An apartment usually has enough free sockets, but it often turns out that at least two devices need to be plugged into one of them. The solution to the problem is very simple if you take care in advance of how to connect a double socket. This is one of the most reliable ways to once and for all solve the problem of falling out tees, which simultaneously loosen the contacts of single sockets.

Connecting the cable

Connect to an existing outlet like this:

- the end of the new cable is cut to a convenient length;

- free the ends of the cores from insulation to a length of 1 cm. There is a special tool for this operation - a stripper (also known as a crimper), which eliminates the possibility of damage to the core. In its absence, the insulation is carefully cut off with an ordinary knife, trying not to damage the core;

- the bare ends of the strands are bent into loops and lightly squeezed with pliers;

- Having pressed the spacer antennae, remove the inner part of the socket and loosen the screws on the phase and zero terminals. The grounding conductor is completely unscrewed;

- the power cores of the new cable are inserted into the terminals and the screws are tightened. Now each terminal has two wires - from the power cable and from the jumper for the new socket. The colors of the insulation on the cores in each terminal are the same.

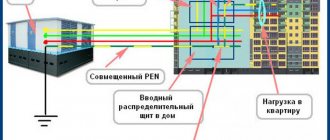

Grounding is connected differently. For it, connecting with a cable is unacceptable due to low reliability: if the contact in one of the sockets burns out, all subsequent ones will be left without grounding. According to the PUE, it is necessary to maintain the continuity of the conductor by making a branch for each socket.

Do this:

- a crimp sleeve is put on the unscrewed grounding conductor of the supply cable and two more conductors are inserted into it: from the jumper cable and a short section - a branch for the existing socket;

- press the sleeve with press pliers;

- put a heat-shrinkable tube on it and heat the latter with a hot air gun or lighter (insulation);

- Screw the branch to the grounding contact of the existing outlet.

Do the same when connecting each subsequent socket of the cable. The existing outlet is being assembled

It is important to make sure that the limiter on its inside (a rectangular metal plate) does not squeeze the jumper wire. If this is discovered, a cutout is made for the wire in the socket box, and if necessary, the hole in the wall is deepened

Features of RJ-45 cable pinout

Before connecting Internet sockets, you need to clearly know and understand where and what color to mount each individual twisted pair wire. To do this, you need to know the crimping scheme and the rules for crimping RJ-45 cables yourself.

There are two main types of RJ-45 wire pinouts: straight and crossed. The first type of cable is used to connect end devices (computer/PC, smart TV/Smart TV, switch/Switch) to the so-called router.

The second type of cable is used to connect devices with similar functions (computer - computer, router - router, switch - switch) to each other.

For a direct scheme, the color matches the color in this order: white-orange, orange, white-green, blue, white-blue, green, white-brown, brown. For the cross, everything is the same, but the green ones change places with the orange ones, respectively

First, we leave about 100-150 mm from the plane of the wall along the length of the cable, and cut off the rest of the cable. This length will be sufficient for possible subsequent rewiring of the wiring.

Before starting electrical installation work, you can familiarize yourself with the crimping diagrams for twisted pair cables with 8 and 4 cores, discussed in our other article.

Now you need to free 4 pairs of wires from the outer sheath and from the foil (it acts as protective shielding), if any.

Inside the twisted pair there is also a special thread with which you can easily release all the necessary wiring. You can also use a regular knife or a special cutting surface, which is equipped with almost all crimping pliers.

Crimping pliers will help you easily mount any RJ-45 and RJ-11 connector, the main thing to remember is that if the tool itself does not press the wires enough, then you can press it with a knife or a thin screwdriver

At the next stage, we straighten all twisted pairs of multi-colored wires and carefully “seat” each individual color into its niche according to the color pinout in the socket terminal block.

This must be done in such a way that the rest of the wire with “untouched” insulation falls under the fixing clamp of the terminal block. Now we tighten the fixing bolts with a screwdriver on the terminal block and at the same time press the remaining wires so that they do not come out of their seats.

Finally, with a “feeling of strength,” we recess the clamping connectors on the terminal block with a screwdriver and separately secure each core in the terminal group, while cutting through the braid of small wires. Then we cut off the remains. The wiring must all be located at the same height from the base of the terminal block.

You may also find information about ways to extend twisted pair cables useful.

Connection diagram of switches to the network

Connection diagram for single-key light switch

Connection diagram for a two-key light switch. The black phase wiring is connected with a screw to the block terminal marked with the letter L (phase). The blue neutral wire connects to the terminal marked N. The cable should be screwed tightly, but not too tightly so as to break it.

Useful: Microwave motion sensor: circuit and connection to Arduino

Connecting the phase conductor to the switch

Screwing the phase conductor

Connecting the neutral conductor to the button

Typically, a grounding conductor is not required for mounting the switch, so its tip is insulated and inserted into a small clamp (or tightly wrapped with electrical tape using this method).

Insulated end of grounding conductor

Which grounding method to choose

It is possible to correctly connect grounding to sockets in an apartment or house only if there is a grounding bus in the distribution panel. If it is not there, then you can’t do anything on your own - you need to seek connection from the appropriate authorities. All work must be carried out by services servicing the house, and their results are entered into the electrical wiring diagram.

In the private sector, you can make a separate grounding circuit, but it is better to solve this issue during the construction of the house, since in addition to installing the grounding bus itself, you will have to additionally redo the finished wiring.

Open and closed wiring

The difference between the methods is noticeable to the naked eye. The closed wiring is located inside the wall, for which grooves (grooves) are punched or cut into it, in which the connecting wire is hidden under a layer of putty. Open wiring is laid along the surface of the wall, on which it is held in special fasteners or laid in plastic guides - cable channels.

Accordingly, if you can see the wires that fit into the outlet, then the wiring is of an open type. Otherwise, closed wiring is used, for the installation of which the walls were cut.

These two methods of connecting an outlet can be combined with each other - if the old points are connected in a closed way, then nothing prevents you from connecting a new one in an open way. There is only one choice - in wooden houses the socket can be connected exclusively in an open way, just like all other electrical wiring.

Advantages:

- You don't have to cut the wall to install a new outlet. This is especially true for those premises that have already been renovated.

- Installation does not require tools such as a wall chaser or a hammer drill.

- In the event of a breakdown, you don’t have to open the wall - all the wiring is in front of your eyes.

- Installation speed. Even after all the work has been completed, adding another point to the existing wiring is a matter of several minutes.

- If desired, you can quickly completely change the wiring - ideal for temporary connection schemes.

Flaws:

- There is a high probability of external influence on the wiring - children, pets, you can simply accidentally hook it. This disadvantage is mitigated by laying wires in cable channels.

- Exposed wires spoil the entire interior of the room. True, it all depends on the design abilities of the owner of the room - cable channels will fit perfectly into modern design solutions, and if the room is made in a retro style, then special wires and other accessories are produced for this.

- The need to purchase special fasteners, even if cable ducts are not used - in wooden houses, open wiring should be laid at a distance of 0.5-1 cm from the wall surface. Wires are often laid inside iron pipes - all these requirements are aimed at increasing the safety of using open electrical wiring.

Despite some significant disadvantages, it is used almost everywhere - the advantages of its use still outweigh.

Advantages:

- The wires to the socket fit into the wall, so wallpaper or other finishing can be done freely on the outside.

- Meets all fire safety requirements (in concrete buildings) - even if a short circuit occurs, there is no fear of a fire from the wires in the wall.

- There is a very low probability of damage to the wiring - it can only be damaged when drilling walls.

Read more: How many amperes are in an outlet?

Flaws:

- For installation you need to cut the walls.

- It is difficult to carry out repair work.

- If the walls are finished, then after installing an additional outlet you will have to redo it.

Sockets in drywall

This is both hidden and open wiring - it belongs to the first category because the wires are not visible, and it falls into the second category because the wires are not walled into the wall and can be reached. In addition to standard tools (unless you are installing a socket block), you will need steel wire for installation. The procedure is as follows:

- The socket and socket box are removed from the wall. They are screwed to the drywall, so there is no need to break anything.

- The steel wire is inserted into the hole and pushed in the direction where the new socket is planned to be installed. At this stage, you just need to make sure that there is a gap between the plasterboard slabs, profiles and the wall into which the corrugation with wire will pass (wiring unprotected from mechanical damage cannot be left inside).

- If you can find the way with the wire, then a hole is drilled in the right place for a new socket box. A strong rope is screwed to the wire and it is pulled back.

- Then, using a rope, a corrugation is pulled between the sockets, the wires are inserted into it and connected.

If it is not possible to stretch the wire between the profiles, then a more radical remedy is used - unscrew a sheet of drywall, stretch the wire and screw it back. All that remains is to putty the damaged joints and install the socket. In some cases, instead of unscrewing the whole sheet, a hole of the desired shape is simply cut out in the drywall (after unscrewing the fastening screws), which is then put in place and puttied.

Selecting the cable cross-section and connecting it

The cross-section of the cable cores is selected depending on the planned load (in kW) and the core material. It is not at all necessary to do all the wiring with a cable with the same core. You can save money without compromising safety. To do this, a cross-section is selected for each section depending on the power of the devices that will be connected here. Their power consumption is summed up, about 20% of the reserve is added, and the cross section is selected based on this value in the table.

Table for selecting electrical cable cross-section depending on the load

To connect the power supply in a wooden house, fire safety requirements are also added. The main thing is that the wire sheath must be non-flammable. Such wires have the letters “ng” in their names. To ensure the required degree of protection, double (VVG) or triple (NYM) cable insulation is also required.

To ensure that electrical wiring in a wooden house is done correctly with your own hands, it is best to use cables with multi-colored cores. Then you will definitely not confuse zero with phase or ground. Typically the colors are distributed like this:

- “earth” - yellow-green;

- "zero" - blue;

- “phase” – brown.

If you buy a cable made in Europe, the colors are different:

- “earth” - yellow-green;

- "zero" - white;

- "phase" - red.

Options for arranging two outlets from one

Having decided to independently install an additional electrical outlet, you will need to learn how to correctly install a new outlet from an existing outlet and familiarize yourself with the recommendations and advice of experienced craftsmen.

If you do not have confidence in your own abilities, then it is better to invite an electrician who has considerable practical experience behind him.

When installing an additional outlet yourself, you have to decide what it will be like:

- a new point, a couple of meters away from the existing one;

- double model instead of single;

- a whole block of 3-6 points.

Depending on your individual needs, you should choose the most appropriate option. If there is simply not enough one more electrical point to turn on all the necessary devices, then it is more convenient and easier to install a dual model.

Even a beginner who has no experience or special knowledge of electrical installation work can implement such a solution.

The electric stove requires a separate power cable that can withstand a large load

When you move the sofa in the room and change the location of the TV, or buy a PC for older children, you can’t get by with a double socket. You will need to install an additional one or two new ones.

And if the power consumption needs are higher, but the thickness of the wire cross-section allows it, it is best to install a block with 4-6 slots. This solution can fit harmoniously into the interior without cluttering the walls with unnecessary details.

Ways to connect sockets

Today, connecting sockets is carried out in two ways: in the first, a separate electrical wiring line is installed for each point, in the second, several points are connected to one branch at once.

The type of sockets installed is closely related to the type of wiring: whether single-phase sockets are used, equipped with or without grounding, or three-phase devices are installed to power devices that operate on a 380-volt network.

The vast majority of technical devices that need to be connected to the power supply are located or confined to the kitchen and bathroom:

Sockets for powerful consumers, for example, electric ovens or boilers, are connected with a separate line. Whenever possible, use whole pieces of cable during installation, devoid of any connections. Electrical lines are laid separately from the shield to each point, which somewhat resembles the rays emanating from a star.

If it is necessary to connect each such consumer, the powered point must withstand a rated current of 16 - 32A. The circuit breaker at the input is also designed for a current with the same indicator.

A daisy chain connection is chosen if it is necessary to power the electrical outlets of one group. These groups are formed in accordance with the location of appliances around the house.

Sockets with separate lines are the only correct option for servicing powerful household appliances such as a washing machine or electric stove.

The method involves connecting all elements to a common power supply line.

To reduce the risk of damaging several points at once, experts recommend including no more than two or three outlets in one system. This point is clearly stated in SP 31-110-2003: it is allowed to connect up to three additional electrical receivers with a cable.

A significant “disadvantage” of such a circuit is that if one of the cores is accidentally damaged at the point of contact, all the elements following it stop working

The only condition is that the total current load does not exceed twice the operating rated current of the first (head) electrical receiver.

But, in any case, the circuit created in this way is designed for a load whose total value does not exceed 16A. If operating conditions are not observed, there is a high probability of emergency situations.

When connecting sockets, it is not at all necessary to use a pure type of wiring. With the right approach, they can be combined, for example, connecting the power cable to the junction box. And after it, direct one cable in the form of a loop, and lead the other separately to the power supply point of powerful equipment in the house.

The number of supply lines laid from the panel depends on how many electrical wiring routes are supposed to be laid.

To connect an electric fireplace with a power of 2 kW, it is worth providing a separate independent socket, but the iron can safely be powered from points connected by a daisy chain method

Regardless of the type of method chosen, electrical wiring can be done in one of two options:

- open - involves laying wires on the wall surface;

- closed - involves hollowing out channels for laying power lines in concrete and brick walls, selecting a channel in wood for laying a cable pulled into a corrugated pipe.

The open version is more convenient and simpler in terms of not only installation, but also maintenance and control. But regarding the aesthetic aspect, an open wire is not always appropriate. And besides, the open installation method “eats up” part of the usable space: it is impossible to hang a shelf on top of the cable or move furniture close to the wall.

With an open installation method, cable ducts or plastic skirting boards are used to protect the PE conductor from mechanical damage and make it more presentable.

The interior of most cable channels has partitions between which it is convenient to place wires. The condition of the route is monitored through the upper removable part.

The closed wiring option is convenient because it eliminates the possibility of accidental damage to the cable, making it invisible to others.

To minimize the need to “rip apart” the walls to create grooves, closed wiring is performed at the stage of construction or repair work until finishing is completed

But the “invisibility” of closed wiring can also play a cruel joke when trying to “hammer a nail.” Therefore, there is an unspoken rule: lay the wires in relation to the sockets strictly vertically or horizontally.

Features of installation of daisy chain connection

As already noted, the daisy chain method is used to connect sockets located in the same group, which power low-power devices, such as a computer, audio equipment...

This type of connection is more economical and technically simpler. After all, to implement it there is no need to lay a lot of cables and use additional protection. But it is worth noting that each additional point of the created chain will make it more vulnerable.

For example, we know that the rated current per outlet should not exceed 16A. If you connect such a load to one point, then nothing bad will happen. But when you turn on such a load on at least 2-3 sockets of one line, its total readings will increase, and as a result, the power cable may not withstand it.

The key condition for a daisy chain connection is that the cross-section of the jumper conductors will correspond to the conductors of the main supply line

According to the PUE, during a daisy chain connection, it is not allowed to break the PE conductor of the protective grounding wire. In any case, its contour must remain unbroken.

The use of one of the technical solutions helps to reduce material costs when connecting PE conductors to sockets:

Installation using connectors

This type of connection is chosen when it is necessary to connect sockets that are located almost close to each other.

With a daisy-chain connection, the main wire supplied from the power panel goes to the seat of the multi-place socket box. From it it powers the first socket, from which, through its own contacts, power goes to the second socket, from the second to the third.

All conductor wires: blue for neutral “neutral”, red-brown for “phase” and yellow-green for “grounding” - are connected in parallel

When installing with a cable, the incoming and outgoing cables are connected directly to the contact part of the device. For this reason, craftsmen recommend using models equipped with a flat spring contact.

As a last resort, samples whose contacts are made in the form of a plate pressed with a bolt are suitable. Devices in which the role of a contact is played by an ordinary bolt are not at all suitable for this purpose.

One of the mandatory operational requirements when connecting sockets with a cable is the need to reduce the contact resistance in the circuit between the contact terminals of the socket and the contacts of the electrical plug.

To achieve the desired effect, the terminals are shaped to increase the area of the contacts themselves, as well as the force of their compression. Today, Scotchlok connectors are often used to install protective zeros. This type of clip connector is equipped with mortise contacts.

To create a branch, the clip connector is mounted inside the installation box, placed between the bottom of the device and the socket mechanism

To use a clip connector, you should choose products that provide additional space to accommodate it.

Through the contact of the first socket, the phase wire of the power cable and the PE conductor of the loop are supplied, which goes further to the second socket. On the second contact there are neutral wires of the power cable and a cable to the second socket. The same principle is used to connect to the third and subsequent outlet, if its presence was provided for in the power wiring diagram.

According to the PUE clause 1.7.144, in order to connect the open conductive part of the device to the neutral or grounding conductor, it is necessary to make a branch in the cavity of the casings of electrical installation products intended for this purpose. These include sockets.

The main task when connecting sockets equipped with grounding is to ensure a reliable connection of elements along the entire line. After all, if for any reason the grounding contact burns out in the main power socket, all other participants in the circuit will lose the protective zero. Therefore, if it is necessary to branch the grounding conductor, the most reliable type of connection is used - crimping.

To perform crimping, the cleaned ends of the wires are inserted into the cavity of a special metal sleeve and crimped using hand press pliers.

The method involves, in addition to the use of conventional twisting of wires, additional insulation and crimping of their ends using a sleeve. This ensures uninterrupted contact of the chain elements and its high mechanical strength.

Installing an additional junction box

This method involves installing a branch box or connecting block connected to the shield next to the socket cable. In this case, the cable is branched in the distribution box in the area before being connected to the socket box.

The use of an additional branch box for PE conductors also allows connecting grounding contacts in parallel when wiring sockets with a cable

The connections inside the branch box leading to each outlet are most often made by welding. It is recommended that the insulated ends of all conductors be laid in junction boxes so that they do not intersect or touch each other.

When planning to make new connections from the junction box in the future, at the installation stage it is worth leaving a cable reserve of 15-20 cm long

In both cases, when connecting the phase and neutral wires to the sockets, a loop is formed, and a branch is formed from the PE conductor. Therefore, when wiring sockets, it is important to observe the polarity of the contacts: remove the neutral conductor from the terminal with neutral. Do the same with the phase wire.

Taking into account the number of working electrical appliances, the number of sockets in the room can reach 10 pieces. Using tees and extension cords is not always convenient, and it is also dangerous. In this case, they solve the problem by installing socket blocks instead of a single socket.

The design of the socket block, which includes up to four separate elements, is connected according to the same principle as a single socket.

The main difference between an overhead frame and a socket block is that each element in it is assembled into a sequential loop from one to another

When connecting blocks, the conductor cores are connected in any of the described ways. Bare areas are insulated with heat-shrinkable tubing or wrapped with insulating tape.

How are sockets and switches connected?

We hope that the general part of the circuit structure is clear to everyone. Now let's see how the electrical points are connected to it.

Connection diagram for luminaires via a two-key switch

So, we have a group power wire that comes into the junction box. This wire can have two or three cores. According to modern standards, three-core wires are used for these purposes. It is worth saying that the connection diagram will not change much depending on the number of available wires.

- All three wires will have different color markings. White or pink is phase, blue is zero, and yellow-green is ground. Be careful and careful when making connections, as there is always a chance that the electrician connected the wires to the machine incorrectly. Pre-check the wires for voltage with a tester.

- Let's start the analysis by connecting the outlet. The phase and zero are connected to its power contacts, while the “ground” is connected to the grounding contact. That is, to connect it to the network, all three wires are used.

Grounding is required to transfer charge from the device body to the ground loop, which avoids electric shock.

- With the switch, everything is a little more complicated, since this part of the circuit also includes a lighting device.

- So, we have three wires in the box - they are separated from each other and we can clearly see the color coding, which corresponds to the actual parameters of the circuit. A two-wire or three-wire wire is laid from the distribution box to the switch box - the first is taken for a single-key switch, and the second for a two-key switch. If there are even more keys, then the number of conductors increases proportionally.

- We screw the stripped ends of the wire to the switch terminals. Let us say right away that only phase wires will be suitable for this device, regardless of their number. The fact is that the task of the switch is to break the circuit and stop the supply of electricity to the lighting fixture. That is, the ends of the wire are input and output.

- Already in the distribution box, one core connects to the phase conductor of the group wire. The second core is connected to another wire, which is extended to the lamp as a phase. This wire also has two or three cores - the second is connected to zero according to the color marking, and the third is connected to ground. We do the same if the switch is two-key, but according to a slightly more complicated scheme. Here the task is to divide the lighting fixtures into groups and turn them on separately.

Connecting wires in a junction box

Video - Connecting a socket and switch

If you have read the above carefully, then you already understand that the connection diagrams for the points are completely different and there is simply no zero or grounding in the switch box so that you can connect the outlet. So how can this be done? Let's name all acceptable methods.

Installation instructions from existing

First, they determine which one will be sufficient. Secondly, special attention is paid to the choice of wire to prevent overheating of the contacts.

Varieties

GOST, for use in domestic premises, recommends several types of

- No grounding. Type C 1a. Provides operation of simple devices; in operating mode it can withstand up to 250 W, 10A DC and AC up to 16A.

- With two contacts on the sides for grounding. Type C 2a. Designed for connecting heating columns, washing machines, electric ovens, pumps and other household appliances. The power parameters are similar to the previous ones.

- Equipped with pin format grounding (how to install a grounded socket?). Type C 3a. Designed to connect powerful energy consumers. Characteristics are the same as C2a.

- Type C5. Old type, withstands up to 6A.

- Euro sockets with a protruding body and widely spaced holes for the plug. They are type C6 and are suitable for devices with the same plugs.

Each device consists of

- pads;

- protective housing;

- contacts.

Wire selection

If the requirements of the standards are not met, the contacts overheat

- A three-core cable is suitable for grounded ones.

- Without grounding - two-wire, in which the yellow conductor is intended for grounding:

- blue - for the neutral wire;

- red and brown - for the phase.

- Ungrounded wiring consists of two wires - zero and phase.

- Three-core (grounding, neutral and phase) increases the safety of cable operation and helps to avoid electric shock.

For installation of wiring inside the room, it is advisable to use a wire with a copper core

Serial and parallel connection

- Professionals advise connecting additional sockets in parallel when the cable to the new point is pulled from the junction box. This method is the safest.

- Most often, a serial connection is chosen, in which the next one is taken from one point, that is, the cable is connected from an existing socket to an additional one. This method is also called a loop method; it is chosen when it is inappropriate to use the first one.

Sequential rules

The main condition for serial connection is the ability to use electrical appliances with low power

Advantages and disadvantages

The final version of the wiring diagram

To determine the optimal connection diagram for sockets and switches, it is necessary to prepare a wiring plan, calculate the number of devices and the possible maximum power. At the same time, in newly built buildings it is necessary to plan future possibilities without unnecessary modesty: an additional TV, the purchase of a separate freezer, and the like.

Based on the data received, the connection type is selected. The advantages of the sequential method include:

- simple connection system and circuit assembly;

- the ability to adjust the voltage level, make it less;

- You can use one fuse per circuit.

The disadvantage becomes obvious after a malfunction occurs - if one socket breaks, the rest will not work.

Compliance with safety precautions when installing sockets

Compliance with basic safety standards will allow you to perform high-quality work on connecting and operating sockets

Work with electricity is classified as dangerous. Even low voltage leads to burns, injuries and other unpleasant consequences. Compliance with safety precautions:

- de-energize the room in which the work is being carried out;

- check the area before starting with a special device (you can plug the device into the network);

- use rubber gloves and equipment with rubberized handles;

- when “increasing” the length, it is not enough to twist the wires; soldering is required;

- contact with connected bare cables is not allowed;

- the excess should not “stick out” - it is shortened and placed in the wall;

- check whether the devices are suitable for the current and voltage levels used.

Anyone can connect sockets using these methods.

The schemes have advantages and disadvantages; before the final choice, it is important to establish the power of the equipment and the method of branching the wiring

Preparing to connect

First of all, de-energize this section of the electrical wiring and make sure that there is no voltage using an indicator screwdriver.

Determined by the method of laying the wire, there are two options:

- open: along the surface of the wall in the cable channel. The method is fast and low-cost, but unaesthetic;

- hidden: in a groove (groove), subsequently filled with solution. A more attractive way: only the sockets will be visible on the wall.

If the sockets are removed significantly, you can reduce the length of the grooves or cable channels by laying the cable along the following path: from the source socket down in the groove or cable channel to the baseboard, then under the baseboard to the place under the new outlet and then again in the groove or cable channel directly to the outlet.

Further:

- drill a hole in the wall with a crown for a new socket;

- fix the cable channel with dowels or cut out a groove - depending on the adopted installation method. It is convenient to cut the furrow with a professional wall chaser with a built-in vacuum cleaner. The home craftsman should rent this expensive tool. If this is not possible, use a hammer drill to drill a series of holes along the route, and then use a chisel to knock out the spaces between them. Or you can make two slits along the boundaries of the future groove with a grinder and remove the wall body enclosed between them in any way convenient for the performer;

- A corrugated pipe is placed in the groove, a piece of wire is placed in it, and then the groove is sealed with plaster or cement mortar. The corrugated tube will provide the ability to replace a damaged wire without opening the groove.

If the thickness of the plaster on the wall is at least 4 mm, you can do it simpler:

- cut the wallpaper along the cable line, wet the edges and then spread them apart;

- scratch a groove in the plaster so that only the cable can fit in it;

- lay the cable and fill the groove, then glue the wallpaper back on.

When the routing is open, a cutout is made in the front panel of the existing outlet to release the wire: it will allow it to fit snugly against the wall.

The length of the cable for connecting a new outlet is selected so that there is a margin of 20 cm on each side. This is necessary for a quality connection.

Options for arranging two outlets from one

Having decided to independently install an additional electrical outlet, you will need to learn how to correctly install a new outlet from an existing outlet and familiarize yourself with the recommendations and advice of experienced craftsmen.

If you do not have confidence in your own abilities, then it is better to invite an electrician who has considerable practical experience behind him.

When installing an additional outlet yourself, you have to decide what it will be like:

- a new point, a couple of meters away from the existing one;

- double model instead of single;

- a whole block of 3-6 points.

Depending on your individual needs, you should choose the most appropriate option. If there is simply not enough one more electrical point to turn on all the necessary devices, then it is more convenient and easier to install a dual model.

Even a beginner who has no experience or special knowledge of electrical installation work can implement such a solution. But if this is your first time connecting sockets, we recommend that you first study the following material, which provides step-by-step instructions on connecting electrical points.

The electric stove requires a separate power cable that can withstand a large load

When you move the sofa in the room and change the location of the TV, or buy a PC for older children, you can’t get by with a double socket. You will need to install an additional one or two new ones.

And if the power consumption needs are higher, but the thickness of the wire cross-section allows it, it is best to install a block with 4-6 slots. This solution can fit harmoniously into the interior without cluttering the walls with unnecessary details.

Connection materials

The wire for connecting the electrical point must be made of the same metal as the main cable. For example, when using an aluminum cable, the jumper must also be made of aluminum.

To ensure an even distribution of incoming electricity, the cable used for connection must have the same cross-section as the main wiring in the room

To install a double socket you also need:

- flat and Phillips screwdrivers;

- braid stripping tool;

- pliers;

- insulating tape.

For safety reasons in case of fire, it is recommended that any electrical wires be laid in corrugation. This solution is also convenient because it does not require breaking through the wall, and also simplifies the replacement of damaged wires during subsequent operation.

Installing a block with two and three keys

Installation of such a block makes it possible to control two light sources in different rooms, or two in one room. In this case, not 4 wires are supplied from the distribution box, but five.

- The phase is connected to the jumper of the switching block.

- Only the neutral wire and the grounding conductor are attached to the socket contacts.

- Then the two remaining conductors are connected to the switch contacts.

- In the distribution box, twists are made of the cores that supply the core and those that go to the lighting fixtures.

Three-key combined devices are the best option for small apartments. They often have a bathtub, a toilet and a kitchen nearby, and the lighting is switched on on one wall. If there are three keys, then you will need a cable with six cores, three of which are also connected to the switch terminals.

Types of double sockets

The main elements of an electrical outlet are the outer protective casing and the working part, which includes the base and contacts.

They are connected to each other by screw terminals - clamps necessary for connecting the cable of electrical equipment.

The only drawback of double sockets is that it is problematic to connect two high-power electricity consumers through them simultaneously

There is a misconception that double sockets are identical to assembled or dual models and represent several independent devices located close to each other, interconnected by cables.

If a double socket is connected to one power circuit, then electrical installation work is carried out according to a scheme similar to connecting a single socket. The only difference is the serial connection of two contact pairs within the electrical installation product

Technological progress does not stand still. Modern models are more advanced designs. In terms of rated voltage and current, they are strikingly different from the sockets that were ubiquitous during the Soviet era.

For example, if in old-style models the permissible current did not exceed 10A, then for modern electrical installation equipment this figure is 16A.

Each part of a double socket can be connected to a separate power circuit if you first remove the brass jumper connecting them at the terminal

In reality, a double socket has one clamp and several distribution strips. Due to this, the electric current is supplied to both sockets equally, but its level will be divided depending on the power of the devices powered from the network.

Therefore, when replacing a failed old device with a new one, it is worth knowing its design features, which require certain nuances during installation.

The distance between the output contacts, as well as the diameter of the plug pins, in modern models is larger than in traditional analogues, and is 4.8 mm instead of 4 mm

According to modification, double sockets are classified into the following main types:

- Open and closed execution. In closed models, the holes are hidden behind curtains, which move to the side when the device is turned on. Devices of this type are indispensable for homes where there are small children. The curtains only work when pressed at the same time. Thanks to this, even if a foreign object is deliberately inserted, nothing dangerous happens.

- Without grounding and with grounding contacts. In models of the second type, grounding contacts are installed on the socket body, which protect electrical appliances and the user from breaking currents that accidentally “exit” the plastic body.

- For installation in rooms with high humidity and outdoor installation. Models of the first option are marked IP-44. They are equipped with a housing that protects the device from moisture penetration. Devices for outdoor installation are marked IP-55. Their highly durable housings are protected from dust contamination and moisture penetration.

Each type has a corresponding letter marking. For example: “A” indicates that this is an American double socket, “B” indicates the presence of a grounding contact.

Depending on the type of design and material of manufacture, devices are also divided into standard and polar, overhead and custom-madeAmong the latest developments, programmed sockets are especially popular. Devices equipped with a timer turn on and off independently from the power supply after a set time interval has elapsed.

The protective housing of modern sockets is made of heat-resistant, unbreakable plastic. To enhance its decorative qualities, it is decorated with various inserts.

Thanks to the variety of design options, you can choose devices that will be invisible in the interior or, on the contrary, act as a worthy decoration.

When planning to install a double socket yourself, experts recommend choosing simple models without any modifications. Or give preference to double sockets with a spring-loaded plug ejector. Such models are convenient because they are equipped with springs that are activated when the plug is removed from the device.

To protect yourself by minimizing the risk of accidents, you should choose products from proven companies, ABB, and Legrand.

Choosing the appropriate wiring method

Table of the ratio of core cross-section to current loads

All methods of getting power from an outlet for another outlet can be divided into several groups. According to the method of fastening - inside the wall, outside or from the outside of the main power point with the wires leading out. Further work is carried out in a similar way.

Key operating points:

- Cable thickness. The cross-section of the child outlet should not be less than the parent one.

- Design decision. Directly depends on the interior of the room and does not affect the technical characteristics.

- Connection procedure. Household appliances may have two or three contacts. In the first case, these are phase and neutral wires, which are connected to different contacts. With a three-wire connection, grounding is added. It is connected to a mounting bolt on the device body.

- Grounding. If the main outlet has it, subsequent power points should also have it. According to the requirements of the PUE, the cable must be solid.

Electrical markings

Any quality work begins with accurate markings. Most often, professionals use laser levels and axle builders for this.

With their help, you can quickly and accurately mark the centers for all the sockets in the room. It would seem that a couple of millimeters will not play a decisive role here. What's wrong with one block at the beginning of the room being slightly higher than the other at the end.

However, very often in apartments you come across wallpaper with horizontal or vertical stripes. And these stripes will clearly show when the socket box is not installed level.

The same can be said about the seams on the tiles.

Therefore, place all socket boxes in the room in the same plane. The recommended distances are as follows:

for sockets – 30cm from the floor

for light switches – 60-90cm

everything above the countertop, in the bathroom or kitchen – 110cm

After all the centers of the socket boxes have been marked, then proceed to marking the mounting points for the lamps, both on the walls and on the ceiling.

At the same time, you can mark out places for hanging plasterboard structures. Since in the future, when all the cables and corrugations are on the ceiling, marking the fasteners for drywall will not be very convenient.

But it’s worth bothering with all this if you will also be installing the structures.

After all this, proceed to making marks for the corrugation fasteners. The most important thing is that they do not interfere with each other.

Usually, competent marking, even with the use of modern measuring instruments, takes a full day of work. Prepare yourself in advance for exactly this period. If you are in a hurry, it will definitely backfire on you during further installation.

How the new input cable was laid

Mark the wire attachment points directly on the wall. We drill holes and install fasteners. They will allow you to maintain a distance between the wall and the wire. The fastening is searched for using the phrase “facade fastening for wire.”

Corrugated cable fastenings along the facade

The screed is usually included in the kit.

Cable mounts are mounted under the canopy along the facade of the house

To be honest, we managed to meet only one height requirement – at least 2.5 m from the ground.

Gander for fastening SIP and input cable, there will also be a connection point

After installation is complete it looks like this:

New entrance to the house: SIP and corrugated cable on a gander

We are done with this stage.

Installation process

Before electrical work, turn off the power

Preparatory work

- Disassemble the socket by unscrewing the cover.

- The socket box is also removed and access is gained to the terminals to which the wires are attached.

- When installing externally on a concrete wall, you need to pre-drill holes for the socket box at the fastening locations in order to be able to use plastic dowels. Self-tapping screws are suitable for a wooden base.

- The hidden method is complicated by drilling a hole for the socket box. To do this, use a chisel with a hammer, an impact drill, or a hammer drill with a core drill for concrete.

- A round hole is cut with a drill, and the groove is brought to the desired size with other tools.

- A groove is made with a puncher or drill, a wire is laid, which is hidden under the plaster.

Connecting the cable

- Remove the cover from the device, exposing the inside where the terminals are located. Remove the flexible insulation that hides three parts of the wire: phase, ground and neutral. Moves apart for ease of installation. When working with hidden wiring, leave a 20-centimeter margin.

- Carefully strip all three wires of insulation to about one centimeter without damaging the core.

- Loops are formed and flattened with pliers to ensure optimal contact.

- Then, pulling it under the screws, they press it against the terminals with force for better fixation of the exposed contacts.

- They adhere to color coding: the yellow wire corresponds to grounding, the other two are phase and neutral.

- The device is assembled by screwing the inner part to the working part.

Connecting the cable

- The cable is stripped, two loops are formed, flattened, and securely fixed with terminals.

- The wires are wired according to the color coding.

- Then screw the housing into place.

On our website you can also learn about the features of installing sockets with USB and Wi-Fi.

How to hide a wire

Methods of using elements to hide wires

The method of fixing the electrical outlet depends on its use. It can be screwed to the baseboard or left as a carrier. This method is used for outdoor products. The cables can be hidden in a special cable channel, which is glued to the wallpaper or secured between the baseboard and the socket cover.

If the socket is installed for a long period, the wires can be hidden under a layer of plaster. If the wall is covered with wallpaper, you can cut it along the laying line. Next, you need to carefully peel off a small part of the wallpaper and make a hole in the wall for the cables. The wires are laid in the furrow made, puttied and covered with wallpaper.

Drilling out socket boxes

Next begins the noisiest and dustiest part of electrical installation work - drilling and chipping.

In order to minimize the amount of dust, construction vacuum cleaners are used.

In addition, each tool in this case must have an outlet with a pipe or a dust removal device.

Small hammer drill, medium hammer, large hammer, wall chaser, all of these tools must have dust removal, otherwise your vacuum cleaner will be of no use.

First, the centers of the socket boxes are drilled out using a d-6mm drill. Then, based on the material of the walls, a tool is selected for arranging niches for socket boxes.

It could be:

medium hammer drill with diamond bit

large hammer drill with impact bit

wall chaser with a cut 60mm deep

How to choose a good double socket

Table of degrees of protection

When choosing a product, you should pay attention to the following criteria:

- The size of the mounting box corresponds to standard holes in the walls. It is advisable to install a double socket in one socket box without carrying out additional drilling work to expand or deepen it.

- Degree of protection. For a family with no children, conventional models with an IP22 rating are sufficient. Products with degrees of protection IP33 and IP43 are equipped with curtains that protect the contacts from splashes and penetration of solid objects. For the bathroom and kitchen, it is better to take IP44 sockets, which are not afraid of splashes and streams of water flowing along the wall.

- Contact standard. You should stop at F or C. Products of this type are adapted for all types of plugs and are equipped with a contact for grounding.

- Power. Sockets for 10A (2.5 kW) and 16A (4 kW) are available for sale. It is advisable to purchase a more powerful model to be able to connect consumers such as a welding machine or a washing vacuum cleaner.

- Internal organization. Preference should be given to models that are equipped with a protective cover for the contact group. The terminal tightening screws must be on the outside. This will help to maintain the device without dismantling it. You should choose products with terminals equipped with spring clips.

- Mounting feet. They must be made of thick steel that will not bend when installing the mechanism in the socket box.

- Restriction of access to terminals. It is necessary that each wire has its own hole, which will eliminate installation errors.

What power is household wiring designed for?

We came to the conclusion that the amount of current in the socket can be:

- normal for switched devices;

- or critical, creating the preconditions for accidents in household wiring.

Let's focus on the second point. Electricians are well aware that all sockets are connected in parallel.

This means that the total resistance of their consumers increases the total current through the home wiring.

Normal operation

Let's consider two groups of consumers powered by their own circuits:

- refrigerator with a power of up to 1000 W through a 6-amp outlet and its own circuit breaker;

- a washing machine and a washing vacuum cleaner of 2000 watts each, connected to individual 16 A sockets through a separate power circuit breaker.

All chains and sockets operate in normal mode, have a current reserve and a power reserve.

The current in two outlets will not exceed 9 amperes. At the same time, 18 A will flow through the circuit breaker, which is unacceptable for a rating of 16. Therefore, the circuit breaker must be chosen larger: 20 or 25 amperes. The input circuit breaker will begin to pass 22.5 A through itself, which will eliminate its nominal value by 20 amperes.

Emergency operation

The number of consumers is the same, but they are connected via a tee to one 16-amp outlet.

All currents from consumers are collected in a tee. Do you know exactly its maximum load?

The one that works for me is the one in the first photo. Its rated current is only 6 amperes.

However, we will continue the analysis, assuming that the tee will not burn out, although this is unlikely. All currents of 22.5 amperes will flow through the 16 A outlet and the circuit breaker. An emergency situation occurs that must be prevented by protection.

Electrical outlet device

Almost any master had to deal with connecting an outlet. At first glance, this procedure is very simple, but there are many nuances hidden beneath it. To prevent a self-connected outlet from becoming a source of problems, you need to understand the principle of its operation. It consists of the following components:

- Decorative overlay with fixed screw.

- Socket box. To fasten the element inside the mounting hole, it has tabs, with the help of which the insert is attached to the hole. The pads, whose contacts are movable, are more difficult to install, but thanks to their design it is possible to adjust the position in tilt and height. It is advisable to choose models with two-toothed feet. Compared to single-tooth ones, they are much more reliable.

- Contact box assembled. The terminals can be connected in various ways, such as with contact screws directly, or they can be made as a single unit. Two contacts, neutral and phase, as well as grounding which is located separately.

How to steal electricity through grounding. How to steal electricity from an apartment

In Russia, illegal connection to the power grid is quite common, through which electricity is stolen. Electricity is stolen from private and apartment buildings. There are several ways to steal electricity from the network.

Methods of theft:

- Remake the counter;

- Affect the operation of the meter.

With certain skills and knowledge of the design and operation of meters, you can remake them in such a way that they begin to count electricity by 30 - 50% less. For this purpose, these devices are equipped with additional elements.

For example, if the meter is electronic, additional transistors and electronic devices are soldered into its circuit, with the help of which the meter is remotely controlled.

If the device is mechanical, then in this case, the operation of its mechanical parts is changed. For example, they reduce the number of teeth on a gear.

Note! You are responsible for illegal connection to the power grid. If electricians discover an illegal connection to the electrical network, then a huge fine will be imposed on the consumer.

There are several ways to influence the operation of the meter. But in most cases, you will need access to the electrical elements of the device. In older models, it was possible to change the polarity of the connection, due to which the counter began to spin in the opposite direction.

To bypass the meter, some craftsmen will shorten the phase input and output of the meter with a jumper. Thus, the phase bypasses the counting mechanism of the device.

Older models of devices were stopped mechanically, using various wires or plates.

You can influence the operation of the meter using a powerful magnet. But it is worth noting that modern models are equipped with additional protection.