There is an opinion that outdoor construction work, including the installation of a fence, must be completed before the onset of cold weather. To the question: “Is it possible to install a fence in winter?” – the majority of ordinary people will answer negatively. Indeed, it is more comfortable to do construction work in the warm season. But the need to install fencing arises regardless of the time of year or the comfort of performing the work. The question of the feasibility of winter installation depends on the type of fencing and the type of foundation. You will find all the answers to questions that arise during the winter installation of fencing in this material.

Problems with installing a fence in winter

The main problems of installing a fence in winter that most craftsmen encounter are the following:

- preliminary clearing of the area from snow is required;

- inconvenient to work in cold conditions;

- the soil freezes;

- At sub-zero temperatures, the properties of concrete change.

Figure No. 2. When installing fences in winter, builders face a number of difficulties, including cold and wind.

The last point deserves special attention. Is it possible to install a fence in winter if the setting of the cement mortar slows down at a temperature of +5 ºС, and stops completely at zero? To solve this problem, chemical antifreeze compounds have been invented.

Note! Prepare a “winter” solution using water saturated with a catalyst. Only after this the remaining ingredients are added to the mixture. Since the substance hardens quickly, we recommend mixing it in small portions as needed.

Disadvantages of performing work in winter

Before starting work, you need to assess its feasibility. Construction at temperatures below +5°C is a difficult task. Most materials are not recommended for use in colder weather. This is especially true for concrete and cement mortars.

Speaking of disadvantages, it is worth mentioning the inconvenience. A person will need warm clothing that restricts movement. In this case, all processes will be performed much slower than in the warm season.

The second disadvantage is the complexity of soil development. Frozen soil is difficult to dig. Work slows down and labor costs increase. In this case, special equipment or additional measures may be required.

When working with concrete, we must not forget about its hardening. The material gains brand strength (the one indicated in the brand) in 28 days at an average temperature of 20°C. At temperatures below +5°C, strength development practically stops. At the same time, the properties of concrete change, which leads to the formation of cracks and premature destruction.

Fences are installed in the winter months only if there is an urgent need. In other cases, it is better to postpone the issue until spring, since the most important disadvantages of the design will be its cost and quality.

Pros of installing a fence in winter

Erecting fences in winter is in some ways convenient. Many land owners do not know whether they install fences in winter, and therefore often postpone construction until spring.

Figure No. 3. Installing a fence in winter is a great New Year gift

In the period from November to March, workers, special equipment and tools are released. You don't have to wait in line at the company. Prices for building materials and freight are falling.

What is better - to build it yourself or order a turnkey fence in winter?

You should order turnkey fencing in winter if confidence in the quality of the constructed structure is important to you. In addition, it is worth considering how labor-intensive the process is of digging a large number of holes, up to one and a half meters deep, without special equipment.

If you don’t want to waste your time and energy, enter into an agreement with the Monolith-Fence company. The craftsmen will deliver the parts of the future fencing within the specified period and install them on the site using professional equipment. All you have to do is accept the finished project.

Ways to install poles in winter

Standard methods of installing poles in winter with a depth of 1.2 m and sprinkling with ordinary soil are not suitable. This technology risks causing the fence to tilt when the soil thaws.

For this reason, three main installation methods are chosen for the winter months:

- concreting pillars (with drilling holes to a depth below the soil freezing level);

- butting;

- introduction of screw piles into the ground.

All three options guarantee the stability of the structures. However, it is the butting of pillars that is the cheapest. Learn more about each technology.

Driving piles

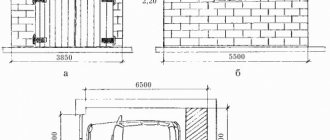

Scheme No. 1. The principle of screwing in piles

The construction of such a fence involves the introduction of screw piles into the soil. The latter are pipes with screw-shaped sections in the base area. The presence of a screw allows the pile to enter the most dense (including frozen) soil. After installation, the internal cavity of the pipe is filled with concrete mortar.

Concreting

It involves drilling a hole to a depth exceeding the frozen area of the soil, into which cement mortar with reinforcing additives is then poured.

Butting

Butting a fence is one of the most common “winter” methods. In this case, the soil removed from the pit is replaced with material that does not freeze at sub-zero temperatures. This technology is cheap and reliable.

Butting method

Butting is the most convenient and cost-effective way to attach fence posts using materials that are not subject to freezing. The bottling technology is not at all complicated and is quite accessible for independent implementation:

- removal of snow mass along the perimeter of the fence construction area;

- marking the territory and designating places for installing support pillars;

- drilling a hole with a diameter of no more than 20 cm to a depth of one and a half meters;

- thorough removal of soil from drilled holes;

- filling the holes with a sand cushion no more than 10-15 cm high;

- installing a metal profile or concrete fence post on a sand cushion and leveling it in a vertical position using a plumb level;

- filling into the free space between the support pillar and the walls of the hole the so-called rubble, represented by fine crushed stone and medium-fraction gravel.

Butting with crushed stone

It is necessary to fill the rubble stone in parts, tamping each layer very carefully. At all stages of butting, it is extremely important to control the vertical position of all fixed posts.

As practice shows, if the technology of rubble backfilling during the winter construction of a fence was followed in full, then in the spring there is no movement of the support pillars at all, and the durability and quality of the fence are beyond doubt.

Construction of a fence in winter in stages

The construction of a fence in winter using the butting method takes place in 6 stages.

- Stage 1. Cleaning the area. Using snow removal equipment or a shovel, clear the area of snow.

- Stage 2. Marking the site. Mark the territory using pegs. A cord is pulled between the pegs (it indicates the perimeter of the fence). The standard distance between supports is 2.5 m.

- Stage 3. Drilling holes for pillars. In the areas marked with pegs, holes are drilled 20–30 cm below the soil freezing level. The standard pit depth is 130–150 cm. Special equipment and motorized drills are used for drilling.

Scheme No. 2. Butting supports for installing a fence in winter

- Stage 4. Installation of pillars. Then 10 cm of sand is poured into the drilled hole. Install the pipe and fill it with the first batch of crushed stone and gravel (approximately 50 cm). Level the support and compact the crushed stone. Then another portion of rubble is poured in and compacted. And so on until the hole is filled to the top.

- Stage 5. Installation of logs. Horizontal crossbars are attached to the posts (2-3 spans per fence of standard height).

- Stage 6. Installation of spans. Sheets of corrugated sheets are attached to the joists using self-tapping screws. Plugs are installed on the poles to protect the pipe.

Problems and their solutions

Building a fence in frosty conditions is often fraught with difficulties. When solving problems, you should carefully study ways to optimize the process:

- The correct method of installing supports reduces the risk of subsequent deformation of the structure.

- The use of anti-frost additives that improve the polymerization of mortars makes concreting easier.

- When the ground freezes, it is advisable to use a motor drill.

Building a fence in winter is a troublesome task. To save money, time and health, it is better to turn to specialists.

Installing fence posts in winter

In this paragraph we will talk in more detail about the installation of vertical supports through concreting and butting. We briefly touched on this point in paragraphs 3 and 4 of the previous section.

Butting of pillars

A hole with a diameter of 20 cm and a depth of up to 150 cm is drilled in the ground. The soil is thrown away and sand is filled in instead. A support (profiled metal pipe or concrete pile) is placed on a prepared 10–15 cm cushion, controlling the vertical with a plumb line.

Rubble (crushed stone or fine gravel - up to 20 mm) is poured between the soil and the post. The hole is filled in parts, compacting each layer. Butting is good because the backfill does not freeze and does not move in the spring when the soil begins to thaw.

Concreting of foundations

Concreting a fence in winter is convenient because the supports installed in cement mortar can withstand heavy loads and do not change the configuration. The main difficulty of the technology is preliminary drilling of a hole to a depth of 1.2 m.

Figure No. 4. Spot concreting of fence posts

Note! The distance between the pits (and, accordingly, between the supports) should be no more than 2.5–3 meters. Otherwise, the pillars may not withstand the load.

Then reinforcement frames are placed on four sides of the support. They give concrete flexural and tensile strength. This point is especially important for regions with heaving soils. After reinforcing the base, concrete mortar is poured.

Use of antifreeze additives for concrete

Pouring the foundation in winter is achieved using simple but relatively costly methods. Warming up the concrete solution during hardening is a complex process, especially if the fence being installed has many support pillars. This method involves large monetary and energy costs.

The method of increasing the frost resistance of casting compositions through special additives becomes more economical and convenient. Hardening of the concrete solution at sub-zero temperatures is ensured by anti-frost additives. Their proportions:

- to -5°C – 5-6% of the total amount of the mixture;

- -5-10°C – 6-8%;

- below -15°C – 8-10%.

There are 5 types of antifreeze additives:

- Plasticizers. This group includes naphthalene and melamine resin sulfates, organic polymer acrylates. Such components not only make the solutions waterproof and frost-resistant, but also ensure the mobility of concrete mixtures, and this facilitates the construction process. A mixture with such additives fills any form and is used for different types of concrete. Plasticizers, by absorbing water vapor from the air, make it possible to reduce the volume of added liquid when making concrete. They prevent delamination and cracking. In addition, plasticizing additives increase the strength of concrete by 25%.

- Strengthening additives. These include calcium chloride, calcium nitrate, aluminum and iron sulfates. Due to them, the concrete mixture hardens faster and becomes stronger. They are used in the first 3 days of hardening - it is at this time that they demonstrate maximum effectiveness.

- Corrosion resistant additives. Protect reinforced concrete fences from oxidation and low temperatures. Thanks to the properties of these components, the service life of concrete increases and the material becomes resistant to aggressive substances.

- Mobility regulators - such additives extend the time of use of the prepared solution if long-term concreting is expected or if the composition needs to be transported over long distances.

- Frost-resistant - they reduce the crystallization temperature of water, as well as the setting speed, without affecting the formation of concrete.

There are also combined supplements containing two or more components. They improve several properties of concrete at once. For example, they make it waterproof, more durable, frost-resistant, durable, and also protect against mold formation.

Due to such additives, concrete can be worked at temperatures down to -20°C, its strength increases without additional heat treatment, and the final strength characteristics of the material increase by at least 10%. In addition, they improve the adhesion of concrete to reinforcement and metal elements.

How to build a fence in winter with your own hands?

The first thing you should decide on is how to install the support structures. If you prefer concreting to buttings and piles, the following tips for preparing frost-resistant cement mortar will help you.

To fill the foundation for a fence in winter, add special additives to the mixture: potash, sodium or calcium nitrate in the following proportions:

- at temperatures down to -5 ºС - 5-6%;

- up to -10 ºС - 6-8%;

- up to -15 ºС - 8-10%.

If the thermometer drops below -15 ºС, sodium nitrate is not used, and the potash concentration is adjusted to 12–15%.

Note! You can increase the antifreeze properties of the additive if you add a catalyst for concrete hardening (sodium formate, acetylacetone) to the mixture. There are also ready-made plasticizers: hydroconcrete S-3M-15, lignopan, betonsan, sementol.

Another good way to improve the characteristics of a solution is to create a thermos effect. To do this, heat-insulating material (foam plastic, mineral wool) is laid on concrete bases and covered with plastic film on top to protect it from water.

Pouring concrete

The following technologies are used for concrete work in cold weather:

- Isolation of the structure from the environment (creation of a “thermos”). To do this, the solution is poured into warm formwork and additionally covered on top. A mixture with a temperature of +15 to +30 ° C is used, strength is gained due to the initial heat content. To speed up the process, additives are introduced into the concrete, and it is also provided for its short-term heating at the initial stage to a temperature of 60-80°, followed by compaction in this state.

- Electric heating of the mixture laid in the formwork to permissible temperatures (not higher than +30°C). The process is not stopped until the structure reaches the required strength.

- Antifreeze additives and hardening accelerators. Such substances make it possible to reduce the freezing temperature of concrete to -20°C during the construction of a fence (for the construction of more critical structures, the maximum value will be -15°C).

In winter, the concrete mixture is prepared in heated rooms independently or ordered from factories. During storage, all components must be protected from snow and cold; outdoor storage is not allowed.

- Fences

Tools needed for winter fence installation

Figure No. 5. A motor drill is one of the necessary tools when installing a fence.

You will need the following tools for winter installation:

- welding machine for welding crossbars;

- motorized drill for drilling holes and/or shovel;

- sledgehammer;

- level/plumb for adjusting the position of the posts;

- tape measure, rope and pegs for marking the area.

Required tools and materials

In winter, fences are built with lightweight structures suitable for installation in the cold season:

- temporary shield fences;

- fences using metal mesh, lattice;

- forged structures;

- stacked panel fences.

The option with the least subsequent deformation is a fence made of corrugated sheets; in winter, its installation does not cause difficulties or excessive material costs.

To install the fencing structure, it is necessary to prepare equipment and materials in advance:

- metal welding machine;

- power tools – drill, grinder;

- hand tools – hammer, sledgehammer, tape measure, shovel, pliers, level;

- motor drill

Advantages and disadvantages of winter installation

To answer the question - do they put up fences in winter - it is worth familiarizing yourself with the positive and negative aspects of carrying out construction work in winter.

The advantages of installing a fence in winter include:

- decreased demand for construction work in winter allows you to avoid waiting for the necessary equipment and construction crew to become available;

- seasonal reduction in the cost of building materials reduces the cost of building a fence;

- the risk of damaging plants growing in flower beds and beds in spring and autumn disappears;

- It is easier to transport construction and bulk materials on frozen ground;

- availability of seasonal discounts and promotional offers in companies specializing in the manufacture and installation of fences.

In pursuit of saving money, do not forget that installing a fence in winter is associated with additional difficulties.

In addition to the need to wear warm, bulky clothes, there are a number of disadvantages of winter installation of a different nature:

- freezing of the upper layers of the soil complicates the process of drilling holes for installing support pillars;

- at low temperatures, water freezes, which affects the quality of concrete polymerization;

- the need to use expensive additives against freezing of concrete mortar;

- difficult weather conditions with snow make it difficult to install a fence;

- the need to attract special equipment to develop frozen soil for construction;

- difficulties in compacting the space around the supports with frozen soil;

- the impossibility of using a strip foundation or the method of driving in pillars;

- short daylight hours prolong the work period.

Before installing a fence in winter, you should not only weigh the pros and cons, but also choose the right method for constructing the foundation and installing the main structures.

What problems might you encounter?

There are several main problems that even experts face:

- the need to clear the area of snow;

- it is inconvenient to carry out work in winter;

- the top layer of soil is frozen;

- changes in the properties of concrete at low temperatures (but concrete is rarely used when installing pillars).

It is especially worth paying attention to the last point. Is it possible to install a fence in winter, given that at temperatures above +5C the setting of the solution slows down greatly? In this case, special chemical compositions are used that allow working with cement in any weather.

Erecting a fence in the spring

The main problem with spring construction may be the high groundwater level. At the same time, you can even install a fence “deep in water.” Typically, the soil, saturated with water and loosened after winter heaving, is soft enough, so driving a steel pipe to the required depth is possible without drilling a pit. You should only take into account the aggressiveness of the soil and choose the right material for the support or its anti-corrosion coating.