Ideal parking for a car is almost the most important dream of any motorist. And this place can be made with your own hands. The article will focus on a garage with a canopy, which is not only convenient, but also a modern, economical, functional and efficient design.

This is a great way to make smart use of the space in front of your garage. We will tell you about the advantages and disadvantages of such a structure and how the work should be carried out in order to ultimately get a reliable parking space for your favorite four-wheeled assistant.

Construction of a garage with a canopy, 4.5x9.5 m (September-October 2018)

Dmitrovsky district, Tseleevo

Foundation - monolith slab

Basement - concrete blocks

The walls are made of aerated concrete blocks with a monolithic belt.

Canopy - on metal stands

The rafter system is wooden.

The roof is metal tile.

Rules for the use of raw materials

There are rules for handling polycarbonate sheets established by experience:

- You should not store the material in the light; you should consider the way they are stored in the warehouse;

- the material should not crack from twisting;

- The protective film can be removed only after finishing work with the sheets;

- work on installing the flooring should be carried out quickly;

- The slabs must be laid with the UV-resistant side facing outwards, as indicated on the surface of the protective film.

Leaving cellular polycarbonate in the film in the open light will cause it to stick tightly to the plate, that is, a photochemical reaction, causing the material to become unusable.

Construction of a garage with a basement and a canopy, total size 16.1x6.8 m (2018)

New Riga, Davydovskoye

Basement - monolithic, 6.3x2.5x2.3(h)

The foundation is a monolithic slab.

The base is made of solid concrete blocks with monolithic sections.

The frame of the canopy is metal structures.

The walls are made of aerated concrete blocks with monolithic belts.

The rafter system is wooden.

The roof is metal tile.

Construction progress in photographs:

Advantages and nuances of construction

The photo of polycarbonate canopies shows universal outdoor structures that perfectly transmit natural light and have a wide range of colors.

The raw material is quite light, transparent and has a variety of convenient thickness formats, this helps to create any type of structure: from simple to curved parts. In addition, they easily and harmoniously fit into any interior and landscape of a personal plot.

Polycarbonate canopies are divided into the following types:

- separate, self-standing ones are most often acceptable for swimming pools, gazebos, greenhouses, carports in parking lots and over outbuildings;

- the mobile type quickly moves to any selected point of the perimeter: barbecue roof, compact gazebo;

- as an extension to a garage, bathhouse, veranda, porch canopy.

These structures can be rectangular, curved, or two-story. They are also divided into open and closed models, for which the walls on the sides are usually covered with glass, gratings, lining, or thick textiles.

The building includes pillars for vertical support and the roof itself. To make frames, wood, metal beams, concrete, brick, and stone are used.

Construction of a garage for ATVs, with a utility block and a canopy, 3.6 x 8.1 m (2018)

Istra district, Kotovo, Znamya-2

Foundation - monolithic slab, made by the Customer

The base is made of solid concrete blocks.

The walls are made of Bonolit aerated concrete blocks with monolithic belts.

The rafter system is wooden.

The roof is metal tile.

Construction progress in photographs:

Dimensions

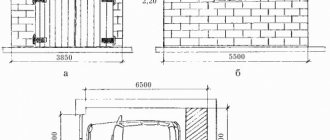

Since the dimensions of cars can vary significantly, in each case the optimal dimensions are determined depending on the car available.

The height is usually around 2.5 meters. This is more than enough even for an SUV with a loaded trunk. And to determine the length and width of the canopy, at least a meter is added to the external dimensions of the machine. Agree, it is quite enough if there is a distance of half a meter to the pillars.

Example of a carport for one car

But to protect against precipitation, it is better to make the roof overhangs longer: they will also protect from slanting rain and snow.

When determining the size of a canopy for two cars, take the distance between the rear-view mirrors to be 50 cm. The same amount is calculated for the pillars. And the length of the canopy is determined by the longest car.

When calculating the width of the canopy for two cars, take the distance between the rear-view mirrors equal to 50 cm. The distance to the pillars is also considered half a meter

Construction of a garage with a canopy, 5 x 14 m.

Shishkin Les, New Moscow

Garage with a canopy.

The foundation is a shallow strip foundation.

The walls are reinforced masonry made of aerated concrete blocks.

The structure of the canopy is planed timber.

Open rafter system.

The roof is flexible tiles.

The building is functionally divided into 2 zones - a closed garage in the back and an open shed in front at the entrance. A garage with a shed is built under one gable roof. In order to optimize construction costs, according to the client’s instructions, the garage foundation was designed in the form of a shallow reinforced concrete strip. Despite the fact that the warranty does not apply to this type of foundation, adherence to construction technology and high-quality materials made it possible to produce a reliable foundation strip, which was not subject to deformation during operation and confirmed the correctness of the choice of design solution.

Details - follow the link.

Material selection

An additional shelter for a car can be ordered from a specialized organization or built independently. For the second case, it is recommended to select projects that involve the installation of wooden or metal structures.

For the first option, a timber or rounded log with a cross-section from 100 to 200 millimeters is suitable. In this case, mainly corrugated sheeting is used for the roof. The latter is not recommended for installation on the roof of large canopies installed next to the garage. Corrugated sheeting does not allow sunlight to pass through, therefore, during the implementation of this project, a significant part of the site will be shaded.

The metal frame for additional shelter is made of round (diameter 50-150 millimeters) or profile (section 60x60, 80x80, 100x100 millimeters) pipe. When laying roofing, polycarbonate is most often used. This material is easy to work with, bends at a slight angle (suitable for organizing a hemispherical roof) and withstands temperature changes and small mechanical loads.

When constructing a roof, it is highly not recommended to use mineral or ordinary glass. The material is fragile, therefore, with heavy snowfall, it cracks.

After installation, metal and wooden structures should be treated with paint that protects them from moisture.

Construction of a garage 4.5 x 6.5 m with a canopy and attic space (2016)

New Moscow, Zverevo village

Photo of a garage with an attic and a canopy.

The foundation is a monolithic slab.

The walls are reinforced masonry made of expanded clay concrete blocks.

The roof is pitched.

The roof is metal tile.

How to make all the calculations?

The final cost of a carport installed next to a garage depends on the type of materials used and the size of the structure. The cheapest option is considered to be an extension with a pitched roof covered with corrugated sheet metal or polycarbonate.

The dimensions of the future structure must exceed the dimensions of the car:

- in width - by 1 meter;

- in length - 300-800 millimeters on each side.

If the structure is being built to store two cars, the distance between the cars should be 800 millimeters.

Hanging structures consist of the following elements:

- pillars;

- farms;

- sheathing.

The parameters of the pillars are indicated above. When making calculations, you should remember that the supports must be concreted. Each pole is installed at a distance of up to 1.7 meters. If this indicator is exceeded, the reliability of the shelter decreases.

For the lathing, steel pipes with a cross-section of 40x40 millimeters are used. Wooden beams are installed in increments of 25-30 centimeters, metal ones - every 70-80 centimeters.

Taking into account the above parameters, a scheme is developed, on the basis of which an additional shelter is erected. Using this plan, you can pre-calculate the amount of materials required and the total cost.

Construction of a garage with a canopy, 13.0 x 6.0 m (2016)

Ramensky district, Tatarintsevo

Project of a garage with a basement, utility room, attic and canopy, photo report.

The foundation is a monolithic slab.

The walls are reinforced masonry made of foam blocks.

The roof is metal tile.

Project preparation

The construction of a canopy begins with the preparation of the project. It includes a drawing with basic dimensions and a description of the parameters of the future design. The project takes into account optimal operating conditions, coating composition, characteristics of the base and coating.

- Choosing the best winter option.

All the benefits of a carport are fully realized in winter.

When developing a project, the climatic features of the area must be taken into account.

Construction of an extension garage with a canopy 19.5 x 6.7 m (2016)

KP "Pokrovsky", New Riga

Garage with a canopy.

The foundation is a monolithic slab.

The walls are made of aerated concrete blocks.

The roof is metal tile.

Pros of polycarbonate

This building material has many unique qualities that make it almost irreplaceable in many cases. This:

- Sufficient light transmission (transparency), reaching up to 85% (depending on the color and thickness of the sheet);

- It is lightweight, for example, when compared with glass, its weight is about 7-8 times less;

- Good flexibility of the canvas even without preliminary preparatory work;

- Evenly diffuses light;

- Excellent resistance to impacts and damage, the ability to withstand the load of gusts of wind, the severity of snow;

- Good heat and sound insulation properties;

- Special protection protects against chemical or UV exposure;

- Affordable for almost any family;

- Modern aesthetic appearance of buildings;

- Harmless to humans;

- Ability to withstand a wide temperature range - from −50 to +115 degrees;

- A high-quality product with a protective coating will reliably serve its owners for up to 20-25 years.

Its main advantage when building a canopy with your own hands is the ease of installation, even without assistants and in short periods of time.

Bungalow

For exotic lovers, you can use thick hewn branches for the structure; the covering can be made of reed mats or sheaves.

If you do not achieve complete tightness, do not worry, digging is not dangerous for such a structure. But in terms of price, such a structure is super profitable, and the material is easily available.

How to lay out the site

The easiest and most inexpensive way to make a platform under a carport is to fill it with gravel. To do this, you will need to remove the turf, dig the curb, pour crushed stone and compact it well using tamping platforms. Then the platform will be rigid and ruts will not form.

Compacted crushed stone is a good surface for car parking

Recently, areas paved with paving slabs or paving stones have become more popular. They have a more attractive appearance, but their construction is more expensive. Preparation begins the same way: first the soil is removed. But the pit is made about 20-25 cm deep. Crushed stone is poured onto the bottom, which is also compacted well. Then it is advisable to spread a layer of geotextile on the crushed stone. This is a non-woven material that will prevent the sand that will be poured on top from spilling out and mixing with gravel. Geotextiles also redistribute the load more evenly, preventing the base from sagging under the wheels of a car (it is used in road construction). A layer of sand is already poured onto it, which is also compacted. Paving slabs, clinker bricks, cobblestones and other similar materials are laid in the sand.

Paving slabs

In the middle in terms of costs is a concrete site. The base is also prepared from compacted crushed stone. Wooden planks are laid on it at a distance of 1 m, which are set level or with a slight slope to drain water. These strips serve as beacons during pouring, and then play the role of damping joints, compensating for the thermal expansion of concrete. With this structure, cracks appear less frequently.

A metal mesh made of galvanized wire is laid between the slats. You can, of course, use stainless steel, but it is expensive. The thickness of the wire is 3-4 mm, the cell is 10*10 cm. The top is filled with concrete not lower than M 250. The thickness of the concrete layer is 7-10 cm.

Concrete platform under a carport