The creation of an optimal microclimate and the consumption of thermal energy for heating a private house during the cold season largely depends on the thermal insulation properties of the building materials from which the building is constructed. One of these characteristics is heat capacity. This value must be taken into account when choosing building materials for constructing a private house. Therefore, the heat capacity of some building materials will be considered next.

Properties and classification of building materials.

Definition and formula of heat capacity

Each substance, to one degree or another, is capable of absorbing, storing and retaining thermal energy. To describe this process, the concept of heat capacity was introduced, which is the property of a material to absorb thermal energy when heating the surrounding air.

To heat any material with mass m from temperature tstart to temperature tstop, you will need to spend a certain amount of thermal energy Q, which will be proportional to the mass and temperature difference ΔT (tfin-tstart). Therefore, the heat capacity formula will look like this: Q = c*m*ΔT, where c is the heat capacity coefficient (specific value). It can be calculated using the formula: c = Q/(m* ΔТ) (kcal/(kg* °C)).

Conventionally assuming that the mass of the substance is 1 kg, and ΔТ = 1°C, we can obtain that c = Q (kcal). This means that the specific heat capacity is equal to the amount of thermal energy that is expended to heat a material weighing 1 kg by 1°C.

Tips and tricks for choosing materials

- Don’t be lazy to spend time studying technical literature on the thermal conductivity properties of materials. This step will minimize financial and thermal losses.

- Don't ignore the climate in your region. Information about GOSTs on this matter can be easily found on the Internet.

- Before you begin laying insulation, make sure that the surface of the wall or ceiling is free of moisture. Otherwise, mold will form between the surfaces over time.

- If you plan to install non-moisture resistant material on an external wall, take care to carefully treat it with waterproofing adhesive.

- Do not insulate internal surfaces with synthetic materials. This will negatively affect your health.

Using heat capacity in practice

Table of heat capacity of building materials.

Building materials with high heat capacity are used for the construction of heat-resistant structures. This is very important for private houses in which people live permanently. The fact is that such structures allow you to store (accumulate) heat, thanks to which the house maintains a comfortable temperature for quite a long time. First, the heating device heats the air and the walls, after which the walls themselves warm the air. This allows you to save money on heating and make your stay more comfortable. For a house in which people live periodically (for example, on weekends), the high thermal capacity of the building material will have the opposite effect: such a building will be quite difficult to heat quickly.

The heat capacity values of building materials are given in SNiP II-3-79. Below is a table of the main building materials and their specific heat capacity values.

Table 1

| Material | Density, kg/m3 | Specific heat capacity, kJ/(kg*°C) |

| Expanded polystyrene | 40 | 1,34 |

| Minvata | 125 | 0,84 |

| Gas and foam concrete | 650 | 0,84 |

| Gypsum sheets | 800 | 0,84 |

| Tree | 500 | 2,3 |

| Plywood | 600 | 2,3 |

| Ceramic brick | 1600 | 0,88 |

| Concrete | 2300 | 0,84 |

| Reinforced concrete | 2500 | 0,84 |

| Brickwork | 1800 | 0,88 |

Brick has a high heat capacity, so it is ideal for building houses and constructing stoves.

Speaking about heat capacity, it should be noted that heating stoves are recommended to be built from brick, since the value of its heat capacity is quite high. This allows you to use the stove as a kind of heat accumulator. Heat accumulators in heating systems (especially in water heating systems) are used more and more every year. Such devices are convenient because they only need to be heated well once with the intense fire of a solid fuel boiler, after which they will heat your home for a whole day or even more. This will significantly save your budget.

Comparison of insulation by type and properties

Mineral wool has low thermal conductivity. This quality gives this material an advantage over most modern insulation materials. The TechnoNikol company offers a varied range of mineral wool for thermal insulation and finishing of premises.

Rocklight slabs

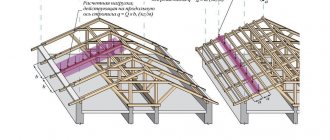

Rocklight is a thermal insulation board made of stone wool for heat and sound insulation coating. This type of slab is used in private housing construction. Ideal for thermal insulation of roofs and other structures. It is one of the best thermal insulation materials.

The main advantages of Rocklight

- Correctly chosen insulation can last a very long time in operation.

- Simple installation (installation of thermal insulation with Rocklight slabs is very convenient due to their light weight. The slabs are produced in packs, sheets measuring 1200 * 60 * 50 mm. They are convenient to install in frames, combine with each other and use for insulation in several layers)

- Fire safety (non-flammable material)

- No influence of moisture on the slabs (cotton wool practically does not absorb moisture)

- Good thermal insulation properties (mineral wool from which the slabs are made provides excellent resistance to cold. Thermal conductivity corresponds to cold climates and is 0.036 W/m.

"Technoblock" slabs

Insulator in the form of mineral wool slabs. Medium density material from 40 to 50 kg/m3. Therefore, this type does not withstand high loads and is used in the construction of low-rise buildings. It is used in finishing the facades of houses and for siding. You can use insulation by laying it in two layers.

Advantages of Technoblock:

- Sound absorption (due to the plates, noise penetration is reduced)

- Vapor permeability (air circulation)

- Moisture resistance

- Long service life (manufacturer provides a guarantee of up to 80 years)

- Low thermal conductivity. Is no more than 0.034 W/m.

- Thanks to its high thermal insulation properties, the insulator maintains a comfortable microclimate in residential premises, which allows you to save on heating costs.

"Technoruf"

Non-flammable stone wool slabs to create a thermal insulation layer. Tekhnoruf products are resistant to deformation, therefore they retain their qualities perfectly. The boards are resistant to moisture, therefore preventing the appearance of dampness indoors.

Purpose:

- Wall

- Floor

- Attics

- Attic floors

The products are formed from closely intertwined fine fibers of cotton wool origin. They have a high level of sound insulation, which helps reduce airborne and impact noise levels.

Quality:

- Durability (the boards consist of vertical and horizontal fibers, which makes them durable and increases their service life)

- Resistance of insulation to fire (plates made of non-combustible material, thanks to this they can be used in premises for any purpose)

- Light weight of the slabs (this quality allows installation quickly and on any surface).

- Low thermal conductivity 0.041 W/m

"Technovent"

"Technovent" - new generation insulation materials based on mineral basalt wool.

The assortment includes 3 lines of material:

- "Standard";

- "Optima";

- "Prof."

The difference between these materials is:

- material hardness;

- density.

All three types of material are intended for insulation of ventilated facade structures, and are optimized for creating single-layer protective thermal insulation.

High performance in:

- fireproof;

- environmental cleanliness;

- ease of installation.

"Technoflor"

"Technoflor" is a material that is designed for thermal and sound insulation of floors. Rigid mineral wool panels are used for surfaces subject to heavy loads. Energy-saving material that is not subject to temperature changes. Provides 100% sound insulation.

Fire-resistant, does not rot and is not susceptible to negative environmental influences. Indispensable for insulating sports-type floors that are exposed to heavy mechanical loads. Used for insulation of floating floors, for heated floors with the method of laying wool on the ground or installing wool on a concrete base.

The Technoflor product is produced in sheets with dimensions: 1000x500x40mm and 1200x600x200mm. The service life of this product from the TechnoNikol series reaches 80 years.

"Technoacoustic"

Environmentally friendly material intended for use as sound insulation:

- used for interior and exterior work;

- to absorb noise;

- frame partitions;

- suspended ceilings;

- floors.

It has the ability to retain and absorb noise up to 60 dB. In this regard, it provides a high level of acoustic protection of walls.

"Heat roll"

“Teploroll” is a new generation of rolled thermal insulation. Available in the form of mats. The mats are highly durable. Provide high thermal insulation and sound insulation qualities. Used in insulation and insulation of roofs, partitions and ceilings. Widely used in the construction of private houses.

Peculiarities:

- the material does not burn or rot;

- has a low level of thermal conductivity;

- resistant to the formation of mold and mildew, does not collapse under high humidity;

- not subject to destruction;

- non-toxic and absolutely safe for human health.

Thermal insulation has a good level of noise suppression. Easy to install due to its short length.

"Techno T"

These are rigid stone wool slabs that are used in civil and industrial construction for thermal insulation. Due to this, this material has limitations in use. Withstands a wide temperature range from −180 C to +750 C.

This is a feature of the material and the main difference from conventional building insulation. Allows installation of thermal insulation of air ducts, gas ducts, industrial furnaces.

Plates can be produced treated with aluminum foil or fiberglass on one side. Foil insulation provides a number of advantages. The foil coating of the insulation does not allow moisture to get under the coating, thereby ensuring moisture penetration. Foil does not allow cold air to pass through and does not release heat. Thanks to the high heat transfer coefficient, it can withstand temperature changes. Capable of reflecting ultraviolet rays.

Why is Penoplex in demand among consumers?

Might be interesting

Thermal insulation

Why polyurethane foam insulation is the best...

Thermal insulation

Self-adhesive thermal insulation: how to choose and apply?

Thermal insulation

How to insulate a roof from the inside and not make mistakes?

Thermal insulation

Roofing and drainage: heating rules

Penoplex is a highly effective new generation material. It is universal for home insulation. Unlike mineral wool, expanded polystyrene is not afraid of moisture. Thanks to this, it does not require additional waterproofing. Provides high thermal protection, works like a thermos. Does not burn. During installation, it can be mounted directly on the ground surface. Dense insulator, tolerates mechanical loads well, has low vapor permeability.

Recommendations for use:

- To insulate the floor and basement of a house (if it has non-residential status);

- Ideal for working on flat roofs;

- Insulation of septic tanks and wells;

- Thermal insulation of facades and internal walls.

Penoplex does not allow moisture to pass through, so it is not suitable for ventilated facades.

Material advantages

- Low thermal conductivity;

- Minimum water absorption;

- High compressive strength;

- Durability;

- Frost resistance;

- Not subject to rotting, plastic material.

Heat capacity of building materials

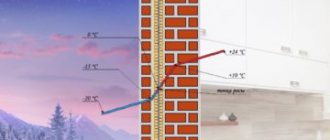

What should the walls of a private house be like in order to comply with building codes? The answer to this question has several nuances. To understand them, an example will be given of the heat capacity of the 2 most popular building materials: concrete and wood. The heat capacity of concrete is 0.84 kJ/(kg*°C), and that of wood is 2.3 kJ/(kg*°C).

At first glance, you might think that wood is a more heat-intensive material than concrete. This is true, because wood contains almost 3 times more thermal energy than concrete. To heat 1 kg of wood you need to spend 2.3 kJ of thermal energy, but when cooling it will also release 2.3 kJ into space. At the same time, 1 kg of concrete structure can accumulate and, accordingly, release only 0.84 kJ.

But don't rush to conclusions. For example, you need to find out what heat capacity 1 m2 of concrete and wooden walls 30 cm thick will have. To do this, you first need to calculate the weight of such structures. 1 m2 of this concrete wall will weigh: 2300 kg/m3*0.3 m3 = 690 kg. 1 m2 of wooden wall will weigh: 500 kg/m3*0.3 m3 = 150 kg.

Table comparing the thermal conductivity of logs with brickwork.

Next, you need to calculate how much thermal energy will be contained in these walls at a temperature of 22°C. To do this, you need to multiply the heat capacity by the temperature and weight of the material:

- for a concrete wall: 0.84*690*22 = 12751 kJ;

- for a wooden structure: 2.3*150*22 = 7590 kJ.

From the obtained result we can conclude that 1 m3 of wood will accumulate heat almost 2 times less than concrete. An intermediate material in terms of heat capacity between concrete and wood is brickwork, a unit volume of which under the same conditions will contain 9199 kJ of thermal energy. At the same time, aerated concrete, as a building material, will contain only 3326 kJ, which will be significantly less than wood. However, in practice, the thickness of a wooden structure can be 15-20 cm, when aerated concrete can be laid in several rows, significantly increasing the specific heat capacity of the wall.

Comparison of thermal insulation materials

The most popular materials for installation are polyurethane foam and penoizol. The widespread use of these materials in construction is due to their low cost and excellent thermal insulation.

The waterproofing properties of penoizol allow it to be used as a roofing material.

Only vacuum insulation is more effective than polyurethane foam, and this is very expensive.

Polyurethane foam can be used in ready-made thermal insulation parts - blocks, panels. And it can be used in special compositions that are sprayed onto almost any surface: wood, glass, metal, concrete, brick, paint. As a result, there is no need to make fasteners for insulation.

Expanded polystyrene competes with polyurethane foam. Due to its low weight, even a thick layer of foam does not exert a significant load on the supporting structures. Consists of closed cells, tightly structured.

You can insulate with foam plastic:

- Exterior walls;

- Roofs;

- Floors;

- Pipelines.

To install polystyrene foam on vertical sections, it is not necessary to attach a frame. Rigid sheets of insulation can be glued to the surface or fastened mechanically.

Another one of the most popular modern materials is foil polyethylene. The bottom layer is covered with foamed polyethylene. The top layer is covered with aluminum foil, which reflects heat up to 97%.

This type of insulation is used in the construction of heated floors, for sound insulation of ventilation shafts, pipelines, and expansion tanks. The material does not allow steam and water to pass through. It insulates heat and sound at the same time. In this case, it is laid in a thin layer.

One layer of 4 mm polyethylene can replace 8 cm thick mineral wool.

Use of various materials in construction

Tree

For comfortable living in a home, it is very important that the material has high heat capacity and low thermal conductivity.

In this regard, wood is the best option for houses not only for permanent but also for temporary residence. A wooden building that is not heated for a long time will respond well to changes in air temperature. Therefore, heating of such a building will occur quickly and efficiently.

https://ostroymaterialah.ru/www.youtube.com/watch?v=3TP5Liv9V00

Coniferous species are mainly used in construction: pine, spruce, cedar, fir. In terms of price-quality ratio, the best option is pine. Whatever you choose to design a wooden house, you need to consider the following rule: the thicker the walls, the better. However, here you also need to take into account your financial capabilities, since with an increase in the thickness of the timber, its cost will increase significantly.

Brick

This building material has always been a symbol of stability and strength. The brick has good strength and resistance to negative environmental influences. However, if we take into account the fact that brick walls are mainly constructed with a thickness of 51 and 64 cm, then in order to create good thermal insulation they additionally need to be covered with a layer of thermal insulation material. Brick houses are great for permanent residence. Once heated, such structures are capable of releasing the heat accumulated in them into space for a long time.

https://ostroymaterialah.ru/www.youtube.com/watch?v=1hbfkbFtePQ

When choosing a material for building a house, you should take into account not only its thermal conductivity and heat capacity, but also how often people will live in such a house. The right choice will allow you to maintain coziness and comfort in your home throughout the year.

Explanations of the indicators in the table of thermal conductivity of materials and insulation: their classification

Depending on the design features of the structure that needs to be insulated, the type of insulation is selected. So, for example, if a wall is built of red brick in two rows, then 5 cm thick foam plastic is suitable for complete insulation.

Thanks to the wide range of densities of foam sheets, they can be used to perfectly thermally insulate OSB walls and plaster the top, which will also increase the efficiency of the insulation. Classification of thermal insulation

Based on the method of heat transfer, thermal insulation materials are divided into two types:

- Insulation that absorbs any impact of cold, heat, chemical exposure, etc.;

- Insulation that can reflect all types of impact on it;

Based on the thermal conductivity coefficients of the material from which the insulation is made, it is divided into classes:

- And class. This insulation has the lowest thermal conductivity, the maximum value of which is 0.06 W (m*C);

- B class. It has an average SI parameter and reaches 0.115 W (m*C);

- To class. It is endowed with high thermal conductivity and demonstrates an indicator of 0.175 W (m*C);

Note! Not all insulation materials are resistant to high temperatures. For example, ecowool, straw, chipboard, fiberboard and peat need reliable protection from external conditions.

Where bulk and organic materials are used

Bulk and organic materials are used in construction. Bulk materials include expanded perlite.

Characteristics:

- Incombustible;

- Environmentally friendly material;

- Not susceptible to water.

It is used for the production of lightweight concrete and thermal insulation products, for insulation of ceilings and floors. More suitable for horizontal surfaces.

Organic materials include flax and cork. They are safe for people, but are flammable materials. Therefore, polyurethane foam, penoizol and mineral wool can be called advantageous in their characteristics for finishing materials. They are affordable to consumers, practical, and have a long service life.