A gas generator from mains gas is the most common power source. Of course, there are devices that operate on other types of fuel. But they have a number of disadvantages.

A gas generator running on mains gas makes virtually no noise during operation and does not emit harmful substances into the environment. This device is easy to install and use.

Advantages

Among the positive aspects of gas generators it is worth highlighting:

- Operation of the device for a long time. The generator operates until the main pipeline runs out of fuel. To make it possible to work more, an additional balloon system is installed. This indicator is the main one in comparison with other types of equipment.

- Low cost per cubic meter of gas compared to other types of fuel. In addition, fuel can remain in cylinders for an unlimited time, unlike alternative sources.

- Long service life. Parts, namely structural elements, practically do not wear out. As a result, a small amount of combustion products comes out of the apparatus. Therefore, the occurrence of corrosion is reduced to a minimum.

- Environmental friendliness. During its operation, no harmful substances are released.

What are the environmental problems?

Natural gas has a significantly lower environmental impact than coal. Based on the data, burning natural gas generates about half as much carbon dioxide, or CO2, as coal, fewer particulate matter, and very little sulfur dioxide or toxic air emissions. However, burning natural gas can produce nitrogen oxides and carbon monoxide in amounts comparable to burning coal. Continued use of these resources inevitably results in emissions of methane, a potent greenhouse gas that contributes to global climate change. Natural gas drilling and exploration can negatively impact wildlife habitat, wildlife, and the overall health of the atmosphere. Possible negative impacts associated with these fuels include erosion, decreased soil productivity, increased runoff, landslides and flooding.

When comparing natural gas to burning coal, CO2 emissions are significantly lower, but burning natural gas still results in a net increase in CO2 emissions and therefore may contribute to climate change.

Depending on the type of combustion technology and plant design, a gas plant can have a significant impact on water resources. Combustion turbines do not use significant amounts of water, but combined cycle power plants have a steam cooling section that can require significant amounts of water.

Flaws

Like all devices, a gas generator using mains gas has disadvantages:

- Increased explosiveness of fuel. Various explosions and fires occur more often than when using other devices. Therefore, it is necessary to provide additional transportation conditions.

- Collection of documentation. To use a gas generator on main gas, you must obtain a permit and also develop a project. Its cost will be much higher than the device itself.

- Exhaust ventilation should be provided in the room where the generator will be located.

- When sub-zero temperatures appear, the fuel cylinder must be moved to a warmer room.

Types of devices

There are two types of generators that can be used in residential areas. These are reserve and permanent.

The first type of gas generator can operate for up to 20 hours. The device is cooled using air. It can function beyond the allotted time. But at the same time, its motor life will be reduced. The generator can only operate when it is cooled down. Therefore, most people use it during a power outage.

If you need to use a gas element for a long time, you should choose the second type of such device. Its main feature is liquid cooling. Such equipment can turn on and off independently. Therefore, it has time to cool down during these periods of time. When this happens, inverters, along with batteries, supply electricity to other devices. Devices of this type can be used at high power, and in the event of a breakdown, they can be quickly repaired.

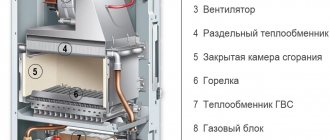

Operating principle and device

An electric gas generator is a unit consisting of an internal combustion engine that uses gas as fuel, and the generator itself, located on the same shaft. A generator is an electrical machine consisting of a rotating rotor and a stationary stator. The rotor rotated by the engine creates voltage at the terminals of the stator winding, which is consumed by the load.

Two types of generators can be used in power generating units:

- Synchronous;

- Asynchronous.

The synchronous generator is equipped with an excitation winding located on the rotor and fed with direct current through a brush mechanism. The rotor magnetic field created by the excitation current induces a rotating magnetic field in the stator windings, and the rotation of these fields occurs synchronously. The frequency of the generated voltage is determined by the angular speed of rotation of the rotor, so the latter must be constant, which is achieved by the speed control system of the drive internal combustion engine.

By changing the excitation current, the amplitude of the output voltage is regulated. Such generators have voltage feedback. This allows them to quickly respond to sudden changes in load (for example, when starting electric motors) and, by adjusting the excitation current, maintain the output voltage level.

The disadvantages of generators of this type include a rather complex design due to the presence of a power supply system for the excitation winding and a brush mechanism, which is a fairly common cause of failures.

An asynchronous generator does not have a brush mechanism, since on its rotor instead of windings there are permanent magnets, which, when the rotor rotates, create a rotating field in the stator windings. The design of such a generator is simpler and more reliable, but in terms of its functional qualities, it is inferior to a synchronous generator. Due to the inability to regulate the voltage level, the power of such a generator must be selected with a certain margin.

A separate class of devices is formed by natural gas generators containing inverter converters. In such designs, asynchronous generators are used, which have a multi-pole design, generating a high-frequency voltage, which, after rectification, is supplied to the input of the inverter. The inverter converts DC voltage, providing a strictly sinusoidal shape and a stabilized output signal level.

Gas generators for home using main gas

When operating this equipment, two types of gas are used. This is liquefied and mainline. In the first case, fuel is consumed from cylinders, and in the second, from the main pipeline. There are devices that can operate on another type of fuel, for example, methane.

It is recommended to use liquefied fuel generators if a heating boiler is installed in the house.

With a generator power of 6 kW, a cylinder with a capacity of 50 liters is enough to work for 20 hours.

The main gas pipeline, which is connected to the house, is an advantageous source of power. Before installing it, you need to find out the pressure in the pipeline. If the value is low, such a gas generator for the home will not operate at high power. Before connecting it, you must obtain permission from the relevant company.

Petrol, converted to gas

The second no less interesting nuance when purchasing is a gas generator converted to use gas. Many, of course, claim that this is the same thing, that such electrical installations can operate on both gasoline and gas at the same time. However:

- Engine manufacturers refute this by producing different series of engines for gas and gasoline.

- Such models will be more difficult to obtain, since most likely there will be no certificate for such an electric generator, or after the sale it will turn out that it is not suitable and you will be left alone with the gas trust.

- It is known that lubrication in portable gas generators is partially produced by fuel; if it is gas, alas, the resource will decrease.

And the last thing:

If you nevertheless decide to power the gas generator from a cylinder, calculate the consumption and autonomy, as a rule, this is several hours for 50 liters of gas (not clean, of course).

If you have any questions about connection and whether it is possible to do this for you, write to us

Selecting a gas generator

To select a suitable element for a living space, the following characteristics must be taken into account. Fuel consumption, power, voltage, etc. So, let's look at the available capacities of this equipment:

- 5-6 kW - such a device is suitable for a small residential building to conduct electricity in it, as well as for cooking;

- 15-20 kW - the equipment can operate for 12 hours, which makes it possible to obtain the necessary comfort in the room by connecting different types of electrical appliances. Such long-term power supply is possible thanks to air cooling;

- 10-25 kW – this equipment operates for a long time using liquid cooling; most of these devices are used in country houses or cottages;

- over 25 kW – I use such powerful devices for production purposes in small enterprises.

As for such an indicator as voltage, there are single-phase and three-phase gas devices. The first type is used to supply electric current to any household appliances with a voltage of 220 V. The second type is most often used in country houses or cottages for mixed power supply with a voltage of 220-380 V.

If, when using a three-phase type, three consumers are not connected to the device, then a single-phase automation system can be used.

The same can be done with a single-phase type, that is, install three-phase automation and use the device for three consumers.

When choosing a gas generator, you should pay attention to the electric start and automatic system. These functions are responsible for automatically turning on and off the equipment. In addition, the gas generator from the main gas with auto-start has an oil sensor that protects it from breakdowns.

Criterias of choice

Once the decision has been made to select a unit that uses gas as fuel, gas generators for generating electricity using natural gas should be considered. After the type of fuel, the next important criterion that must be followed when choosing is the power of the generating plant.

When choosing a generator for constant power supply to a facility, you need to take into account not only the current load, but also the forecast of its increase in the future. Such a unit is very expensive and is designed for a long period of operation. A situation where the installation of, for example, an air conditioner or a dishwasher becomes impossible due to insufficient generator power cannot be allowed.

If the generator is intended to be used as backup power only for the main load, its power must be determined. This could only be part of the home lighting, TV and computer. If you add an electric stove and kitchen electrical appliances, the required generator power, and accordingly its price, will increase.

In addition to the power of the selected generator, power quality indicators may be important. For example, there may be electronic devices in the home that are critical to the shape of the supply voltage waveform. In this case, you should check whether the quality of the electricity generated by the generator meets the conditions necessary for the correct operation of these devices.

It is necessary to take into account the overall dimensions of the unit. After all, to install it you will need to choose a suitable place.

Installation

As a rule, such devices are equipped with a special protective casing. To install the equipment, the following conditions are necessary:

- the temperature in the room must be above 0°C, if this condition is not met, then insulation is necessary;

- supply and exhaust ventilation must be provided in the room;

- care must be taken to remove combustion products.

Today there are models that can be installed outdoors. This is why they are equipped with a special casing. Their advantage is that they will not take up space in the room. In addition, they will function outdoors even in sub-zero temperatures and precipitation. It can also work at -30°C. The cost of such equipment reaches 200,000 rubles. This price is significantly higher than that of analogues using diesel fuel with the same characteristics. But such a system quickly pays for itself if there is a gas heating boiler in the house.

How is gas energy generated?

There are two main types of power plants used to convert natural gas energy into electricity - open cycle and combined cycle.

The simplest: an open cycle in which natural gas is burned to create pressure. The pressure drives the blades of the gas turbine, causing it to rotate and convert thermal energy into mechanical energy. The shaft connects the gas turbine to the gas turbine generator, so when the turbine rotates, so does the generator. The generator uses an electromagnetic field to convert mechanical energy into electrical energy. By driving the turbine, which is connected to the generator, it causes the generator magnets to spin and create an electric current.

In a combined cycle power plant, the heat that is generated from combustion drives a turbine whose purpose is to boil water and create steam, driving a second turbine to produce even more electricity. This allows such power plants to convert up to 50% of the energy contained in natural gas - much more than the 33% conversion of coal-fired power plants.

For this reason, gas-fired combined cycle power plants are typically used to provide daily base load, while open-air plants operate during peak demand.

Combustion turbines are based on the principle of jet engines. With turbine technology, natural gas is burned to create superheated air, which is then pumped into pipes and used to drive the turbine.

Natural gas energy can also be used in fuel cell technologies, which rely on chemical reactions to create electricity at much higher efficiency levels than can be achieved by burning fossil fuels.

Arrangement of the premises

As a rule, these devices are installed in the basement, boiler room or other convenient room. The element can only operate when exposed to positive temperatures. The location must meet all technical requirements for boiler rooms:

- the volume of the room must be more than 15 m3;

- supply and exhaust ventilation must be provided;

- it is necessary to ensure the removal of combustion products;

- You cannot install a gas generator from the main gas, running on liquefied fuel, in the basement.

In addition, the requirements apply to fuel and pipeline:

- To use the devices, a certain pressure must be present inside the main pipeline. This indicator should be in the range from 1.3 to 2.5 kPa. A valve is installed on the supply section of the main gas pipeline to shut off the gas flow.

- For liquefied fuel, the requirements are no different from the previous version. If a cylinder is used, it must be equipped with a valve and pressure regulator.

- The gas generator must be equipped with a manual start.

Questions regarding approval when connecting a gas generator

Gas is already connected. There is a boiler and a stove. Consumption maximum 6.6 cubic meters per hour. Counter G6. I chose a generator with a flow rate of 4.9 cubic meters per hour. I contacted the design company and started asking questions. For the specifications, we need to do a heat calculation - okay, we did it. But I didn’t understand why.

Question 1. Why do heat calculations for a generator. The first time you connected, it was already done. Who is right? But the specifications have been received, which is already good. We made a project to insert into an existing exit from the ground with a separate meter, taps, etc. Mosoblgaz closed it down because there should be only one metering station in the house.

Question 2. Is this the incompetence of the designer or the greed of Mosobgaz? The cost of the project has gone up. Replacing a pipe meter with a different diameter, etc. The meter is in the G10 project, simple without data transfer. They turned it around again - they say it is necessary to install a shut-off valve. valve which costs 60,000 rubles + and a prepaid smart card.

Question 3. Who is delusional – the project company or Mosoblgaz? Please clarify the situation. With all respect, Andrew.

Hello. You asked a rather difficult question, which should have been properly addressed to Mosoblgaz, but I will try to answer it to the best of my knowledge and understanding of the situation. As far as I understand, you are applying for a conversion to replace the gas boiler with a new one.

———– Question 1. As far as I know, the list of documents required for Mosoblgaz to obtain technical specifications:

1. Statement of the future consumer. 2. Copy of passport. 3. One of the title documents for the object. 4. Situational plan for the location of the object. 5. Permission from the Moscow fuel and energy complex to use a natural resource. 6. Territorial planning documents.

In the RECOMMENDED column, I quote verbatim: “To determine the hourly gas consumption and the power of the installed gas equipment used to generate electrical energy, as well as for servicing swimming pools, greenhouses, winter gardens, etc., perform a thermal calculation.” As you can see, the heat calculation is advisory in nature. But there is a loophole - you change the project and the organization has the absolute right to recalculate the energy efficiency of the facility.

———– Question 2. SP 62.13330.2011 Gas distribution systems clause 7.10: “Each facility where gas-using equipment is installed must be equipped with a single gas metering unit in accordance with the regulatory legal documents of the Russian Federation.”

They didn't lie. There really can only be one accounting unit.

———– Question 3. This question caused difficulties for me, since Article 544 of the Civil Code of the Russian Federation states that: “Payment for energy is made for the amount of energy actually accepted by the subscriber in accordance with energy metering data, unless otherwise provided by law or other legal acts or agreement of the parties. The procedure for payments for energy is determined by law, other legal acts or agreement of the parties.”

That is, a prepaid smart system contradicts this law, since the gas supply will be blocked for the volume of gas that has not yet been accepted.

And here is how Mosblgaz is trying to explain its requirements to consumers verbatim:

“The choice of meter is determined by the design decision of the organization carrying out the gasification project for your residential building. Installed meters must be included in the state register of measuring instruments, have a valid certificate of approval of the type of measuring instruments, with an unexpired verification period. Meters must provide measurement of gas volume in all flow ranges, based on the power of the installed gas-using equipment.

State Unitary Enterprise MO Mosoblgaz recommends designing and purchasing a gas meter of the OMEGA ETK GSM G-4 brand without a smart card produced by Gazdevice CJSC. The presence of a GSM radio module allows you to automatically (remotely) transmit gas meter readings. The consumer has the right to pay the cost of supplied gas using the above-mentioned gas meter without making an advance payment, monthly, until the 10th day of the month following the expired billing month. At the same time, payment for consumed gas can be made in any way convenient for you, including by bank card without charging a commission using the “Client Personal Account” service on the website.”

In fact, here they are delusional, but they do not hide, as you can see, that their requirements are RECOMMENDATIVE in nature, and not mandatory. As far as I have heard, the installation of such meters can only be required from July 1 and for now the project applies to apartment buildings, and not to private houses. Moreover, installation there will be carried out during major repairs and design of engineering systems under construction and not at the expense of consumers (but we’ll wait and see).

“They say you need to install a shut-off valve. a valve that costs 60,000 rubles” - I, as a resident of a non-Moscow region, do not understand the cost of 60,000 rubles. Our most expensive one costs about 13 thousand, if you look hard enough. Okay, let's look at the documents to see how things stand with the shut-off valves.

Fire safety rules (PPB 01-03): “p. 84. Pipelines supplying gas to household and industrial appliances for its combustion, at facilities put into operation after completion of construction, major repairs, reconstruction and (or) technical re-equipment, must be equipped with heat-sensitive shut-off devices (valves) that automatically shut off the gas main when the ambient temperature in the room during a fire reaches 100 °C. The specified devices (valves) must be installed in the room directly in front of the tap on the gas main.”

And as I remember, one of the SNiPs also regulates something for email. valves

I advise you to document everything that is said to you in words, and let them justify all refusals in writing. So far I have only found uncertainty about smart phones. They easily justify everything else.

Please keep us updated on developments, the question is very interesting.

Connecting the device

Many people ask the question: how to connect a gas generator to the main gas?

This process is simple, and if you have some knowledge, you can do it yourself. In this case, no permits will be required.

Before connecting a gas generator to the main gas, it is necessary to coordinate all points with the gas supply company. The list of actions is specified in regulatory documents. The main ones are the certificate for the purchase of the device, as well as its technical passport. Next, the following questions are resolved:

- Making changes to an existing project.

- Conclusion of an agreement between the owner and the gas supplier on generator maintenance.

- Concluding an agreement on responsibility for fulfilling certain obligations.

Selection and procedure for connecting gas generators to main gas, gas tank or cylinders

Selection and procedure for connecting household gas generators to main gas or to a gas holder or cylinders!

Gas fuel does not tolerate careless handling. Connecting an alternative source of electricity supply to the main line can only be done by specialists. First you need to contact your local Oblgaz structure. Here you will order design documentation for the implementation of a generator cut into a common gas pipeline. You must have documents such as a certificate and instructions for the equipment on hand. Gas workers will analyze the submitted materials and give an opinion on the possibility of connecting the generator.

After completing the design work, it is time to install the equipment. It is accompanied by the installation of gas pipes. The generating set is supplied with all necessary mounting elements. Only certified specialists are authorized to carry out work.

This is followed by commissioning with the participation of a representative of the selling company. Commissioning is permitted by the state commission after checking the connection’s compliance with approved standards. When purchasing a power plant, do not forget about the need to calculate power consumption taking into account starting currents for home equipment.

Types of units and power indicators

Generating power is selected taking into account the electrical load. Low-power generators 6-15 kW will be the optimal solution if there is a need for a backup power source in suburban real estate. The generators feature a closed all-weather casing design and are mounted in an open space.

When servicing residential buildings with many points of energy consumption, preference is given to stationary gas generators with a power rating of 15 kW or more. They are also produced in a protected design in the form of an all-weather casing, which allows the unit to be installed in outdoor conditions. The equipment plays the role of a backup power source.

Gas generators consume natural gas when connected to the appropriate communications. However, in country villages there is not always main gas. In this situation, the way out is to use gas cylinders or a gas holder with a propane-butane mixture.

The choice of technology requires special attention. Not every modification of the generator allows the use of liquefied fuel. Many models combine natural gas with an analogue in a liquid state. Fuel combustion occurs at a reduced level of thermal conductivity and minimal presence of methane with a low risk of detonation. Under similar conditions, fuel with a high thermal capacity is consumed. It is changed by turning the switch.

Main settings

To correctly select a power plant operating using gas fuel, it is worth familiarizing yourself with its technical documentation. It provides various parameters. The engine model and the nature of its start are indicated, which can be manual, electric or automatic. The operating temperature range is also important: as a rule, it ranges from -35 to +40 °C. Important characteristics are fuel type, inlet pressure, gas flow and continuous operation time.

The functionality of the generator set also matters. Manufacturers often provide information on the basic kit. It is complemented by a variety of options. Check the opportunity to buy a gas electric generator with auto-start, which is responsible for starting the power plant in automatic mode. The generator starts in the absence of mains voltage, the appearance of which interrupts its operation. Also check whether the basic kit includes heating and a battery. The components listed may already be included in the kit.

220V or 380V? Phase calculation

It is imperative to find out the voltage produced by the equipment. For many models it reaches 220V at a frequency of 50 Hz. Such generators operate in electrical networks with one and three phases. They are sufficient for the use of boiler equipment, household appliances and lighting.

A gas power plant is connected only by specialists who also carry out the wiring. There are models operated in three-phase networks, where the voltage is 380 V. Before buying a gas generator, find out its voltage.

Reliable and efficient operation of equipment depends on correct connection. Networks consisting of three phases for energy consumers with one phase require uniform load distribution between phases. A skew of 30% is considered normal, but no more. Therefore, it would be more correct to buy a single-phase gas electric generator with an adapted automatic start unit for three phases and avoid phase imbalance! But if you plan to use consumers running on 380V when the main power supply is turned off, you need to consider three-phase gas electric generators!

Cable networks

Having received the results of calculating the load on the electrical network, taking into account all energy consuming points, they proceed to the design of a redundant network. A line is led from the power plant in the direction of the distribution panel block. A branch is made from it to the backup feeders. A cable channel is created to lay the line.

It is necessary to monitor the correct connection of the backup network to the city input. For this purpose, changeover switches are used, with the help of which the power source is manually selected, be it a generator or a centralized network. Automatically started units are equipped with contactors instead of switches.

Reviews

Most consumers are satisfied that they chose this type of equipment.

A gas generator can operate for a long time, since natural fuel does not wear out parts. In addition, such gas is cheaper than other types of fuel. Among the disadvantages is the need to collect additional documentation, which takes a lot of time and effort.