26.12.2017

One of the most important stages in creating an autonomous sewer system will be the installation of a septic tank. The choice of material plays an important role, since the reliability and duration of operation of the device depends on it. The strength of the material affects the operation of the entire treatment system.

Metal is one of the most popular options for arranging a seasonal system. This material has its advantages and disadvantages, which are worth knowing about before you start equipping the treatment system.

Advantages and disadvantages of a metal septic tank

The main advantages of using this material will be:

· Since the metal structure is heavy, it cannot be forced out of the soil surface under the pressure that is created on the soil walls. The heavy weight of the structure is a disadvantage during installation work, but it is unable to maintain the good functioning of the system during actual operation.

· The metal has high strength, so it is not susceptible to any damage caused by mechanical shocks during installation of the system. Even with severe damage during operation, the material will not deform.

· A high level of sealing makes it possible to eliminate equipment leakage. Thanks to this, the soil will be completely protected from dirty wastewater entering it, and the tank will not be overfilled.

The main disadvantage of a metal septic tank is the tendency of this material to corrosion. To avoid troubles such as rust, it is recommended to treat the system with special compounds.

Some use stainless steel tanks and thus solve the problem of corrosion. But this option is irrational, since the cost of this material will cost twice as much as ordinary metal.

Another disadvantage will be the need to use lifting equipment during installation of the structure. Since the metal structure is heavy, it will not be possible to lift it on your own.

How to make a metal septic tank in the country?

If your dacha does not have a full range of plumbing fixtures, then it is best to create a septic tank from old metal containers. The ideal option would be to use steel or aluminum barrels. When choosing the size of the container, you need to consider the composition of your family and the amount of water regularly consumed by everyone. If the family is not large (up to 5 people), then you can use the option of 200 liter barrels. The most important thing is that the material is durable and the walls of the metal structure are intact.

We offer you the following sequence for installing a metal septic tank:

· Digging a pit to accommodate tanks. When performing this work, you need to take into account the dimensions of the container.

· The bottom of the dug hole must be filled with sand and compacted. The layer must be at least 10 cm so that the barrel can be well fixed. Some use reinforcement loops as fixation.

· System installation.

· Connection of the barrel and pipe system. In this case, the master must take into account the need for holes through which wastewater will be pumped out.

· Filling voids between the walls and the tank.

Source: bioseptik.ru

Construction of the above-ground part of the street toilet

After constructing the foundation for the outdoor toilet with your own hands and installing the container, you need to start building the booth. This process consists of the following steps:

- You need to lay a piece of roofing felt on the surface of the foundation.

- A wooden beam measuring 100x100 mm should be used for the bottom frame of the base under the floor. Before this, it must be treated with an antiseptic solution.

- To build a reliable foundation, install the bars around the perimeter of the structure and in the middle of the long side of the structure, attach them with nuts, after placing them on metal pins.

- Using 40 mm thick boards, build the floor of the future toilet. In this case, it is necessary to leave a hole under the toilet where the container is located.

- Attach 4 wooden columns to the corners of the base. Two of them should have a height of 2 m, and the other two should have a height of 2.2 m. Choose bars with a cross section of 100x50 mm. They need to be attached using metal corners and wooden spacers. Before final installation of the frame, check the verticality of the posts.

- On the front wall under the doors, install additional columns of the same section. The width of the opening should be 0.7 m and the height 1.97.

- Fasten the racks on the other side with a vertical jumper at a level of 1.77 m, which will also serve as the base for the roof.

- Along the structure, leaning on the installed jumpers, attach two rafter legs.

- As roof sheathing, use 40 mm thick boards, which must be attached to the rafters using regular nails.

- Using screws, install an OSB sheet to the lattice covering, which will act as a base for the roofing material.

- Use soft bitumen shingles or roofing felt as a covering. It is necessary to choose materials that will not create additional load on the structure.

- For wall cladding, use a tongue-and-groove or half-tongue board 2-4 cm thick.

- To prevent the inside of the building from being hot in summer and cold in winter, you need to make thermal insulation with your own hands. To do this, install foam sheets in the inner plane of the frame. After this, you need to additionally sew up the walls with another layer of board.

- Apply a special impregnation to all wooden elements, which will protect their surface from the harmful effects of moisture and other negative environmental factors. You can also additionally use fire retardants.

- Install doors on the curtains. You can equip them with a small window to illuminate the interior space during the daytime.

Typology and design of metal septic tanks

Like other septic tanks, metal ones can be divided primarily by the number of chambers used in them, which can be from one to three.

o The number is selected based on two key factors: the required quality of treatment, as well as the volume of wastewater entering the septic tank on a daily basis. Sometimes, instead of installing several cameras, they do it differently - they install several single-chamber solutions, but at different levels. But the most commonly used option is a sump with two chambers. This is especially optimal when the dacha or country house is not very large.

In general, a septic tank is a tank mounted on a concrete foundation and made of stainless or carbon steel, which is coated on both sides with anti-corrosion compounds.

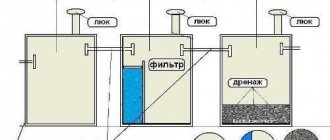

If we talk about a sump tank consisting of two tanks, then the latter are connected to each other using a pipe through which the water, after it has settled in the first compartment and gets rid of solid sediment, flows into the second. The first compartment is actively ventilated, but in the second, due to the type of processes occurring there, no air enters - which helps to effectively decompose organic compounds in this drain.

Then the wastewater is cleaned and begins to be discharged into the ground, where filtration is completed. The area where wastewater is actually absorbed is the so-called filtration field. There are no paths made there, no structures are erected - just thirty square meters of mostly sandy soil for high-quality cleaning and the absence of discomfort.

What features does the design have?

The more sections the wastewater passes through, the cleaner it becomes at the final stage. The most common model is a three-section one, designed to filter viscous dark brown wastewater.

At the final stage, a hole is made in the last barrel that opens onto the filtration field. This post-treatment drainage mechanism consists of perforated pipes located underground. The pipeline is placed in trenches, where geotexile is preliminarily laid, and sand/gravel is backfilled on top.

Note! Such a complex structure is recommended to be installed to clean the dirtiest sewage.

To clean light dirt from a bathhouse or kitchen, one or two compartments are enough. The simplest two-chamber system consists of tanks and an outer plastic pipe with a diameter of 110 mm. If the diameter is smaller, the structure will not cope with a large amount of waste. Iron barrels are installed if groundwater is below 8 meters; if the level is slightly higher, there is no better option than plastic containers.

The slope of the sewer line is 0.03. The vertical value is 3 cm per meter. The post-treatment of light wastewater is carried out in an absorption well located in a second tank filled with gravel/sand.

Installation and maintenance of metal septic tanks

A metal septic tank, in turn, is distinguished by its weight, so, as a rule, it is impossible to do without special equipment. In any case, it is first important to dig a pit, remembering to step back at least five meters from the house. Then crushed stone is poured onto the bottom, and a concrete foundation is placed on top of it. Of course, everything depends on the size of the container that needs to be placed in the pit. The tank is firmly attached to the concrete, as a result of which it will not be pushed out by groundwater, and such a danger always exists, even with heavy metal solutions.

To install the container correctly, it must first be filled with water. By the way, it is important to choose a container of the correct volume. For example, 4 people require 2.5 cubic meters. The volume is calculated as follows: take 250 liters per person and multiply by three.

The fact that a septic tank is installed does not mean that you can forget about it. It is important to clean the containers once or twice a year by calling a sewage disposal truck, but once every seven to ten years it is necessary to completely replace part of the soil.

Source: pro-septick.ru

Introduction

The installation of a septic tank with high groundwater levels takes into account specific installation rules, the violation of which leads to serious consequences. Preliminary design of a treatment plant occurs only after collecting information about the hydrogeological situation. Modern technologies make it possible to build septic tanks for a long time in conditions where groundwater occurs at the upper level (0.2-1 m).

Important: Groundwater measurements are carried out in spring or autumn, that is, during snowmelt or heavy rains. If there is a well, the localization of water is assessed by the distance from the edge of the liquid to the surface of the earth. In the absence of a well, the procedure is carried out using a garden drill, piercing the soil in several places.

Performance

The performance of any treatment facility means its ability to effectively treat a given volume of wastewater generated during the operation of a country house. This indicator determines the number and size of chambers of the purchased structure. With limited volumes of wastewater, it is permissible to use a single-chamber pre-treatment septic tank, which is quite capable of processing a small mass of household waste.

The simplest low-capacity septic tank

To efficiently process large masses of wastewater (with a daily volume of generated waste exceeding 1 m3), you will need a septic tank model with increased productivity.

If your summer cottage is intended for seasonal family vacations, it will be possible to get by with a standard pre-treatment facility with a volume of up to 1 m3.

This simplest version of a cleaning device is usually used as a simple storage tank, periodically emptied by the owner himself, or with the help of special sewage disposal equipment.

Anyone who would like to decide on the choice of a septic tank and plans to live in their country house permanently is not advisable to choose this option. If there is a large amount of waste generated, you will have to use the services of vacuum cleaners too often, which nowadays are not at all cheap.

Device options

Currently, every owner of a private home can choose an autonomous waste collection system that is suitable for their living conditions. The most well-known types of such structures include installations using the biological principle of purification and so-called storage (capacitive) septic tanks.

Biological treatment plant

In installations with biological treatment, the efficiency of the system can reach 70%, which, as a rule, is quite enough for the waste to be purified directly in the soil (without dangerous contamination).

Since anaerobic wastewater treatment methods are accompanied by the release of gases harmful to health, a special drain riser is used when constructing such treatment facilities.

Septic tanks differ in the number of treatment chambers

In addition to the indicators indicated above, septic tank models used in domestic conditions may differ in the following parameters:

- body material (concrete, plastic, metal or fiberglass);

- its orientation when placed in the ground (vertical or horizontal position);

- number of cleaning chambers (from 2 to 4 separate tanks);

- its volume, selected depending on the daily amount of waste generated.

Concrete structures

Made from concrete rings

Concrete settling tanks are made from reinforced concrete rings of standard size, or are poured into pre-prepared formwork directly at the installation site. In the first case, the costs of installing a septic tank increase significantly due to the need to transport the rings to the installation site and their subsequent installation using special lifting equipment.

Self-made from concrete

With the second embodiment, the duration of work noticeably increases, since the operation of the settling tank can only begin after the concrete has completely set. Septic tanks made from reinforced concrete rings are difficult to seal, they are difficult to repair and are bulky. On the other hand, such structures (unlike plastic ones) are not threatened by excess pressure from soil and groundwater.

Metal settling tanks

Metal septic tank

Since metal septic tank bodies require periodic treatment with anti-corrosion compounds, their maintenance will be too expensive. On the other hand, the indisputable advantage of metal is the ability to manufacture a system of overflow pipes of a rather complex configuration from it.

From metal barrels

The welding joints used in this case are characterized by a high degree of tightness, and flange connectors with rubber cuffs can be used for coupling with plastic pipes.

The high hull strength and large mass of such devices allow them to be installed in the soil without the threat of being pushed out by groundwater.

Plastic devices

From Eurocubes

A septic tank for a summer residence made of plastic material is convenient in that it can be installed manually, while the tightness of all necessary connections is ensured through the use of ordinary rubber cuffs.

The plastic housing does not require special protection, while the reliability of the built-in structural elements (system of partitions and overflow pipes) is guaranteed by the manufacturer. Septic tank Unilos is energy-dependent

When installed in the soil, plastic containers should be filled with water, which will ensure that their shape is preserved by equalizing internal and external pressures.

Plastic Tank

If the model you purchased is equipped with special elements that increase the rigidity of the structure, the septic tank can be buried “dry” (without filling with water).

Source: KakPravilnoSdelat.ru

Classification

All septic tanks that are used today to install a sewage system can be classified according to the following criteria:

According to the working method:

- accumulative;

- with soil filtration;

- with deep cleaning.

According to the material of manufacture:

- brick;

- reinforced concrete monolithic and conventional prefabricated well rings;

- metal;

- based on polymers and fiberglass;

- from other materials.

Diagram of a septic tank made of concrete rings.

Depending on location:

- vertical;

- horizontal.

According to the location of the chambers of the cleaning tank:

- superficial, that is, located above the surface of the soil;

- underground, laid in specially prepared trenches.

By connection method to utility networks:

- volatile, that is, operating from the electrical network;

- Autonomous, not requiring electricity to operate.

Types of septic tanks

According to their type and purpose, septic tanks are divided into storage tanks and devices with a wastewater treatment function. The simplest equipment for local sewerage is a single-chamber septic tank into which wastewater flows through pipes. As it fills, it must be pumped out using a sewer truck.

Unlike a cesspool, sewage does not enter the soil. The sealed sewer hatch reliably protects the container from debris and ensures safety for children and pets. Adding anaerobic bacteria to the septic tank allows you to get rid of unpleasant odors and ensure water purification . In the absence of oxygen, they contribute to the decomposition of organic matter, creating sludge from it.

The use of two-chamber septic tanks allows for better cleaning and the use of the resulting water for irrigation and washing. In the first tank, cleaning takes place according to the principle of a single-chamber septic tank. Then the clarified water is poured into the second chamber, where it is further purified using the natural settling of existing particles or aerobic bacteria are used, which guarantees a higher quality of the resulting liquid.

The most complex options are three- or four-chamber systems and sewage water treatment plants. In them, the liquid goes through several stages, with alternating exposure to aerobic and anaerobic bacteria. Such models of septic tanks can be equipped with compressors for pumping water, automatic control systems with sensors. Water after such processing is environmentally friendly and can be disposed of in the soil or used for irrigation.

Septic tanks are subject to serious impacts during operation. Therefore, the material from which they are made must be:

- Durable.

- Resistant to moisture.

- Inert towards aggressive chemical and biological compounds.

How does a sewerage scheme work?

Regardless of the number of containers, septic tanks work the same. Once in the first chamber, the wastewater is divided into heavy fractions, which settle to the bottom, and light fractions, which remain on top. Mechanical cleaning is complemented by the activity of anaerobes, which convert organic matter into gases. They escape into the atmosphere through the drain pipe of the internal sewage system or the ventilation riser in the septic tank.

A fatty film forms on top. To prevent it from getting into the next chamber, a tee is installed on the overflow, which is lowered into the drains below the film. There may not be a second tank, then the wastewater purified by gravity and anaerobic methods is discharged to filtration facilities, where post-treatment occurs. Such structures are common among summer residents who come only on weekends. But it should be borne in mind that a single-chamber septic tank quickly silts up and needs to be cleaned more often.

The processes in the second chamber do not differ from those that occurred in the storage chamber. Here, the pre-treated wastewater becomes even lighter. Silt falls to the bottom, and the remaining organic matter is processed by anaerobes. Then the water is sent by gravity for additional filtration or goes into an aerobic septic tank. This is where the final cleaning takes place.

Materials for the manufacture of septic tanks

Currently, the following are used in the manufacture of septic tanks:

- Plastic.

- Metal.

- Fiberglass.

The most common are plastic containers. These drives are made of polyethylene and polypropylene. Each of the materials has its own advantages and disadvantages. Their common advantage is resistance to moisture, chemical and biological active substances.

Septic tanks made from polyethylene using rotation technology are highly durable. But at the same time, the material is fragile, so the containers have special stiffening ribs. The structure can retain its functional properties for 30 years, thanks to its multi-layer structure. Polyethylene containers have a wide operating temperature range: -50°C - +70°C. The disadvantage of these septic tanks is that the upper temperature limit is too low. During the destruction of organic contaminants by anaerobic bacteria, the temperature of the liquid in the container may exceed the permissible norm, which creates a risk of deformation.

Polypropylene is inferior in density to polyethylene, but is more resistant to various impacts. Therefore, this material is most often used in the manufacture of cleaning systems and stations. For polypropylene containers, the upper limit of the operating temperature range is +140°C, so any deformation is excluded even with extreme heating of wastewater. The service life of such septic tanks is 50 years, subject to installation and operating conditions. The disadvantage of such products is the small thickness of the walls. It is no more than 2 cm. But the addition of stiffeners makes it possible to provide the necessary resistance to mechanical stress.

Metal containers for septic tanks are currently used much less frequently. This is due to the destruction of the material under the influence of moisture, even during anti-corrosion treatment. The service life of such products does not exceed 10−15 years. The disadvantages include the labor-intensive work involved in installing a metal septic tank. It is impossible to install the container without the use of special equipment. If waste water freezes, the housing may be damaged. But in some cases, the use of metal containers is the only option for local sewerage equipment.

Fiberglass septic tanks are made from resin and fiberglass. In terms of their reliability, they are not inferior to metal ones, and their durability is similar to plastic septic tanks. In addition, errors when installing such containers will not affect the quality of their work, unlike polypropylene and polyethylene options. But due to the high cost of products, their popularity is now low.

Types of concrete rings

The rings differ in the type of construction:

The final structural element of a reinforced concrete septic tank

- With a bottom. A monolithic product, which is installed first in the pit, with wall walls on top. Used to create a sealed container, leaks do not occur during the entire period of operation. Standard height is 0.9 m.

- Castle ones. With special recesses in the upper and lower parts. During installation, a reliable connection occurs. Indispensable for the construction of septic tanks on floating soils.

- With lid. There is a hole in the ceiling for a hatch. This is the final element of the well. The monolithic product increases the strength of the entire structure.

Rules for choosing containers for septic tanks

When choosing a container for local sewerage equipment, several factors so that the purchased model ideally performs its functions.

Storage tanks for septic tanks are inexpensive and easy to install. Adding bacteria to them allows you to eliminate odors and purify wastewater. This container requires no maintenance. The owner's only concern is the regular pumping of liquid from the storage tank. Installing such a septic tank is advisable in a summer cottage. Temporary residence will allow you to empty the container infrequently. Drives are available in different volumes, which makes it possible to choose the best option. Any type of container is perfect for a summer cottage:

- plastic;

- metal.

When purchasing a storage device made of metal, please note that it must be properly treated with special anti-corrosion agents. Bitumen protection is short-lived and quickly decomposes in the soil.

Permanent residence requires the installation of more efficient septic tanks. In this case, the best options would be systems and autonomous sewerage stations that do not require regular pumping of water. The choice of model volume depends on the number of people living in the house. On average, calculations provide for 150 liters per person.

In areas where there are power outages and power surges, it is advisable to install non-volatile systems in which liquid naturally flows from chamber to chamber.

When choosing an autonomous station or system, you should pay attention to the manufacturer and focus on products that have already proven themselves in the consumer market.