A channel staircase is a strong and reliable structure, manufactured with one or more flights, straight or helical configuration. Can be installed outside or inside buildings of any purpose - residential, industrial or administrative. With the help of decorative elements made of polymers, wood, metal and glass, the design can be adapted to any interior or façade style.

Metal stairs

The design of a metal staircase has all the necessary safety and durability parameters. That is why they often rely on this type of product. Metal is practically not susceptible to corrosion, it advantageously emphasizes the style of the room and brings rigor and elegance to the design. Looking at the wide variety of metal stairs on offer, you can understand that even a person who has no experience in such incarnations can make them with his own hands.

Drawing with dimensions of a metal staircase

The most important thing is to choose a design that will be feasible to draw, prepare and install in the space of the room or outside it.

Advantages

- Metal stairs leading to the second floor can be created in a wide variety of design solutions.

- They can be painted in a variety of colors, so there is a chance to choose one that perfectly matches the overall picture of the interior.

- The material is not subject to corrosion if properly processed; this allows such structures to be installed in various humidity conditions, as well as in any climatic zones.

- The structure of the product is durable and reliable in terms of safety. The use of metal stringers makes the structure even stronger.

- Stairs can be either simple or intricate.

- Installation of the product is quite simple, so it can be done even by two people.

Mounted metal staircase frame

Flaws

- One of the disadvantages is the bulkiness of the gangway and railings. But thanks to the skills of modern developers, you can easily select a circuit that will best match the load for a particular room.

- Some curves and decorative elements are difficult to implement without special skills.

Based on the priorities and shortcomings of the material and design as a whole, you can bet in favor or against such a decision.

steps

Cladding 40 mm thick from elite “Extra” wood, which is famous for its clean structure without knots. Customers choose one of five types of wood based on their budget and desired wood grain. The steps are dried and glued properly, which means they can withstand loads at any point and last for decades.

Pine

For a summer house, bathhouse, garage Subject to rapid wear Density 500 kg/m3

from 16,405 per meter of lift

Larch

For wet rooms Medium density rock, 570 kg/m3

from 24,650 per meter of lift

Beech

For houses with room humidity and temperature Density 670 kg/m3

from 32,810 per meter of lift

Ash

Premium breed Resistance to impacts, scratches Density 690 kg/m3

from 49,300 per meter of lift

Oak

Premium breed Maximum strength Density 750 kg/m3

from 52,360 per meter of lift

Metal staircase on stringers

It is much easier to make a drawing of a metal staircase if the structure is equipped with the help of stringers. This is due to the fact that you need to calculate the distance for each step and prepare the material that will subsequently be fixed to the base. Stringers are the base (foundation) in the form of a future staircase.

It can be made from different materials and be fixed as required by the room. Of course, to purchase suitable stringers, measurements are still required.

After all, the design must fit the parameters of the space allocated for the stairs. A ladder on metal stringers will help even inexperienced craftsmen complete the installation task.

The main thing is to correctly make drawings of the stairs with a mark of the place where the gangway will be located. And also have on hand the tools and materials necessary to implement this idea in your own home.

Advantages

Design option for a metal staircase

Due to the fact that gangways equipped with stringers have earned their vocation, the positive aspects of this solution are obvious:

- This makes the work process easier;

- Allows you to easily organize the order of actions;

- Such structures are strong and durable;

- Thanks to stringers, even an inexperienced specialist or just a home owner will be able to realize his plans and make them a reality;

- This element allows you to devote more time to details and design experiments that will decorate the staircase project to the second floor.

These are not all the positive aspects of staircases on stringers; each owner of a private house finds his own independent advantages.

Flaws

It is necessary to correctly determine the size of the base for the steps so that the structure fits clearly into the interior. It is not difficult to make such calculations. Simply measure the height, angle and width of the required installation.

Results

The last stage of processing is the primer, which is applied in a dense layer without gaps, in one layer with a spray gun or brush. For proper drying, you need to wait at least a day. Most often, GF No. 21 soil is used for priming, which has a brown and sometimes grayish tint. If you process all the metal of the frame in the correct sequence, you can ensure a long service life and protect yourself from further expenses for another treatment.

How to make a drawing of a metal staircase

Making a drawing of a metal staircase with your own hands is quite simple. To do this, you need to take measurements of the space in which the steps leading to the second floor will be located.

Required materials for measuring

In order to measure space, you should have the following accessories on hand:

- Tape measure with maximum length;

- Surface level meter;

- Chalk or a special felt-tip pen that can be used to make the necessary marks on the wall, floor and ceiling.

This is a minimum set of accessories that will help you carry out the measurement process efficiently and quickly.

Required materials for the drawing

To make the diagram as accurate and correct as possible, you should also prepare a number of stationery items. Namely:

- A sharpened pencil or black marker with a thin tip;

- A sheet of paper or whatman paper;

- Ruler;

- Compass.

You should draw the diagram carefully and carefully so that during the actual installation process you do not make errors that are difficult to correct.

What parameters need to be measured

In order not to make a mistake and correctly make a drawing with your own hands, you will need to make the following measurements:

- The height from the floor to the beginning of the second floor level at the selected angle of inclination.

- Distance from floor to steps. If you plan to install a solid structure, strengthening it on the floor, then this measurement can be omitted.

Diagram with dimensions of a metal staircase - The distance from the highest step, which is parallel to the ceiling, to the ceiling itself. This space must be at least two meters so that a person of any height can climb to the second floor without bending.

- To properly make metal stairs with your own hands, you should determine the width of future steps. They must be at least 25 centimeters.

- The height of the membrane located under the step should also be calculated. Its optimal size is 15 centimeters.

After taking measurements, you can transfer the recorded parameters onto a sheet of paper, forming a diagram of future gangways.

What nuances must be taken into account during the process?

When taking measurements, be sure to pay special attention to the following factors:

- Be sure to measure the height at the required angle;

- It is also worth considering that the height of the future gangway should be at the level of the beginning of the second floor, and not at the level of the ceiling of the first tier of the apartment;

Height and diagram of a metal staircase - When installing metal stairs in your house, you should take into account that these structures weigh quite a lot. Therefore, it is necessary to strengthen the walls before starting work or simply make sure of their strength if the house was built recently.

Installation Features

During installation work, special attention is paid to the accuracy of installation of support beams (stringers), which are often played by channels. To prevent distortion, small metal plates are screwed onto dowels, bolts or screws at the point of contact between the supports. Next, the supports are welded or screwed to them.

After this, the steps are attached to the metal frame. They are pre-assembled using welded or prefabricated technologies in the form of separate structures - corners with shelves. Then they are mounted one by one by welding with the corners down or up - depending on the type of material of the steps. This method is suitable for finishing wood, porcelain stoneware, concrete, corrugated metal and tiles.

What types of metal stairs are there?

The design of staircases in a house can be different, but each of them is worthy and is often chosen by the owners of private country houses. The designs of metal stairs are:

| Screw | Such gangways will help save maximum usable space in the room. The steps will favorably emphasize the sophistication of the design and add a spark to the overall picture of the interior space. The only thing that can stop you is the difficulty of implementing the drawing yourself. Without special skills, a person cannot cope with the measurements required for such a complex structure. And also the direct process of installing stair structures requires some skill and skill. Knowing all the features of a spiral staircase, a person will be able to realize the idea of installing such a structure on a gangway. After the implementation of the plan, the interior will immediately sparkle with new colors. |

| Marching | This option is most often used to implement the idea of installing staircase structures. For such an array it is easy to draw a diagram even for those who have never encountered such a task before. Marching stairs can be straight, leading to the second floor or with turns (this helps to save space). Measuring the parameters required for drawing any of these types of gangways is very simple. It is enough to have the necessary tools and devices at hand. Direct installation of the structure is also elementary. You just need to follow the step-by-step actions that you can read about in any relevant literature. |

| Mounted | There are structures leading to the second floor that are supported on the wall. No supports are installed under such structures. The main load-bearing and load-bearing structure is the wall. Therefore, before proceeding, you should make sure that the walls are strong and ready to withstand such a high load. If yes, then you can safely equip a hanging metal staircase. Such a staircase will help save space and make the style of the room elegant. |

No. 2. Do it yourself or hire specialists?

When assessing your strengths, you must be extremely objective. If you have sufficient experience working with a welding machine, a desire to understand the principles of calculating stairs, as well as a sufficient amount of time and a faithful assistant, then you can try to make a staircase from a channel and a corner with your own hands. If you have to make the first frame in your life, then it is better to give preference to the simplest possible straight staircase, since rotary and screw structures are already at the level of professionals.

If you have even the slightest doubt about your skills, it is better to immediately contact a specialist . But even here, alas, not everything is so simple, since there is a high probability of running into specialists of too broad a profile who do not know all the details concerning the construction of stairs on a metal frame. Ordinary welders are often also unable to cope with the task, since they do not know all the nuances of the ladder business, and as a result, the durable frame they create will be difficult or impossible to cover with wood.

It is best to contact a company that specializes in the manufacture of metal frames for stairs. In the Moscow region, the pioneer in this direction was the “Factory of Staircases on a Metal Frame,” which designs, manufactures and installs staircases from angles, channels and profiles, and also sheaths them at the request of the customer. A responsible attitude to your work allows you to give a 10-year guarantee on the frame. All welding work takes place in the workshop, which saves the customer’s time. The company produces stairs of any complexity, and so that you can be sure of the quality, you can visit the production and see everything with your own eyes.

Regardless of your decision to make the frame yourself or order it from specialists, you need to know the basic principles of calculation and stages of work, because it concerns your home.

What are the advantages of drawings of future structures

By drawing a diagram of the design of the future staircase, a person makes his task easier in the process of installing the gangway.

Metal staircase installation process

This will help:

- Make the installation process fast;

- Do-it-yourself drawings will save money;

- Include imagination in the process of developing a plan for a future structure;

- Make the kind of staircase you dream about, and not according to the templates of manufacturing companies;

- Feel like a real owner of the house;

- Eliminate banal patterns from the walls of your own home;

- Create a design that fits perfectly into the interior.

Therefore, it is worth paying tribute to the issue of independently carrying out drawing work on planning the future staircase.

Building plan development

Plan of the first floor of a house with a staircase in the hall

A staircase is an integral part of any structure whose height is more than one floor. Therefore, first of all, it is necessary to draw up a plan of the staircase on the drawing of the first floor, and determine its elevation on the second floor. This will make it possible to choose the type of structure and its dimensions.

A plan is a horizontal projection of a section of a floor on a plane. It indicates:

- Overall dimensions of the building;

- The location of all rooms on the floor, indicating their internal dimensions;

- Placement of a flight of stairs;

- Places for installing windows and doors, dimensions of openings for them;

- Thickness of load-bearing walls, partitions and columns.

When drawing up a plan for the entire building, certain rules must be followed:

- At the bottom of the plan is the main façade;

- When placing plans of several floors on one sheet, they should be drawn from top to bottom or from left to right, in ascending order of floor numbers;

- The plan indicates the direction of door opening with thin lines;

- The flight of stairs is supplemented by an arrow that indicates its slope from bottom to top: at the bottom of the flight is always the beginning of the arrow.

Terminology

Before making a drawing of a staircase, it is worth getting acquainted with the names of different models and constituent structural elements.

| Stair type | Peculiarities |

| The depiction of stairs in the drawings looks like straight lines. |

| The appearance of this staircase is a circle with a support post in the center. |

| The drawing of a spiral staircase is different from a spiral one. In this case, its dimensions are described by a circle, the internal support of which is located not at the geometric center of the structure, but at some distance from it. |

| The design of a staircase with a turn is distinguished by the presence of two flight sections, between which there are winder steps or intermediate platforms. |

| Such stairs are prefabricated - the drawing includes several identical structural elements. |

| The supporting frame of the structure is steel elements that connect the steps to each other - bolts. |

| Drawings of ready-made firemen's ladders differ from conventional marching structures in size and angles of inclination. They can be vertical, as in the photo. |

In addition to their purpose and appearance, stairs differ in the materials used for their manufacture. It can be:

- Reinforced concrete;

- Metal;

- Tree;

- Glass;

- Natural or artificial stone (read more here);

- Ceramics;

- Some types of plastic.

Structural elements

Before depicting a staircase in a drawing, it is necessary to correctly select its component elements.

These include:

- A flight of stairs is a straight section of a structure;

- The tread is the horizontal surface of the step;

- Riser - a vertical part of the structure that supports the tread;

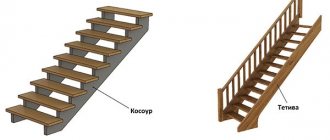

- A stringer is a supporting element on top of which steps are placed. Usually there are two of them in the design, but some products have one element;

- Bowstrings. These are beams that the steps cut into rather than rest on;

- Intermediate platform - a horizontal section located between two flights;

- Winder steps are alternative elements of the platform between flights that have a trapezoidal shape;

- Clearance - the distance from the step to the elements located above the head;

- Middle line. This is a virtual line along which one person ascends or descends. For the screw model, the middle line shifts slightly towards the wider end of the step.

Designation of structures on drawings

When developing a project for a house with stairs, the flight structure is conventionally designated as in the figure. In this case, the circle marks the bottom of the product, and the arrow marks the top.

Designation on the drawings of stairs

In addition to the shape, the drawing also shows the material of manufacture.

For example:

- The tree in cross section is hatched with circular and radial lines, which imitate the annual rings of wood and radial cracks on it. In a longitudinal section, longitudinal lines are drawn imitating texture. If the staircase material does not fall into the cut line, it is not hatched;

- Reinforced concrete stairs in the drawings are depicted in cross-section with irregularly shaped circles between diagonal shading;

- Metal structural parts in sections are hatched with diagonal lines at an angle of 45°. If stairs and their drawings are on a very small scale and the element thickness is less than 2 mm, they have a solid fill.

Metal staircase to the second floor from the street

Metal is a material that can be used in a wide variety of spaces. Therefore, the decision to arrange steps leading to the second floor of the building from the street is quite acceptable.

Advantages

- The material does not deteriorate from the influence of climatic factors.

Fastening by welding metal stringers - When properly treated with special means, it will last for many years without changing its original appearance.

- When installing a stepped structure on the street, you can make some mistakes when measuring the required spaces, and some measurements are completely unnecessary.

- Metal gangways will fit perfectly under any facade of the house. It is enough to simply paint the product in the most appropriate color.

- If you choose an exclusive version of the gangway design, with beautiful curves and unusual lines, you can decorate the view of the house from the street.

Flaws

Inconvenient during the cold season. Steps may become slippery if there is precipitation. But this can be prevented by installing special stops at the edges of the steps.

How to make your work easier

- A drawing of a metal staircase will help to carry out the process of installing the staircase as efficiently and correctly as possible. Therefore, this factor should not be neglected.

Diagram of a modular metal staircase

A correct and well-thought-out diagram will help make each element of the steps practical and elegant. The stepped structure will help to decorate, refine and add fresh solutions to the interior of a private home. - But you can also make the work easier by inviting relatives or friends to participate. Working in pairs or three, the installation process will be completed much faster and with better quality. The main thing is to correctly distribute tasks between assistants.

- You can write step-by-step instructions for yourself in advance so that you can follow them clearly. This will help you not to miss important details, each of which greatly influences the final result of the work.

In order for everything to work out at the highest level, you should not hold yourself back in such zeal. Of course, drawing and installing a metal staircase yourself is not easy. But it is worth challenging such difficulties and winning this relay. When a home-made staircase appears in your home, a feeling of pride will fill you and inspire you to take further actions.

Advantages of metal frames

For houses made of all materials

Suitable for construction in country houses from timber (taking into account shrinkage), aerated concrete, SIP panels, brick, monolith.

Installation at any stage

Possibility of installing the frame and steps in two stages at any stage of construction. Use during “dirty” work without the risk of damaging the cladding.

Silence

No friction between the metal and the steps, unlike solid wood stairs, which will quickly dry out and creak under load.

Withstand loads of 700 kg

The reinforced all-welded assembly gives the structure stability, strength and high load-bearing capacity.

Durability

Immunity to changes in temperature and humidity thanks to multi-stage processing and protective coating.

Plastic covers

What types of stairs are there and which one is better?

PVC overlays are used mainly for landscaping and protecting the edges of steps from damage in interior spaces. PVC overlays are available for sale, both flat and typical - in the shape of corners for steps. An additional property of PVC linings is the improvement of visual aesthetic perception and decoration of the entire interior. They are made of elastic PVC material, which, when heated to 80 degrees, easily takes a given shape, including curved ones.

Corner and flat PVC overlays are very popular in everyday use, as they are wear-resistant, durable and relatively low in price, like aluminum materials.

There may be simple plastic covers, or there may be such beautiful LED panels