stainless steel, which is characterized by increased resistance to corrosion.

When purchasing paint sprayers with a remote compressor, attention is paid to the power indicator, as well as performance, and the recommended area of application. There are simply a huge number of different models on sale, which are classified according to design characteristics.

Leading manufacturers

If you have completely decided on all the requirements, characteristics and properties of the compressor intended for painting a car, now you should look for the appropriate model on sale

Here it is worth paying attention to the rating of manufacturers that enjoy well-deserved popularity, demand and consumer trust

Among the most worthy candidates are the following brands:

- Fubag;

- Metabo;

- Elitech;

- Patriot;

- Abac;

- AVS;

- Hyundai;

- Berkut;

- Aggressor.

It is also interesting that in Russia there is an increased demand for products from a domestic manufacturer represented by the Aggressor company. This fact should not be very surprising, since the quality level is really high, the performance is excellent, and the price is noticeably lower than many foreign analogues with the same characteristics and functionality.

Therefore, it is really worth looking for a compressor model that suits your operating parameters among the listed manufacturers. Each company can offer a decent range. Decide for yourself what exactly you choose.

Compressors are truly a great help in the car painting process. Using it for such purposes does not deprive it of its additional capabilities.

Whether to use it to inflate tires is a secondary question. High-performance models can quickly inflate tires, but they are definitely not camping equipment. It is unlikely that you will be able to carry a large compressor in the trunk. Therefore, it is better to always have at your disposal a regular compact compressor that can be easily folded onto a shelf in the car, put away in the spare wheel area, and, if necessary, powered from the cigarette lighter and inflated the tires.

Oil-free piston compressor

Piston-type designs have become quite widespread. A similar compressor for painting with a spray gun can be purchased at various specialized stores; special attention is paid to oil-free devices. The design features are the following:

- The device has a fairly large body, which is made of steel or cast iron.

- Inside there are moving elements represented by a piston. They perform a reciprocating movement, due to which the required pressure is created.

- A working chamber is required to create a volume in which air accumulates.

- The movement is transmitted using a rod; an electric motor is used as the source of movement.

A feature of the considered version of the compressor for the spray gun is that there is no lubricant between the moving and stationary elements. This is due to the fact that it can enter the working environment, significantly reducing its performance.

Oil in the system is required for the following reasons:

- Cooling.

- Reduced wear.

In this case, the device operates without lubricating fluid. That is why such a compressor for a spray gun cannot last for a long period; it needs to be allowed to cool down.

Rating of popular models

"Caliber EKRP-600/0.8"

A low-cost electric paint sprayer designed to work with compounds whose density does not exceed 30 DIN. “Caliber EKRP-600/0.8” is a compact tool where the engine and reservoir are located separately. The paint tank is made of plastic, its capacity is 0.8 liters. The container is located at the bottom. The reservoir is connected to the compressor by a flexible “corrugation”, the length of which is 2 meters.

The spray gun has three operating modes, thanks to which you can adjust the density of the liquid supply. The kit includes a special funnel for filling the container, which can also be used to determine the density of the paint. The diameter of the nozzle is 0.8 millimeters.

Bort BFP-400

The second most popular electric spray gun. Works with compounds no denser than 35 DIN, as in the previous model, the viscosity of the liquid is checked using a special funnel included. This device has a design consisting of a gun, pump and compressor connected together. The volume of the paint tank is 0.8 liters. The pistol weighs only 1.13 kilograms.

The handle is made of a correct and comfortable shape, for a secure hold there is additional rubberization. You can adjust the force with which the substance will be applied to the surface; for this there is a special regulator on the sprayer.

Elitech CE 400P

The pistol is Russian-made, in it the motor and the pistol are connected. The handle has rubber inserts for better grip. The reservoir for coloring compounds is located at the bottom, made of transparent plastic, its volume is 0.8 liters. The feeding power can be adjusted; there is a special wheel for this. The size and shape of the jet can also be changed. The weight of the model is 1.53 kilograms.

"Zubr KPE-500"

Spray gun with built-in motor, suitable for all types of paint compositions. The permissible viscosity is 100 DIN, with this indicator the device can even work with putties and varnishes. The spray nozzle has a size of 2.6 millimeters. Bottom reservoir. The application force and the shape of the jet are changed with a special regulator. The density of the substance can be determined using the glass included in the kit.

Patriot SG 550

American manufacturer. Here the gun and motor are located separately, the paint container is lower. The engine itself can be located on the floor during operation or using a shoulder strap directly on the painter’s shoulder. The corrugation connecting the gun to the compressor is 2 meters long. The permissible viscosity of the liquid is 50 DIN; to determine the density, as with previous models, the kit includes a special cup.

Hammer PRZ350

Electric gun with built-in motor. Designed to work with liquids whose density is higher than 60 DIN. Density can be determined using a special glass included in the kit. The reservoir is lower, its volume is 0.8 liters. The kit also includes two spray nozzles measuring 1.8 and 2.6 millimeters. The jet size and pressure can be adjusted.

"Stavr KE-800"

Paint sprayer with portable motor. Works with substances with a density greater than 130 DIN. The compressor weighs 2.2 kilograms; using the included belt, you can hang it on your shoulder or leave it on the floor. The geometry and force of the jet are adjustable.

Bosch PFS 2000

Pistol from a well-known manufacturer. Suitable for dyes with a density not exceeding 60 DIN. It has a special sprayer design, thanks to which the paint lies on the surface in an even layer. The nozzle has a size of 2.6 millimeters. The gun and motor are located separately. The liquid reservoir is located at the bottom, its volume is 0.8 liters. The package includes additional nozzles, a spare container and a filter.

Wagner W100

Model from a German manufacturer. Has a built-in motor, suitable for medium and dense substances with a viscosity of no higher than 90 DIN. It has a lower container with a volume of 0.8 liters. Spray nozzle size 2.6 millimeters.

Piston oil compressor

To reduce the degree of wear of the device, as well as to eliminate the possibility of overheating of the moving elements of the piston system, oil is added. It is worth considering that there are special oils on sale that are intended for use in compressor units for spray guns. The features of such models are the following:

- Cooling of moving and rubbing elements is ensured. Due to this, the structure can last much longer without interruption for cooling.

- The degree of wear of the structure is reduced. As practice shows, correctly selected oil increases the service life several times.

- The permissible maximum load at which the equipment can operate is increased.

In order to ensure reliable operation of the entire system, a filter is installed. Its purpose is to separate oil from air, as it significantly reduces the quality of the paint material.

Test Spray

Having adjusted your spray gun and selected the optimal nozzle, do not rush to start painting the required object.

To make sure the settings are correct, do a few test sprays on paper, cardboard, or other vertical surface that you don't mind getting dirty. It is necessary to carry out this procedure to assess the shape of the torch, the uniformity of application and distribution of the material over its area. The most important test is considered to be the form check, and we will look at it first. Imprint shape

The spray gun torch, ideally, is an elongated oval with slightly blurred edges. The width can vary between 200-400 mm. The paint transfer must be uniform over the entire spray area and form an even print, without depressions or bevels.

When spraying, the spray gun must be held at a certain distance: 10-15 cm for HVLP, a little further (15-20 cm) for LVLP, and as far as possible (20-25 cm) for conventional sprayers (HP).

It takes no more than a second to open the paint supply. If the torch of your spray gun has the above distortions, you should know that they are caused by unregulated air pressure, clogged or defective nozzle. The dumbbell-shaped figure eight indicates increased air supply, which is corrected by lowering the inlet pressure. Too much paint accumulation in the center can be reduced by tightening the appropriate adjustment screw. If one of the air cap holes is clogged or defective, the torch spot takes the shape of a banana, which can be eliminated by cleaning or replacing the element.

Paint distribution

the area of the sprayed spot affects the uniformity of the layer and is checked quite simply. To do this, turn the air cap 90° (for horizontal spraying), and press the trigger for 2-3 seconds until smudges begin to appear. If the drops are evenly spaced and have the same length, then the dispersion of paint molecules is correct and does not require additional calibration. If smudges predominate in the center or on the sides, the air or material supply should be adjusted.

Spray quality

is a subjective indicator of the effectiveness of a pneumatic spray gun and is determined based on the size of the droplets transferred to the object. The size of the mixture particles can vary, increasing from bottom to top. Increasing the inlet pressure increases paint dispersion and reduces the layer size, making it rough and “dry”. To ensure that the spray gun layer does not cause any complaints, use the optimal operating pressure.

article from the Rating section

- 40

Pneumatic tools Painting tools

Save this page on your social media. network and return to it at any time.

ADD A COMMENT

Screw compressor

Screw compressors for spray guns have become very widespread in industry. The pressure in this case is created by the rotation of two screws. The advantages of this design option are:

- Low oil consumption compared to the option with moving pistons.

- During operation, vibration and noise are significantly reduced. That is why installation does not require a special foundation, which simplifies installation work.

- The cooling efficiency is significantly increased, since the procedure is carried out automatically. In addition, if necessary, the heat can be reused to heat rooms.

- High performance also determines the wide distribution of the device.

- Reliability of operation, ease of operation, safety in use and many other points. Most models have an automatic control and monitoring device.

As previously noted, there are quite a large number of different types of screw compressors for spray guns. The classic design is represented by a combination of the following elements:

- Filter.

- Suction valve.

- Screw block.

- Belt drive.

- Engine.

- Oil filter.

- Safety valve.

- Thermostat.

Such a mechanism can last for a long period.

HP - high pressure group

This is the most common type of paint application device used when working on cars. This is a kind of “classic of the genre”. The output pressure of such a spray gun is about 1.2-1.5 atmospheres.

If we talk about the recommended value at the compressor output, it can be within fairly wide limits - from 2.5 to 5 atmospheres. Here we have a fairly small air flow - it ranges from 100 to 300 liters per minute.

Among the advantages of such devices are the following factors:

- the large width of the beam ensures uniform coloring of the surface;

- high performance of the spray gun.

Paint and varnish set Miol 80-990 (HP - high pressure system)

Among the disadvantages, experts name the following inconveniences:

- low paint transfer rate - up to 45%. The rest of the material is sprayed around without any benefit, bouncing off the surface being painted;

- air vortex flows arise that wrap the material, and it lies in such a way that then it is necessary to grind and polish the surface after painting.

Coaxial and Belt Drive Systems

The belt drive eliminates the possibility of engine overload. Among the features we note:

- Engine life is extended.

- Eliminates the possibility of overheating due to high load.

- The structure is large.

- Loss of efficiency.

Direct drive reduces the size of the device and also eliminates the possibility of loss of efficiency. However, in this case there is a high probability of engine overload. HP systems have become very widespread.

Why do you need a receiver and how to choose its volume

The receiver is represented by a vessel with air, where it is under pressure. The main purpose is to equalize the pressure when air enters the compressor. Otherwise, a situation may arise where the air mass is transported by pulsation. Due to this, the operational characteristics of the mechanism are significantly reduced. In addition, you can eliminate the possibility of condensation.

When choosing, pay attention to the following points:

- Volume.

- Equipment performance.

- The type of material used in the manufacture of the case.

Do not forget that the mechanism must be securely connected to the system. Otherwise, there is a possibility of a leak occurring, which will cause a decrease in pressure.

Manage procrastination

If outsourcing isn't practical and you find yourself regularly putting off an important task, try turning on a procrastination control mechanism. When you realize you're mindlessly tidying up your desk instead of preparing a client presentation, take note of that moment and try to get back to what's important. Oddly enough, this technique works: just take it and start doing it

Does not exceed? Formulate and write down the consequences of not completing a task.

Oddly enough, this technique works: just take it and start doing it. Does not exceed? Formulate and write down the consequences of not completing the task.

You can set aside 30 minutes a day that you honestly devote to your friends' posts on Facebook. The main thing is to note the end of this blissful half hour and return to solving the problem.

Photo: Unsplash

Another option for dealing with your smartphone getting stuck is to put it away, delete all games, and hide social media icons. After all, there are strict methods such as blockers of individual sites or the Internet as a whole, applications that limit your stay on a specific site. For example, Freedom, Cold Turkey, SelfControl and others.

If you have been procrastinating on a task for a month using all available means, check: is it really related to the strategic goal? Is there a resource? What exactly is stopping you? How to get around this? One client of mine hated cold calling strangers. When meeting in person, such problems did not arise; he was all charm and confidence and could “sell” his interlocutor even a joint project, even a pink elephant.

As a result, it was decided to delegate the “first calls” to the maximum extent possible to the assistant, deputies, or transfer communication to the format of letters and work on the reasons with a psychologist.

How not to ruin the paint: removing impurities

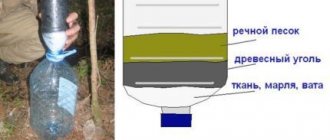

Another important element of the system is the filter. Its purpose is to separate impurities from the environment. Filters are required for:

- Oil compartments. Many types of compressors for spray guns operate exclusively with a lubricant in the system. However, it can significantly reduce the quality of the resulting surface. There are special oil filters that are installed in the system.

- Removing dust. Air intake is often carried out through a placed nozzle, at the end of which a filter element is also fixed. It separates dust and large particles from the air mass.

- Moisture separation. Moisture can also cause a significant reduction in the quality of the paintwork. That is why moisture separators are installed.

Only in this case can the high quality of the resulting coating be ensured.

There are quite a large number of different filters; when choosing, attention is paid to the degree of purification, quality of painting and duration of operation.

How a pneumatic spray gun works - detailed description

The principle of operation of the spray gun is based on blowing compressed air onto the paint material flowing from the nozzle. Air, when combined with the liquid paint composition, is transferred to the surface to be painted. This method of combining and transferring paint to the surface allows for its uniform distribution. The uniform distribution of the paint material depends on the compressed air pressure.

It is important to understand here that the greater the compressed air pressure, the correspondingly smaller the paint drops will be. This affects the quality of the paint layer.

That is why, in order to achieve the most efficient and accurate application of paint through a spray gun, it is important to pay attention to the amount of air pressure. Next, consider a detailed description of the operating principle of an air gun:

At the bottom of the spray gun handle there is a fitting through which the tool is connected to the compressor. The handle has a channel through which air passes and fills the air chamber. This chamber is located near the lower adjustment screw. There is a control valve in the chamber, through which the air pressure is adjusted. If the tool does not have an air pressure regulator, then there is also no restriction valve. From the chamber, air at the appropriate pressure flows further through the channels of the gun, which occurs when the operator presses the trigger. The trigger is connected to the air chamber through a rod, which acts on the bypass valve, thereby opening the air supply. The harder the trigger is pressed, the greater the pressure. That is why the trigger can be called regulating. Air from the chamber flows through the channel into another adjustable chamber. Its purpose is to shape the size of the torch. By moving the regulator, the first or second channel opens. Depending on the selected channel, the size of the torch is formed. From this chamber, the air passes through the spray channel and enters the middle row of the distribution ring of the gun. Coming out of the holes, the air passes through the round holes of the middle row of the nozzle. From the middle row of the nozzle, the air is transferred to the head and comes out. through holes that are located closer to the material supply nozzle. As a result, we get a torch that is round in shape and small in size. If the torch size regulator is set to the “max” position, then the air will pass not only through the first, but also the second channel, and move through the middle and outer holes of the nozzle. Compressed air exits through the outer and middle nozzle holes (they are also called horns), thereby forming a large-sized flattened (flat) torch. The material is supplied from a special container, which does not necessarily have to be on top. The container can be at the bottom or on the side, but the most common option is when the tank is on top. When filling the tank, paint flows through a channel into a special chamber, filling it. Its supply from the chamber to the nozzle is carried out when a valve in the form of a shut-off needle is opened, which is controlled by a trigger. When pressed the trigger simultaneously supplies air and paint material to the nozzles of the gun

It is important to know that the trigger has two positions. The first position is called half-pressing, in which air is supplied through the channels and released through the holes of the air cap

When the trigger is pressed harder, the valve opens to supply the material. The farther the needle moves from the channel that opens access to the nozzle hole, the higher the speed of paint spraying, as well as the greater the flow rate. Adjustment is carried out using the material feed adjustment screw

As a result, the following happens - the material coming out of the central hole of the nozzle is picked up by the compressed air coming out of the nozzle holes and transferred to the directed surface. The drops of paint are so small that it goes on as evenly and smoothly as possible.

It should also be noted that not all spray guns have an air pressure regulator. On such instruments, adjustment is carried out using a screw on an additionally connected gearbox or on a compressor.

This is interesting!

The paint does not flow out of the nozzle hole automatically, but due to the vacuum formed from the pressure of the compressed air exiting through the holes in the air chamber.

https://youtube.com/watch?v=_-FRMq0HcmQ%3F

Main blower power supply type

Industrial installations in most cases operate on a voltage of 380 V. This is due to the fact that such installations are characterized by high productivity. For home workshops, a design option is suitable that can operate on a 220 V network.

The type of power supply largely depends on the power of the equipment used. Do not forget that three-phase equipment places a serious load on the electrical supply cable.

In conclusion, we note that when choosing a compressor, you should pay attention to the popularity of the brand. Some manufacturers use high-quality materials when producing their products, others try to save money. The resistance of the mechanism to environmental influences will depend on this.