Spending a few summer days at the dacha is always pleasant, but if there is also a swimming pool there, the holiday becomes simply luxurious!

The one who managed to convince his wife that the bathhouse was desperately needed and that the tomatoes that were supposed to be planted in its place would still be eaten by the Colorado potato beetle - solved the most difficult part of the problem.

But complete victory is still far away. Now it is necessary to think through and ensure the removal of dirt, microbes and various debris from the water, otherwise the cool, sparkling refuge from the summer heat will very quickly turn into a musty swamp. In this article we will talk about water purification systems and learn how to make a sand filter for a pool with your own hands.

What types of pool filters are there?

Today, there are many different devices that are ready to diligently take care of the cleanliness of your pool.

All of them can be divided into several groups:

- Chemical : the cartridges of such filters contain an active substance that has disinfecting properties. It mercilessly deals with bacteria and microbes that wish to join you without an invitation. Devices of this type are impressive in size, but this is not their main drawback. The fact is that the bather himself is to some extent exposed to the effects of the filter filler, which, alas, does not improve health. Therefore, you won’t be able to splash around in the pool for a long time; in addition, after swimming you will definitely need to take a shower.

- Mechanical : water is pumped through a layer of substance that acts as a very fine sieve. The filter does not have a bactericidal effect on microorganisms, but the largest of them are still retained. At the same time, the cost of mechanical filters, as well as their size, is much less than that of chemical ones. Unfortunately, the performance of these devices is equally low, so it is advisable to use them for cleaning only small pools.

With regard to chemical filters, the principle “the more expensive the better” is especially evident. Those who had to use both cheap and expensive devices noted a significant difference in the degree of impact on the skin. So the conclusion is obvious: when purchasing a filter of this type, attempts to save money will be very inappropriate.

Sand filter after installation

Based on the type of filler, mechanical filters are divided into the following types:

- Sand: the advantages of a sand filter are its low cost, and also the fact that such a device can easily be made with your own hands. True, it is not highly efficient: all particles with sizes less than 20 microns (microns) will again end up in the pool. To clean the filter (an operation carried out approximately once a week), a large amount of water is required, which is pumped in the opposite direction, after which it is discharged into the sewer. Sand is often supplemented with layers of gravel or activated carbon, which helps to increase the efficiency of the filter.

- Cartridge : filters in this category occupy an average position in both price and efficiency. The device consists of a housing and replaceable cartridges installed in it - up to 4 pieces. The latter are made of paper and polyester. All particles larger than 5 microns are retained. An important advantage of cartridge filters is ease of maintenance: the cartridge can be quickly washed under running water, and when its service life comes to an end, it can be easily replaced with a new one.

- Diatoms (terrestrial) : Sedimentary rocks formed by the fossilized remains of ancient diatoms are a very effective filter substance. In addition, the effect of such soil on water can be considered healing due to the high concentration of silicon dioxide in it. The device cannot cope only with those contaminants that are less than 1 micron in size. As with sand filters, periodic backwashing with water is required.

The disadvantages of diatomaceous earth filters are their high cost and the need to hire a specialist to replace the filler, which is due to its high toxicity.

Components, how much do the parts cost?

Swimming pool owners who decide to buy a sand filter should remember:

- There is almost a 100% probability that the basic package will not include a bag with filler (additional expenses from 400 rubles) and a drain hose.

- The need to check the length of other connecting hoses and the presence of fittings. In most cases, they exist, but their size does not allow for proper placement of the filter, and the quality leaves much to be desired. The approximate cost of purchasing them is 2000 rubles.

- Quite often there is no pump in the kit (which is especially important when purchasing European brands). The cost of filters increases by 20-30%.

During operation, filters are also often lost or worn out:

- drain plugs or covers;

- O-rings or gaskets for drains, valves, pre-filters and other connections;

- plugs, bends and adapters;

- mode switching gaskets (700 rubles) or the control valve itself (up to 8,000 rubles).

Often wearing parts should be purchased in reserve or in advance; spending on seals rarely exceeds 100-200 rubles. Ideally, this purchase is made simultaneously with the purchase of a filter from the same supplier; if this is not possible, when ordering components, their dimensions are carefully specified.

Sand filter device

A sand filter for a pool is a container filled with sand, into which pipes are cut in at the top and bottom. There is also a tight-fitting lid with a lock. There is a fitting cut into the cover for connecting a pressure gauge.

The latter helps to assess the degree of filter clogging: if the pressure increases significantly when pumping water, then it’s time to rinse the sand.

Sand filter device

The filter is switched to the washing mode by switching the valves. In this case, water begins to enter the device not from above, but from below - this is called backwashing. At the same time, a drain valve opens at the top, through which dirty water is discharged into the sewer.

In the “Washing” mode, the filter should work for about 5 minutes. Then the valves are switched to the “Tamping” mode and only then (also after 5 minutes) – to the “Filtration” mode.

Roof drainage is an important element of the drainage system, because proper drainage will ensure the safety of the building and foundation. How to properly drain water from a roof? Let's consider the types of drainage systems, materials, as well as installation features.

Read about making a septic tank with your own hands and using barrels here.

And in this topic https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/istochniki/kolodets/kopka-svoimi-rukami.html you will learn how to properly dig a well with your own hands. Selecting a location, protection from surface contamination, design of the above-ground part.

Manufacturers

Comparison table of various companies producing sand filters:

| Brand name | Main country of production | Year of foundation | Products offered | Price range (RUB) |

| Bestway | China | 1994 | Filter pumps with a capacity from 2006 to 11355 l/h for above-ground swimming pools | 2200-15500 |

| Intex | 1966 | Filter pumps Krystal Clear, ≈from 4.5 to 12 m3/h | Up to 30000 | |

| Emaux | 1997 | Polypropylene and p/e filters, from 3 to 50 m3/h | 9700-87600 | |

| Kripsol | Spain | 1987 | Series Balear (polyester and laminated fiberglass), Artik (polyester), S2 and Granada, (polypropylene), 6-125 m3/h | 11700-78500 |

| JSC "Astral CIS", Astralpool | Spain, Russia | On the Russian market since 2000 | Over 10 series with capacity up to 56 m3/h | 32500-370000 |

| Hayward | USA-France | 1925 | PowerLine, Pro Top and PRO Side series, polyamide filters for SwimPro spas, up to 55 m3/h, HCF filtration barrels, up to 353 m3/h | 12700-146500, negotiable for commercial systems |

| Behncke | Germany | 1978 | Wear-resistant filters FEX-3 and Koln, 6-14 m3/h. Can be used in industrial water treatment systems | 38000-94000 |

| Gemas | Türkiye | 1993 | 8 lines of sand filters made of high-quality plastic, thermoplastic and fiberglass, from 6 to 64 m3/h | 18000-150000 |

Homemade sand filter for the pool - step-by-step manufacturing instructions

When arranging a swimming pool, you can save a certain amount (from 6.5 to 13 thousand rubles) by installing a homemade sand filter made with your own hands instead of a purchased one. In the step-by-step instructions below, the entire process of manufacturing a cleaning device is discussed in as much detail as possible.

We select sand

This point can be considered key, because the effectiveness of the filter depends on how much sand is “charged” into it.

The most effective and durable is glass, but it cannot be called affordable.

In most cases, quartz sand is used, the service life of which is about 3 years.

As practice has shown, fractions from 0.5 to 1.4 mm have the best filtering ability.

River sand, which is also called beach or quarry sand, cannot be used as a sand filter filler.

Sand, which is sold in stores specifically for filtration units, can be used without prior preparation. If the material gets to you through other means, it must be boiled, first rinsed with clean running water.

You can buy quartz sand at any hardware store; the approximate cost of a 25-kilogram bag is 600 rubles.

Case manufacturing

The plastic or metal container from which the filter housing will be made should have a volume of 40 to 60 liters. It is mandatory to have a tight-fitting lid with a secure lock.

The container must be equipped with two fittings: one (input) is cut into the upper part, the second (outlet) - at the very bottom. The insertion points should be carefully sealed.

Homemade sand filter

On the lower hole on the inside of the body you need to attach several layers of nylon mesh, which will hold the sand filler.

A coarse filter is installed at the inlet - a nylon mesh attached to a piece of plastic bottle.

Another fitting - for connecting a pressure gauge - should be cut into the cover.

Sand filling

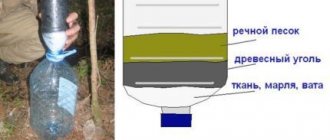

Filling of the filler should be done with the simultaneous supply of water. As already mentioned, the filter can be made multilayer, using, in addition to sand, gravel, as well as activated carbon or graphite.

The coarsest sand should be poured in first, then the finer ones. If this principle is followed, filter washing will be faster and more efficient.

Assembly and connection

When filling is completed, the filter is closed with a lid, onto which a pressure gauge is then screwed.

A hose coming from the pump is connected to the upper fitting using a clamp, and another hose for draining water into the pool is connected to the lower fitting.

To flush the device, the hoses are connected according to a different scheme: the line from the pump is connected to the lower pipe, the drain leading to the sewer is connected to the upper.

At first you will have to do this every day, but as the water purifies, the need for flushing will arise less and less.

A piece of plastic bottle with a nylon mesh - an improvised coarse filter - can be fixed not in the sand filter, but on the suction pipe of the pump. In this case, the entire filter system will be under its protection.

It is impossible to live without water in a summer cottage. In addition, the water must be of high quality and it must be supplied uninterruptedly. How to find water for a well on a site? Let's consider methods for detecting groundwater: analysis of vegetation, the help of absorbents and other methods.

We will discuss the operating principle of a vortex pump in this section. Comparative characteristics of centrifugal and vortex pumps.

Cartridge with pump pump

This filter for cleaning a pool is the easiest to assemble with your own hands. The design consists of a container, inside of which there are 3 – 4 cartridges . Their material is somewhat reminiscent of polyester.

With the help of a pump, water enters through one tube, is filtered and returns to the pool from the second pipe. For high-quality cleaning, it is very important to place the collection and supply holes for purified water as far as possible from each other .

Required materials and tools

We will need the following materials:

- Filtration cartridge with a diameter of 50 mm.

- Polypropylene pipe of the same diameter. The length of the pipe depends on the power of the pump. A pipe 2 to 3 meters long should be sufficient.

- Turn for a pipe made of the same material.

- Threaded rod M12. If the pin is longer, then several filters can be installed at once. This will improve the quality of cleaning , but this design will require a more powerful pump.

- Pump pump. Its power depends on the volume of the pool and the number of cartridges. For a single-cartridge filter designed for a pool of 250 - 300 m3, a pump of 25 - 30 W is enough .

- Expanded polystyrene plugs.

Assembly

First you need to attach the pump to one side of the pipe. After this, the cartridge is inserted on the other side, and we secure it with a pin. To do this, it is necessary to drill a hole in the plug and turn it through which a pin is passed, after which the structure is secured with a nut.

In order for the finished device to float on the water, the ends of the tube must be tightly closed . To do this, use polystyrene foam plugs. Once you have carefully secured everything and closed the ends of the tube, your filter can be considered ready.

How to use?

No additional hoses are required to connect to outlets and water intakes. Simply place your filter in water. At a depth of approximately 50 - 60 cm, the pump captures liquid and delivers it into the tube.

There the water reaches the cartridge, the cleaning process takes place, after which it immediately returns back. This design is capable of processing approximately 2500 liters per hour .

Sand replacement

Ordinary quartz sand must be replaced every three years. Some purchased installations (for example, Intex sand pool filters) use sand, which requires replacement less frequently - approximately once every 5 years. The operation is not difficult at all:

- Turn off the pump supplying water to the filter.

- If you are using a factory-made filter system, close the nozzles and close the skimmer valves.

- If the filter is installed inside the pool, the water from the bath must be drained.

- Disconnect the filter from the system.

- After opening the hatch, remove all sand from the housing, not forgetting to clean the nozzles.

- Lay new sand under water pressure. As mentioned above, the bottom layer should be formed by the coarsest sand, then the material of the middle fraction is laid, and the finest sand is laid on top.

- All that remains is to close the filter cover with the latch and connect it to the system.

After each sand filter maintenance operation, be it changing the sand or washing it, check that the pressure gauge hole is not clogged with dirt or sand.

Drawing and work diagram

To assemble the filter with your own hands, you need to make your own drawing with the correct calculations or use ready-made diagrams available on the Internet. We offer two do-it-yourself drawings for assembling a sand filter from scrap materials.

Drawing No. 1

Sand filter cross-section

Drawing No. 2

Schematic illustration of a sand filter

Principle of operation

Diagram of the filter in the pool

Tools

For a simple sand-based filter design we will need:

- A container with a wide “neck” (plastic or milk can);

- Quartz or glass special sand;

- Pump with screw-on valve and switching modes;

- Thick corrugated hoses;

- Squeegees with rubber or plastic gaskets;

- Metal or plastic clamps;

- Coarse filter;

- Fixing pressure gauge;

- Water intake with the smallest mesh.

Read more: Seal for refrigerator Biryusa; Replacing the rubber seal on a door with your own hands

The pump power must correspond to the volume of the pool. The water in it must pass through the filter at least 3 times every 24 hours. So, for example, for a reservoir of 8 cubic meters. (24 cubic meters per day) you will need a pump with a capacity of 40 l/min. The device must also provide additional power reserve.

Sand filter assembly pump

Owner reviews

Most sand filter users rate positively:

- ease of connection to frame and inflatable pools,

- power,

- speed and quality of filtration,

- price/reliability ratio.

A number of owners note the need to clarify the configuration and quality of the case before purchasing. No serious operational deficiencies were found in sand filters. Reviews can be found here, here and here.