Russian invention is the source of various innovations and inventions. We find use for seemingly unnecessary things and objects that have served their purpose. For example, old car tires, the rubber of which is worn out and not suitable for use.

Car cameras have long been an item of garden decoration, and now they are used as a material for load-bearing construction. Used tires are used to construct foundations for light frame houses, bathhouses, gazebos, utility rooms and garage buildings.

What are the advantages of using car wheels, and how to build a foundation from tires with your own hands?

A little history and facts

Mikhail Semykin, a resident of St. Petersburg, was the first to notice old car tires. He was interested in the strength of the material, and he wondered how to use this property in private construction. After all, all developers are faced with the fact that it takes an exorbitant amount of concrete and metal to build a reliable foundation for a building.

For his first experiment, Mikhail used decommissioned trolleybus tires. When, after a year of observation, the construction did not change a single one of the parameters, Semykin finalized the technology and patented it. Since then, the method of laying a tire foundation has been named after him.

When submitting documents, the author attached information and his calculations, proving that the design has proven itself to be excellent in unstable soils and when they are deeply frozen. And the paper projects are confirmed by a real three-story house built by him and standing on tires. Moreover, the total area of the building exceeds 250 square meters.

Foundation made of tires, made in the form of pillars Source prosto-banya.ru

The neighbors laugh

The instigators of the unusual construction are three women: a mother and two daughters. They laugh from the start, saying that they built, built, and finally built, although the construction is still at least two years away from completion. The future owner of the house, Irina, plans to finish building it for retirement. However, even now the house looks like a house, and it’s okay that on the first floor there are piles of boards and window openings filled with tires, and on the second floor an adult can fall through the holes between the floorboards.

“When they just started building, everyone laughed at us,” says Irina. “They also built houses and cottages in the area, and builders came to us and asked: “What kind of nonsense are you doing?” The three of us started. Me, Ksyusha and eldest daughter Natasha. Natasha’s husband openly laughed and twirled his finger at his temple. My husband also did not support me in any way - now he is bragging to his relatives. While the first floor was being built, they crawled home on all fours - try swinging a four-kilogram sledgehammer all day!

— Gradually, friends and friends of friends began to get involved in the construction; whole groups of students from the institute, technical schools, and cadets came. We had refugees from Ukraine living here, in an old house, and they also helped us build. Everyone reacted positively: firstly, it’s interesting to see, and secondly, why not help? Moreover, it’s not just somewhere to go, but to nature, with a river nearby. In the morning you can help, and in the evening you can fry sausages, kebabs...

Types of structures

In fact, a foundation made from tires is not much different from a regular concrete one. It also has three types of structures, but the main feature is the conservation of funds for its construction. For example, in one case it is possible to lay the base without concrete at all. And in another way you can save it significantly.

Structurally, the tire foundation is divided into:

- Slab . For which a pit is required. Its depth should accommodate at least two tires laid flat. The tires in the pit are distributed evenly, one to one. And a concrete pad is poured on top of the structure, on which the building is installed. This foundation is used on swampy, weak soil. It allows you to distribute the load more evenly and reduce shrinkage.

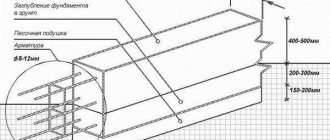

- Tape . For it, a trench is dug under each of the load-bearing walls, and its width should be greater than the size of the wheels. The ditch must be deep enough to accommodate at least two recumbent tires.

Foundation made of tires laid in a trench Source fermer.ru

- Columnar . The most economical of the options, but characterized by excellent reliability and durability. This installation is used for buildings consisting of lightweight materials and has proven itself even in areas prone to seismic activity.

Each design requires a special approach. Each installation is performed using a specific technology and has its own nuances. But in general, the method has proven itself exclusively on the positive side.

Installation of formwork

After compaction and preparation of the base, you can proceed to pouring the foundation. To do this, waterproofing is installed in the form of sheets of roofing material. At the next stage, the formwork is installed, for which timber and a board prepared in advance are used.

This part of the foundation is assembled in such a way that the result is a monolithic concrete slab. This will become the top part of the base. It is especially important to reinforce the structure using channels and metal, which are connected to each other with wire. Sometimes it will be enough to use a monolithic concrete slab, but in this case its economic feasibility and cost should be assessed and calculated.

Advantages of a tire base

The main advantage of a foundation made from scrap tires is the low cost of the method. In most cases, you will only have to spend money on delivering raw materials to the construction site. Some car repair shops and car service stations will even be happy to get rid of tires that have been lying on the premises for years.

But a worn tread does not affect the overall properties of the entire tire at all. And it remains elastic indefinitely and can withstand heavy loads. There is also no need to spend money on arranging good waterproofing. Because the material is not afraid of sudden increases in humidity. Therefore, the microclimate in the building will always remain favorable.

Laying the first row of tires in the base for constructing a garage Source probani.guru

See also: Catalog of companies that specialize in repairing foundations of any complexity

Tires are not afraid of low temperatures, even deep frosts. In this case, the properties of the material do not change at all. And an additional bonus is the tire’s ability to dampen seismic vibrations. Therefore, increased elasticity will come in handy in areas with an increased risk of earthquakes.

But in addition to information about the advantages, it would be nice to find out whether the foundation on tires has disadvantages. Unfortunately, they exist. And the main drawback is that the materials from which car ramps are made decompose under the influence of ultraviolet radiation. Therefore, it is necessary to take care that direct sunlight does not fall on the rubber.

True, this problem is often solved by eliminating another. A columnar foundation raises the building slightly above the ground. Therefore, the sight of old tires under the house significantly spoils the impression. And the owners have to think about how to decorate the structure. And having coped with this task, they at the same time hide the material from the sun.

As a rule, visible tires are covered by sheathing the perimeter with corrugated sheets. But many simply cover the rubber with a protective layer of special paint, the color of which harmonizes with the entire structure.

Laying tires in a visible base in the form of a geometric pattern Source i-netcontrol.com

Application area

As already mentioned, this foundation is excellent for heaving soils and areas with seismic activity. As for the type of buildings, it is best to install on the base:

- Frame houses . In this case, a pit is dug and tires are laid in several rows.

- Outbuildings (sheds, garages) . For a small room, support pillars at each corner are sufficient.

- Baths, as well as summer gazebos . These structures do not even require backfilling of the support.

- Solid fences . Tires are laid in one row in a trench.

Tires will also help out those who want to equip a parking lot with a canopy near their house. At the same time, tires filled with screenings will easily withstand the weight of even several loaded cars.

But, no matter how well the excellent qualities of tires are marketed, experts do not recommend erecting brick or cinder block buildings on such a foundation. It is best to opt for a frame structure made of timber. And for heavy materials, make a standard strip base of reinforced concrete.

Construction Features

The principle of these foundations is extremely simple: car tires act as a form, which is filled with broken bricks or gravel and poured with concrete. As a result, the filler and construction mixture do not spill out beyond the tires, forming a single concrete column.

To make the structure more reliable, stable and durable, it is recommended to use steel reinforcement. It is installed in the center of the tires or along the 4 edges of the inner radius, each rod opposite each other. This gives the structure additional rigidity. Do not forget that before laying the foundation you need to clear and level the land.

Laying technology

To successfully implement your plan, you need to prepare in detail. A project is drawn up, which includes a drawing. The structure of the soil is studied and the possible load is calculated. Based on the data obtained, the type of foundation is selected and an estimate is drawn up.

Slab

This foundation is perfect for frame-type residential buildings. It is advisable to select the largest wheels for it. Tires from tractors, buses and heavy trucks are well suited. The size of the material affects the stability and strength of the structure.

Many developers have doubts whether to fill the tire foundation with concrete or not. This is due to the fear that the design may not be entirely reliable. Meanwhile, calculations show that one stack of columnar base can withstand up to two tons of load. Filling with mortar is needed as needed - to obtain additional rigidity.

Pouring concrete over a tire base Source sakh.com

All work is done in stages:

- The site is cleared according to the size of the project.

- A pit is dug to a depth of at least 30 cm (fertile layer).

- The bottom of the pit is leveled using a building level.

- The slopes are laid flat in the pit, as tightly as possible.

- All voids are filled with construction waste, broken bricks, or better yet, gravel.

- A standard reinforced concrete floor is laid on the prepared base.

If large tractor wheels are used, then one row of tires in the pit is sufficient. The use of much smaller tires will require them to be laid in two rows. This must also be done if the soil is waterlogged. And experts do not recommend using sand to fill voids. It shrinks significantly.

Instead of floor slabs, pouring concrete is used. To do this, roofing material is spread over the tires and formwork is constructed. Reinforcement is carried out and filled with cement mortar. Let it sit for a week before starting to build the walls.

Filled tire for the foundation Source img-fotki.yandex.ru

There are hands, but no money

The idea came to Kachalina suddenly after bitter thoughts about an imminent retirement and the lack of her own living space. She could not build a good house from timber or brick - it was expensive. And so I started looking on the Internet for alternative types of construction. There were houses made from bottles, glass and plastic, from bags of earth, from straw, etc. The choice settled on tires after a friend from the USA told me about her neighbors. The government took away their housing with a mortgage, and with the money that was returned to them, they bought a piece of land and built a house... out of tires.

- Only there they hired a company that builds tire houses. Everything is done there at once: heating, water, light, sewage are thought out in advance. We do everything ourselves. We have hands, no money... But we also think through everything - there are air ducts, sewerage is already included in the project.

A tire house costs many times less than a regular one. The family spent 200 thousand rubles on the roof, and the rest was “mined.”

Irina says that a tire house costs many times less than a regular one. The family spent 200 thousand rubles on the roof, and the rest was “mined.” A house made of timber costs at least 450-500 thousand. And if you start a stone project, then you need at least 1 million. Plus the foundation! And they are all on tires, free of charge.

“They bought tires from tire shops—they went and begged for old wheels. First, I rode the bus and noticed where the tire shops were, then I went to negotiate. They do not have the right to store more than 10 used wheels, so any workshop is happy to get rid of them! I took the gazelle and drove around them all at once, collecting the wheels. The diameters came across different ones, but I tried to take the 16th diameter. Then in one tire shop, in Igris, I asked twice, and the third time the director himself called and said, pick it up again. But I don’t have a car... Then he himself began to carry it for me, in large quantities.

— As they say, the whole world was looking for materials. The neighbors called and said where they could get what they didn’t need... They still have about two dozen window frames near the entrance to the house. Half plastic, half wood. There are piles of old tires in the garden...

“I couldn’t find Straw for a long time.” One friend calls me: “You, she says, were looking for straw in the fields, but we have a lot of it here at the Dynamo stadium. There were races there, but then they didn’t take us out.” I turned to the director, this way and that, and he said: “Yes, take it! We’ll deliver it to you ourselves!” And soon four KamAZ trucks with soldiers brought the straw. You should have seen the faces of your neighbors! Such a landing!

Briefly about the main thing

To summarize, it should be noted:

- Discarded car tires can easily replace reinforced concrete when constructing a foundation.

- Such foundations are suitable for both light outbuildings and frame residential buildings.

- In the latter case, it is better to build a slab foundation and, if necessary, increase its rigidity by pouring concrete.

- For unstable soil and in seismic zones, the use of a columnar foundation for construction is more justified.

But in general, experts give only positive assessments of the strength and reliability of the resulting structures. In addition, the method is significantly more economical than all other known ones.

Ratings 0

Carrying out pouring

The foundation of car tires is filled with concrete mortar, to which a plasticizer is added - this component will ensure the absence of cracks and chips. The poured solution is covered with a rag, which is pre-soaked in ammonia, which saves time on drying.

The slab is left in this state for 10 days to consolidate and ensure the strength of the structure. The formwork is then dismantled.

The most important thing is to ensure that the slab is perfectly horizontal. To do this, when pouring the permanent one, check the building level.