An office, apartment or cottage is equipped with ventilation systems that provide access to fresh air and removal of polluted and dusty air.

It is especially important to organize air exchange in modern homes, where plastic windows, high-quality doors and the best finishing materials are installed - all of them are sealed and do not allow outside air to penetrate.

Supply ventilation “blows” oxygen into the room, exhaust ventilation is a way to remove exhaust air. It is not practical to do these types of ventilation separately. Therefore, we will consider how to install supply and exhaust ventilation with your own hands, and how much the work will cost if you hire specialists.

Regulatory requirements for apartment ventilation

Since air exchange directly affects the quality of life, scientific research was carried out to determine its optimal parameters, the results of which are reflected in regulations.

The main document regulating the rules for organizing ventilation of residential premises is SP 54.13330.2016 “Residential multi-apartment buildings”, updated version of SNiP 01-31-2003 .

Rules for calculating the minimum volume of air exchange

The minimum air volume for various types of premises can be calculated using the data in Table 9.1. SP 54.13330.2016 .

When calculating, you cannot simply sum up the resulting numbers. For living rooms, air exchange means the flow of air from outside and its outflow into the kitchen, bathroom, etc., and for technical rooms - the influx from living rooms and its release outside the apartment.

Therefore, it is necessary to separately calculate the required volumes of inflow and exhaust in order to obtain the maximum value of these two quantities as a result.

There is one caveat here. The designer of an apartment building is required to calculate the inflow value to calculate the heat balance, and the exhaust value to calculate the parameters of the ventilation units.

Residents of apartments have the right, at their discretion, to implement ventilation with a lower capacity, which is what happens in the vast majority of cases.

An example of calculating the minimum volume of air exchange for standard apartments in accordance with the requirements of SP 54.13330.2016. It needs to be carried out to understand the required power of ventilation devices

It is possible to independently determine the volume of air exchange with good accuracy only when using forced ventilation.

We reviewed detailed ventilation calculations with formulas and real calculation examples for specific rooms in another article.

With natural air circulation, it is necessary to pay attention to the following indicators:

- excess moisture in the air (can be measured using a hygrometer) - is expressed in the appearance of fungus on the walls and ceiling, as well as fogging of window glass in the winter;

- lack of oxygen or excess carbon dioxide (can be measured using a gas analyzer) - is expressed in difficulty breathing for all people who are in the apartment.

If such effects can be observed throughout the apartment, this means a lack of general supply or exhaust ventilation. If they occur in separate rooms, then this indicates local air exchange problems associated with the formation of zones of air stagnation.

Modern indoor gas analyzers show carbon dioxide content, temperature and relative humidity - the main indicators of the microclimate of a living space

How to ensure air circulation?

According to clauses 9.6 and 9.7 of SP 54.13330.2016 , the influx of outside air must be ensured in living rooms and the kitchen, and removal - from kitchens, bathrooms and restrooms.

At the same time, it is unacceptable for air to enter other parts of the apartment from technical rooms. It must be ducted directly into the ventilation shaft.

Thus, it is quite easy to draw up a diagram of air movement depending on the layout of the apartment, when its intake from the outside will take place in rooms with windows, and the outflow will occur at the exit points of the ventilation shafts.

An example of a diagram of air movement in an apartment with a standard layout if there are two exits to ventilation shafts located in the kitchen and bathroom

The movement of air between the rooms of the apartment should also occur with the doors tightly closed.

To do this, you can do the following:

- installation of special ventilation holes, which are ordinary holes in the door, closed with special decorative elements;

- using a door frame without a threshold, which allows you to leave a 5-10 mm high gap between the floor and the closed door;

- owners of domestic cats are often forced to install holes in interior doors, which also serve as ventilation holes.

The procedure for organizing ventilation in doors made of solid wood, chipboard or MDF is quite simple. To do this, you need to use a drill or jigsaw to cut holes into which special rings will be placed on glue.

Or you can make one window and cover it with a decorative grille, which must be attached to the door with self-tapping screws.

In order to cut a ventilation hole in an interior door and cover it with a decorative grille, you only need a jigsaw and an adhesive gun

Cutting ventilation holes in a plastic or even glass door yourself is quite difficult. This requires skill and a special tool, otherwise there is a high risk of damage to the door, as well as possible serious injury.

How to make natural ventilation in a private house

The purpose of any type of ventilation in a private house is constant air exchange between the premises of the house and the street due to different temperatures and pressures. An example of natural ventilation is conventional ventilation. The problematic nature of such a simple method is obvious: it is not always possible to ventilate the house in winter, and some rooms simply do not have windows.

In log houses, you can do without natural ventilation - the tree “breathes”, providing constant air exchange. Fresh air also enters the house through window openings, chimneys, and log joints. In a house made of brick or other material, natural ventilation is mandatory.

To install natural ventilation in a private house, you need at least two hoods, which are usually installed in the bathroom and kitchen. The ventilation scheme adopted at the design stage must ensure:

- constant air exchange with the street;

- supply of fresh air to all rooms of the house without drafts;

- comfortable temperature in all rooms of the house;

- quick removal of polluted air from the kitchen, bathroom, bathroom.

Organization of fresh air supply

The latest house-building technologies, as well as the active use of plastic windows, reliably protect modern housing from freezing and drafts. At the same time, the problem of lack of fresh air arises, the supply of which is necessary to create a favorable microclimate.

You can do fresh air ventilation in your apartment either independently or order a ready-made solution from specialists.

Reduced tightness of window units

In old houses, air enters the rooms mainly through cracks in the window frames. Therefore, one of the most common ways to create sufficient supply ventilation is to organize the passage of air through the elements of plastic windows and balcony doors.

For windows, the best solution is to install a supply ventilation valve when installing the window unit.

The supply valve is installed at the top of the window frame. The incoming cold air rushes down and mixes with the warmer room air

Installation of the supply valve is discussed at the order stage. If the window is already installed, then you can install the air passage device yourself, however, this procedure is quite labor-intensive and specific, which is why it is better to entrust it to professionals.

There are also several methods for reducing the tightness of a window based on partial removal of the seal:

- Make part of the seal removable so that in strong winds you can put it back.

- In the lower part from the outside of the window and in the upper part from the inside, remove small fragments of the seal (5-7 cm long). This will allow air to penetrate between the frame and the window frame, heat up and escape into the room.

However, these are extreme measures: they cannot be used often in winter due to the formation of condensation, its freezing with the formation of ice and failure of the mechanism for fixing the window position.

Image gallery

Photo from

Manually adjustable valve

Automatic window valve

Handle with supply valve

Supply valve for wooden window

Installation of wall-mounted supply ventilation

From the standpoint of ventilation efficiency and ease of self-installation, the best solution is to install a wall supply valve. This device allows you to regulate the rate at which outside air enters the room.

The simplest ventilation wall valve allows you to adjust the power of air flow and protects your home from dust and noise

The procedure for installing a wall valve is as follows:

- It is necessary to drill a hole in the wall with a slight slope outward. For brick walls, an ordinary drill is suitable, but for panel houses you will have to use a diamond drilling procedure. In this case, it is advisable to use a vacuum cleaner with a water collection ring.

- Insert the air duct and properly insulate it, otherwise the valve may freeze. Mineral wool and polyurethane foam can be used as materials.

- Attach the valve body, mark the mounting points, drill holes and insert dowels. After putting the case on, screw it to the wall.

Finally, install the outer grille. Safety precautions must be observed here.

Image gallery

Photo from

Stage 1 - marking and drilling holes

Stage 2 - heat and sound insulation of the hole

Stage 3 – installation of decorative grille

Step 4 - Valve Head Installation

We also advise you to read our other article, which contains a step-by-step process for installing a ventilation valve into a wall.

When choosing a valve installation location, the following points must be considered:

- ease and safety of installation of external grilles for apartments not located on the ground floor;

- correct placement of the internal valve head from the point of view of room design;

- possibility of heating incoming air from stationary heating devices.

Therefore, the most popular location for installing the valve is the space between the window and the radiator.

For more intensive air supply, valves with built-in fans are used. However, they require an electrical supply and produce some noise, especially audible at night.

Installing two or three devices that provide natural air flow is easier and cheaper than installing a wall supply valve with ventilation

In addition to the supply valve equipped with a fan, you can connect a humidifier and a heater to maintain a favorable microclimate in the living room.

However, they must be correctly integrated into the design of the room, since the entire structure will take up much more space than the head of an ordinary device.

Specialized premises

Features of ventilation manufacturing directly depend on the functions and specifics of the room where it will be installed. If the natural type cannot provide effective air exchange, you will have to install a forced one. This variety is suitable for specialized rooms such as the bathroom, kitchen and toilet.

We recommend that you read: Air ducts for organizing ventilation - types and installation

When installing important components of the future system, you need to be guided by certain requirements :

- Kitchen exhaust units should handle as much of the free space above the hob as possible, but not block the exhaust grille at the top of the wall.

- To reduce the electricity consumption when a bathroom fan is running, you need to connect it to a light switch. In this case, the device will start only when a person is in the room.

- The ventilation of the bathroom is equipped with a special box, which is connected to a common shaft, and check valves are installed on the fans. This way, air flows from the toilet and bathroom will not mix.

- Bathroom models should be as reliable as possible and resistant to high humidity. Experts advise using devices mounted in a polypropylene or acrylic case.

- When purchasing a silent fan, it is important to understand that such devices operate much quieter, but they consume a lot of electrical energy.

Installation of duct air exchange systems

When installing duct ventilation systems or kitchen hoods, special boxes or flexible corrugated pipes are used.

They are also needed to move air from technical rooms to a remote entrance to the ventilation shaft. You can carry out the installation work of such an air duct on your own.

Basic rules for duct design

For apartments there is no need to use metal ventilation ducts designed to pass air flow at high speeds and to operate at sub-zero temperatures. Plastic boxes are easy to install and easily fit into the design of any room.

You can find many offers of plastic air ducts for ventilation, differing in color, cross-sectional area, shape, method of connecting sections and method of fastening to walls and ceilings.

The presence of a large number of shaped elements allows you to create a ventilation duct of any geometry. The choice between a round and rectangular cross-sectional shape is not fundamental from a technical point of view.

The cross-sectional area should be selected so that the flow velocity does not exceed 2 m/s. Otherwise, noise will occur in the channel, and an increase in resistance will lead to rapid wear of the equipment.

The size of the plastic ventilation duct for an apartment must be selected so that the air flow speed at maximum load is from 1 to 2 m/s

When designing duct geometry, it is desirable to minimize the number of turns, narrowings and transitions that increase aerodynamic resistance to flow, generate noise and accumulate grease and dust deposits.

Features of installation of plastic boxes

The plastic parts of the ventilation duct are lightweight, so they do not require any special actions during fastening.

Depending on their location, installation proceeds as follows:

- Inside the cabinets, the elements are secured to the cabinet walls using clamps. Foam or foam inserts are introduced into places where they pass through walls and partitions to prevent rattling during system operation.

- Above the cabinets, the elements are secured using any holders and screws.

- The structure is fixed to the wall and ceiling using special clamps, which can be purchased for any channel size. The distance between fasteners should be no more than 1 meter.

Immediately after installing the ventilation duct, which will subsequently be hidden behind a suspended or suspended ceiling, it is necessary to check its operation at the maximum possible air flow power. Detected problems are easier to fix immediately while access to the system is not difficult.

It is quite simple to securely secure the elements of the plastic ventilation duct using special clamps. They are not expensive, so it is better not to use independent solutions

By coating the joints of the elements with silicone sealant, you can obtain an additional guarantee of the tightness of the structural joints.

For these purposes, there is no need to use glue or “liquid nails”-type compounds, since in the future it will be almost impossible to disassemble the system for maintenance or change its configuration.

If depressurization does occur, and to eliminate it there is no way to disassemble the air duct, then in this case it is necessary to wrap the problematic joint with self-adhesive tape to match the color of the shaped elements.

Types of commissioning work

The commissioning process includes comprehensive testing of the system as a whole and verification of each component. Regardless of the purpose of the technological system, commissioning of electronic equipment is an integral stage in the installation of systems or their repair in order to ensure correct and quick commissioning.

Commissioning of ventilation systems involves checking the operating efficiency and putting the ventilation system into operation. During the work, the components of the ventilation system are checked when operating at full capacity: air flow, uniformity of distribution, quality of ventilation ducts.

- Preparatory work: obtaining technical documentation from the customer - design and operational, included in the equipment delivery package; obtaining agreed installations of protection and automation devices from the customer; selection of instruments and technical means for adjustment; selection of a set of acceptance documentation; development of a work program taking into account safety measures.

- Commissioning work, stage No. 1: external inspection of equipment for compliance with the design, assessment of its condition; identification of external defects; checking the correct execution of switching circuits; checking and setting up individual elements and functional groups; checking parameters and taking characteristics of individual elements and devices; automatic adjustment.

- Commissioning work, stage No. 2: removing and adjusting the static and dynamic characteristics of individual elements and complete devices and comparing them with the design data of the project, as well as with the data of the manufacturers’ instructions; testing control, protection and signaling circuits in operating modes; checking equipment operation under load.

- Commissioning work, stage No. 3: ensuring mutual connections and joint operation of devices as part of the ventilation system; ensuring parameters and modes provided for by the project, as well as their stable operation in operating modes through adjustments.

- Documentation: preparation of reporting and acceptance documentation.

Also, there are repeated commissioning works, which should be understood as work caused by a change in the technological process, equipment operating mode, which is associated with a partial change in the project, as well as forced replacement of equipment.

Commissioning work is carried out using special equipment, taking into account the critical situation and operation of the system. When ventilation systems pass a kind of test, they are put into operation.

Distance between fastenings

SP 60.13330 and SP 73.13330.2012 indicate how to calculate the fastening of square and round air ducts. The recommendations of equipment manufacturers specified in the instructions are also taken into account. To get the correct result, you need to know the length of the air ducts and the permissible distance between the fasteners.

Fastenings for horizontal non-insulated metal wafer-free air ducts are installed at a distance of no more than 4 meters from each other. This requirement equally applies to supports, hangers, and clamps.

The rule applies to rectangular and round air ducts whose diameter or largest side does not exceed 40 cm. For air ducts with a rectangular cross-section or a diameter of more than 40 cm, the distance between fasteners is reduced to 3 meters.

Horizontal metal non-insulated air ducts on a flange connection with a diameter or larger side of up to 2 meters are mounted with a step of no more than 6 meters between fasteners. Attachment to flanges is not permitted. The maximum distance between fastenings of vertical metal air ducts is 4.5 meters.

When designing even the simplest kitchen hood, gaps are left between the surface of the air duct and the walls, ceiling, other communications and interior items

To connect main sections of air ducts, flexible air ducts made of polymer film can be used as shaped elements. In some cases, they serve as the main elements for constructing a ventilation line.

Rings made of steel wire are used to secure flexible polymer air ducts. The diameter of the wire should be within 3-4 mm, and the diameter of the ring itself should be 10 percent larger than the diameter of the air duct. The step between the rings is no more than 2 meters.

With this type of installation, a support cable is pulled along the air duct, to which the rings are attached. The cable itself is attached to building structures in increments of 20 to 30 meters. The flexible air duct must be tensioned so that sagging does not form between the rings, reducing the pressure in the system.

Advantages and disadvantages

The advantages of such a mechanism will be the following points.

This version of the ventilation system, equipped with a filtration system, makes it possible to carry out preliminary cleaning of air flows coming from the street, which will be quite important for the formation of a high-quality microclimate in rooms where a large number of people live. With proper planning for the use of such a system, it is possible to extract heat from the exhaust gases and heat the incoming air. This solution makes it possible to significantly reduce heating costs and recover about 60 percent of heat losses through the recovery process. Automatic air flow control, which reacts to whether there are people in the room, also reacts to the intensity of air exchange, reducing it when there is no one in the apartment. High performance. Silence.

Such a system, like any other, has its drawbacks.

- Oversized. For small apartments, it would be a good solution to install a small copy of the supply and exhaust mechanism, that is, a small monoblock ventilation unit.

- Difficult installation. Such an installation usually fits only on a balcony or is generally installed on a bracket outside the window, and the air ducts are behind the suspended ceiling. Yes, and installation must be carried out even before the final finishing of the apartment, that is, all this is done during the renovation.

Other solutions

The market does not stand still, and today new solutions are being offered. For example, there are recuperation systems that immediately, through one hole in the wall, remove exhaust air and supply fresh air. This is an ideal solution if you have taken care of ventilation after renovation or if you need to solve the problem only in some rooms. The main thing is that these rooms have at least one wall facing the street.

There is a device that removes exhaust air through one hole and takes in fresh air. At the same time, it also heats/cools it

There is only one drawback of this method of organizing ventilation in a house or apartment - the price of such equipment. The cost of one such device is more than $400.

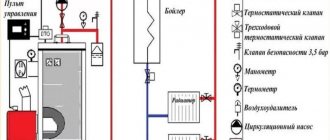

Installation of supply and exhaust ventilation with recovery

In winter, heated housing can very quickly release warm heated air, while a lot of energy is spent on heating the incoming, cold air. Ventilation “with extinction” is a system in which a special device is installed - a recuperator. Thanks to its heat exchanger, the air coming in from the street is heated by the warm air coming out without mixing with it.

If a recuperator is included in the ventilation circuit, the input and output channels must converge and run parallel in the device body.

It is not recommended to place the recuperator above living rooms. It is better to place it in the corridor or utility room.

You need to take into account the position in which it is recommended to install a particular model. Sometimes devices must be installed only vertically, or only flat.

If the design of the recuperator provides for moisture collection, it should be located only in a warm room. The drainage is done at an angle to the nearest sewer riser.

Pay attention to recuperators with cellulose cassettes. Such devices are not so susceptible to icing and do not require the installation of a drain.

In addition, having been absorbed into the cellulose walls, moisture enters the incoming flow channel and moisturizes it. Thus, the recuperator becomes a bit of a humidifier.

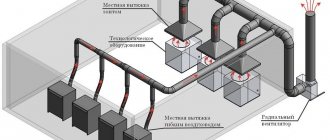

Calculation of local hood parameters

To absorb emissions and vapors hazardous to human health, suction units made in the form of umbrellas are installed. If they are difficult to purchase, you can always make them by preparing the appropriate drawing.

At the first stage, the following data and parameters are determined:

- area of release of harmful substances – a * b, as well as the diameter of the umbrella – d;

- air movement speed at the work site - VB;

- calculation of local exhaust ventilation is carried out taking into account the suction speed into the umbrella - Vз

- the height of the installation of the structure above the source of hazardous pollutants is designated Z.

One of the key parameters that determines the efficiency of absorption of harmful substances is the installation height of the exhaust hood. Engineers recommend hanging it as low as possible to the work area so that all fumes and emissions are effectively absorbed and removed.

The installation of exhaust ventilation is carried out based on the following dimensions of the umbrella:

D = 0.8×Z+d, taking into account other parameters – A = 0.8×Z+a, while B = 0.8×Z+b.

The optimal level of umbrella opening is 60 degrees. With this value, the danger of the formation of stagnant zones is eliminated. If we are talking about a very low room, it is better to increase the opening angle to 90 degrees. As for the height of the lower edge, it ranges from 180 cm. The hood is connected to the ventilation in such a way that there is access to the folding curtains from 3 sides.

For rooms where the speed of movement of air masses is from 0.4 m/s, it is better to supplement the umbrella with special folding curtains. The presented calculation data will help you more accurately determine the cost of the finished product, as well as determine the appropriate equipment. However, before connecting the hood to the ventilation, it is better to consult with a specialist who can carry out the appropriate calculations and recommend specific models of devices.

Financial expenses

Design and installation of ventilation systems is impossible without financial costs. The services of a professional craftsman will cost more. The final amount of expenses depends on a number of conditions:

- Room area.

- Its intended purpose.

- Number of residents.

- Location of housing in relation to cardinal directions.

- The size and number of window openings.

An assessment of the listed parameters allows you to navigate the choice of equipment when installing ventilation yourself. For example, the approximate cost of work for a two-room apartment with a minimum number of medium-sized windows facing the north side is 40 thousand rubles.

What is a check valve for?

The main function of the valve is to allow air to flow in only one direction and to close immediately if reverse flow occurs. It is implemented quite simply: the flow area is blocked by a damper rotating on a transverse axis inside the channel. Second option: the passage is closed with thin polymer petals.

Before outlining the scope of application of valves, let us recall an important point: most domestic ventilation systems work naturally. The draft of a vertical pipe or shaft creates a vacuum and sucks out air; a fresh influx compensates for the losses. In what cases is a check valve used:

- When connecting a kitchen hood to the shaft outlet. To maintain natural air exchange when the fan is turned off, the ventilation duct is connected to a tee with a return device.

- If forced exhaust is organized using a horizontal air duct laid through the wall. After the fan stops, the valve will prevent cold air from outside from entering the room.

- In supply and exhaust ventilation systems with forced impulse - for flow distribution.

- When it is necessary to eliminate mistakes made by designers or installers of ventilation systems at the lowest cost.

A grille with a ventilation valve helps a lot against wind blowing on the upper floors of high-rise buildings. Another case: the end of the exhaust pipe is not raised high enough above the roof of a country house or is poorly protected from the wind. But inflow will still be needed, otherwise weak draft will not open the valve leaf.

Ventilation of the meat industry

Examples of ventilation system calculations are based on the specifics of the functioning of various departments:

- raw materials, machine, extrusion, separation of semi-finished products: general forced exhaust from the upper tier, there is also an influx of fresh air supplied down evenly throughout the room;

- ventilation of the sausage shop (hard smoked sausages, smoked pork meats), thermal and offal departments: general mechanical with additional local ventilation, in summer the influx into the upper zone is natural (in winter - with mechanical stimulation);

- dumpling compartment: local exhaust hoods are used, air supply units in the upper zone supply the flow evenly, the movement speed is low;

- smoke generating zones: general exhaust ventilation from the upper tier, the inflow is supplied directly to the work area mechanically in winter and in the off-season, natural supply in summer.