Purifying water with homemade filters is a standard activity for camping and field conditions. After all, it is unwise to carry huge bottles on yourself due to the incredible physical costs. In addition, this is irrational due to the almost ubiquitous presence of the liquid component of the earth’s shell necessary for the body.

The liquid people need is indeed available everywhere, but its sanitary condition is not always compatible with consumption. But you can make a very effective water filter with your own hands even on a multi-day route, being far from populated areas, with a minimum of available tools.

We will introduce you to the most effective and easy-to-implement devices for purifying dirty water. Here you will find diagrams, recommendations and a detailed description of manufacturing technology. The material offered for review is systematized, supplemented with visual illustrations and video instructions.

How to choose filter media?

When choosing a container for a filter, you need to carefully calculate everything, because the cleaning properties primarily depend on the correctly formed “filling”. The volume of the filter container must be such that it can easily accommodate all components.

Natural materials are widely used as absorbents, such as quartz river or washed quarry sand, gravel, activated carbon and zeolite. As you know, any filter begins with a primary coarse layer. Often this role is assigned to cotton-based fabric materials.

The water in the filter must undergo several stages of purification. The upper layers trap large inclusions and contaminants, the lower layers prevent the penetration of small particles

Natural materials are very impractical from a hygiene point of view. Firstly, in a humid environment, such a filter layer is subject to rotting processes, which causes an unpleasant odor. Secondly, the structure of the fabric implies very rapid contamination of the filter with unwanted particles, which increases the need to change the layer.

Much better performance is observed in synthetic analogues. More preferable in this regard is lutrasil. The material has moisture-resistant qualities and is more resistant to contamination than cotton or bandage.

Non-woven polypropylene fabric - lutrasil can be used as a bottom layer intended for final water purification

A completely budget option for a fabric filter can be considered a synthetic layer, which is used in making coffee.

Quartz sand does an excellent job of retaining small particles, as well as filtering heavy chemical compounds. While gravel, on the contrary, will better screen out large inclusions of unwanted materials. A mineral called zeolite has an incomparable cleansing effect.

Zeolite is widely used in water purification. It extracts heavy metals, organic compounds, phenol, nitrates, ammonium nitrogen, etc.

The active action of the substance will cope with water pollution with metal and salt suspension, and also neutralizes pesticides and other processed products of the agricultural industry.

Is it really necessary to purify water from natural sources?

Today, in almost every kitchen you can find the simplest design filter for water purification, made in the form of a transparent jug, inside of which there is a replaceable container (cartridge) with an adsorbent composition.

Water filter jug Aquaphor “Ultra”.

These devices are inexpensive and great for purifying small amounts of water. It would seem - why not a solution for a long trip to the country, where you have to use water from a well or even an open reservoir, and there is no stationary cleaning system?

The jug itself is not that expensive, and is sold complete with a filter cartridge, which must be periodically replaced with a new one as the installed resource becomes dirty. But if you have to purify a large amount of water, then the cartridge will have to be changed often, and, by the way, it costs not so little. That is, you have to take a spare one with you so that you don’t have to return to the city to buy a new one.

It also happens that not only the water intended for drinking and cooking, but all the water entering the house must pass through a filter. It is clear that an ordinary jug will not be enough here, since it simply will not cope with such a voluminous task. This is especially important when water is taken from open reservoirs or wells, since it often contains fine particles of clay, sand, organic matter, and waste products of microorganisms. This water is not suitable for drinking.

In addition, various waste from agricultural work accumulates in the soil, from where it inevitably ends up in groundwater over time. Therefore, water that is not specially purified may contain nitric acids, nitrates, chlorine impurities, sulfates, pesticides and other toxic compounds. And if we add here the proliferating landfills of household waste, industrial emissions and automobile exhausts carried by precipitation, spilled petroleum products...

Prices for Barrier water filters

Filter Barrier

Thus, drinking untreated water from sources that have not been tested at the laboratory level is extremely risky. And cleaning with the help of simple filter jugs is not at all a suitable way to get rid of these compounds dangerous to humans - such devices are, rather, designed for post-purification of tap water that has already undergone a certain preparation cycle.

And yet, even such a jug (with a working cartridge, of course) is better than nothing at all. But what to do if, as they say, “circumstances are pressing,” and there is no way to use the factory filter device? The solution is to try to make, at least temporarily, a filter with your own hands.

Activated carbon cleaning devices

The most common group of homemade filters involves the use of activated carbon. The drug can be purchased at any pharmacy in unlimited quantities. Its reserves will practically not increase the weight of the luggage and will not take up much space in the backpack.

But in terms of cleaning power, coal has few rivals. It perfectly adsorbs toxic substances, absorbs an impressive range of heavy metals, and mercilessly fights harmful microorganisms.

Small-sized camping varieties

Perhaps the best quality filtration results are shown by homemade options based on activated carbon. The absorbent will equally successfully cope with the retention of both mineral formations and toxic substances.

Image gallery

Photo from

Cigar case for making a filter

Screw-on housing cover

Hole in the bottom of a cigar case

Filter filling of the device

The properties of the material include the ability to impart transparency to liquids, as well as eliminate unpleasant odors and waste products of microorganisms.

When choosing coal, you need to pay attention to the structure of the mineral. Too fine and powdery will penetrate into the water, while coarse, on the contrary, will not provide the proper level of purification. (Granular starting material should be preferred).

Activated carbon is the most popular material in homemade filter devices. It is advisable to fill it in layers so that there is powdery material below, granules on top, and the fractional composition increases in height

An important factor is the degree of so-called “roasting” of the coal. If you overdo this procedure, the absorbent will quickly lose all its valuable qualities.

Coal can be bought at any supermarket, or made at home. The best absorbent qualities are observed in deciduous wood, in particular birch.

It is not recommended to use coniferous trees, as the essential oils they contain can give the filtered water a pine-like smell.

To obtain coal, you need to load wood into any metal container and heat it over a fire (preferably put it in a stove). After the wood gets red hot, remove the container and let it cool - that’s it, the charcoal is ready for use in the filtration system.

Image gallery

Photo from

Filter for water purification in field conditions

The design of an extremely simple filter device

More serious filter design

Filter material for homemade products

A completely camp option would be a homemade carbon-based filter for water from the ashes of a burnt-out fire. If necessary, it is better to use whole pieces approximately 4 cm in length.

As a rule, anything can serve as a housing for such an improvised system, but mainly a plastic container or bottle is used for convenience.

Coal retains organic compounds, hydrocarbons, chlorine, and permanganate. Effectively removes odors and color from purified water

Making a carbon water purifier

Before assembly, you need to select a more optimal housing option.

For this you will need:

- Several plastic containers (bottles or PVC pipe, in some cases you can use food containers. Due to their strength, they will serve well as the base of the cartridge).

- Tools for processing plastic (various sharp objects: awl, scissors, stationery knife, screwdriver).

- Absorbent material (in this case activated carbon).

- Additional filter granules (quartz sand, gravel).

- Material for the primary fabric filter (medical bandage, gauze or coffee filter).

- Plastic covers or plugs.

To ensure the tightness of the structure, polymer substances should be used at the junctions of the modules (if the filter is multi-level and consists of several parts). Moisture-resistant silicone glue or insulating tape work well.

To install the hanging structure, you need to first cut off the bottom of the plastic bottle using a stationery knife. Then make two holes opposite each other to attach the hinges. Now the improvised body can be hung, for example, on a tree branch.

Next, you need to make an outlet valve from where the filtered liquid will flow. At this stage, the design feature depends on individual preferences. You can organize something according to the principle of a shower - make many small holes in the lid, or you can drill one large one.

The next step will be the actual installation of the components. After screwing on the perforated lid, the body is turned over or hung by the hinges. Then, the first step is to place a bandage or gauze folded several times. The use of a coffee filter is also encouraged.

In some cases, you can find designs where the role of the primary filter material is played by a fabric cover, sewn specifically to the size of the housing. This greatly simplifies the task of changing the absorbent and saves time.

It is worth paying attention to the fact that the installation of absorbent components should be done in a “pyramid” type. This means that the first step is always a fine-grained absorbent (coal), then comes a layer of quartz sand, and then comes the turn of river pebbles or gravel.

Each subsequent filter layer has a different, most often finer, structure than the previous one. This promotes more thorough cleaning

For greater efficiency, it is recommended to alternate several layers of pebbles, however, do not forget that excess material can impede the flow of water. It is better to cover the filler hole with some kind of cloth or lid to prevent unwanted objects from getting inside the cartridge.

The principle of operation of such a filter is the passive flow of water through all layers. Under the action of the granules, the contaminated liquid is cleaned and flows out of the perforated hole. Initially, you need to pass several liters of water through the filter. The first filtering procedure will wash the layers and remove contaminants.

The disadvantages of the system include the rather slow cleaning speed and the need to constantly add new liquid after completing the filtration procedure.

The disadvantages of homemade water filters with natural fillers include low speed, the need to frequently change filter layers, and not very high cleaning quality

Useful homemade PVC pipe

To purify water in a suburban area, you can also make an effective purifier that can compete with factory products. It will be needed to treat water collected in a mine well or in a water well, but will be especially useful if the water is drawn from a river, pond or lake.

To build the structure you will need a piece of plastic water pipe and 2 containers. You can connect two bottles, where the upper segment will act as a coarse filter.

The filter can be made from improvised materials without the help of special equipment. Everything you need can be found in everyone’s home

As expected, a primary layer of gauze or cotton wool is first placed inside, while some kind of mesh backing, for example, made of plastic, is constructed so that the layers do not mix. A plastic cap that can be glued into a PVC pipe is well suited for this, then drill several small diameter holes around the circumference.

Perforations in the plastic baffle are necessary to retain synthetic or natural fibers in the primary filter

Next begins the stage of filling the initial cartridge with synthetic material (sintepon can be used).

After this, close the module again with the lid, only this time you should not resort to using glue, because this part must be removable in order to be able to replace and clean the filter material.

The filler should be laid tightly, but at the same time not too much so that the layer does not interfere with the passage of water

Then the turn of the plastic pipe begins. You need to cut off the neck of the bottle and secure it inside the pipe so that you can use the thread.

It should be secured tightly to avoid leaks (silicone glue works well). It is recommended to wrap the outer side and edging of the neck with several layers of electrical tape for greater strength.

The insulation must also be wound in several layers in order to prevent the possibility of leakage

As usual, you need to insert a cap into the other end of the tube and make a perforation. A fabric layer should be placed on the inner surface of the improvised cassette.

After all the manipulations, the structure is ready to be filled with granulate (in this case, activated carbon). For better efficiency, you can alternate layers of minerals inside the pipe.

It is best to use synthetic material as a filter layer, because... it is more durable and does not need frequent replacement

Once complete, the primary filter and carbon module are screwed together using threads. Then plastic bottles are added on both sides. That's it, the cut PVC carbon filter is ready for use.

The homemade design does not require special conditions of use and does not take up much space when disassembled.

Filtering methods

There are two ways to purify moonshine with charcoal: the infusion method and the flow filtration method.

- Infusion method. Charcoal tablets are placed in a container with moonshine for several days. Shake the container periodically. After cleaning is complete, filter through gauze and cotton wool.

- The flow filtration method consists of flowing moonshine through a cylindrical vessel filled with coal, followed by cleaning through cotton wool and gauze.

For the flow filtration method, you can purchase an industrial carbon column with a pump in stores. It is a stainless steel pipe with removable covers at the top and bottom.

The top lid has a fitting for supplying unrefined moonshine, and the bottom for draining filtered moonshine. But the cost of factory equipment is high. You can make a similar house design using improvised materials.

To produce a coal column you will need:

- Activated carbon

- plastic 2-3 liter bottle

- gauze

- cotton wool

- tool for punching holes in plastic

Water filter for aquarium

As you know, for the normal functioning of aquatic inhabitants, it is necessary to clean the tank in a timely manner and maintain the purity of the water. Owners of small aquariums will come in very handy with instructions on how to build a filter at home.

The body of a homemade filter for purifying hard water can be any plastic tube of a suitable diameter, including, in the absence of one, 2 syringes will work well.

Before assembly, you need to prepare some additional parts: a spray bottle (often used in bottles with detergents), a sponge with a high degree of rigidity, as well as a mechanism by which the structure will be attached to the wall of the aquarium (suction cup).

The main advantage of the design is ease of manufacture. All components can be easily found at home

The first step is to remove the moving part of the syringe; it will not be useful. Then, using hot glue or other sealant, connect the blanks to each other, after cutting off the spouts.

For water flow it is necessary to make perforations. An ordinary soldering iron will do an excellent job of this, and if you don’t have one, you can heat any metal object, such as a nail, over the fire and make holes over the entire area of the syringe.

To optimize the speed of water passage through the filter, it is recommended to make holes at an even distance from each other

In some cases, you can put some granules into the filter capsule; the best option would be to use zeolite, because The absorbent does a good job of filtering nitrates. Next, you need to place the atomizer inside the housing, and its flexible tube should run evenly along the entire length of the cassette.

Then the improvised cartridge should be completely wrapped with a sponge and the outer layer should be secured so that it does not unwind. That's all, the power of such a filter is quite enough to purify water in a small aquarium.

The design is quite compact and can fit into any small tank

Application in industrial premises

Clean air is necessary not only at home, but also at work. The environmental situation at the location of the enterprise depends on this. In production facilities, main compressed air filters are used, which have a large throughput and a high degree of purification. Industrial filters consist of fibers distributed in such a way that dirt particles accumulate as they pass through their layers. Cleaning devices used in the industrial sector can be divided into 2 types:

- preliminary – deep electrostatic and dry fine fiber;

- mesh - equipped with irrigation and capable of self-cleaning.

To normalize the operation of the ventilation system in industrial premises, a special filter and air pressure regulator is installed to lower the air pressure in the line and maintain it in a certain range.

The use of activated carbon filters is very extensive, since human health completely depends on the cleanliness of the air and the sorbing properties are undeniable. Even a car will not move without oxygen purified to the proper level. Dust and harmful gases are constantly floating in the air, so you shouldn’t skimp on your own health and install a carbon air filter. Not only the kitchen needs an exhaust device; any room deserves an air filter for an apartment or a private house.

Sand option for the pool

As already mentioned, the process of constructing small-sized variations of filter systems is quite simple, however, if we are talking about a large reservoir, it is necessary to think through all the nuances of the purification system.

Many people have probably encountered the problem of “blooming” water. Most often, this process is observed in the warm season, and if a private pool is also equipped with a heating system, such an incident can occur at any time.

It’s fair to say that the problem of green water can be completely solved with improvised means, namely, removed mechanically, but sometimes a layer of algae can sink to the very bottom and removing the surface film will not solve the problem.

Image gallery

Photo from

Homemade sand filter for the pool

Filter material for filling the device

Pump to stimulate water movement

Cover for a homemade sand filter

In addition, not only algae can act as a pollutant, but also fallen leaves, as well as sand and all kinds of microparticles if the pool is located outside.

Faced with problems of this kind, people begin to frantically buy all sorts of detergents and cleaning products in the hope of getting rid of annoying green islands. But the active chemical action of substances can only help with the pollutant that is on the surface and in order to clean the tank to the very bottom, completely different methods are needed.

To completely clean the pool, there are special filter systems. They work on the principle of a “vacuum cleaner”, namely, they pump liters of contaminated liquid through a compressor. The filtration process is a repeated transfer of water from one part of the pool to another.

This mechanism is often used in large municipal or private institutions, where the volume of the pool sometimes reaches thousands of liters, so the best solution is an automated filtration system.

But it is not profitable for the average user to invest in such bulky equipment if, for example, it is necessary to clean only a small seasonal inflatable tank.

Just for such reservoirs there are instructions for constructing a sand filter.

The body of the device contains a filler with filtering properties (sand). You can replace the material with any other

During the assembly process, you will need any container that can serve as a cartridge. The water tunnel from the primary filter can be made from a plastic pipe 2 meters long (if the pool is large).

You also need to take into account that the tunnel design involves a 90-degree rotation, so a PVC corner is needed. The inner diameter of the cartridge and pipe should be about 50 mm.

A threaded bushing with a diameter of M10 can be used as a support pin for cleaning modules. The convenience of this design allows you to connect several filter cassettes into one, which turns a regular filter into a multi-level one. This increases absorption efficiency and ultimately results in cleaner water.

At the first stage, you need to make two holes (it is better to use a hammer drill).

The first is in the filter plug, and the second is in the PVC corner, then connect the two parts using a pin and nut. A water compressor should be attached to the other end of the tube. The power of the equipment should be selected based on the volume of the pool.

In order for the filter to float, it is necessary to make a special foam backing.

The purification process is circular, and occurs by taking water from the lower layers of the pool and pumping it through the filter using a pump.

The advantage of this design is the absence of additional elements for releasing filtered water, as well as the possibility of replacing the cartridge. It is better to carry out the rinsing procedure over a separate container to avoid dirty liquid getting back into the pool. It is better to use a bucket for this.

In addition, the cost of this installation is significantly less than branded analogues. Everything you need can be purchased at specialized retail outlets, for example, a compressor is sold in any pet store, PVC pipes and corners in construction supermarkets, and a replacement cartridge in the markets in the plumbing department.

A big advantage when creating a floating filtration system is the freedom of design. If you have decorative components on hand, you can disguise the filter as any object that fits into the composition of the pool, for example, a ship.

How does the process of filtration and purification of moonshine occur?

You can filter fusel milk both before re-distillation and the finished product 10 - 20 days before use. If another distillation of alcohol is planned, and there is a desire or need to clean the moonshine from fusel oils and other harmful impurities, you must first lower the strength of the product. To do this, it is diluted with spring or melt water to the desired degree. For more information about filtration and purification of moonshine, watch this video:

After this, the homemade column is filled with diluted alcohol and wait until all the liquid seeps through the filter (if necessary, change the cotton wool at the neck several times). Filtration is repeated twice. The fact that the raw material turns black is not at all scary - it will be as pure as a tear after distillation.

To further purify moonshine from impurities and fusel oils, you can combine two filtration methods - flow and infusion. To do this, pass fusel through a coal column 2 - 3 times, and add a little more coal powder to the resulting product (40 g of coal per 1 liter of liquid).

After the alcohol and charcoal have been infused for 2-3 days, and a thick sediment has formed at the bottom of the container, you can begin to rectify the drink. For cleaning, the same design that was made for charcoal filtration is quite suitable. It needs to be freed from coal residues (by the way, coal dust can be dried and used one more time) and washed thoroughly. For the most effective cleaning method, watch this video:

Throw away cotton wool, filters or cotton pads, and take clean ones instead. The neck of the bottle is filled with a cotton seal, the cap with holes is screwed on until it stops and the bottle is placed neck down on a three-liter jar. The entire free volume of the bottle is filled with cloudy moonshine and covered with a saucer to avoid evaporation of alcohol.

To do this, the uncleaned drink is poured back into the container, the cotton wool or filter is replaced with a clean one, and cleaning continues. You can drink your product immediately after cleaning, or you can dilute it to the desired strength and let it brew for a couple of days.

Homemade water filter

At home, anyone can build an installation consisting of three containers connected in series. Such a water filter works only under a certain pressure of the water supply system.

Plastic or glass containers can be used as future cassettes, and the segments must be connected using a ¼-inch adapter nipple.

The filter is connected directly to the water supply system and does not require installation of additional communications

For convenience, the adapters have entry/exit guides. They will make sure that the assembly process is successful. Another important point is the tightness of the installation. To avoid leaks, it is recommended to wrap each thread in Teflon tape and seal the joints with synthetic material.

A filter of this type is connected to the system as a tee and connected in series with the water supply pipes. The same coal can be used as granulate. It will clean raw water from harmful microparticles and prevent the appearance of scale on the heating elements of an electric kettle and washing machine.

Which product requires filtration?

The fact that uncontrollably consumed alcohol is harmful to health is brought to the attention of people already at school. Severe intoxication, damage to the liver, cardiovascular system, neurological and mental disorders are just some of the ailments that occur to those who abuse alcohol. Sometimes the blame for poisoning is placed on low-quality “left-handed” alcohol. It is quite logical that those who follow the “drinking culture” want to protect their body, and at the same time reduce the cost of alcohol.

The use of coal columns for purifying moonshine with an industrial-type pump, or the simplest filters created in a homemade way, should become an obligatory link in the technological process of every craftsman, for whom not only the volume, but also the quality of the resulting product is important.

The most common forms of contaminants are:

- acetone;

- methanol;

- isopropyl and isoamyl alcohols;

- furfural and other compounds.

Once in the human body, they cause irritation of the mucous membranes of the mouth and eyes. Severe vomiting, hallucinations, rashes and ulcers on the skin, incoherent speech, fainting and even coma - this is what can happen if the concentration of harmful substances in a home product is exceeded. Some of them settle in the steam tank. To check their concentration in the finished product, you need to put alcohol in a metal spoon and set it on fire. At the end of combustion, you can visually observe combustion residues - a brown, viscous substance.

If it is not possible to purchase an industrial filter, then there is nothing left but to make an activated carbon column to clean moonshine with your own hands.

Materials for filtration equipment

The efficiency of cleaning depends on the quality of the filtration material; a limited number of them are used in wells, the main ones being:

Stainless steel. In addition to strength, the material has flexibility and excellent corrosion resistance; the durability of stainless steel is tens of years. It is used to make strong meshes and wires that are mounted on top of the pipes. The disadvantages include the high cost of stainless steel products.

Plastic. Plastic is another common material for the manufacture of filters in water sources; meshes and cords are made from it, which are cheaper than stainless steel. Plastic is corrosion-resistant and inert to most chemicals, easy to install and has a long service life. The disadvantages of plastics include low physical strength, which does not allow them to withstand heavy loads at significant depths.

Non-ferrous metals. Copper, brass, and bronze can be used in the manufacture of water filters without any restrictions; they have high corrosion resistance and a long service life. Soft alloys with a high copper content are recommended for use at shallow depths to avoid deformation from strong water pressure. In the manufacture of filter elements, brass mesh and thick wire made of brass or copper are used.

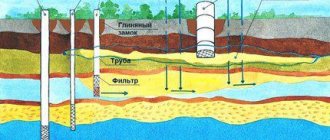

Rice. 4 Filter for casing pipe - installation in the well

Steel. Steel filters are susceptible to corrosion and can be used as a budget option in water intake sources intended for technical needs. Increased content of iron oxide in water as a result of iron corrosion of more than 0.3 mg. per liter leaves a yellow residue on water main equipment and plumbing fixtures. Galvanized steel also rusts over time to form zinc oxides, which are harmful to human health - this material is not recommended for use in water filter elements.

Principle of operation

Activated carbon is produced by special processing of carbon-containing raw materials (roasting without access of air + steaming + treatment with reagents), as a result of which it is possible to achieve the formation of a huge number of tiny pores with a radius from 0.2 to 200 nm.

At the same time, the surface area that interacts with pollutants increases millions of times: for example, in 1 g of activated carbon it can range from 500 to 2200 square meters. m.

Such a material acquires adsorption properties, that is, the ability to capture and retain large amounts of impurities due to attraction between molecules.

The pollutants that activated carbon deals with are organic in nature. These are various petroleum products, benzene, phenol, polycyclic aromatic hydrocarbons, phosphorus and organochlorine pesticides. In addition, it removes active chlorine molecules from water (dechlorination).

Stationary filter device consisting of three flasks

Now let's figure out how to make an effective filter yourself to connect it directly to the system. For these purposes, we will need three flasks with the same geometric parameters into which we need to place the filler.

From containers prepared in this way, we will make a productive stationary filter for purifying tap water, guided by the following diagram:

- Take two 1/4 inch adapter nipples. Use them to connect all three flasks into one structure.

- Seal the joints of the nipples (their threads) with fluoroplastic sealing tape (the so-called FUM material).

- Using straight adapters, connect the 1/4-inch holes of the two outer flasks to the tube.

- Cut the prepared filter into the pipeline (you will need a half-inch connector and a tee).

- Connect a regular water tap to the filter outlet tube.

High-quality water in modern conditions, especially drinking water, is a very rare occurrence. If several decades ago there were still clean springs and wells, now they are very rare even in rural areas. Agricultural companies pollute the soil no less than industry and herbicides. Mineral fertilizers inevitably penetrate into the sources. Water filtration has become a necessity.

Jug-type installations have become frequent guests in kitchens in the city and in the country. They are effective for small volumes of liquid. But if you need to clean tens or hundreds of liters, such devices are unsuitable. When there is a well, borehole, or swimming pool on the property, water filters are necessary. You can buy ones designed for these purposes, but those made by yourself are always cheaper.