A house with an attic made of aerated concrete is an excellent option for high-quality, comfortable, beautiful and efficient housing. Aerated concrete has a number of positive characteristics that make it one of the most popular modern materials for low/high-rise construction. And the design of a house with an attic will allow you to realize any idea and build housing that exactly meets all the requirements and wishes.

The main advantages of houses with an attic:

- Thanks to the complex pattern of the pitched roof, such a structure looks very advantageous and aesthetically pleasing - more interesting than a hip, flat roof. The attic was invented by François Mansart during the time of Louis XIV - he decided to arrange such housing in attics for representatives of the poor. And today in Europe you can see a lot of similar projects.

- Reduced construction costs - an attic requires less investment compared to a full floor. After all, the roof slopes act as the ceiling and walls.

- Wide choice of projects and layouts - thanks to the unconventional geometry of floors and walls, you can find the most unusual options and designs: the attic can be made into a single space or divided into rooms.

Video description

^Today we will discuss how to build an inexpensive house from aerated concrete.

How much does a turnkey aerated concrete house cost in the following video: The construction market presents projects made from all possible materials, from brick and natural stone, to hand-built houses and structures made from SIP panels. Among this variety, the leaders in popularity are projects of aerated concrete houses with an attic, which can be made in any architectural style: classic, modern, minimalist or hi-tech.

Composition of aerated concrete Source ams78.ru

The popularity is largely explained by the qualities of aerated concrete - an artificial stone that contains quartz sand, water, cement, lime and gas-forming additives. This mixture produces a building material with a porous structure characteristic of all cellular concrete. The volume of aerated concrete is evenly filled with air cavities, but not completely isolated, as in foam concrete, but communicating with each other. This porous structure determines all the wonderful qualities of aerated concrete blocks.

Start of the construction process

What you will need for construction: a wheelbarrow and a concrete mixer, a shovel and a level, self-tapping screws and a screwdriver, a tape measure and a plumb line, a marker and a pencil, a trowel and a spatula, lacing and a construction knife, a stapler and staples for it, a chainsaw or a hacksaw.

Before construction, it is important to prepare the site - remove debris and vegetation, mark the area. First, the location of the future building on the site is determined, everything is marked out, and the volumes of materials are calculated. It is advisable to purchase all materials in advance and put them in a specially designated place.

House made of aerated concrete: the advantage of choice

The value of aerated concrete lies in the fact that it is an inexpensive, accessible material with an impressive set of positive qualities. Builders know the following advantages of aerated concrete blocks:

- Form . Aerated concrete blocks have ideal geometry. This allows you to create a structure of any shape and style; The masonry turns out beautiful and even.

- Weight . The light weight of the blocks makes them easier to transport. Relatively light walls place minimal load on the foundation.

Fast construction - the advantage of aerated concrete blocks Source dnepr-remont.com.ua

- Economical . Construction is made cheaper not only due to the low cost of the material (one of the cheapest). The budget is reduced due to thin masonry seams (1-3 mm thick seams mean little consumption of thin-layer adhesive composition) and the lightness of the blocks (construction equipment is not used, labor costs are reduced).

- Simple processing . Aerated concrete blocks are easy to use; They are easy to cut and sand.

- Fast and easy installation . A house made of aerated concrete blocks is built much faster than a similar structure made of brick or timber. The construction of walls is accelerated due to the porous structure of the material, which provides a combination of large volume and relatively low weight.

Houses made of aerated concrete receive the following valuable advantages:

- Price . A house made of aerated concrete will cost less than a similar building made of brick or timber.

- Thermal efficiency . The cellular structure of aerated concrete maintains good thermal insulation, reducing heating costs in winter (and air conditioning in summer). The ability to retain heat makes it possible to build external walls without additional insulation.

Attic with decorative balcony Source juliz.pl

See also: Catalog of companies that specialize in the construction of houses from aerated concrete blocks.

- Vapor permeability . A valuable property of aerated concrete that maintains an optimal microclimate in residential premises. Water vapor escapes freely; the main thing is that the wall decoration also consists of vapor-permeable materials.

- Environmental friendliness . The material is produced in a factory with quality control at every stage of work. It contains natural raw materials that are safe for health and the environment.

- Fire safety . The blocks are made from inorganic raw materials and are non-combustible materials. Aerated concrete walls can withstand open flames for a long time (2-4 hours).

- Performance characteristics . Aerated concrete walls have good sound insulation (comparable to the characteristics of a brick wall), frost resistance and strength, which does not decrease over time.

- Design possibilities . Aerated concrete goes well with any natural or artificial materials - wood, stone, glass, iron.

Cottage with a small terrace Source yandex.ru

See also: Catalog of house projects made from aerated concrete blocks.

Despite the impressive list of advantages, the material also has weaknesses. The construction market offers aerated concrete of various grades, differing in density and intended for different types of construction work. Density affects other characteristics: the higher it is, the better the parameters of strength, heat and sound insulation. Grades with a minimum density are lighter in weight, but have low compressive strength and are less resistant to damage.

House with an attic

Projects of country houses with an attic are an attractive alternative to a two-story building. In order for the future house to be durable and perform all its inherent functions, the attic structure needs competent calculation, and the construction should be entrusted to experienced specialists. A building made of aerated concrete with an attic, erected taking into account the characteristics of the material, has the following characteristics:

- Appearance . The presence of additional living space under the high roof makes the building proportional. Full-fledged two-story cottages most often look bulky (unless vertical elements are deliberately used in the architecture or facade decoration).

Phased construction

Before starting the construction of a house with an attic floor made of aerated concrete, it is necessary to study all stages of the work.

Foundation

A complex foundation is not needed here - a depth of a maximum of 1.5 meters and a width of at least 40 centimeters is sufficient. It is best to choose a monolithic strip type of base.

How to make a foundation:

- Dig a trench of appropriate size under it.

- Fill the bottom of the hole with sand in a layer of 20 centimeters and crushed stone in a layer of 15 centimeters, compact everything well.

- Make a reinforcing frame.

- Pour the foundation with concrete.

- Wait about 20-28 days until the concrete solution hardens and gains strength.

Afterwards, a ground floor is built from brick or rubble, and then a building is erected from aerated concrete.

Walls

After the base of the house is ready and the masonry has hardened, they begin to build the walls. The quality of the masonry depends on how smooth the base was made; if necessary, it is leveled with a thin cement screed. The laying of aerated concrete walls is carried out using a special glue, according to a standard staggered pattern.

If concrete mortar is used for masonry, then the walls inside should be lined with foam plastic boards, and the seams should be sealed with polyurethane foam, which will improve the thermal insulation characteristics and avoid cold bridges.

Attic

An attic is most often made of wood, although different materials are suitable for construction.

How to build an attic:

- You need to insert wooden blocks into the ceiling ceilings and mount rafters to them.

- The attic frame is usually made of wood (beams), and logs are placed on them for strapping, which will become the base for the entire box.

- The frame for future walls is attached to the beams, it is sheathed with two layers of boards (placing them in a checkerboard pattern).

- The triangular voids that appear as a result of the construction of the attic can act as part of the interior or be covered with finishing materials.

- Insulation inside and outside the attic walls is carried out using mineral wool.

Roof

The roofs of such houses are usually made of corrugated sheets, slate, and ceramic tiles. If corrugated sheeting is selected (it must be coated with anti-corrosion paint), then the remaining parts (ridge, valley, cornices) must be selected from metal.

Corrugated sheeting is installed quickly and easily - start from the bottom to make the correct overlap of the pieces of material. Each sheet is fastened with screws in 9 places - with a head for a hexagonal nozzle and a silicone gasket. If the roof slope is steep, then the work will be more difficult to complete - then you will definitely need a mounting belt.

Final Moments

After the main elements are completed, they begin covering the entire surface of the attic - it is best to choose plasterboard. First, a vapor barrier material is laid, then plasterboard sheets are mounted with screws to the surface.

Ventilation holes must be installed on the back and front walls of the attic - they will provide a favorable indoor microclimate and an optimal level of humidity.

Interior finishing begins only after all roof installation work has been completed. MDF panels are best suited for this purpose; they look good and are easy to install, maintain and use. The ceiling is made one/two-level using plasterboard.

A house with an attic made of aerated concrete can be found today both in Moscow and in the regions. Such housing is becoming increasingly popular due to the many advantages, accessibility and comfort of living. If you carry out the calculations correctly and follow the construction technology, you can get a strong, reliable, durable and beautiful house in a short time at a reasonable cost.

Video description

About the 8x10 project with an attic in the following video:

- Design features . A house with an attic is suitable for any plot of land and will fit into any landscape environment. If you have chosen a similar project, keep in mind that the usable area of the attic is somewhat smaller than the area of the first or full second floor. The size of the usable area depends on the proportions of the roof and the angle of inclination of the slopes.

- Savings during construction . The living area increases due to the non-residential attic space, the length of the foundation (one of the most resource-intensive construction items) is reduced. Material costs are reduced.

- Savings during operation . Heat loss through the roof and walls of attic spaces is reduced (compared to a cold attic).

- Design possibilities . The unusual ceiling and walls of the attic are simply designed to create an exclusive interior. Any room will acquire a cozy and original look - from the bedroom and nursery, to the office and bathroom.

In a modern style Source eplan.house

A house with an attic is not without some disadvantages:

- Heating and thermal insulation . The main problem is that if you are arranging full-fledged living quarters, the attic must be properly insulated and, in winter, heated.

- Network engineering . You cannot do without well-designed water supply and sewerage systems, heating systems, ventilation and electricity, the supply of which to the second floor can be costly.

- Difficulties in interior design . Difficulties can arise from blind spots that you can't get close to without bending over, and walls that you can't hang anything on. Most regular furniture won't fit into the space, and the closet will likely have to be custom-made.

- Difficulty of operation . The prospect of using stairs every day is not always suitable for older people, and for young children it carries the risk of injury.

About the aerated concrete cottage project

Construction companies offer a variety of house designs with the possibility of construction, including a house design with an 8x10 attic made of aerated concrete. Many of the proposed one- or two-story designs can be converted into a home with a loft, which will require minor adjustments. Changes in documentation are carried out for a small surcharge or without it (if you also order construction). If no project suits you (you don’t like it or won’t fit into a site with a complex shape), you have the option of ordering a project “from scratch.” In this case you receive the following services:

- Completely individual design , taking into account the wishes of the customer and the features of the terrain.

- Development of drawings and calculations in accordance with the selected construction material - aerated concrete, which can be combined with wood or stone.

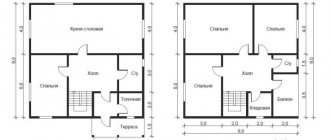

Layout of the 1st floor and attic Source drevolog.ru

Design Features

Due to the need for additional finishing, foam blocks are rarely used for the construction of small summer houses; the main purpose of the material is houses for year-round use. The only limitation is the height of the building, which should not exceed three floors. It is possible to increase the height of a building only if stronger material is used for load-bearing walls. Foam block can be used to build warehouses, summer kitchens, hangars, garages and outbuildings.

Designing a house is not a child’s drawing; you need to calculate every single corner of your future home Source yurlkink.ru

Layout of a cottage made of aerated concrete blocks

Projects for an 8 x 10 aerated concrete house with an attic, offered to future owners, are varied in their design, but equally comfortable and functional. Aerated concrete walls provide structural strength and resistance of the building to natural influences, and reliably preserve the microclimate of residential premises. The layout of attic dwellings differs from project to project and is often influenced by the architectural style of the house. The layout may look like this:

- Classic . Intuitive and therefore the most common option. On the ground floor there is a living room, kitchen, hallway, bathroom, hall in front of the stairs; the attic is given over to personal apartments.

Roof

Many projects of gas-block houses involve the use of ceramic tiles or corrugated sheets as roofing. The use of slate, which was popular in past decades, is not recommended for residential premises.

An example of a cottage roof with a tiled attic

The most budget-friendly option among modern proposals can be called corrugated sheets made of galvanized sheets painted with protective paint. When choosing this roofing material, you need to pay attention to the fact that roofing elements such as eaves, ridge and valley must also be made of metal.