Not so long ago, three-phase input to a consumer’s facility was considered the prerogative of industrial enterprises. Although, if you look in detail at the energy supply diagrams of apartment buildings, it turns out that residents receive the coveted 220 volts from the three-phase power supply panel. Surely, many of you have noticed that in the event of an accident on an electrical main, power may not be lost in the entire house at once, but as if in a checkerboard pattern. At the same time, in conversations among repairmen the phrase is heard: “the second phase has been knocked out...”.

This means that consumers in a high-rise building are distributed into three groups (usually with an even load). A three-phase power cable (four-core, excluding a separate working grounding bus) with a common meter and a single machine was installed at the facility. The output has 3 lines with a voltage of 380 volts between them, and a working zero. Next, in each of the three directions, a two-core power wire is laid (without taking into account the working grounding), on which the usual 220 volts are between phase and zero.

Since consumers in their apartment distribution panels have access to only one phase, such a power supply still does not apply to three-phase.

However, there are residential buildings (including apartment buildings) in which the entrance panel looks the same as in the previous illustration. For example, houses that do not have natural gas. Three-phase electric stoves are often installed in apartments. Three phases may be needed in rooms with an electric water heater or heating boiler. Such electrical equipment can also use three phases with a voltage of 380 volts.

How everything works

Anyone with basic skills can now connect an outlet from a switch.

We will try to talk in detail about all the problems that may arise in such situations. An electrical outlet should under no circumstances become a source of all sorts of dangerous situations. This is especially true for houses and apartments where there are many energy-intensive appliances. Here you will have to seriously understand the entire structure. You must become familiar with the entire switchgear.

The socket is equipped with decorative elements that are secured with screws. There is also a sub-socket and block on which the frame, grounding, front panel, protection curtains, phase, protective mechanism and housing are located. Don't forget about the fastening tabs, contacts and terminals.

We connect a three-phase 380 volt outlet ourselves

Often in manufacturing plants, during construction or in offices, powerful electrical appliances are used that require three-phase power supply at 380 V. And if connecting a regular outlet to a single-phase power supply is quite simple, then connecting a three-phase connector has its own nuances, since a four- or five-core cable (with grounding)

Therefore, in order for the connection to be safe and not lead to failure of electrical equipment, it is important to connect all conductors correctly and not confuse phase and neutral

What sockets are used when connecting 380 volt electrical appliances

In our country, two types of sockets are mainly used: PC32 and 115 (125) 3P+PE+N, as well as their foreign analogues:

- PC32 type connectors are used exclusively for non-movable electrical appliances, such as electric stoves, stationary water heaters, machine tools, etc.

- Sockets 115 (125) 3P+PE+N are suitable where mobile electrical equipment is used, for example in workshops or at construction sites. In this case, the devices are connected to the network using a flexible copper cable. This type of connector can also be used to power stationary devices.

It is advisable to install imported sockets if the design of the room requires it, or if the plug on the power cord of the electrical appliance has the appropriate configuration.

Note! When choosing an outlet, you need to take into account the amount of current for which it is designed. This value must be no less than the current consumed by the electrical equipment used

General connection provisions for all types of three-phase sockets

When installing a three-phase outlet, you must:

- Turn off the power supply and check the absence of voltage using an indicator screwdriver or tester.

- In random order, connect three phase conductors A, B and C to the contacts with markers L1, L2, L3. The location of the phases is unimportant, since only the direction of rotation of the connected electric motor depends on it. If the rotor rotates in the wrong direction, then it is enough to rearrange any two phase wires at the terminals of the electromagnetic starter of the device or in the machine.

- Connect the zero to the contact marked N.

- Connect the protective ground wire coming from the ground loop to the contact with the PE (ground) marker.

In the case when a four-pin socket is used to connect stationary electrical equipment, the device is grounded by a conductor not connected to the plug connector. The grounding stranded copper cable is connected directly to the metal body of the device under a bolt in a place marked accordingly. The wire cross-section should be the same or larger than that of the power cable.

Connecting a PC32 type socket

The process of connecting connectors of this type does not differ from the algorithm described above. Three phase conductors are connected to contacts L1, L2, L3. Zero is connected to terminal N, and the grounding conductor is connected to terminal PE.

Connecting a socket type 115 (125) 3P+PE+N

To avoid confusion, it is better to start connecting this outlet with grounding. The corresponding contact is located at the bottom, next to the guide groove, thanks to which the plug will always be oriented correctly when inserted into the connector.

The neutral terminal N is located to the right of the PE contact. The core of the working zero is connected to it. The remaining three terminals (L1, L2, L3) are connected to the phase conductors in random order.

As you can see, connecting a three-phase outlet is not so difficult and is accessible to anyone with technical skills.

Types of three-phase sockets

Unlike single-phase, 3-phase sockets differ not only in the degree of protection and installation method.

- Protection can be from electric shock, as well as from dust and moisture. The IP** system determines how well the housing withstands the external environment. The first digit (dust) can be from 0 to 6, the second digit (moisture, water) from 0 to 9. That is, the IP-69 marking means the outlet is completely sealed.

- The number of connectors is determined by the method of connecting the consumer. A star circuit requires a minimum of 5 sockets. Three phases, working zero and protective grounding.

This is the most common scheme. The connector configuration has several standards set by the manufacturer. Sockets of this type must be purchased in pairs with a plug. Sockets and plugs of different brands may not fit together. This is what the five-pin kit from Legrand looks like:

When connecting according to the "triangle" scheme, a working zero is not needed. The socket will have 4 contacts: three phase and protective ground. The socket might look like this:or like this:

In addition, there are high-quality kits made according to GOST USSR, with in-line connectors.

Theoretically, such sockets can also operate in a star configuration, if the protective grounding is carried out along a separate line, bypassing the socket. But this is unsafe: there is no certainty that the ground is connected correctly.

The safest connection for a three-phase socket is 7 pins. This is an option for a star circuit, but each phase has its own protective ground. This method is gaining popularity in the European Union, but practical application for three-phase electrical installations is questionable.

- There are three main modifications according to the installation method:

- Three-phase socket for hidden installation. The mounting box is firmly mounted into the wall, the socket is installed flush.

Not to be confused with the concept of “triple socket for hidden installation”, in this case we are talking about a set of 3 single-phase sockets in one housing. - Overhead socket. Not the most convenient option for home installation: too bulky.

- For outdoor installation. Such kits usually have protection no lower than IP-67.

Connection type

How to properly connect the outlet(s), based on the number and characteristics of electrical appliances that will be connected to them? First you need to select the connection type. There are two of them:

- "loop", or serial connection;

- "star" or parallel connection.

“Loop” - connecting each subsequent outlet actually from the previous one. This applies to zero, phase and grounding. In this way it is convenient to assemble up to five or more sockets in one row, vertical or horizontal. The disadvantage is that it is not recommended to connect powerful equipment to such outlets.

“Star” - with this socket connection scheme, it is connected directly to the distribution box. It is done like this:

- Using special caps, regular electrical tape or other devices, the required number of wires leading to the sockets is connected to the power wire in the distribution box;

- Each outlet receives its own wires from the distribution box, which allows you to connect devices with high power consumption without risk to the outlet itself;

- To make such a connection, you should choose wires that are smaller in cross-section and capabilities than the wire connected to the junction box. For example, if a 25A cable with a cross section of 2.5 sq.m. is supplied to the box. mm, you can connect 16A wires with a cross section of 1.5 square meters to it. mm.

How to connect two sockets to one wire

The double socket is considered quite popular. In a single housing you will be able to see two electrical connection points. They are intended for power supply from one working group of phase, zero and ground. Sometimes many electricians may have significant wiring questions. The double socket connection diagram will help you complete this process efficiently.

We are confident that thanks to this diagram, readers of the All-Electricity website will be able to perform the correct connection process. Also in this article you can see a simple diagram for connecting a double socket with and without grounding.

Double socket connection diagram

Now you need to study the connection diagram. In the photo you can see the optimal and important connection diagram for a double socket.

As you can see, everything is quite simple. During connection, you need to connect the wires correctly. Grounding should be connected in the central terminal, zero should be connected to the right, and phase should be connected to the left. While making connections, you also need to know that the ground is connected in the center and the other two wires can be swapped. The connection diagram for a double socket without grounding looks exactly the same, only there will be no PE wire here. If you are interested, then you can read about the wiring diagram in the garage.

Connection diagrams

Even a novice master will not face any special difficulties, everything is very clear, but it is better to consider the features of each option.

Single-phase network without grounding

The diagram is indicated by numbers:

1 - general machine;

2 - the one that turns off the phase on a specific line;

3 - zero bus;

4 - distribution boxes, separate for each outlet;

5 - cables.

Any electrical specialist knows that the phase should be located on the left, but owners often break this rule. If there are problems in the electrical network, they create additional difficulties for themselves when diagnosing, as well as in the case of self-repair.

Single-phase network, but with grounding

In this case, only one element is added, number 6, this is the main grounding bus for the protective conductor (PE). It is indicated in green.

There is another option, used for outbuildings if they have open wiring. In this case, the grounding runs along the floor - along the perimeter of the walls, and a separate wire leads to the sockets below. There are no other differences in the eyeliner.

Mixed connection and grounding in series connection

If you decide to use a series connection of sockets, you can strengthen the overall design by using a mixed method. The essence of the method is as follows:

- A central cable is connected to the distribution box from the common panel board.

- In the preliminary wiring plan, the most distant point of access to power is selected.

- The selected outlet is connected from the distribution box cable.

- The rest are powered from this device.

This method increases the reliability of the network. If an outlet fails, the others continue to work. Disabling the entire system is possible only in the event of a malfunction of the main cable, twisted in the junction box.

Grounding is a must. With a serial connection, if a wire burns out at one point, the rest are left without protection. The optimal way to connect sockets to each other for grounding is mixed. The main cable is fixed under the ceiling, then branches are made for each access point.

This technique has disadvantages - the large length of the wires used, the need to install several junction boxes (for each branch). To know for sure whether high-power devices can be connected to the network, it is necessary to calculate the voltage before the cable wiring stage. An accurate calculation will help you choose how to connect the sockets in the end - in series, parallel or mixed.

Installation technology: how to do it?

Advice It is necessary to study the type of socket being installed and choose the most suitable method.

socket installation

How to install a surface-mounted device?

Actions should be performed according to the following algorithm:

- The power supply in the apartment or house is turned off.

- The decorative cover is removed from the device.

- The device is applied to the fixation site.

- The points at which the dowels will be screwed are marked with a pencil or marker.

- Using a drill, recesses are drilled to a depth equal to the dowel casing.

- The covers are inserted and the upper part of the hole is widened if necessary so that the caps do not interfere with the device's tight fit to the wall.

- The dowels are inserted into the holes of the mounting plate, screwed in with a screwdriver or driven in with a hammer.

- The zero and phase wires are inserted into the terminals.

- The socket is fixed and checked for fastening strength.

- Functionality is checked.

Hidden wiring products

- A marking of the mounting location is required, and if there are no wires laid from the junction box, then also the grooves for the wiring.

- A recess is drilled for the box using a core drill or with pobedit coating (in concrete, brick walls).

- Ditches are being dug for laying wiring.

Connection after such operations is performed as follows:

- The mains power in the apartment is turned off.

- The holes are prepared and cleaned of dust.

- With cement or gypsum mortar placed on the internal cavity, a socket box is inserted.

- It is necessary to wait until the material sets so as not to disturb the position of the box.

- To connect the wires from the junction box, the insulation is removed from 0.5-1 cm at the end.

- The wires are inserted into the holes of the terminals and secured by tightening the screws. It is necessary to tighten them well so that the dangling wire does not lead to heating or sparking of the contact.

- The device is installed on self-tapping screws and fixed on the socket box.

- Functionality is checked.

correct installation of the socket Attention The voltage between ground and phase, neutral and phase must be 220 V if measurements are carried out with a multimeter.

Device connection diagram

- First, at a distance of approximately 10 cm from the edge, it is necessary to strip the overall insulation of the wire to gain access to the three cores. Even remove about 0.5-1 cm of insulation from the ends of the wires with a knife or wire cutters. It is necessary to perform all operations very carefully so as not to damage the insulation, which will lead to a short circuit and burnout of the outlet. To connect the ground wire there is an additional hole, which is located further from the power outputs. The operation of the device is not affected by the order in which the wires are connected.

- It is necessary to ensure good insulation and reliable contacts. To do this, put on thermal attachments, push them closer to the terminals and melt them with a lighter. The main thing is not to overexpose the fire, so as not to melt the insulation completely, 1-2 seconds is enough.

- It is necessary to firmly tighten the screws that secure the wires so that heating or sparking does not occur due to poor contact.

Installation features

When a person lives in a new apartment, house, the housing is built taking into account safety requirements, the electrical cables in it are three-core. Connecting the outlet will be easy. But if there is no third contact, you will have to ground the wire - you need to contact the management company and invite specialists. Residents of the upper floors will bear lower costs.

How to ground a power outlet: options

In an apartment where grounding is not provided, it can be done in two ways:

- Pull the bus from the home to the switchboard on the landing. This is done with copper wire.

- Establish grounding, replacing grounding with it. By zeroing we mean connecting the ground contact to the zero contact. This connection method can be dangerous.

Connection to the grounding bus in the distribution panel

If the apartment has a distribution box, you should run the cable to it or to the panel, connect the phase and neutral to the device, and at the output route the wires to the places where the sockets are installed.

Location of phase and zero

In order to correctly and safely carry out work on installing a grounded outlet, it is important to determine the location of the phase and zero. Before starting the search, you need to turn off the machines in order to de-energize the line or the entire apartment. Next, using a special screwdriver, phase is revealed (the light bulb or neon indicator is illuminated) and zero (there is no light). There will be a ground wire between them.

By dismantling the old device, you can identify the location of the phase and neutral by color. Coloring the wire will help you not to confuse their location:

- at zero - blue, blue-white;

- at the phase - black, red or brown;

- at grounding - yellow-green.

There is no clear prescription for where the phase and zero will be located - they can be swapped. It is important to correctly secure the ground wire to the top or central terminal, and attach the phase and neutral to the remaining two in any order to close the circuit.

Wire color coding

It is prohibited to install a jumper to the grounding terminal from the neutral - this is life-threatening due to the risk of phase voltage reaching the socket block.

Connecting wires: specifics

In high-quality products, the wires are tightly clamped with special terminals and do not fall out, but sometimes you have to disassemble them and tighten the fasteners. There is a reliable way to reduce the work to a minimum.

It is necessary to bend the wires stripped of insulation into rings 0.5 cm in diameter and bring them under the top of the bolts. This way the contacts will heat up slightly, and the contact area between the protective contacts and conductive elements will become maximum.

Place for socket

Before grounding the outlet and installing it, you need to decide on the location of the device. It will depend on the devices intended for use. The device is often placed 30 cm from the baseboard, but individual needs also need to be taken into account.

If you have to damage the wallpaper to install a new socket, you should place it near the baseboard to run cables through it (such a position for the device will be inconvenient). For a medium-sized room, 3-4 nests are enough.

Installation of a grounded socket on a baseboard

Sockets can be external or internal. The former protrude above the surface of the wall, the latter are “recessed” completely into the wall. This should be taken into account when choosing their location. The easiest way to install products is at the repair stage - this way you can avoid dirt, dust, and inconvenience.

Mounting the socket

Installation of a grounded socket with hidden wiring begins with the installation of a plastic socket box, which must be purchased separately. You also need to check the cross-section of the cable in the wall and the wires in the purchased product - they must be the same. The installation procedure for the device is as follows:

- De-energize the apartment by turning off the machine or unscrewing the plugs.

- Mark on the wall the place for the socket box (glass) with a pencil.

- Make a niche with the required dimensions using a hammer drill.

- Mix a small amount of gypsum (cement, alabaster).

- Fix the plastic cup in the niche with plaster and secure the wiring.

- After 20 minutes, tighten the fastening bolts on the glass.

Next, prepare the cables - they need to be divided into separate cores by 7-10 cm, and the ends should be stripped of insulation by 0.5 cm. Modern sockets are equipped with contacts with special clamps; they are easy to install. Each wire should be connected to the corresponding power wire (according to the diagram).

Installing a grounded outlet

After connecting the socket with grounding, its working part should be screwed with self-tapping screws to the previously installed glass. Hide the wires in a glass. At the end of the work, screw the lid on. If the device is located next to the baseboard, it is better to immediately buy protective plugs - they will protect the outlet openings from water entering while washing the floor.

Open wiring socket

If you have to ground an open wiring outlet, you need to take its features into account. For overhead-type products, the internal strip has holes for fastening. To position the device evenly, you need to remove the cover, make marks for the dowels and carefully drill holes. Insert 2.5 cm dowels and 5 mm plugs into them.

Design and installation locations of socket blocks

The design of the socket block differs from a conventional socket only in the number of “seats”. It consists of a plastic body and an internal part, represented by terminals with contacts and terminals, to which springs for the plugs are attached.

Most modern models are equipped with grounding contacts, which are designed to increase the safety of the system and reduce voltage from all electrical appliances connected through the unit.

The number of connection points of the installed socket block is determined based on the availability of household appliances placed in one group

There are two types of socket blocks:

- Designed for hidden wiring. Installed into the thickness of the wall using a module made of glass-shaped socket boxes;

- Designed for open wiring. They are installed on the wall surface using a plate-shaped socket box.

In addition to the two main types of socket blocks, there is also a very practical retractable type. They are easily mounted in a countertop or cabinet, from which they can be pulled out when needed. Their operating principle is similar to power supplies located on/in the wall.

Socket blocks are often installed in kitchens, placing them behind the work table at a height of 10 cm, inside kitchen cabinets and behind the walls of adjacent cabinets at a level of 30-60 cm from the finished floor. They are convenient to use when connecting a group of low-power household appliances: hoods, multicookers, refrigerators...

The recessed housing of the retractable socket group, consisting of three to five electrical outlets, remains hidden in the tabletop until you lightly press on its top panel

When arranging halls and living rooms, they are placed near computer desks or behind the TV screen. Socket groups of three electrical points can often be found in bathrooms. But in this case, devices with waterproof housings are used, placing them at a distance of at least 60 cm from the water source.

How does a socket with three contacts work when there is a current leak?

The three-wire system works by splitting the PEN conductor on the switchboard of the transformer substation or in the input switchboard of the building into zeros:

- worker N;

- protective RE.

Through the wires of the working zero, a path is formed for the passage of rated load currents, ensuring the functionality of the electrical circuit. Short circuit currents arising during operation are eliminated by breaking the circuit with the contacts of the machine or plug.

When an insulation breakdown occurs, leading to the appearance of a dangerous potential on the body of an electrical consumer, the current will flow through the connected PE conductor and this will immediately reduce the potential to deliberately grounded metal parts.

Therefore, with a three-wire circuit, the voltage between the housing and the ground should not exceed a value dangerous to human life.

Therefore, the current that can pass through the victim’s body with such a connection should not cause noticeable harm to health. In addition, the probability of operation of circuit breakers with this method is significantly increased, and human touch to the potential of the housing to create a trip circuit is not required.

Almost complete safety of this scheme can only be ensured by the integrated use of automatic devices or RCDs.

Safety precautions

- use high-quality tools with good insulation;

- wear protective clothing and shoes with rubber soles;

- perform actions only during the day in good lighting;

- turn off the power in the electrical panel to avoid electric shock;

- make sure that no one turns on the electricity: hang a warning sign on the panel, personally warn your neighbors;

- make sure that there is complete absence of wiring in places where it is planned to drill and groove walls for electrical wiring and socket boxes;

- It is good to tighten all screws in the terminals so that there is no sparking or heating in such connections;

- carry out work in a dry room.

To install a triple socket you will need to perform the following work:

- Preparation;

- marking walls;

- drilling a hole for the box;

- the installation itself.

Installation check

After installing a three-phase outlet, before starting operation, always check the circuit for errors.

For most devices, phases to a plug or socket can be connected to any terminals, except those intended for working and protective cables.

In some cases, some equipment with three-phase motors will not work correctly, because... The direction of rotation of the engine will be opposite. For normal operation, any two wiring with phases should be interchanged with each other.

At the same time, if you confuse the connections of the working and protective zero, this can lead to dire consequences: the protection against short circuit and electric shock will be disrupted, and there will be a risk of using the electrical installation.

Immediately after completion of installation work, perform the following actions: Carry out a thorough inspection of all contacts for their reliability. Measure the parameters of the insulation resistance of the cores.

The insulation resistance is checked with a multimeter or tester.

To do this you need:

- One probe is placed on the terminal with the protective wire, the other touches the remaining terminals in turn.

- The first probe is placed on the terminal with the working zero, the second is alternately passed along the contacts with the phases.

- One probe is applied to the phase point, the other is carried out along the remaining phases.

- Check the remaining phases.

If during any test there is a small resistance, this indicates an installation error or a malfunction of the wiring itself. If everything is done correctly, there will be a dash on the dial of the device, indicating a very high resistance. Only under this condition can the position of the machine petal be moved to “ON”.

Connection diagrams

Several cables can come into the junction box.

Firstly, this is a three-wire power cable from the lighting circuit breaker installed in the electrical panel. Secondly, a 4-wire cable goes down to the three-key switch, which you have already connected from below.

Well, then there may be options. If you have one chandelier with 3, 6, 9 bulbs, then you can connect it with one single five or 4-core VVGnG-Ls cable with a cross-section of 1.5 mm2.

If you have three independent lamps, in different parts of the room or house, then you will have to run a separate 3-core cable to each of them. Let's consider the last option in more detail.

Preparatory activities for installation

You should begin preparing for installation by choosing the installation location. The Euro standard involves fixing the device at a distance of about 20–40 cm from the floor. This is important in order to comply with basic safety and aesthetic rules.

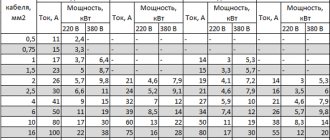

The second important activity is the calculation of current strength. It must be remembered that network elements are always designed for a given operating current. If this point is not observed, operational safety is sharply reduced, and there is a high probability of overloads and, as a consequence, overheating. The wire cross-section must also match the load. In this case, it should be at least 1 square. mm for copper and at least 2.5 sq. mm - for aluminum. The three-core option will be the most successful.

Parts and products for installing sockets should be selected based on the specified room parameters and operating current. It is also important to respect the aesthetic features of the apartment, to choose the safest and most suitable materials in color and appearance. Installation of hidden and external devices also has different requirements.

At a distance of 20–40 cm from the floor, you need to make markings using a pencil or marker. It is also advisable to use a level to create a straight horizontal line. To do this, marking the first installation center, you need to set aside half the width of the trim on the socket box. It is also useful to apply markings in the form of horizontal and vertical lines.

Determining the possibility of connecting an outlet

Before proceeding directly to the connection, we should determine the possibility and correctness of our decision. To do this, you should determine the cross-section of a suitable wire, the rated current of the circuit breaker that powers this group, as well as the absence of prohibitions on installing sockets in a room of this type.

There is no way to do without calculations when installing an outlet.

So:

- Before installing a triple socket into an already operating electrical network group, you should determine whether the circuit breaker can withstand the additional load. To do this, we need to calculate the possible rated current in the outlet. This is done by summing the rated currents of the most powerful consumers of electrical energy that can be connected to a given outlet.

- If we know only the rated power of these devices, then we calculate the rated current based on the formula I=P/U×cosα. Where I is the rated current, P is the rated power of the device (usually indicated in the passport or on the device body) and cosα is the coefficient power of the electrical appliance (the operating instructions for the device should help you find its value, but if you haven’t found it, you can take it equal to 1).

- Now, by summing up all rated currents for a given group, we can check the machine’s compliance with these parameters. Often the machine needs to be replaced with a more powerful one. But if the outlet is designed to connect low-power video and audio equipment, then this may not be necessary.

Note! According to clause 6.2.2 of the PUE, the maximum permissible rated current of the circuit breaker supplying the group network cannot be more than 25A. So, if you already have a 25A machine installed, you will have to think about dividing the group or restrictions on connecting devices to this group.

- Also, if the installation of a triple socket in an already existing group involves monitoring the cross-section of the supply wire. Often, if the machine is not suitable, then the existing wiring will not meet the new requirements. Therefore, again, you will have to think about the restrictions on the connected load for this group.

- Well, finally, you need to decide, is it possible to install an outlet here at all? The socket cannot be installed in bathrooms or storage rooms. At the same time, there is an exception for bathrooms, which allows installation when an RCD is installed in the power circuit of this group.

The photo shows metal plugs for a socket on a combustible basis

- In addition, if a triple socket must be installed on a combustible base, care should be taken to ensure its fire safety. To do this, the mountings for the socket must be made of fireproof materials. Typically, steel products are used for this.

Installation of sockets

Before looking for how to wire a 4-socket outlet, it is better to become familiar with the requirements and installation process of a simple single device. The fact is that there is no difference in installing double, triple sockets, or devices with a large number of sockets.

Complete blackout is the first condition for any electrical work. When installing, be sure to pay attention to the color coding of the wires. Phase wires (L) can be:

- white;

- turquoise;

- brown;

- red;

- orange;

- pink;

- gray;

- purple;

- black.

But still, 3 colors are more often used - white, black or brown. Neutral (N) - zero working contact - blue or blue. Grounding (PE), which is often called “zero protection,” has a shell of yellow and green stripes (longitudinal, transverse), sometimes a yellow-green tint, and can also be purely yellow or only green.

The process of installing sockets looks like this:

- First, a hole of the required diameter is drilled in the wall for the socket box, and grooves are made for electrical wiring. These operations are not necessary if the task is simple - replacing a failed socket. In this case, pull the end of the power cable out and remove all accumulated debris using a vacuum cleaner or brush.

- To install the socket box, prepare a cement/gypsum mortar. After applying it, insert the installation box into the hole, pull the cable into it, and fix it flush with the wall. Leave the work until the solution has completely set.

- Then the insulation is removed from the ends of the wires, they are inserted into the contact mounts (phase - on the left, zero - on the right, protective cable - in the center) and tightened with a screwdriver. Check the connection for strength.

- The body is installed inside the box, aligned horizontally, and temporarily fixed on both sides with self-tapping screws. The position is corrected using a level, then the fasteners and spacer tabs are tightened, finally fixing the socket body

- Attach the cover to the body and tighten the central screw. Turn on the electricity and use the indicator to check the functionality of the outlet.

What is high voltage power used for?

Lightning overvoltage affects the quality of electricity.

Any technological and household processes depend on the quality of electrical voltage. Poor quality power means power outages, surges, complete or partial interruption of supply. Several factors can influence:

- weather conditions: lightning surge, lightning strike, etc.;

- failure or breakdown of equipment at power plants - such distributors were built more than 30-40 years ago, wear and low throughput lead to undesirable consequences;

- incorrect distribution of cables, power points;

- incorrectly selected devices: power sockets for 220V or more, switches, distribution boxes, etc.

The increasing load on power supply networks every day leads to the need to improve and replace equipment. Without this, the following problems may occur:

- instability of voltage supply;

- inability to control growth or other changes in load;

- failure and increase in power resonance.

The construction of new power lines is associated with high costs

The construction of new power lines is associated with significant costs and is often simply impossible for environmental reasons. Therefore, it is necessary to increase the power of energy transmitted along existing lines, mainly by increasing the current strength. This is only achievable under the following conditions:

- no restrictions on heat load;

- the presence of a stable distribution of currents between the cable lines supplying a particular building.

A 3-phase socket allows you to increase the voltage flow to a specific power point. In most cases, new wiring is not required. You can check the need for new wiring yourself or with the help of an electrician.

Is it possible to connect an outlet to the switch?

Imagine the situation: you have renovated your premises, all the electrical wiring is walled up in the walls, and there are no backup boxes or socket boxes. An outlet needs to be installed in one of the rooms. Placing it next to the distribution box is irrational, the location is too high. But I don’t want to lay open wiring (especially, ditch the wall).

There is a switch in a convenient location that clearly has voltage. How to make a socket from a switch if it is possible to aesthetically place them next to each other?

To answer this question, let’s remember: what types of lighting schemes with switches are there?

Classic connection: tap from the distribution box.

The neutral conductor is inserted into the lamp from the box. In the box itself, a break in the phase cable is organized (it is opened using a switch), then the phase enters the lamp along the same path as the zero.

With this scheme, only the phase conductor is present in the body (installation box) of the switch. It will not be possible to organize a closed electrical circuit to connect an additional electrical appliance (via an outlet). You can use the phase from the switch, but you still have to lead the zero from the distribution box, which makes the idea pointless.

Conclusion: With this type of lighting arrangement, it is impossible to connect the socket to the switch.

The switch is located between the power source and the lighting fixture.

This scheme is less common, but in some rooms it is used. If at the design stage it was decided not to use distribution boxes in the lighting network, you are in luck. The switch wiring box contains both neutral and phase wires.

The sequence of work is as follows:

- We dismantle the existing switch without touching the installation box.

- We determine the routes for laying the input and output cables. If you have a diagram and plan for the electrical supply of the room, this is not difficult to do.

- Carefully drill a hole for the socket box.

- We install terminal blocks in the switch box and connect the socket according to the following diagram:

Since the current wiring is intended for lighting, most likely the cable cross-section is no more than 1.5 mm². The maximum possible load for such a cable (provided that it is copper): 3.3 kW. That is, not very powerful electrical appliances can be plugged into this outlet. The maximum is a vacuum cleaner. Well, phone chargers, a power supply for a router or an antenna amplifier - no problem.

Expansion of the power network in a separate room, due to disconnection in existing switching devices, is possible. As a rule, the switch is connected to the outlet. The opposite situation is possible only with a certain wiring diagram.

How to make a socket with three wires

This method is used when you need to connect additional ones from one electrical outlet, but you cannot drill into the walls. The procedure for installing and connecting wires in this case is as follows:

- Power outage. It is necessary to de-energize the entire apartment or room in which the work will be carried out. Using a tester, you need to make sure that there is no voltage.

- Removing the protective cover from the main power point.

- Removing the socket by loosening the retaining contacts.

- Connecting wires to the new power point.

- Next, it is checked whether the limiter will not squeeze the wires. If it interferes with the cables, you need to carefully break off a small piece from the socket box or wall to the size of the wire.

- Reinstalling the socket.

- Creating a hole in the decorative cover for the wire.

- Installing the cover.

Basic mistakes

Brown wire - phase, blue - neutral, yellow-green - ground

Installing an additional outlet is usually not difficult. But beginners can make the following mistakes:

Wrong choice of wire cross-section. You need a cable of the same thickness as the main outlet. Using a wire made of a different material. Connecting two different wires causes additional difficulties, and the contact itself is less reliable.

Violation of the order of connecting wires

Particular attention should be paid to the grounding conductor. If it is not available in the house (especially in old buildings), it is better to purchase sockets without ground. Unreliable contact

You need to familiarize yourself in advance with the existing methods of creating a contact and practice connecting on spare sections of wires. Installing wires diagonally. Standards only allow vertical cable routing.

There is also a risk of buying a model that is not suitable in design. This is not a critical error from a technical point of view, but can disrupt the overall concept of the room. Therefore, when purchasing, it is recommended to select the color of the product, its shape and size in advance. Manufacturers of electrical products offer a wide range of products; any buyer will find a product that suits the style.

Sockets in drywall

This is both hidden and open wiring - it belongs to the first category because the wires are not visible, and it falls into the second category because the wires are not walled into the wall and can be reached. In addition to standard tools (unless you are installing a socket block), you will need steel wire for installation. The procedure is as follows:

- The socket and socket box are removed from the wall. They are screwed to the drywall, so there is no need to break anything.

- The steel wire is inserted into the hole and pushed in the direction where the new socket is planned to be installed. At this stage, you just need to make sure that there is a gap between the plasterboard slabs, profiles and the wall into which the corrugation with wire will pass (wiring unprotected from mechanical damage cannot be left inside).

- If you can find the way with the wire, then a hole is drilled in the right place for a new socket box. A strong rope is screwed to the wire and it is pulled back.

- Then, using a rope, a corrugation is pulled between the sockets, the wires are inserted into it and connected.

Installing a block with two and three keys

Installation of such a block makes it possible to control two light sources in different rooms, or two in one room. In this case, not 4 wires are supplied from the distribution box, but five.

- The phase is connected to the jumper of the switching block.

- Only the neutral wire and the grounding conductor are attached to the socket contacts.

- Then the two remaining conductors are connected to the switch contacts.

- In the distribution box, twists are made of the cores that supply the core and those that go to the lighting fixtures.

Three-key combined devices are the best option for small apartments. They often have a bathtub, a toilet and a kitchen nearby, and the lighting is switched on on one wall. If there are three keys, then you will need a cable with six cores, three of which are also connected to the switch terminals.

Wire selection

The wire is selected according to this principle:

number of cores If you decide to install a socket with a grounding contact (see above), it is connected with a 3-wire wire. Otherwise, use 2-wire;

material. In general, when installing wiring, it is recommended to use copper cable - brand VVGng (in non-flammable insulation) or NYM (imported analogue). Copper is superior to aluminum in electrical conductivity and ductility (the aluminum core breaks off after several bends).

But with a daisy chain connection, a wire made of the same material is used that is connected to the first outlet. If a copper conductor is directly connected to an aluminum conductor, when current flows, both materials are destroyed due to an electrochemical reaction. A special neutral alloy adapter is required.

Aluminum wires (brand AVVG, etc.) are found in old houses

Therefore, before installation, it is important to open the existing outlet and see what it is powered by;

core section Also selected according to the wire connected to the first socket (when using cables of the same material)

There is no point in using a wire with a larger cross-section, since the throughput of the “chain” is still determined by the capabilities of its weakest link.

For household sockets, the minimum recommended core cross-section is 2.5 mm2 (for copper wire). Such cables, when laid hidden, can withstand a current of up to 16 A (when open, even more due to good heat dissipation), so you can safely plug in any device into the outlet, except for particularly powerful ones - an electric stove and an instantaneous water heater.

Installing an indoor outlet

It must be said right away that all sockets are divided into internal and external. Their operating principle is the same. The difference between them is that external sockets are installed directly on the wall, and internal ones are installed in boxes (socket boxes), which are “hidden” in the wall.

First of all, for safety reasons, it is necessary to disconnect all electrical wiring in the apartment from the power supply. We are talking about automatic switches in the electrical panel, which is usually located in the hallway of the apartment or on the landing.

If you are left completely without electricity in your home, you may need lighting in your workplace. It’s good if there is enough daylight, but in the dark you need to think about alternative lighting sources, for example, a flashlight may come in handy.

Necessarily! Additionally, use a multimeter or an indicator screwdriver to make sure that there is no voltage in the outlet.

Prepare your tools:

- Wire cutters

- Level

- Pliers

- Screwdriver

- Pencil

- Knife.

How to connect the socket correctly: instructions for self-installation

Connecting an outlet is not a very complicated procedure and can be done by residents independently, without the involvement of an electrician.

But at the same time, certain rules and requirements must be observed so that the new electrical appliance does not become a source of danger.

Let's consider how to properly connect an outlet with your own hands, what is the sequence of actions and what needs to be taken into account when carrying out work.

Typical types of sockets

Sockets, like any other element of a household electrical network, have a certain operational life. Over time, they need to be replaced with new devices, which is necessary for safety reasons - to avoid short circuits and electric shock to residents.

Before installing a socket, you need to select the most suitable model that meets specific technical requirements.

There is a wide variety of electrical household devices on the modern market, differing in material of manufacture, design, installation method, and level of security.

According to the method of installation, sockets are:

- Overhead options are most often used in wooden houses, since placing electrical equipment inside fire-hazardous materials such as wood is not recommended.

The contacts and wires in a surface-type socket are located outside the wall, in a protective casing made of dielectric materials. Electrical wiring is also supplied to them from outside the wall, hidden in decorative cable ducts. - Built-in models are designed for installation inside brick, concrete or plasterboard walls.

Before connecting built-in sockets, a recess of the required depth and diameter is made in the wall. A fastening element is inserted into it - a glass-socket box, in which the electrical appliance is secured. Such sockets practically do not extend beyond the surface of the wall, with the exception of the external decorative lining. The wiring to them is supplied either under the facing material (plasterboard, wall panels) or in grooves. Grooves are specially made deep grooves in the wall into which wires are laid, after which they are sealed with plaster or putty.

According to the type of wiring connection, sockets are:

- Screw. The electrical wires in this type of socket are secured to the terminals using screw-on terminals.

- Spring-loaded. Instead of screws, they use spring-loaded clamps to hold the wires to the terminals.

Depending on the number of contacts, devices are available in 2- and 3-pin types. The first type is used in houses where the electrical wiring consists of only two wires, a phase and a neutral. 3-pin options are installed where the third, grounding wire enters the wiring.

Similar models are recommended for connecting a number of household appliances, for example, computer processors and washing machines.12

There is also a limitation on the maximum power of connected devices. The standard option is 220 volts and 16 amperes.

But kitchen electric stoves require three-phase outlets capable of withstanding a voltage of 380 volts at a current of 32 amperes. For rooms with high humidity, or where there is a risk of water ingress, it is necessary to install waterproof modifications equipped with a sealed lid. These rooms include a bathroom, a toilet, a kitchen, and a balcony.

In recent years, “smart sockets” equipped with timers and relays for ejecting the plug when overheated have appeared on sale.

There are even models that can maintain remote communication with residents via Bluetooth or an Internet connection, executing their commands to turn on/off.

Construction and components

The design of a regular socket is quite simple. However, in order to properly connect the outlet, you need to understand all its constituent elements.

The device consists of the following parts:

- The base on which all other components are attached.

- Electrically conductive elements – clamps and contacts.

- An external overlay that plays a protective and decorative role.

Ceramic models are the most durable and fireproof.

However, they are quite fragile and the connection of sockets made of ceramics must be done as carefully as possible.

Most often, plastic is used in the manufacture of the body and cover panel. Such models are cheaper, but their service life is shorter. Electrically conductive parts are made of brass, bronze or other copper alloys. They are resistant to corrosion and do not rust, maintaining good contact.

Standard installation steps

If there are several outlets, then you can choose one of the connection options.

Next, we’ll take a step-by-step look at how to properly install sockets in your home.

Despite its apparent simplicity, this work should be approached as responsibly as possible and without undue haste.

After all, installation errors can create a danger of electric shock or even cause a short circuit with subsequent fire.

Disassembling the socket The socket is disassembled Preparing the wiring for connection Stripping the wires Fastening the wires in the terminals Fixing the inside of the socket Checking the level of the installed socket Installing a decorative panel

Preparations before installation

Installing an outlet begins with preparing the necessary set of tools. It includes:

- Screwdriver, flat or Phillips, depending on the type of fasteners.

- A sharp knife or side cutters for stripping wires.

- Pliers.

- Indicator screwdriver.

- Insulating tape.

In the case where you are not replacing a device that has expired, but installing a new socket, you will need a set of construction and finishing tools. Connecting a built-in socket will be especially time-consuming. Here you will need:

- A hammer drill for making a hole in a wall.

- Glass socket.

- Building level.

- Ruler.

- Putty knife.

- Plaster mixture.

Power outage is a guarantee of safety

When working with electrical appliances, you must follow safety rules to avoid electric shock. Therefore, before connecting the outlet, it is necessary to disconnect the electrical wiring. This can be done in the distribution panel by turning the toggle switches of the machines to the “off” position.

After this, using an indicator screwdriver, you need to make sure that you have turned off the desired circuit breaker and that the power wires going to the outlet are actually de-energized.

It would also be a good idea to warn all the inhabitants of the apartment that you are busy with renovations.

Otherwise, there is a danger that one of them will decide to independently find out why there is no light in the house and turn it on to the switchboard.

If the distribution panel is located on the landing, it is recommended to write a note in capital letters so that none of the neighboring residents also inadvertently turns on the switch for supplying electricity to your apartment.

Selecting a socket connection diagram

The next step is to choose how to connect the sockets in the correct way. There are several schemes that can be used to connect to the home electrical network:

- Connecting a socket in series from a socket.

- Parallel. In this case, each device is supplied with its own line from the common one, through a distribution box.

- Mixed option. Here, the sockets are partially connected in parallel, and partially in series.

Choose one option or another based on the expected power of the connected household appliances. If some powerful devices will be connected to the outlet, for example, an electric heater, an automatic washing machine, it is better to connect a separate line to it. If no special loads are expected, you can choose a sequential circuit.

Installation of mounting boxes

The simplest option is to replace the old outlet with a new one. The work here is performed in the following sequence:

- After making sure that the wiring is de-energized, remove the front cover by unscrewing the fixing bolt.

- Disconnect the wires from the terminals by unscrewing the fixing bolts.

- We unscrew the base from the wall for overhead models, or loosen the fastenings in the socket boxes for built-in ones.

- We remove the old socket and install a new one in its place.

- We connect the wiring to the contacts and close the outer cover.

- We turn on the machine in the distribution panel and check the operation of the new outlet.

When installing the device in a new location, you will have to spend more time and effort. Especially if you have to install a built-in socket. The first step is to select a place on the wall where it is best to install it.

There are building standards that contain the following distance standards for installing sockets and laying electrical wiring:

- Height from floor for sockets ≥ 30 cm.

- Electrical wiring can be laid at floor level, provided it is located in special baseboards equipped with cable ducts.

- Distance from window or door ≥ 10 cm.

- From ceilings ≥ 20 cm.

Having decided on the installation location, you should mark this place with a pencil. Here, using a puncher, a hole is made for mounting boxes - socket boxes. In drywall, it can be cut using a sharp knife or a special drill attachment. The diameter of the hole should not be less than the diameter of the socket box; no deformations of the box during installation are allowed. The socket box is secured in the wall hole using dowel-nails, and for plasterboard walls there are special modifications with presser feet. The gap between the mounting box and the wall is sealed with a plaster mixture or putty.

The power supply cable is supplied to the installation site:

- In cable ducts, outside walls.

- Under decorative cladding (plasterboard, wall panels), in corrugated insulating pipes.

- In grooves punched into plaster, concrete or brick.

The wires are inserted from the outside into the hole in the socket box, and brought out from the inside at a distance of 7-8 cm. If it is necessary to install 2 or 3 sockets, use a level to outline a horizontal or vertical straight line, along which recesses for the socket boxes are carefully made. Sockets located on the same line look much more aesthetically pleasing.

Connecting and checking the device

The last step is to connect the outlet to the mains. Using a knife or side cutters, two or three wires are stripped, depending on the type of wiring - with or without grounding.

By default, “ground” corresponds to the yellow-green wire. It connects to the middle pin of the socket. The remaining two wires are connected to the remaining outermost contacts intended for electrical appliance plugs.

The wires are fixed with clamping screws, after which the base of the socket is secured in the cup holder with screws. The final stage of electrical installation work is the installation of the outer cover. After it is tightened with a bolt, you can begin to check the operation of the new socket.

To do this, turn on the power supply in the switchboard, and use an indicator screwdriver to test the presence of power in the network.

Conclusions and useful video on the topic

A properly installed socket can last for more than one year. The main thing is to carry out all work in accordance with the technical requirements of building standards. The attached video shows the main stages of installing and connecting an outlet in the house.

Did you find this article helpful?

Give it a thumbs up! Subscribe to my

Open and closed wiring

The difference between the methods is noticeable to the naked eye. The closed wiring is located inside the wall, for which grooves (grooves) are punched or cut into it, in which the connecting wire is hidden under a layer of putty. Open wiring is laid along the surface of the wall, on which it is held in special fasteners or laid in plastic guides - cable channels.

Accordingly, if you can see the wires that fit into the outlet, then the wiring is of an open type. Otherwise, closed wiring is used, for the installation of which the walls were cut.

These two methods of connecting an outlet can be combined with each other - if the old points are connected in a closed way, then nothing prevents you from connecting a new one in an open way. There is only one choice - in wooden houses the socket can be connected exclusively in an open way, just like all other electrical wiring.

Open wiring - advantages and disadvantages

An analogy with the most common extension cord (surge protector), which is essentially an additional branch of the electrical network, but is connected not to a junction box, but to an outlet, will help you understand why open wiring is good.

Advantages:

- You don't have to cut the wall to install a new outlet. This is especially true for those premises that have already been renovated.

- Installation does not require tools such as a wall chaser or a hammer drill.

- In the event of a breakdown, you don’t have to open the wall - all the wiring is in front of your eyes.

- Installation speed. Even after all the work has been completed, adding another point to the existing wiring is a matter of several minutes.

- If desired, you can quickly completely change the wiring - ideal for temporary connection schemes.

Flaws:

- There is a high probability of external influence on the wiring - children, pets, you can simply accidentally hook it. This disadvantage is mitigated by laying wires in cable channels.

- Exposed wires spoil the entire interior of the room. True, it all depends on the design abilities of the owner of the room - cable channels will fit perfectly into modern design solutions, and if the room is made in a retro style, then special wires and other accessories are produced for this.

- The need to purchase special fasteners, even if cable ducts are not used - in wooden houses, open wiring should be laid at a distance of 0.5-1 cm from the wall surface. Wires are often laid inside iron pipes - all these requirements are aimed at increasing the safety of using open electrical wiring.

As a result, this connection method justifies itself if for some reason there is no point in laying the wires to the outlet inside the wall. Besides the fact that the wiring will be visible, there will be no differences in the operation of the outlet.

Hidden wiring - pros and cons

Despite some significant disadvantages, it is used almost everywhere - the advantages of its use still outweigh.

Advantages:

- The wires to the socket fit into the wall, so wallpaper or other finishing can be done freely on the outside.

- Meets all fire safety requirements (in concrete buildings) - even if a short circuit occurs, there is no fear of a fire from the wires in the wall.

- There is a very low probability of damage to the wiring - it can only be damaged when drilling walls.

Flaws:

- For installation you need to cut the walls.

- It is difficult to carry out repair work.

- If the walls are finished, then after installing an additional outlet you will have to redo it.

The disadvantages are leveled out by preliminary calculations - if you plan in advance where and which block of sockets should be installed, then problems usually do not arise in the future.

Pros and cons of triple sockets

The number of household appliances in modern apartments is constantly increasing. This happens at such a speed that the number of installed sockets does not meet the growing needs, especially if it alone is forced to supply a large area. In this regard, apartment owners install blocks of three or more outlets.

Most often this happens in the kitchen, where it is not always possible to use an extension cord, and the need to use several devices at the same time arises quite often.

Triple sockets have gained popularity due to several advantages:

- Reliable and safe fastenings.

- No additional wiring required.

- The ability to quickly switch from single sockets to triple sockets while simultaneously improving the overall functionality of the home electrical network.

- Easy and quick repairs if any malfunctions occur.

- Simple installation, convenient operation, relatively low cost.

However, despite the obvious advantages, most people prefer to install several separate outlets in one place rather than use a single block. This is primarily due to the specific disadvantages characteristic of such products.

Among the disadvantages are the following:

- The mechanical load on the socket increases significantly. Gradually it will begin to collapse and fall into disrepair. This will cause certain negative processes, including short circuits.

- Increased electrical load since the triple socket itself is designed to power multiple devices. If the permissible load is not taken into account, then not only the installation product will fail, but also the electrical wiring.

- Significant overall dimensions increase the risk of mechanical damage. This especially affects the quadruple socket, as well as blocks with even more sections.

However, with normal load calculations made with a certain margin, the triple block of sockets will perfectly cope with its functions, creating more convenient and comfortable conditions when using household electrical appliances.

Drilling out socket boxes

Next begins the noisiest and dustiest part of electrical installation work - drilling and chipping.

In order to minimize the amount of dust, construction vacuum cleaners are used.

In addition, each tool in this case must have an outlet with a pipe or a dust removal device.

Small hammer drill, medium hammer, large hammer, wall chaser, all of these tools must have dust removal, otherwise your vacuum cleaner will be of no use.

First, the centers of the socket boxes are drilled out using a d-6mm drill. Then, based on the material of the walls, a tool is selected for arranging niches for socket boxes.

It could be:

medium hammer drill with diamond bit

large hammer drill with impact bit

wall chaser with a cut 60mm deep

How to install socket boxes for a triple socket

The installation process begins with determining the location of the block of three outlets. The functionality of the structure will directly depend on the correct location. For example, in the kitchen, it is convenient to install three sockets in one socket above the countertop. This way, you can simultaneously connect your microwave oven, multicooker and other household appliances without worrying about the length of the cord.

In a room, it is better to install such a unit behind the TV, skillfully masking all connected wires with a wide screen. It is possible to install such a block of sockets in bathrooms, but here it is important to comply with fire safety requirements. In particular:

- The minimum distance to flowing water is 60 centimeters (zone 3);

- The socket group must be sealed and moisture-resistant with an appropriate degree of IP protection.

Having decided on the installation location, you need to prepare the tool and you can start marking the walls. To install a triple socket in one socket box you will need:

- 1. Construction level;

- 2. Roulette;

- 3. Pencil or marker;

- 4. A hammer drill with an attachment for punching walls and a crown.

Please note that it is better to install a block of three sockets at the initial stages of repair work, until the finishing is applied to the walls.

Wall marking

Please note that this is a very important stage of work, on which the geometry of the sockets and the ease of connecting the wiring will depend. Therefore, marking walls must be approached with maximum responsibility. When marking, you need to be guided by the number of sockets combined into a block.

When carrying out work, be sure to use a building level: this way you will gain confidence that the structure will be perfectly level and there will be no problems with installation and connection. If a block of three sockets sits crookedly, the mistake made will immediately be evident.

There are certain requirements for marking walls for installing electrical outlets. For example, the distance between the centers of the socket boxes is exactly 72 mm. Take this into account when applying markings. Failure to comply with this parameter will lead to the fact that the decorative panel simply will not “sit” in its place.

In addition, the groove for laying wires must run strictly horizontally or vertically from the socket box. Only after meeting these requirements can you drill holes and tap the walls.

Drilling a hole in the wall

After the walls are marked, you need to make a mounting hole for the socket box. This is not difficult to do, the main thing is to have a good hammer drill with a special diamond bit for concrete on hand. Such “crowns” are used for drilling holes of a given diameter in brick walls and concrete floors.

The algorithm for working with a crown is simple and intuitive, so even a novice master usually has no problems. The nozzle is inserted into the chuck and drilling of a hole in the desired location begins. Drilling ends when the bottom of the bit touches the wall. The remaining concrete is knocked down with a chisel.

If you are installing socket boxes in a plasterboard wall, then you will need a special nozzle for plasterboard walls to drill holes. You can also use a utility knife.

Also, do not forget about the power cable; it is also necessary to make a groove for it. The width of the groove depends on the thickness of the cable that will be connected to the sockets (whether it will be corrugated or not). Our socket group will require a cable with a cross-section of at least 2.5 mm2.

We fix the socket box in the concrete wall

In order for a triple socket in one socket to be kept in the wall, it is necessary to fix the box with alabaster. Here it is important to correctly calculate the amount of mixture that will be applied to the back and side walls. If you overdo it, then the excess alabaster will stick out; an insufficient amount of the mixture will not be able to ensure reliable fixation of the socket box. The amount of alabaster is determined individually, depending on the type of partition.

The consistency of the alabaster mixture should not be too liquid, as it will spread when applied. But you also don’t need to make it too thick, otherwise it will be difficult to apply and smear (besides, the thick mixture will quickly set and dry). I always prepare the mixture by eye, in small portions.

This material will provide better adhesion of the socket box to the wall and will dry quickly. By the way, it is precisely because of the drying speed that alabaster should be preferred to other types of building mixtures.

The process of installing a socket box in a concrete wall is as follows: a diluted mixture is applied to the inner walls, a block is inserted and securely fixed for a while. At this stage, it is important to observe the geometry and align the structure to a given level. Please note that the mounting screws must match both the vertical and horizontal level of the sockets.

When installing a socket box for a triple socket, do not forget about the power cable; we also insert it into the hole. Some craftsmen, on the contrary, fix the socket boxes without a cable and push it into the box only after the solution has dried. Explaining this by saying that the cable, bending, knocks the box out of level. There is no significant difference in this and you can do it the way that is easier and more convenient for you. It's easier for me to install the cable right away.

The alabaster will dry for about two hours, when the mixture sets, you can start connecting the wiring.

Electrician's recommendations

You should adhere to the basic rules when working:

- horizontal transitions from the junction box to the sockets or switch are laid at a height of 2.5 m;

- the insertion of veins is carried out only vertically or horizontally;

- connection points should only be located in mounting boxes;

- for underground cable laying, you need to use only a single piece with a strong armor tape;

- The biggest mistake is installing the switch in the zero gap;

- It is forbidden to install electrical wires near a wooden surface, but if this is unavoidable, then an insulating hose or gasket made of asbestos and steel with a thickness of 0.2 - 0.5 mm is used.

Several rules when connecting 380 volts in a private home

Outdated power lines are gradually being modernized and transferred to the new TN-CS model. With this method, the fourth PEN wire is laid from the supply substation not with one wire, but with two disconnected wires: PE and N.

Input of three-phase voltage into the building

To connect 380 volts to a private house, you must follow some rules:

- voltage is transmitted from the transformer substation via power lines (four wires), which include three phase conductors (L1, L2, L3) and one common neutral wire PEN;

- Most often such a line is overhead and less often cable.

A three-phase connection is based on the connection of all conductors to the input apparatus of the object. Next, the current enters the metering device and passes into the distribution panel, for the purpose of subsequent distribution to electrical receivers.

In the middle of the input device, the working zero N and the protective zero PE are separated. Then they are connected to the main ground bus (GZSh). Then it is connected to the repeated grounding circuit of the room.

The last section of the line from the support to the entrance to the house is carried out by air or underground. It is also called a branch. It is listed on the balance sheet of the power supply organization, so the connection of the house is made with the permission of the owner of the power line.

If the cable line runs underground, then the branch is mounted in a metal cabinet, which will be located near the route, and for overhead power lines - directly on the support. In both cases, the owner is obliged to ensure their safe operation and prevent unauthorized people from invading the electrical panel.

Outgoing lines

With three-phase power supply, an input distribution board (IDB) is installed on the facade of the house. It is in it that the PEN conductor is separated and the input circuit breaker is installed, as well as circuit breakers for the group circuits of the house.

All three phases L1, L2, L3 are connected to a three-pole input circuit breaker (3). An electricity meter is also installed there in order to keep track of the resource consumed. Three conductors from the input machine and conductor N from the main generator are connected to the input terminals of the metering meter. The electricity meter output is connected to a common circuit breaker (four-pole) for protecting the entire house. If it goes off, the entire house will be cut off from power.

The operating voltage between phases is 380 V, and between phases and zero 220 V. After all, this voltage represents three phases in three different wires, only with different instantaneous potentials and a frequency of 50 Hz.

Electrical wiring in the house should be divided into groups, each lighting line is protected by a single-pole circuit breaker (5). Each group is powered from different phases.

In rooms with high humidity levels, you need to use a difavtomat (6), which is triggered when the current reaches no more than 30 milliamps.

For a kitchen group, it is advisable to install a three-pole circuit breaker (9) and a four-pole circuit breaker (10). This is due to the fact that the kitchen power supply is three-phase, so if a phase is short-circuited to zero, it will be necessary to cut off the zero worker and all phase conductors at the same time.

What is grounding

Grounding is the intentional connection of an electrical installation or network point to a grounding device. Sockets in private houses, apartments and businesses are mostly installed grounded. Previously, such devices were called Euro sockets; the technology came from Europe.

Sockets sold in stores have three terminals - phase, neutral and ground. Wiring in new buildings is made of three wires according to safety requirements. Two-wire wiring is often found in old houses and dachas, but it is gradually being replaced by modern ones. Modern sockets differ from old ones in the presence of a third “ground” wire.

Grounded socket device

Grounding purposes in the home

The purpose of grounding is to reduce the risk of short circuits and ensure comfortable living conditions for humans. Each electrical appliance has a housing and insulation of electrical wires; they prevent electric current from harming a person. If the integrity of the insulation is compromised, there is a risk of voltage appearing that can cause an electric shock. Grounding will prevent such consequences.

The advantage of the socket is that the grounding contacts begin to work first, and the current-conducting elements turn on later. If there is a problem with the network, power supply to the product will be interrupted. Installing a product with a grounding contact means protecting electrical appliances from power surges that can damage equipment.

Types of blocks

Before you study information on how to connect an outlet with a switch, you need to know that when choosing, they pay attention not only to the design of the product - its color, shape. Before purchasing, you need to evaluate the technical parameters and the capabilities of the electrical network

The last point is especially important for apartments in old housing stock, where electrical wiring is often in critical condition. The next question is the functionality of the product. When choosing a particular unit, be sure to take into account which devices will be connected to the outlet and what their power is.

Before purchasing, they decide how many devices will be connected to the network in a particular room. When work is planned in wet rooms, the unit must be equipped with special protective curtains or covers.

Types of combined devices