Boiler room in the garage: is this option possible? This question interests many owners of this utility room. In principle, it can be resolved positively, because modern boilers, if all requirements are met, are considered safe; their installation is allowed even in basements and attics. Another thing is that amateur performance should not be allowed, but standard equipment should be used. Otherwise, such installations can lead to big trouble. In addition, most types of boiler rooms are installed if permitted by the relevant organizations.

Which furnace gas industry will accept without complaints: 11 recommendations to avoid problems with connection

Why is the boiler room actually a furnace room, how to design it and what to equip it with

Heating the house from the main house is the cherished dream of many country residents. The “heart” of such a home is the room where the gas boiler is installed. What requirements do gas services place on a boiler room? And how to design a furnace so that it is approved by the gas industry? We have selected key recommendations from the new Code of Practice and will tell you about them in this material.

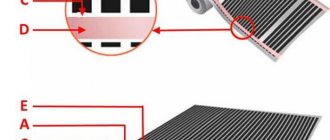

What materials and equipment should be in the furnace room?

Everything is written in the Code of Rules:

- The wall-mounted gas boiler in the combustion chamber must be located at least 20 mm from the walls (back and side) made of fireproof materials.

- Walls made of non-combustible materials must additionally be insulated with non-combustible materials that do not support combustion and the spread of flame. In this case, the boiler is located at a distance of 30 mm from the wall. The insulation should extend beyond the dimensions of the equipment by 100 mm on the sides and 0.7 m on top.

- If a gas boiler is placed on a wooden floor, it must be insulated with fireproof materials. The fire resistance limit of the material is at least 45 minutes. The floor insulation must protrude beyond the dimensions of the equipment body by at least 100 mm. Install the equipment in the furnace so that there is easy access to it for operation and repair.

How should a furnace room with a gas boiler be ventilated?

The dimensions of the exhaust and supply channels are determined by calculation based on the following parameters:

- Ventilation of the combustion chamber occurs naturally.

- The hood should provide three air exchanges in the room in 1 hour.

- The inflow is equal to the exhaust volume + the air required for gas combustion.

In which direction should the door from the furnace open?

The door from the room where the gas boiler is installed must open outward.

What size window should be installed in the furnace room?

The window in the furnace room is made on the basis that the glazing area, and not the entire window with frame, is at least 0.03 square meters. m per 1 cubic meter of room volume. Moreover, the window design must meet the requirements set out in GOST R 56288 “Easily removable window structures with double-glazed windows for buildings”

. In short, the window, in the event of a gas explosion in the furnace and exposure to a blast wave, must, under the influence of pressure, open outward. For example, a sash rotates around its axis, or a double-glazed window, or a frame with a double-glazed window moves and falls out.

Where should gas boilers not be placed?

It is not allowed to install gas-using equipment in bathrooms and toilets.

Is it possible to install a gas boiler in the basement?

First, let's define the terms: “basement” and “ground floor.” So,

- Basement floor

- a floor where the floor level of the premises is below the planning level of the ground by no more than half the height of the room. - Basement floor

- a floor where the floor level of the premises is below the planning level of the ground by more than half the height of the room.

SP 402.1325800.2018 states that heat generators running on natural gas can be placed in the basement and basement floors of residential buildings.

Is it possible to install a gas boiler in the kitchen if there is already a gas stove there?

In the kitchen, you can install a gas stove, and hang a modern gas boiler on the wall, for example, a condensing boiler, which goes well with low-temperature heating systems - liquid heated floors. But there are a number of important limitations:

- If the kitchen has a two-burner gas stove and a gas boiler with a closed combustion chamber

, the volume of the room must be at least 8 m³, with a ceiling height of at least 2.2 m. - If a four-burner gas stove is installed in the kitchen, you must admit, this is what is done in most cases, and a gas boiler with a closed combustion chamber is installed, then the volume of the room must be at least 15 m³.

- If there is a gas stove in the kitchen and a gas boiler with an open combustion chamber hanging

, then another 6 m³ is added to the above-mentioned room volumes.

The kitchen should be ventilated using an exhaust system through a window with a window. If the kitchen has a door, then a gap of at least 0.02 square meters is made between it and the floor for air flow. m.

The volume of the combustion chamber must be at least 15 m³, right?

SP 402.1325800.2018 contains clause 5.5. In short, it says - the volume of the combustion chamber must be at least 15 m³, with a ceiling height of no less than 2.5 m.

Is it true that a ceiling height of 2.5 m is required for a gas boiler?

Due to changes in SNiPs and Codes of Regulations of different editions and different years, confusion arises as to what the height of the ceilings in the furnace room should be. Let's turn to SP 402.1325800.2018. It states that the ceiling height in a separate room where a gas heat generator is installed must be no less than 2.5 m, provided that the boiler is operated with an open combustion chamber

.

Gas boiler room, boiler room and furnace room, are they the same thing?

Many are accustomed to calling the premises in private residential buildings where gas heat generators are installed - boiler rooms or boiler rooms. This is not entirely correct. A boiler room is, most often, a separate facility where engineering equipment is located, which generates heat for multi-storey residential buildings and complexes, as well as commercial and industrial buildings. Boiler rooms are subject to more stringent requirements than conventional furnaces.

for cottages.

The combustion room is an individual room where there is a gas heat generator that produces heat for a private home.

SP 402.1325800.2018 has the following description: a heat generator room is a separate non-residential premises where a boiler and additional engineering equipment are installed. Therefore, below, we will call the boiler room the furnace room.

Project No. 2 – standard with two entrances

A more common placement of cars in a double garage is mutually parallel. However, if there is not enough space on the site for a square building, or the site has an elongated rectangular shape, it is better to choose a garage design that involves sequential placement of cars.

The total area of the building is 53 sq.m.

- Type of walls – combined on a columnar foundation;

- Exterior finishing – siding;

- The roofing material is metal tiles.

The advantages of this project are the presence of two separate gates and an additional exit with a low porch and canopy.

The disadvantages include the lack of additional space for placing shelving and the impressive length - more than 10 m.

Requirements for the premises for installing a gas boiler

The premises in which the gas boiler will operate are specified in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 - these documents eliminate or minimize any emergency situations. Premises for placing gas boilers fall under the classification of fire and explosion hazards, therefore, when designing, planning, installing and setting up equipment for gas heating, all requirements for the premises for installing a gas boiler must be strictly observed.

Regulatory documents and supervisory authorities

All rules and requirements for installing a gas boiler in a private house are specified in:

- SNiP 41-01-2003 “Heating, ventilation and air conditioning”;

- MDS 41.2-2000 “Instructions for the placement of thermal units intended for heating and hot water supply of single-family or semi-detached residential buildings”

- SNiP 42-01-2002 “Gas distribution systems”;

- SNiP 21-01-97 “Fire safety of buildings and structures.”

It is not necessary to study the entire list of documents in detail. In this article we will outline all the most necessary requirements for the room, ventilation and chimney. Compliance with the requirements is checked by specialists from the local gas service, usually Gorgaz, less often Oblgaz or Raigaz.

It is at the local gas service that you need to draw up all the necessary documents (more on them later), conclude a contract for servicing the gas boiler, invite their specialists to check for compliance with the requirements, connect the boiler to the gas main, set it up and start it up for the first time.

Please note that the first start-up must also be carried out exclusively by certified gas service specialists, who will put the appropriate stamp in the boiler passport: without it, manufacturers usually refuse warranty obligations.

General requirements for the installation of gas appliances

In the room intended for the installation of a gas boiler, according to the above standards, there must be good natural lighting: per 1 m 3 there must be at least 0.03 m 2 of window opening area (but not windows - partitions, frames and imposts are not taken into account). It is imperative to equip the room with a supply and exhaust ventilation system according to the following rules: the total volume of forward and reverse air flows per hour, multiplied by 3, is equal to the volume of the entire exhaust device. In addition to a window equipped with a window, a door with access to the street is installed in the room. The table shows the requirements for room volume:

For gas-fired units with a power of more than 6000 W, 0.2 m3 should be added for each extra unit of power.

Supervisory requirements for the premises for installing a gas boiler stipulate that the operation of any appliances for heating an apartment is permitted on each floor of a multi-storey building and in any room of the apartment. Kitchens in multi-storey buildings also meet these requirements, since they are already equipped with appropriate communications. The only condition is that the total thermal power of all devices for heating water and heating the apartment (boilers, boilers, heating elements, heating radiators, batteries or registers) should not exceed a total of 150 kW.

The ceiling height in the room is 2 meters or more. The room in which the gas boiler will be installed and operated must be separated from adjacent rooms by solid fire-resistant walls. Material for walls or partitions must have a fire resistance time limit of 0.75 hours (45 minutes). The boiler room must be designed so that in the event of an operational fire there is no possibility for the fire to spread throughout the apartment.

Gas boilers of the TLO brand, operating on the principle of natural coolant circulation, can be installed and should be operated only in the basement of the house or in the basement.

Requirements for heating with gas from cylinders

As an alternative, you can use bottled gas. Containers should be kept in a closed metal cabinet for storing gas cylinders.

To locate it, you need to choose a place as far as possible from heating devices and flammable appliances.

Gas cylinders in action: a quick and easy option, even taking into account the fact that you have to buy gas cylinder equipment, a reducer and shut-off valves

You cannot install a module with cylinders at floor level, because in this case it will not be possible to notice a gas leak in time and solve the problem.

Installation of a gas wall-mounted boiler - kitchen requirements

- Ceiling - 2 meters and above.

- The total volume of the kitchen is more than 7.5 m3, ventilation is equipped, a window is installed and there is a door opening onto the balcony.

- For air exchange, it is necessary to install a grille at the bottom of the wall or door that opens into the next room; the area of the grille is at least 0.02 m2.

If the kitchen in the apartment does not meet the requirements of SNiP, then gas heating equipment can be installed and operated only with the permission of the gas supervision authority.

It is strictly forbidden to install more than 2 heating devices or more than 2 boilers in one room if the volume of the room is less than 7.5 m3

The existing rules for installing a gas boiler in a private house largely repeat the requirements for boilers that operate in apartments in multi-storey buildings. The differences are caused only by the fact that often in a private house a separate room or building is allocated for heating equipment, which is subject to additional requirements listed below.

Video: different heating options from experienced garage workers

It’s worth watching additional video materials to evaluate the advantages and disadvantages of different methods and to visualize everything clearly.

This video discusses the option of organizing a heating system in a garage on your own, with minimal investment.

The following video tells about the operation of the fireplace stove.

Of particular interest is a furnace that operates on waste oil. It is quite possible to make it with your own hands, and it works on already used oil. There are, of course, some nuances here. But in general, this method is quite rational and safe if it is possible to organize timely cleaning of the waste in a special installation. The arrangement and manufacture of a boiler for heating during mining is described in the following video.

A boiler in a garage will be an excellent solution for organizing a heating system. This will allow you to create comfortable conditions in the garage at any time of the year, work there with high efficiency, and carry out vehicle inspections and repairs.

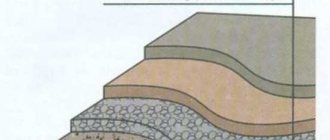

Rules for installing a floor-standing gas boiler

- In a house under construction, it is necessary to plan a separate room for installing a gas-fired boiler. The room should have a natural flow of air through a grille in the door or through a hole in the wall.

- A separate hole must be made for supply and exhaust ventilation - it must be located under the ceiling.

- A hole in the wall for the chimney pipe, a hole below the chimney for a soot brush (for cleaning the chimney pipe), which is made below the main chimney by 20-30 cm.

- The chimney is made airtight so that smoke and carbon dioxide do not flow back into the room. To ensure tightness, a smaller diameter pipe is installed inside the large chimney pipe, through which gas combustion products are discharged.

- The room intended for installation and operation of a gas boiler must be spacious and provide easy access and operation, maintenance and repair of the boiler. The floor in the furnace room must be made of non-combustible materials - concrete screed, natural stone, paving stones. The furnace room must be connected to the water supply for the operation of the water heating device, and be equipped with a sewerage system.

- The area of the room for the boiler is 4 m2, the height of the ceilings in the room is at least 2.5 m2.

- The outer door must be 80 cm wide.

- The top of the chimney should be higher than the roof. The cross-section of the chimney pipe must be larger than the diameter of the boiler outlet.

- To supply power, the boiler room must be equipped with an electrical panel with grounding.

- The gas line is brought into the room in advance. A separate valve must be installed for each gas appliance.

- The walls of the boiler room are plastered - it is strictly prohibited to decorate the walls with flammable materials (MDF, fiberboard, plastic).

Project No. 8 – garage with a relaxation room, sauna and bathroom

If your desire to have a sauna or bathhouse on your property is clear, then in order to save space and building materials, you can combine rooms such as a bathroom, steam room, relaxation room and parking under one roof.

The total area of the building will be 77.61 sq.m. Almost 45 sq.m. is allocated for parking.

- Wall type – brick;

- Exterior finishing – sandwich panels;

- The roofing material is ceramic tiles.

All other rooms also have sufficient space. The presence of an insulated vestibule is especially important. A convenient exit from the steam room has been thought out, leading directly to the bathroom with shower. The disadvantages of the project include its rather large size and the absence of an additional door leading from the garage to the street.

Rules for installing wall-mounted gas boilers in an apartment

Typically, in an apartment, a gas boiler is installed in the kitchen, since it already has a gas line, water supply and sewerage. That is, a priori, all requirements for the installation of gas equipment have already been met - all that remains is to connect the boiler. This state of affairs automatically reduces the cost of laying utilities and energy resources. It is prohibited to install a gas boiler in rooms with high humidity - in a bathroom, laundry room, etc.

There are several additional requirements for wall-mounted boilers:

- The wall or partition for hanging the boiler must be able to support it - equipment cannot be hung on a plasterboard or other light partition.

- If the wall is decorated with flammable materials (wallpaper, vinyl, plastic, MDF, fiberboard), then a 3 mm thick gasket of non-flammable material is installed between the gas wall-mounted boiler and the wall. In this case, the boiler must be secured with special hardware that ensures a distance from the boiler body to the wall of at least 4-5 cm.

- The minimum distance from the boiler to the ceiling and walls of the room is 0.5 meters. The distance from the boiler to the floor is 0.8 meters.

Before installing and starting up gas equipment, you must obtain all relevant documents. The main condition when installing a boiler in a private house that runs on gas is that an agreement on connecting the gas main is first concluded, and a project for the installation of gas equipment and gasification of the house is drawn up. These documents are developed and approved by the gas supplier in the region.

Western European experience

If you type the phrase “garage heating” in the search and look at pictures on English-language sites, you will not find any wood-burning or oil-fired stoves in Western European garages. How do local motorists warm themselves:

- electric portable heaters;

- infrared hanging heaters;

- air heating units (heaters).

The suspended air heating unit does not take up useful space in the garage

We have already discussed the first 2 options above. The third method is also far from new: water heated in the boiler passes through a radiator, blown by a powerful axial fan. Ideally, the unit is suspended from the ceiling and distributes hot air throughout the room.

The advantages of this option are compactness, heating speed and the possibility of air conditioning in the summer (cooled water is sent to the radiator instead of heated water).

Heater made from a car radiator

There is one downside - increased costs for equipment, because the coolant must be heated in the boiler and supplied through pipes to the heater. But if the garage is attached to a private house, then the problem is easily solved by connecting the radiator to the building’s water heating system.

Reference. Many garage craftsmen already use such heating, installing a homemade analogue of a heater made from a car radiator and any suitable fan. How this is implemented, look at the video:

Watch this video on YouTube

Boiler room in the garage

Requirements for the premises of a gas boiler room in a house or cottage (excerpts from regulatory documents)

GENERAL PROVISIONS (BOILER BURNER ROOM)

1 Automated heat generators of full factory readiness with a coolant temperature of water up to 115 ° C and a coolant pressure of up to 1.0 MPa of domestic or foreign production, having permission for use in the prescribed manner, should be accepted as sources of thermal energy.

2 The placement of heating units is provided: - in the kitchen with a power of the heating unit for heating up to 60 kW inclusive, regardless of the presence of a gas stove and gas water heater; — in a separate room on any floor (including the basement or basement) with a total power for heating and hot water supply systems of up to 150 kW inclusive; - in a separate room on the first, ground or basement floor, as well as in a room attached to a residential building, with their total capacity for the heating and hot water supply system up to 350 kW inclusive.

PLANNING AND CONSTRUCTION SOLUTIONS OF THE BOILER ROOM

1 When placing a gas stove, instantaneous water heater for hot water supply and a heating unit for heating with a power of up to 60 kW in the kitchen, the kitchen room must meet the following requirements: - height of at least 2.5 m; — the volume of the boiler room is at least 15 m3 plus 0.2 m3 per 1 kW of power of the thermal unit for heating; - in the kitchen, ventilation should be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the hood plus the amount of air for gas combustion; - the kitchen must have a window with a window. For air flow, a grille or gap with a clear cross-section of at least 0.025 m2 should be provided at the bottom of the door.

2 When placing thermal units with a total power of up to 150 kW in a separate room located on any floor of a residential building, the room must meet the following requirements: - height of at least 2.5 m; — the volume and area of the room are designed based on the conditions for convenient maintenance of thermal units and auxiliary equipment, but not less than 15 m3; - the room must be separated from adjacent rooms by enclosing walls with a fire resistance limit of 0.75 hours, and the limit of fire spread throughout the structure is zero; - natural lighting - based on glazing 0.03 m2 per 1 m3 of room volume; - ventilation in the room must be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the exhaust plus the amount of air for gas combustion;

3 When placing thermal units with a total power of up to 350 kW in a separate room on the ground floor, in the basement or basement of a residential building, the room must meet the following requirements: - height of at least 2.5 m; — the boiler room must be separated from adjacent rooms by enclosing walls with a fire resistance limit of 0.75 hours, and the limit of fire spread throughout the structure is zero; - natural lighting - based on glazing 0.03 m2 per 1 m3 of room volume; - ventilation in the room must be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the exhaust plus the amount of air for gas combustion; — the volume and area of the room are designed based on the conditions for convenient maintenance of thermal units and auxiliary equipment.

4 When placing thermal units with a total thermal power of up to 350 kW in an extension to residential buildings, the extension room must meet the following requirements: - the extension must be located at the blank part of the building wall with a horizontal distance from window and door openings of at least 1 m; - the wall of the extension should not be connected to the wall of the residential building; — the enclosing walls and structures of the extension must have a fire resistance limit of 0.75 hours, and the limit of fire spread throughout the structure is zero; — the height of the boiler room is at least 2.5 m; — the volume and area of the boiler room are designed based on the conditions for convenient maintenance of heat generators and auxiliary equipment; - natural lighting - based on glazing 0.03 m2 per 1 m3 of room volume; - ventilation in the room must be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the exhaust plus the amount of air for gas combustion.

Project No. 5 – a garage with a vestibule, a guest room and a residential attic

This project will be an excellent option if the task is to place as many functional areas as possible in one area and ensure a comfortable stay for frequent guests.

The total area has an average size of 78.8 sq.m. The parking area is 44.2 sq.m. The guest room on the ground floor and the parking space are equipped with small window openings.

- Type of walls – brick;

- Exterior finishing – foam insulation + plaster;

- The roofing material is ceramic tiles.

The advantage is the presence of a vestibule and an additional door leading from the garage, a side staircase leading to the second floor and a common gate.

Disadvantages stairs .

Types of boilers

First, it’s worth considering what types of boilers there are.

- Gas boilers - it is advisable to purchase when in the utility room there is a possibility of diverting a pipe from the gas main. This fuel is considered the most budget-friendly. The heat carrier is a liquid that is heated by the boiler. Heating is provided by the convection method using a fan.

- Electric boilers - it is advisable to install them in a room where the coolant is heated by electricity. The operating principle of such a device is that the liquid in the heat exchanger is heated thanks to electric heating elements.

The essence of the problem

At its core, any garage is a utility room (usually detached) of a warehouse type, but containing a car and substances belonging to the flammable category. These circumstances give rise to increased requirements for fire safety. Naturally, the question arises: is it even possible to place a boiler room in a garage?

When solving this issue, you should understand what a boiler room is and why it is installed. It is possible to set several tasks. Most often, the concept of a garage boiler room means a boiler for heating only the room itself, but sometimes a boiler room in a garage functions as a source of coolant for heating a private home. If in the first case a small standard boiler of various types is used, then in the second case fairly large areas and special permission are needed.

In any case, a garage with a boiler room is not prohibited by regulatory documents. At the same time, it must meet all technical and fire safety requirements. The need to draw up a project and coordinate it with the relevant organizations depends on the type and power of the equipment, the type of fuel consumed and the connection to centralized highways.

Choosing the “right” gas boiler

You can purchase a suitable gas boiler yourself. It is worth paying special attention to each component of the equipment. In particular, this applies to the body material itself, the chimney (if there is one), as well as the ignition system. In addition, you need to find out which gas connection option is available.

The most popular devices are boilers made of cast iron and steel. If you choose between the two, preference should be given to the latter, since cast iron is considered a rather heavy metal. A convenient boiler is one that has an electric igniter installed.

Particular attention should be paid to the chimney. Since combustion products are aggressive, this part must be made of durable material. Alloy steel is considered the ideal option. However, there is equipment where there is no chimney as such (the device is equipped with fans).

What to look for when choosing

The decisive factors when choosing a gas boiler are:

- the material from which its body is made;

- ignition system;

- the presence or absence of the need to install a chimney;

- features of indoor installation;

- method of connection to gas and water supply.

Material

The most common models on the gas equipment market are cast iron and steel models. Cast iron is a high-strength and durable material, but its disadvantage is its heavy weight. Therefore, it is preferable to use steel heaters.

Manual or electric igniter?

Boilers with an electric ignition are much more convenient to use. When installing them, the following conditions must be met:

- uninterrupted power supply;

- separate connection to the power supply network;

- grounding

The solution to the first problem is to install an electrical stabilizer that suppresses voltage surges.

Types of boiler equipment

The chimney stove has an inlet temperature of about 120°C. The gas combustion process produces substances such as carbon monoxide, hot steam, sulfur dioxide, etc. All of them are removed from the garage using a chimney. At low ambient temperatures, vapors condense on the walls of the chimney and flow down.

Combustion products are quite caustic substances, so increased demands are placed on the chimney material. For the construction of a chimney, it is recommended to use alloy steel pipes, as well as carefully insulate them.

The garage can also be heated by boilers that do not require a chimney. They have built-in fans. Condensing boilers with a pulsed gas combustion mechanism are also becoming very popular.

Setting up a boiler room in the garage

Next, we suggest finding out how to organize a boiler room in a garage.

Layout of accommodation

It is better to install a gas boiler in a separate building, the area of which is at least four square meters. There is also a requirement for ceilings - they must be more than two meters. As for the width of the door, its size should be 80 centimeters and above. In addition, the room should be ventilated and have a window that would provide natural light in the room during the day.

It is recommended to build a boiler room at a relative distance from a residential building for several reasons. Firstly, so that the noise from work does not disturb the household. Secondly, the boiler room is a fire hazardous facility .

Preparatory work

First of all, the walls in the garage need to be finished with heat-resistant material. If it is necessary to install a chimney, the pipe is installed above the level of the garage roof, approximately one meter. In addition, it is worth considering how many bends are present on the pipe. So, the lower this figure, the better, since otherwise the substances that are released during combustion will settle on the sections. As a rule, to equip a chimney, a pipe with a diameter of 130 millimeters is taken.

The area of the roof where the connection to the chimney occurs must be protected with fire-resistant material. Take something like galvanized steel.

Ventilation arrangement

To ensure the safe operation of a boiler room in a garage on your own site, you will need to ensure there is a good ventilation system that can cope with the removal of harmful gases from the room.

For these purposes, the owner must correctly calculate the required fan performance.

Fan power is calculated using the following formula:

- M – fan power;

- S – building area;

- H – building height.

This formula includes the fact that the air in the room is renewed on average in 12 hours, and the minimum power reserve of the equipment is estimated at 30%.

Installation of a heating boiler in a garage

For garages, wall-mounted or floor-mounted boilers are often purchased. The equipment is installed on a brick (concrete) stand.

Do not forget that before installation work the walls are treated with a material that is resistant to fire.

The boiler is fixed horizontally and vertically. Walls and other objects in the room should be 30-50 centimeters away from the device.

Connecting the device to gas and water

After the installation work is completed, the boiler is connected to gas and water supply. Water is supplied to equipment standing on the floor from above or to the side. In the version with a wall-mounted boiler, communications are connected to the transverse side.

Also, the remaining components of the device must be installed. In that situation, if there is no need to purchase an electric pump for the room, the pipes are laid with an inclination of five millimeters (per meter of length). Otherwise, there will be difficulties with circulation in the heating.

The better to heat or the choice of energy carrier

In 99% of cases, garage buildings are not connected to centralized heating networks or main gas, so owners have to choose autonomous heating methods. To heat a garage, you can use 4 groups of energy carriers:

- various types of solid fuel - firewood, coal, briquettes, agricultural and other combustible waste;

- diesel fuel, waste oil;

- electricity;

- liquefied gas in cylinders.

Advice. When you start choosing an option for heating your garage in winter, keep in mind an important rule: the more expensive the energy source, the easier and cheaper it is to organize heating that is convenient to use. Conversely, cheap or free fuel in the form of waste and garbage will bring a lot of trouble - labor costs and initial financial investments.

Solid fuel combustion

Wood and various waste are the cheapest fuel for heating, and in some cases it is available completely free of charge. In the southern regions, which are not rich in forests, another type of fuel is widely used - small agro-industrial waste.

For reference. Agricultural waste consists of small particles sifted from grain crops. These are pieces of stems, weeds chopped by a combine, straw and other waste. The energy price is very attractive and starts from 20 USD. e. for 1 ton.

After cleaning the grain, waste remains that is used for heating

. We recommend: The use of bellows expansion joints in heating networks and heat supply

If you decide to heat your garage with solid fuel in the winter, get ready to deal with the following issues:

- purchase or manufacture of a furnace (ideally a boiler);

- chimney installation;

- storage of firewood, coal or waste;

- labor costs for preparation, combustion and soot removal.

Storing firewood in the garage is not a very convenient solution

The gain is in money and excellent heating of a room of any size, the losing points are listed above. Add here the time for kindling and warming up (0.5-1 hour). Hence the conclusion: cheap heating with solid fuel is suitable for owners of garages and boxes who stay there for 4-6 hours or more every day.

Potbelly stove for heating a garage

Potbelly stoves are the most primitive stoves that began to be actively used at the beginning of the last century. Then their popularity sharply decreased due to the spread of centralized heating. However, potbelly stoves are still used, because they are practically the cheapest way to heat a garage.

The potbelly stove is made of metal. The largest part is occupied by the chamber into which the fuel is thrown. The room warms up due to the contact of the stove walls with the surrounding air. Not the least important role is played by the pipe, which also accumulates heat. To prevent heated combustion products from immediately flying out into the street, a pipe of a clearly defined diameter is used, due to which the warm gases make several revolutions in the vertical plane. This allows you to make maximum use of the heat of combustion of the fuel (efficiency reaches 60-80%) and effectively suck in the air necessary for the fuel to burn completely. The diameter of the pipe in mm should be 2.7 times greater than the volume of the stove in liters.

It is important that the chimney has a complex shape: first there is a vertical insulated part, then a horizontal or inclined part, the so-called. hog, which provides up to a quarter of the heat received, because the flue gases burn out here. Potbelly stoves are sold ready-made: there are both the simplest and most primitive options, as well as sophisticated designer ones. If you have the skills, you can assemble a potbelly stove yourself from a barrel or sheet metal.

Advantages:

- a potbelly stove can be heated with any solid fuel, but wood is usually used;

- low price and low cost of operation;

- relatively high efficiency;

- allows you to quickly warm up the room and dry the air in it;

- There are models that can also be used as a stove. They will come in handy for those who spend even too much time in the garage.

Minuses:

- the need for constant monitoring of work;

- high fire danger;

- Suitable for small spaces only;

- the air cools quickly;

- it will be impossible to get rid of the specific smell;

- the need for regular chimney cleaning.

Solid fuel boiler

This is a more expensive, but at the same time, safer and more effective solution. The principle of operation is simple: fuel is burned in the firebox, a container with coolant is heated, which is supplied through pipes and radiators. improved types of boilers are increasingly used

- a pyrolysis boiler has two combustion chambers, in the first the firewood smolderes at a high temperature due to the fact that the amount of air is insufficient. The combustion product is pyrolysis gas, which is burned in the second chamber, releasing much more heat than just wood. The boiler efficiency increases to 90%, and one portion of firewood lasts for 10-13 hours;

- Pellet boilers are fired using pellets obtained from wood waste. They are placed in a bunker, from where they are fed into the firebox in doses. The boiler efficiency reaches 95%; fuel can be loaded once every few days.

The body of solid fuel boilers is made of cast iron or steel. Pyrolysis and pellet boilers are, of course, very convenient, but they are expensive. If funds allow, you can afford such a purchase - it will soon pay off

.

Brick oven

Building a brick oven in a garage is a long, expensive and painstaking task. The fuel for such a stove is usually wood, but coal can also be used. The principle of obtaining heat is still the same. The fuel burns, heats the walls of the stove, and they heat the air. A good option for small spaces. Brick takes longer to warm up than metal, but it also cools more slowly.

Stove Buleryan

The Buleryan stove is often confused with a potbelly stove and a regular wood-burning stove. She actually absorbed a little bit of both. The operating principle is based on convection. The design assumes the presence of pipes at the base of the furnace and in the upper part. Cold air enters through the bottom of the stove, receives heat from the chamber where the fuel is burned, and exits, already heated, through the top. The pipes are 2/3 soldered into the furnace body to ensure maximum heat transfer. The special design of the firebox and chimney allows you to extract maximum heat from fuel combustion. The presence of a chamber for pyrolysis combustion of fuel plays a significant role here. Combustion products are removed through the chimney.

Advantages:

- rapid heating of the room due to convection and heat transfer from the surface of the stove;

- compactness;

- there is no need to frequently add firewood;

- higher safety compared to a potbelly stove.

Minuses:

- price;

- complexity of chimney installation;

- the need for frequent cleaning of soot.

Use of mining and diesel fuel

Heating a box or garage with diesel fuel purchased at a gas station is expensive and extremely unprofitable. An exceptional option is to heat a small area of the room where work is being done using a portable heater, whose characteristics are described in a separate material.

Waste oil is a more financially economical energy carrier, although not the cheapest. This option can be seriously considered when used oils can be obtained at a reduced price. What are the features and pitfalls here:

- Homemade potbelly stoves are used to burn liquid fuel in various types of mines. The safest is a drip stove, which you can order from craftsmen or do it yourself.

- A chimney installation is required.

Drip-type exhaust boiler with forced air supply - Oil containers take up less space than firewood. They are usually placed in the basement.

- The workings need to be settled and filtered.

- The inevitable companions of liquid fuel heating are smell and dirt, although this is not critical for a garage.

- Homemade waste oil stoves are considered a fire hazard.

Note. Due to their cheapness and simplicity, the oil miracle stoves shown in the photo have become especially popular. They tend to shoot flames when the fuel contains a small amount of water or antifreeze, causing a fire.

The advantages of using mining are high heat transfer, quick ignition and warming up of the garage box, ease of use (it’s easier to add oil than to chop and carry wood). The conclusion is this: if fuel is inexpensive, or you spend a little time in the garage, then liquid fuel is a suitable option. The initial investment is comparable to wood heating.

When using diesel fuel, it is worth considering the option of a factory-made diesel air heater of the “Planar” type, shown in the photo. With a fuel consumption of 250 ml in 1 hour, the unit develops heat transfer of up to 2 kW. There are also more powerful heaters - 3 and 4 kW with diesel consumption of 0.37 and 0.5 l/h, respectively. Price – within 330 USD. e.

Autonomous diesel-powered air heaters designed for cars

Electrical heating

Heating with electricity is the most comfortable and cheapest option in terms of initial investment. But during operation you will have to pay the full tariff - it makes no sense to install a two-zone meter, you are not going to work in the garage at night.

Let's list all the advantages of electric heating:

- Heating with electricity is convenient and safe. There is no dust, dirt or odors, no need to carry firewood or barrels of fuel.

- There is a wide selection of different air-type electric heaters on sale: convectors, oil radiators, infrared panels and heat guns.

- You can make a water heating system with an electric boiler (if the power limit allows).

- Heating of the garage begins immediately after turning on the heater; a comfortable temperature for work is reached in just half an hour (again, when there is enough power).

An inexpensive portable fan heater can heat only part of the room where work is being done

There are only two disadvantages, but they are critical: the price of electricity and the limitation of the power consumption limit, which does not allow installing an effective heat source. For example, if the contract with the management company specifies a figure of 3 kW, then a convector with only 2 kW is installed, which is not capable of properly heating the garage in the winter.

For reference. Sometimes car enthusiasts use homemade “goats” and fan heaters in the pits, despite the restrictions. Why you can’t do this: there is a danger of the wiring catching fire, the neighbors’ voltage drops, and if employees check the electrical networks, you will face a large fine or shutdown.

Electric heating is an option for short stays in the garage. They came, turned on the heater, completed the intended work in 1-2 hours, turned off the heating and left. If you turned the room into a workshop where you spend your working hours, you will have to pay significant amounts for energy consumption.

A standard wall convector heats the air in the room much slower than a fan heater

Gas heating

This method of heating a vehicle storage space is acceptable for residents of the Russian Federation, where the retail price of liquefied gas is quite low. It will be too expensive for Ukrainians to heat their garages with propane.

Autonomous heating from gas cylinders is as safe and comfortable as electric heating. Moreover, in the Russian Federation the cost of energy is lower. But there are a number of pitfalls here:

- you need to place the propane tank somewhere so it doesn’t interfere with your work;

- you will have to periodically take the tank to refuel;

During operation, the tank freezes over, causing the gas supply to deteriorate. - To burn propane, you need factory-made equipment; making gas burners yourself is strictly not recommended;

- you will need a chimney pipe to the street.

If you add up the financial costs, the problems of organizing such heating and refueling cylinders, then the negative aspects will cover up some of the positive aspects of ease of use.

Watch this video on YouTube

A comparison of the cost of 1 kW of heat obtained from various energy sources in Russia and Ukraine is published on this page.