Pros and cons of a well in a garage

Having your own water supply in the garage thanks to a well is characterized by a number of advantages:

- free access to water allows you to clean the premises, wash your car, and wash your hands at any time;

- central water supply does not have any impact on water supply;

- a sufficient amount of water allows you to install one well for several garages, which is economical;

- there is no need to spend time and money on additional pipe laying and insulation of the system.

The disadvantage of drilling a water source in the garage is the inability to maintain the system well enough. Constant cleaning of water channels from silt and debris is required. In order to carry out cleaning work, it is necessary to free up all the space.

Contract clauses

To obtain permission to put a water supply system into operation or to install a new supply line to a site, you must draw up an agreement with the water utility. This cannot be done without obtaining all the permissions described above. The clauses in the contract with the water supply company should include:

- Drawing up an agreement on the required connection conditions.

- The amount of time the applicant will receive water service.

- The quality of the water received and the procedure for monitoring this parameter.

- List of conditions under which water supply may be stopped for a short period of time.

- Water meter.

- Terms and conditions under which payments will be made for using the shared network.

- A list of items showing the division of responsibility for the use of water utilities between the consumer and the supplier.

- Rights and obligations that both parties must fulfill, as well as penalties for violating them.

- In what order will disputes between the supplier and the consumer be resolved?

- Permission to collect samples and access to meters for representatives of the supplier company.

Example of a water connection agreement Source rost63.ru

- When and how the user will submit data from the meter, if installed.

- How the user will be informed if the service provider transfers its rights to another organization.

- The conditions under which water will be supplied to those who are connected to the applicant’s water supply, if contractual obligations have been drawn up with the supplying company.

After installing all pipes and water supply units, it is required to draw up a report on the work performed, which must be signed by the applicant. If hidden work was done during the installation process, a separate form is required for this. They can be carried out when laying a pipeline. It is also required to draw up a SES report when flushing pipes and checking water quality for compliance with standards.

Example of a sewer connection agreement Source novostroy-s.com

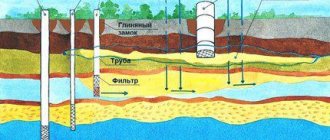

Features of the Abyssinian well

The Abyssinian well is a water source of medium depth. Water flows into the well all year round, and a consistently high level is observed.

Distinctive features of Abyssinian wells from drilled wells are:

- they use surface pumping stations, the operation of which is easier to control and easier to maintain (in conventional wells, a submersible pump);

- water intake depth 8-9 meters (depth of artesian wells 20 meters);

- The diameter of the pipes is 35 mm (the thickness of the pipes for drilled wells is 145 mm).

Drilling a water source in a garage is convenient:

- work is carried out at any temperature and in any weather conditions;

- work takes a maximum of 10 hours;

- water quality meets sanitary standards;

- durability of the structure;

- a properly installed system does not allow particles of earth to get into the water.

If the groundwater flows too deep, installing an Abyssinian well is not suitable.

For the work, a standard pipe measuring one inch and up to 32 meters long is prepared. A filter mechanism is installed at the end. A pump is mounted in the upper part. The drilling machine itself takes up little space. A space of 1.5 x 1.5 meters is required, the height of the room is not lower than 2.5 meters.

Drafting

To obtain permission for land work for a water pipeline, you need to draw up a site plan. This may be necessary if the premises are undergoing major renovations or for newly installed buildings. To obtain such design documentation, you can contact private architectural firms or relevant specialists in the company that owns the water supply network.

During the compilation process, it is required to provide the current number of people living on the site, as well as a layout of sanitary facilities and household appliances that are connected to the water supply. If there are additional sources of water on the site, they are also indicated. You will also need a house plan, a topographical survey of the site, the type of plumbing that is used and a list of restrictions on the use of the plumbing.

With the help of a ready-made project, you can understand the layout of the pipes, the size and material from which they are made, the thickness of the concrete screed if the water supply is installed in a wall or floor, as well as the required amount of material for installation and additional means for pumping water (if the pressure is insufficient).

Step-by-step construction with your own hands

To conduct water into the garage, you need free space in the room for work and placement of equipment. Therefore, it is ideal to carry out work at the stage of constructing the garage during the construction of the foundation. At this stage it is easier to plan the location of the source and install the necessary equipment:

- At the first stage, a borehole is made. Dig a hole in the shape of a square.

- A drilling rig is used to create a well. It is a tripod made of timber or tubes. If the soil is soft, it is enough to hammer the pipe with a sledgehammer.

- A wellpoint filter is installed in the hole made and immersed in the ground.

Having the necessary material, instructions and tools at hand, creating a water supply system will not be difficult.

Necessary materials and equipment

To carry out work on installing an Abyssinian well, the following materials will be required:

- PVC pipes;

- steel pipes;

- needle filter;

- hand drill;

- bolts, screws, nuts;

- steel tape;

- metal grid;

- couplings for connecting pipes;

- pump.

With the right tools, working is much faster and easier. You need to prepare a grinder, a drill, a welding machine, a sledgehammer, keys, and a hammer drill.

Design and calculation of measurements

The prepared pipes must be driven into the ground to a depth of 9 meters:

- The pipes are connected to each other with threaded fittings.

- A filter with a needle is constructed at the base. The needle is a cone-shaped tip. It is very durable and penetrates the soil easily.

- Then comes the filter section. Holes are made along the pipe meter. The pipe section is wrapped with metal mesh and wire.

The design calculations take into account the parameters of the well flow rate, the depth of lowering the pump, the diameter of the surface and internal surface of the pipe.

Installation and excavation work

The plan according to which the Abyssinian well is drilled:

- determine the location of the work and purchase the necessary materials;

- form a needle and filter;

- in the intended location, dig a hole with a diameter of 100 cm and a depth of 55 cm;

- use a drill to make a hole;

- install several parts of the pipe with a needle;

- install a homemade driving tool;

- a pipe is placed in the ground and new parts are welded as work progresses;

- work is carried out until signs of water appear;

- the hole is washed and left for a day;

- It is advisable to concrete the area around the pipe;

- at the final stage, connect the pump.

To arrange a water supply source in the garage, you will also need to purchase a pressure switch, a hydraulic accumulator, tees, a pressure gauge, hoses, taps, sealants and electrodes.

Installation of taps

In order to control the flow of water, ball valves are installed. The tap hole must match the diameter of the pipe:

- The pipe at the installation site of the tap is cut and threaded.

- The tap is screwed in using an adjustable wrench. Do not over-press the structure.

- A sealant is wound onto the threads of the tap in several layers.

After screwing on the tap, you should check the connection location. If water leaks out, the structure is disassembled again and the parts are checked for serviceability.

Filtration system

The filter is an important element of the well. To make it you need to take a pipe 1.5 meters long:

- On a segment equal to one meter, holes with a diameter of 9 mm are made in a checkerboard pattern.

- A cone is welded at the end of the pipe for better penetration into the ground.

- A winding is made from wire, which is installed between the pipe and the filter mesh.

- The filter mesh is chosen with a special galloon weave. The cells of the mesh are diamond-shaped, so they do not become clogged with grains of sand.

The water level is controlled by specially installed sensors. Sensors can be upper and lower level.

How to waterproof an inspection hole

There are many methods, they have different prices and different properties. Let's take a short overview of the most common solutions.

Roll materials

The goal of each material is to create a water-impenetrable barrier, but they all do it differently. There are three of them: rolled, coated and sprayed. Here the division is based on the method of application, but they can also be divided according to the method of protection - some create a film on the surface, while others penetrate deep into the base, endowing it with properties.

Interesting to know! Both coating and spraying materials are applied to the surface in liquid form.

Roll films and membranes are used as surface materials. They can all be divided into bitumen and polymer.

| Insulation, photo: | Description: |

Ruberoid | Rolled waterproofing is classified according to the type of installation: glued, fused and laid. For a pit in a garage, the latter option is most suitable, since it does not have a flat and solid base. However, if the walls are already bricked or concreted, then the first two solutions will have to be applied. The most common built-up roll-type waterproofing is roofing felt. This material has proven itself, and in different climatic conditions. It is cheap and effectively protects walls from water penetration. |

Pasted waterproofing | Paste-type materials are installed without burners. Their base is impregnated with an adhesive substance and can be mounted on a surface. There are also models for which the glue is sold separately. Back in Soviet times, cardboard was used as a similar solution, which was impregnated with bitumen, but it was not durable. Now materials are made based on natural fabric, fiberglass or polyester. Their structure prevents the insulation from being damaged by tensile loads. This material is used for both horizontal and vertical waterproofing. |

The pit is covered with a membrane waterproofing film | Laying materials cannot be used on ready-made surfaces of the inspection pit, but they are suitable for contact with the ground. There are many products in this category, ranging from simple polyethylene film to expensive diffusion membranes. Membranes perform best, as they allow water to pass in the opposite direction, protect reliably from groundwater, and last for 30 years or more. Polyethylene is cheap, but you should avoid it. It will quickly (within 5 years) begin to leak, and the further it goes, the stronger they will become. |

All types of films have one big drawback - they do not create a monolithic coating. Their weak point is the seams. To prevent leaks in them, overlaps of at least 10 cm are made when laying. All joints are carefully taped.

Rolled waterproofing is more suitable for garages under construction. The reason is that it must be located behind the walls of the pit, which are cast from concrete or lined with brick.

Surface coating waterproofing

These materials are sold as ready-made formulations applied to the surfaces to be protected from the outside. They can be used if the walls and floor of the pit are already ready, although there is an exception. The disadvantage of the solution will be that the base will still be in contact with water. This will cause it to collapse.

Material selection:

- Bitumen mastic remains popular due to its low price, but the material cannot saturate the surface to which it is applied, so in some places there may be unnoticeable gaps through which water will leak.

Bitumen mastic is the simplest material for waterproofing

- Waterproofing paint is a dispersion that is easily applied to surfaces. Minimum 3 applications required.

Rubber paint

- You can also recall the old folk methods of waterproofing. This refers to clay, which also has a similar type of application and operating principle. This coating creates good protection, but if there is a lot of water around, it may not cope. Therefore, it is recommended to use it as additional protection. The advantage of clay over store-bought counterparts is that it can be applied to the ground, which means good external protection will be provided.

The walls of the pit are covered with a layer of clay

Surface spray waterproofing

Sprayed materials have become the last word in industry. They are supplied in liquid form, in cylinders. Then they are applied to the surfaces using injection equipment and a sprayer. A durable and monolithic coating is created that lasts for years. Of course, few people will hire a team to apply such materials for a garage.

Let us highlight the most famous materials of this type:

- Polyurea is a complex polymer of a combined type. This is a type of polyurethane. This material is able to maintain its properties under the most difficult operating conditions. It can also serve as a finishing decorative coating - it comes in different colors. Installation can be carried out at very low temperatures in winter - down to -40 degrees.

Treating the Basement with Polyurea

- Shotcrete is a technology for constructing concrete surfaces when the mixture is fed through a special gun, which makes it possible to create plaster of very high density. One of the properties of such concrete is water resistance. It is achieved due to the method of application and the additives included in its composition.

- Liquid rubber is also applied by spraying. Its service life is at least 30 years.

Penetrating waterproofing

There is a category of substances called penetrites. Their main property is the ability to penetrate deep into the thickness of concrete, bind the water inside into crystals, and the concrete becomes waterproof.

Cement-based penetrating waterproofing

For waterproofing a pit in a garage with concrete walls, this treatment will be optimal, and if you combine the material with rubber paint, you can 100% guarantee protection from water.

Interesting to know! Additives can be added to the concrete solution while it is being mixed. Its frozen mass will be waterproof.

This waterproofing contains very finely ground cement and polymer additives. Due to this structure, substances penetrate into porous concrete. Penetrites also contain chemicals that trigger water crystallization processes. The liquid in concrete first turns into a gel-like mass, after which it hardens, crystallizing. The level of water absorption of treated concrete is practically zero.

Penetron is applied to concrete surfaces with a brush

This treatment remains with the concrete forever. The main disadvantage of the material is its high price.

Penetrating waterproofing materials also include some types of soil. These substances have a different base, but their principle of action is similar.

Acrylate-based waterproofing primer

Penetrating deep into the porous material, they crystallize inside, creating a barrier impenetrable to water. In addition, a film that weakly absorbs water remains on the surface of the wall, which improves adhesion and strengthens the material.

Soils quite effectively protect walls from getting wet, but not all of them. Ordinary ones penetrate into concrete by 3 cm, and deep penetration primers - up to 10 cm. They cannot compete with penetrites, since they can penetrate up to 40 cm into the thickness of the material.

We recommend using primers only as an additional measure. As in the previous case, they are recommended to be combined with a moisture-proof finish.

Any mineral base is suitable for primer treatment.

Advice from the author! When applying deep penetration primers with a roller and brushes, it is very difficult to calculate their quantity, since the composition is instantly absorbed into the base. It is much more correct to use a sprayer for these purposes. There should be enough composition so that it flows over the surface. To improve the result, processing should be carried out in several layers.

Internal waterproofing

Finished concrete walls, with a major approach to solving the problem, can be waterproofed from the inside, for which special substances and equipment are used. This technique is called injection.

Fighting the penetration of water into the pit by injecting concrete

Repairs of this type are carried out mainly for the foundations of buildings (read about methods of waterproofing foundations in the article), but in our case it can also be used. Of course, all this is expensive, but it happens that everything has been tried and nothing helps.

The following steps are in progress.

- Holes are drilled in the wall into which special tubes called packers are driven. They are drilled straight or at an angle of 45 degrees, depending on which direction the insulating composition should spread.

- Next, hoses are connected that lead to pumping equipment - it is selected depending on the composition used.

- The insulating substance is injected under pressure into the walls. It penetrates effectively into the thickness of the material and closes all pores.

The principle of penetration of the repair compound is shown in the following figure.

Waterproofing a wall using injection method

Substances with a certain set of properties are used as repair compositions. They must be or have:

- High penetrating abilities.

- Reduced viscosity.

- High adhesion.

- Resistant to aggressive environments.

- Durable.

In total, there are three types of such mixtures: epoxy, polymer-cement and polyurethane resins.

Starting and checking the system operation

At the final stage, the operation of the entire system is regulated. After drilling is completed, muddy water appears.

Initially, before installing the filter, the well is pumped. A vibration pump will be needed. It is also important to decide where the dirty water will be drained:

- The pump is lowered into the hole, turned on and pumping water begins.

- After some time, the pump is pulled out and washed in clean water.

- The washed device is lowered into the well again.

- The procedure is repeated until clean water appears.

After the water becomes clear, the pump is changed to a well centrifugal type.

To ensure uninterrupted operation of the well, a pressure switch, expansion and storage tank, and filters are additionally installed.

What are they pumping out with?

Pumped out from the cellar using automatic pumps.

Automatic pumps are:

- submersible – placed in a liquid;

- external - its upper part is on the surface, its lower part is under water.

On the website you can find a layout diagram of the automatic water pumping system.

Installation algorithm:

- in the center of the basement a recess is made for a tank - a caisson. The caisson is needed to accumulate moisture;

- for better protection they are wrapped in geotextiles;

- install the pump in the tank;

- after filling, the pump turns on automatically;

- after pumping it turns off.

Read more: how to use a pump to pump water out of a basement.

The easiest way to pump out water is with a pump

Water source in the garage: is it possible?

What to do if the pump gets stuck in the well?

How to clean a well yourself?

The importance of protecting the source of water intake and the design of the head

Many owners of country houses want to provide water supply not only inside the house, but also in technical rooms. A well in your own garage is quite possible, but this choice is determined by both advantages and disadvantages.

Video description

This video shows an example of drawing up a water supply plan:

The applicant must receive a package of documents from the construction organization, which includes:

- A title page that displays general data and contains an explanatory note.

- A plan diagram showing the location of the main water supply line.

- Pipe routing diagram, which indicates all the nodes and points at which the fastening is located.

- Three-dimensional diagram of the water supply and heating elements.

- List of materials used for installation and wiring, as well as what they are made of.

Without this diagram, it will be difficult to calculate the amount of water consumed and the correct location of the outlet to the main supply line.

Example of technical conditions Source dasiz.khabarovskadm.ru

Advantage of drilling

Drilling a water source in the garage is about ease of use. The choice of such a location is considered economical, since it does not require additional costs for thermal insulation of the source, installation of a caisson and laying a pipe line to supply water to the house.

To create a well in the garage, you should take into account the dimensions of the room in order to create all the necessary conditions for placing the drilling machine.

The room should be at least 2-3 meters in area with a height of 3 meters. In addition to the appropriate area of the garage, it is worth determining the area for the drilling fluid.

The disadvantage of drilling a well in a garage is the impossibility of quality maintenance of the source. The water source will eventually require a major cleaning of the water vein, so the room should be as free as possible from foreign objects.

Drilling in a garage is best carried out at the stage of construction work at the time of erection of the foundation. At this time, you can easily plan the location of the future source and allocate space for equipment. Drainage from the garage to the street is carried out by concreting an iron pipeline 85 mm wide. This is necessary for further maintenance of the source.

When installing a water source in a garage at the depth of the shaft, high-quality sealing must be carried out. When the groundwater level rises, the standard liquid level increases, without taking into account the initial depth of the well. To prevent flooding of the premises, it is necessary to use a sealing element - a well cap. Also, a special approach should be taken to sealing the source pipe. You can do all the work yourself using waterproofing material in the form of liquid rubber or silicone. These types of material will best resolve the issue of water insulation.

Documentation

The owner of the site, the one who has a power of attorney from him or the service with which he has entered into an agreement can submit an application to draw up an agreement to carry out work, connect water or change supplies. To obtain permission to connect to a neighbor’s water supply (the document sample is similar to the usual one) or the general supply network, you need:

- For individuals, it is necessary to collect details in the form of a postal address of place of registration or residence, full name, identity confirmation document and data for further communication with the applicant.

- Legal entities and private businesses must provide their number in the State Register and the date it was entered, TIN, current residential address with place of registration and postal code, as well as confirmation from the bank, which gives permission that the applicant can sign the contract.

- The application must indicate the name and location of the site or facility that needs to be connected to the network.

- Attach to the package of documents information about additional sources of water supply (volume and owner).

An example of an application with a list of attached documents Source gorodkusa.ru

See also: Catalog of companies that specialize in water supply and sewerage, as well as auditing construction work.

- If there are no additional septic tanks (cesspools, treatment plants) on the site, and standards have been established for waste disposal through the sewer system, then it is necessary to indicate the properties of these restrictions and the number of changes in the volume of network use per year.

- You must provide a copy of the site plan, which contains a sewerage laying diagram, a display of all constructed objects and their characteristics, as well as a list of residents.

- Information should be provided about what type of activity is taking place on the site. This is necessary for carrying out standardized spillways.

You also need to attach to the list of documents for filing the application:

- Copies of all concluded contracts for connection to the public network.

- Copies of documents that are drawn up when connecting, flushing, and cleaning the line and equipment in the designated area or indoors.

- A copy of the papers for measuring instruments (meters) to check these devices for compliance with state standards, their installation diagram and readings at the time of filing the application. If water consumption is less than 0.1 m3/hour, then installing a meter is not necessary, and, therefore, copies of the described documents are not needed.

Example of a meter approval certificate Source ekosf.ru

- A diagram of the location from which samples will be taken.

- Copies of papers that confirm that the applicant owns this site.

- A document on the maximum load on the water supply network, which indicates for what purpose the water will be used (everyday needs, fire system, swimming pool, irrigation).

- Expert decision from federal or private SES, if required.

Before starting the application, it is recommended to make a topographic plan of the site with the help of surveyors, if you do not have one or it was drawn up more than 1 year ago.

Topographic plan of the site Source pro-gkn.ru

Abyssinian well

The Abyssinian spring is a medium-depth well, the creation of which allows water to be supplied to the most inaccessible areas with a small area: basements, garages, verandas. Unlike a standard well, the Abyssinian spring allows you to use water all year round, since the water supply is always at a stable level.

The standard Abyssinian well technology consists of a one-inch pipe, at the lower end of which a filter is mounted. The pipe itself allows a length of up to 30 meters. All pipe elements are collapsible. A pump is mounted on top of the tube. Excavation work to equip a well is carried out in one day. Labor intensity depends on the type of soil and the level of passage of the aquifer.

The drilling machine does not require a large area for placement: a space of about 1.5x1.5 meters with a height of 2.5 meters is sufficient. The water source is equipped with a column or pumping equipment in case of unstable power supply. If water flows underground at a level of 5 meters, you can get by with a garden drill.

Briefly about the main thing

Before submitting an application that will allow the signing of an agreement with a company supplying water supply services, it is required to make a project of the site listing all equipment that consumes water and a topographic map.

Independent connection and installation of water supply must be officially authorized by the relevant services, otherwise administrative punishment will be received.

A connection to the general water supply network may not be necessary if it is possible to install a personal well, borehole and septic tank.

Ratings 0

Advantages and disadvantages of a garage well

An Abyssinian well in a garage has a number of advantages:

drilling is possible under any conditions and temperatures;

speed of the process - no more than 10 hours;

water meets sanitary standards;

ability to drill in minimal space;

does not require a special access road for equipment;

moving the drilling machine inside the garage is possible manually;

reasonable cost, which is much lower than a standard well 7 meters deep;

service life over 25 years;

the strong connection of the casing prevents soil from getting into the water.

The disadvantages include the following:

Drilling should be carried out to a depth of 8 meters.

If the reservoir is leaking at its maximum depth, the pump will need to be buried.

For the type of area where groundwater is deep, this type of well is not recommended.

Cellar drying methods

Removing liquid from the basement and drying it out is carried out in the warm season. Before this, you need to get rid of all the items that are in the cellar. Then the cellar with the garage is opened and dried for 3-4 days.

To speed up the process, you can place a bucket of wood in the center of the basement and light a fire. Using this method, drying will take 8-10 hours.

DIY drilling

To create a borehole yourself, you need to dig a 1.5-meter square hole on four sides.

This is necessary for the collapse of the mouth of the future source. When building a well in your garage with your own hands, you should use a drilling rig. It is a tripod made of tubes or timber. A winch is attached between the equipment, allowing the mounted column to be lowered or raised. If work is carried out without a tower, the extension of columns should not be more than 1.5 meters in height.

The advantages of manual drilling for water extraction include low price, medium depth, fast pumping and the ability to use a hand pump if there is no electricity. The disadvantages of installing a well yourself in a garage or other technical room include limited depth and the inability to pass through difficult-to-pierce soil.

Without pump

If a problem arises, how to pump out a single flood of water from a cellar without using a pump, you can use a vibration pump.

Important! When the basement is repeatedly flooded, the pump is pumped and a pump becomes necessary to pump water out of the cellar.

The problem of basements flooding with water is relevant. There are several methods for dealing with moisture. It is necessary to combat flooding, because a foundation buried under water can collapse, and this will negatively affect the condition of the entire structure.

Water well in the garage

Installing a water well in the garage: photo and detailed description of drilling a well.

I wash my car often; I have a Karcher in the garage, but I had to carry water in buckets. Since the groundwater level in our area is at a depth of 2 meters, I decided to make a well in the garage and install a pumping station.

Next, the entire process of installing the well is shown in the photo.

We dug a hole for the well, approximately 1.2 x 1.2 m in size and 1 meter deep.

I drilled with an ordinary garden auger, 200 mm in diameter. I drilled until wet sand came out, about a meter from the pit.

For the well, I bought PVC pipes for external sewerage (red) with a diameter of 160 mm. Specifically, 2 pipes: 2 m and 1 m. I did not take a single 3-meter pipe, because... It wouldn't be convenient in the future. And their joining is very simple and reliable through a socket with an elastic band. And the depth, taking into account the pit, is quite enough for me.

A special metal filter mesh with a very fine mesh (marked P-56) was also purchased in advance. The mesh is stainless, so it should last a long time. The price per square meter of such a mesh is about 2000 rubles.

Now we begin to modify the PVC pipe for the filter. To do this you need to drill a bunch of holes. I take a 2 m pipe. First, we make markings on the pipe itself with a marker. We retreat 25 cm from the end of the pipe and draw a strip in a circle. Because My grid is 1m long, then we measure another 90 cm from this strip and also draw a line in a circle. So I have a filtration area, and I will drill holes in it. I drew a straight line and placed marks every 10 cm. I took a 16mm diameter wood flap drill and drilled the holes. It turned out like this.

Then I drew lines every 5 cm, and moved the marks for the holes. The end result is this sieve.

Now I start wrapping the pipe with metal mesh. The mesh should protrude 5 cm on both sides beyond the outer holes. The initial part of the mesh should fall on the part of the pipe where there are no holes. So that you can rivet it.

Here you need to stretch the mesh well and twist it around the pipe. I didn't use the whole mesh, I just made a small overlap and cut off the excess. It’s just that it’s a very fine mesh, I was afraid that it could get worse. When I overlapped the mesh, I immediately riveted it in several places. And only after that I cut off the excess. I used 4.8 x 8 mm and 4.8 x 12 mm rivets.

I bought 2 rolls of electrical tape. And a roll of electrical tape went on each side. This is so that the net doesn’t lift up when I lower it.

How to remove water?

There are several ways to remove it. Options for getting rid of water in the cellar:

- installation of a drainage system;

- automatic water pumping system;

- We remove it using waterproofing.

In this video you will learn more about drainage: The drainage system consists of pipes, trenches and a well. Installed during the construction of the house. The basis of the system is a pipe with a diameter of at least 100 mm. There are holes on the pipe. Through the holes, water enters the pipe and accumulates in the collector. 3 types of drainage system:

- Wall-mounted (if there is a basement or plinth).

- Plastic (used in the construction of a house from slabs).

- Ring (trench). The most common type. You can do it yourself.

Operating conditions of the drainage system:

- The sloped trench located around the basement should be below floor level.

- Protecting the pipe from leakage is the use of filter materials. These are crushed stone and geotextiles.

- Drainage must be carried out to the central sewerage system.

If it is impossible to create a drainage system, you can get rid of moisture by automatic pumping.

To get rid of water, you need:

- prepare a hole in the basement measuring at least 50x50x50 centimeters;

- line the hole with bricks to strengthen it;

- pour 10 centimeters of gravel into it;

- buy an automatic pump.

Indoor waterproofing protects against water permeability, making the concrete stronger.

Compound:

- 1 layer – penetrating waterproofing;

- 2nd layer – bitumen mastic;

- layer - plaster.

Apply above the expected flood level.

What you need for waterproofing:

- prepare the necessary materials and tools;

- prepare the basement: pump out the water, clean the walls and floor from dirt, scrub the seams and cracks with a brush.

Advantages

Often, garage buildings are small in size. This is where the car is stored and various tools for its repair, maintenance, etc. are placed. If such a structure is properly arranged, you can even wash your car inside it in order to save on paying for car wash services.

But what if there is no permanent water source in the garage? Many experienced craftsmen will tell you that you can build your own well.

The advantages of such a step are obvious:

- High comfort. You can wash your car, hands, use water to clean the room itself, make tea, etc. at any time.

- Uninterrupted operation. The operation of the well is not affected in any way by the central water supply. Therefore, interruptions in the operation of the system will not lead to problems with water.

- Access to large volumes of water. There is enough water from the source to supply the entire cooperative, so it is quite possible to negotiate with neighbors on the sharing of water for a fee.

- There is no need for insulation work at the wellhead. The optimal air temperature is formed inside the motorhome, so it is fashionable to refuse this type of work.

Recommendations from experts

What is important to know when arranging a water source inside a motorhome with your own hands? It is quite possible to obtain water for permanent use inside the garage if you follow the recommendations of experienced specialists.

We will describe them in detail so that an inexperienced master does not make mistakes when working:

- Before starting work, check with your neighbors for the current water level characteristic of the area;

- it is worth placing the water source closer to the exit, since if repair work is necessary, it will be easier to bring in equipment and remove dirt and debris;

- It is extremely important to first assess the nature of the soil, since different types of soil will require different types of drill.

Flaws

There are also disadvantages to the decision to drill a water source inside the garage.

They consist of the following points:

- Difficulty in providing quality service to the source. Some time after construction, it will require major cleaning by clearing the water vein of silt and debris. It is almost impossible to do this well inside a motorhome unless you free the space from cluttering furniture, cars, and other objects;

- The need for material costs. Setting up a water source with your own hands will be cheap, but the cost of hiring a team of craftsmen can be quite high.

General rules

A garage with water and sewerage is the dream of many car enthusiasts. However, you cannot connect to the household network and discharge wastewater into it. No authority will give permission for such actions, and for unauthorized connection you can receive a serious fine and an order to eliminate the illegal connection.

However, no special permits are required for the construction of an autonomous drainage system. Moreover, the volumes of wastewater are not so large as to pose a threat to the ecology of the region. Sewage must not be allowed to enter the ground, as this poses the risk of contaminating aquifers. At the same time, the statement that the entire area of the garage cooperative is flooded with fuel and lubricating oils cannot serve as an argument and will not be taken into account by anyone.

There is another reason for creating a drainage system. An autonomous sewer system for the garage is needed to remove rainwater. Drainage will allow you to avoid rising soil water levels and prevent flooding of the cellar or inspection hole. However, the design of a storm network is more complex because the volume of wastewater is much larger. It is impossible to collect liquid in a storage container; it must be completely drained.

Many owners plan to build a toilet in the garage. This requires sewerage in the garage; SNiP standards will tell you how to organize it correctly. It’s not difficult to select a corner for the bathroom itself. However, it requires a septic tank. According to current rules, it can be located no closer than 5 meters from buildings and 10 meters from a drinking well. These conditions make it impossible to build a toilet if the garage is part of a cooperative. The owner only owns the area under the garage box itself; he has no right to use the land outside its contour. There are no options left except to make a drain in the garage just to drain waste from the sink. You can buy a neighboring garage and install a septic tank in it, but even here it will not be possible to maintain the required distances according to SNiP. In addition, such a toilet will be too expensive. Therefore, a full bathroom is only possible for garages located on the site of a private house.

Features of drilling in the basement

We will tell you in detail how to make a well inside a motorhome with your own hands without the help of builders with extensive experience. This process is not complicated, it is carried out quite quickly, the main thing is to follow the recommendations of specialists and follow the technology for performing the work.

To get the job, get special equipment - a drilling rig. It is placed inside the garage, which will require clearing the space from foreign objects. In this case, the room must meet certain requirements: area 1.5x1.5 m, height - at least 2.5 m.

If the design parameters are less than those specified, there will be no space to install the unit, and the work itself will not be completed. After installing the drilling rig inside its steel pipe, you need to insert the impact rod. It is used to hit the steel cone at the end of the drill with great force. To soften the soil, water is poured there.

Droplets flow through the filter holes and are absorbed by the ground. The lower the drill goes, the more it is expanded using coupling connections and new pipes.

On a note! The impact rod can only be extended using a coupling connection. Pipe connections are made using couplings, winding the threads by applying a sealant on the paint. You can also connect two pipes by welding.

As drilling progresses, the impacts of the rod will intensify, so the speed of passage will also increase. The rods must be lifted from the water source manually. To do this, it is worth fixing a wheel under the ceiling surface of the garage, through which a rope is thrown to lift a heavy rod.

So you need to find an aquifer that can suck in and remove the flooded water.

If it is found, you need to remove the shock rod and place a flexible hose inside the pipe with a pump at the other end. Using a pump, the water will be drawn through a hose to the surface. After reaching the required depth, a well should be constructed, for which a caisson should be installed in the finished well, and then a filter column made of a pipe, sump, or filter.

On a note! It is possible to make a filter yourself using a filtration mesh, perforation, and casing pipe. You can also choose a ready-made model.

Vegetable garden and more

11/19/2018 admin Comments No comments

In times of high water prices, your own well becomes economically important. We will tell you how to organize a well yourself and what soils are most suitable for drilling.

Garden plants can obtain vital water in three different ways: from above, from below and from the central water supply network. Unfortunately, we have no influence on the “upper” path, that is, on the rain. You can only collect rain moisture in barrels in reserve. Central water supply is not accessible to everyone in principle, and its use regularly becomes more expensive. But water “from below” (ground), on the contrary, is completely accessible, and you do not need to pay a monthly fee for it! However, to drill a well, you will have to work hard.

Water from a borehole or well without filtration is not suitable for drinking, but in the summer it will provide watering for plants and joy for children

We want to drink some water

In the Moscow region, “underground” moisture can be contained in sand layers (not so deep, 6-15 m from the surface of the earth, in some areas, however, 30 m) and in limestone (usually from 30 m and deeper). We will not consider the last case, since this is artesian water, not groundwater, and in order to extract it, it is necessary, firstly, to obtain permission from the authorities, and secondly, to contact specialist drillers.

Getting to groundwater in the upper sandy horizons is much easier - you need a do-it-yourself well in the sand or a well.

Where will we drill a well with our own hands?

How to find out whether we will reach the groundwater level in our area, and where exactly to “drill” into the sand? You can find out from your neighbors about existing wells and the experience of their owners, you can walk around with a “vine”, or just start drilling at random. But the most reliable thing is to find out the required drilling depth from your local water supply agency, which, as a rule, has a detailed map of the groundwater level.

DRIVER (Abyssinian) WELL

When constructing an Abyssinian well, a steel pipe is driven into the ground using a sledgehammer or copra until the groundwater level is reached. In this case, meter-long pipes are lengthened using the nuts of the coupling screw (the threads must be sealed with hemp!). On the first (lowest) segment there is not only a working head with large holes, but also a filter. After passing through them, filtered water enters the pipe and is pumped upward through a pump.

IN THE WELL CHAMBER

If you are using a surface electric pump or a standpipe rather than a submersible one, and it is assumed that the well should function all year round, it makes sense to organize a well chamber.

In it, all electrical appliances and connections will be neatly located and protected from wind and bad weather. You can build the chamber using masonry or, which is simpler and much less expensive, use concrete rings and a lid. Important:

equipment located above the soil freezing level requires thermal protection.

MINE WELL

Essentially, our ordinary village one.

It is not so much drilled as it is dug - the most labor-intensive undertaking. This is due, on the one hand, to the large diameter of the well, and on the other, to the difficulties of installing concrete rings. This cannot be done without heavy equipment for excavating soil and lowering the rings. The advantage of the design is the possibility of repair and cleaning. The construction of such a well is justified only in those places where the groundwater level is located relatively shallow from the surface of the earth. BORED WELL

To construct a bore well, a well is drilled to the groundwater level.

Its diameter depends on the drill casing. For a depth of up to 7 m, an ordinary sewer pipe with a diameter of 115 mm, which will be inserted into the well, is sufficient. The filter pipe is polyethylene. Such pipes are painted blue and are extended to the required length using threaded connections. At the very bottom is the filter section itself, through which water flows. The pump supplies water upward. Important:

the drill pipe cannot be extended (7 m is the maximum length of sections available for sale).

There is such a technology:

for better penetration into the soil, water is supplied to the working head of the pipe with high pressure, thus softening the soil. But this can only be done using professional equipment; a garden hose will not do the job. 1. Hose 2. Flushing pipe 3. Filter

When building an ordinary village mine well, there is a danger of suffocation and falling into quicksand! Soil features:

FLOCK SOILS (sand, gravel, pebbles, crushed stone) are weakly bonded, so the construction of the well is carried out carefully to avoid crumbling. LOAM, CLAY - have cohesion. Digging a well, as well as organizing a well in loamy soils, usually does not cause problems; working with clays is somewhat more difficult. Quicksand is a natural volume, inside of which there is water-saturated fine sand (almost silt) under pressure, which has the property of fluidity. Quicksand are quite easily passable when drilling with mechanical drilling rigs, but practically impassable when drilling wells manually. In wells built on quicksand (ending with quicksand), as a rule, there is a small column of water (up to 1 meter), but with a good flow

1. At the selected location, begin to screw the drilling tool into the ground. Pull the auger to the surface from time to time to remove soil. 2. The earth drill can be significantly extended. To do this, unscrew the T-handle bolt, screw in the extension rod and secure the handle to it. 3. Starting from a certain depth (which one depends on the characteristics of the soil), it is advisable to put the drill aside. Insert the extended pipe into the well, put on the impact coupling and continue working with a sledgehammer. 4. Take care of the tightness of the connections. To do this, screw the clamping screw nut onto both threads. First, it is important not to forget to wrap hemp or Teflon tape around the thread in the opposite direction. 5. Once the desired depth is reached, screw on the valve and the threaded section. The valve allows you to release water from the pipe in the fall, preventing rupture from frost. 6. Hammer the pipe to such a depth that the upper part of the pumping pump is exactly the same height as the upper threaded part.

How often should you check your car tires?

Each tire is constantly exposed to a lot of direct impact, and so they lose some air over time. This is why it is recommended to check your tire pressure regularly. This not only affects driving safety, but also the life of the tires.

Tire pressure should be checked as often as possible - it is suggested that this operation should be performed at least once a month .

Air leakage from tires is a natural phenomenon, so we must not forget to control the tire pressure.

It is worth paying attention to the loading of your car. If you drive in splendid isolation and with an empty trunk, then of course the pressure on the wheels is less, which means the wheels can not be inflated to the maximum level.

Construction stages

When building a sewer system in a garage with your own hands, all work should be done in strict order. Main stages:

- drafting;

- marking, excavation work;

- installation of a storage tank, insulation and sealing;

- pipe connection;

- checking functionality, backfilling the sinuses of the trenches and the nest for the container;

- laying flooring, installing gutters and gratings around the perimeter of the garage.

Only the main steps are indicated; depending on the complexity of the system, additional work may be required.

Design is one of the main stages of creating a drainage system. You cannot take on a job without calculations and preliminary preparation, as this can result in fines and technical problems. First of all, you need to choose a place to place the storage tank. After this, a working drawing of the system is drawn up. When a sewer system is being built in a garage, the diagram makes it possible to provide for a lot of little things on which the effective operation of the drainage line depends. The drawing must be made to scale, taking into account the slope of the pipes. It is imperative to provide water seals and avoid sharp turns in the line.

Construction equipment is used to carry out excavation work. If the garage has already been built, you will have to dig the soil manually. This is much more complicated; you will need to organize temporary storage and removal of excess soil. The depth of the nest for the tank is selected based on the climatic conditions in the region. In any case, the container will need to be insulated. Many owners use a heating cable to restore system operation in cold weather.

The container is installed on a prepared base. A sand cushion is made. On which the tank is installed. Before descending into the recess, it is recommended to waterproof it and properly insulate it.

The pipes are connected in the usual way. The entrance area to the container is carefully isolated and strengthened. The line is laid with a given slope, after which the system is checked for leaks. To do this, pour water into the pipe and observe the connections. If everything works fine, the sinuses are filled with soil and proceed to laying the garage flooring.

What affects air loss in tires?

Tire pressure is affected by both natural air loss and ambient temperature. This is especially important in winter, when temperatures are below zero, when tire pressure is often too low. This state of affairs directly affects tire wear too quickly, as well as greater susceptibility to various types of mechanical damage.

In such situations, it is worth inflating the tires as quickly as possible. However, it happens that during severe frosts the compressors located at gas stations break down - then you should go to the nearest vulcanization shop or tire repair shop.

Drainage system design

When choosing the appropriate way to make a sewer in the garage with your own hands, owners usually get stuck at the stage of choosing a method for removing drains. If you only need a hand-washing basin, installing a small container at the bottom of the garage is sufficient. As it fills, the wastewater is pumped out and removed. However, to organize a small car wash you will need a fairly large tank. It must be installed at the stage of construction of the garage, since installation of a large capacity tank will require excavation work and other measures. You will need to install a sealed tank, which is equipped with a neck with a tightly closing hatch. It must be positioned so that a sewage disposal truck can easily approach and pump out the wastewater.

The composition of the internal section of the system differs little from conventional structures. Standard plastic pipes with a diameter of 50 mm are used, which are connected to the washbasin and to trays for discharging car wash waste. The second end is connected to a vertical pipe (riser) with a diameter of 110 mm. It is immersed in the ground and connected to a storage tank. All pipes must be equipped with water seals to eliminate bad odors. In addition, it is necessary to ensure the slope of all lines so that the wastewater immediately goes into the tank and does not stagnate in the pipes. It is important. since in winter the water can freeze and break the channels. To protect the container, you will need high-quality insulation and a sufficiently large depth of immersion in the ground.

If a car wash is being built, drainage trays must be installed. The sewage system in the garage in the floor is built according to the principle of assembling storm systems. Gutters with gratings are installed along the perimeter of the room, and the floor covering is made with a slight slope towards them. the trays are connected to a network of drains through which the waste flows into the reservoir. It is necessary to immediately provide filters and sand traps, otherwise solid particles will quickly overflow the storage tank and create blockages in the connecting pipes. It is recommended to remove sand from trays and traps after each car wash, until it has caked and does not require the use of additional tools for extraction.

Electric pump. How to manage it?

Working with a compressor is not difficult. Grasp the gun and slide the hose onto the valve while holding the locking tab. Then apply light pressure and release your tongue. When the tube is put on the wheel valve, you should press the “trigger”, thereby pumping the wheel. On the display of the measuring device, track the desired value. Usually around 2 bar is inflated, although this depends on the car model, wheels and season. After inflating the tire, release the trigger, press the lock on the hose and pull it vigorously.

The requirements for the pressure level in each pair of wheels are indicated by the manufacturer in the instructions for the car or on the gas tank flap.

If you don't feel confident enough to inflate your tires yourself, you can take your car to your local tire shop where the experienced staff will take care of it.

It is worth remembering that poorly inflated tires lead to weaker shock absorption on uneven surfaces, poor grip and much faster tire wear.