A do-it-yourself septic tank made of concrete rings allows you to ensure the functioning of your own cleaning structure. After all, owners of country houses and summer cottages are often very interested in the problem of their own sewerage system in the absence of a centralized one.

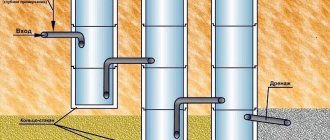

Diagram of a septic tank with three-section filtration.

Currently, numerous ready-made designs are offered, but this is expensive and does not suit the owners of country real estate in all cases. A do-it-yourself septic tank made of concrete rings is one of the simplest, cheapest and most reliable options for solving the problem.

Design features

A septic tank is a settling tank for sewage that performs the task of collecting and purifying it. Their general principle of operation is based on the presence of chambers separated from each other, in which accumulation and subsequent settling, biological preliminary treatment and soil final treatment of sewage and wastewater are carried out. It is recommended to make septic tanks with two chambers for wastewater volumes up to 10 cubic meters per day, and for large volumes - with three chambers.

Diagram of a septic tank.

The general design of the septic tank is presented as follows. The first chamber (section) is directly connected to the sewer discharge and ensures the collection of sewage. This is where the initial settling of wastewater occurs, when the heaviest components precipitate in the form of sludge. This section must be well isolated from the entry of waste elements into the soil.

The second section is connected to the first chamber and acts as an anaerobic reactor in which various chemical and natural biological compounds decompose. Penetration of decomposition products into the soil from this section is also not allowed. Finally, the third chamber carries out the final treatment of wastewater and discharges purified water into the soil through a soil filter. The overall degree of purification should be at least 65%. In practice, two-section systems (there is no second chamber) are most used.

Basic design requirements

The main requirements for the first section are tightness and sufficient volume to collect runoff. The outlet for the transition of the liquid fraction to the next zone should be located below the surface level of the incoming sewage, but above the level of silty sediment.

Dimensions of concrete rings for a septic tank.

If there is a second section, sealing from the soil and supply of beneficial microorganisms and antiseptic compounds (or the use of additional disinfection methods) should be provided.

In this zone, products of acid and methane fermentation, as well as products of biological decomposition, are formed. Introduction of specialized microorganisms, incl. methanogenic bacteria, helps reduce the concentration of hazardous substances.

The third section must ensure the release of purified water into the soil; for this there must be a soil treatment system. In addition, with a two-section septic tank, this zone should also serve as a second chamber. The soil purification system depends on the terrain and the location of soil water.

Choosing ecoseptic material for a summer residence

- Tanks made of plastic and fiberglass

The main materials for making ecoseptic tanks for summer cottages are fiberglass, polyethylene, and polypropylene. Such tanks are mainly used for bioseptic tanks for autonomous sewers.The materials for the manufacture of such containers have high plasticity, so the tank can be of any shape and size. If the septic tank needs to be installed at a shallow depth, you can choose a low rectangular shape. This allows you to place the septic tank below the soil freezing level.

One of the most popular tank shapes is cylindrical. There are no sharp corners, the walls are less rubbed, and the risk of depressurization is reduced. It is quite possible to install such a container on your own.

For biofiltration septic tanks, containers with internal jumpers are used. The installation of such tanks must be carried out strictly on a horizontal surface and using a building level. The container is placed on a previously prepared surface, filled with water, the position is fixed at the level, and only then covered with earth. The reservoir is filled with water to avoid squeezing the walls.

This is interesting!How to decorate a septic tank on the site: several elegant solutions Read more

- Well made of reinforced concrete rings

Reinforced concrete rings are often used to make septic tanks. These are prefabricated structures with grooves and locks. O-rings are provided at the connection points.For the bottom of the well, use a ring with a bottom. Hollow rings with perforated walls are used for the filtration compartment. The structure of the septic tank is prefabricated from reinforced concrete. It consists of additional rings, walls and neck. Products must be made of materials that do not allow moisture to pass through. The outer walls are sealed.

Reinforced concrete rings are ideal for the construction of septic tanks with several compartments. Using pipes located at an angle, the sections are connected to each other. Installation of the structure will require the involvement of heavy construction equipment and workers. But its main advantage is its versatility. If you can provide access for special equipment and an optimal place to work, the entire structure can be installed in a short time. Moreover, it can be of any shape and volume.

- Metal tanks

Some types of autonomous sewage systems are made of metal. Welded structures with internal partitions made of brick, concrete blocks or stones have proven themselves well.The main advantages of a metal tank over a plastic one are strength and resistance to mechanical stress. In order to extend the service life of the metal tank, its surface is treated with anti-corrosion compounds. The tank can be installed only after complete processing.

Soil filtration system

Scheme of a single-chamber septic tank made of concrete rings.

Soil purification, or filtration, is a layer of natural materials of soil origin. The simplest design of such a filter is a filter well, i.e. a layer of sand and gravel at the bottom of the last section of the septic tank. The design can be used if there is a sufficient depth of groundwater and provided that the soil is not made of hard rock. Such a filter is allowed if the distance to groundwater from the bottom of the well is at least 1 m, and from the bottom layer of the filter is at least 0.5 m.

If the soil under the septic tank has a clayey composition or other compacted soil, then filter trenches should be used. In this case, the filter area increases, which is necessary when soil permeability is low. Such drainage systems can be up to 12 m long and must be sloped to ensure gravity flow. If there are special sanitary requirements for the area where the house is located, it will be necessary to build absorbent trenches or platforms (fields) with perforated pipes, through which wastewater is drained with gradual release into the soil, or even the installation of an additional biofilter.

Pumping of local treatment facilities

Local sewerage needs to be pumped out once every 6 months. At the Topas, Yunilos Astra, Biodeka, Genesis, and Eurobion stations there is a special airlift for pumping out sludge. With its help, you can perform pumping yourself. A more effective pumping method is using a drainage pump, which is lowered into a sludge stabilizer. The sludge is pumped into a bucket or other suitable container.

After pumping, the local treatment facility must be filled with water. If you leave the septic tank empty, it will float or be crushed by the soil.

Local treatment plants with a receiving chamber for settling (BioPurit, Tver), as well as pumping wastewater through a biofilter (Evrolos, Kolo Vesi), are serviced by a sewer truck.

Station maintenance is not just pumping out sludge. It is necessary to disconnect and wash the airlifts, check the condition of the electrics and other equipment. To perform this work, it is better to call a service engineer who will quickly and professionally perform the service. When purchasing a local cleaning station from the Zagorod company, you can enter into a service agreement with us. Maintenance under a contract is cheaper than one-time maintenance.

Septic tank placement

Choosing a location for a septic tank.

Solving the question of how to properly make a septic tank begins with choosing the location for its installation. There are a number of objective requirements for placing a septic tank. First of all, fairly stringent requirements for the minimum distance to important objects are standardized. These distances are:

- to a residential building - at least 5 m;

- to a source of drinking water (borehole, well) - 50 m;

- to an open reservoir - 30 m;

- to the nearest road - 4 m;

- to the nearest fruit trees - 4 m.

The distance is calculated from the location of the last section of the septic tank or filter field.

A do-it-yourself septic tank should not be located in a low-lying area where an influx of melt or rainwater is possible, which will significantly increase the volume of filling the section. Sewage pipes (drain into the first section, pipes between sections) must be placed with a slope.

Before building a septic tank from concrete rings, it is necessary to correctly determine its volume. This important parameter is calculated based on the condition that one person receives an average of up to 200 liters of wastewater per day. Accordingly, this volume should be multiplied by the number of people living. If people live in the house permanently, it is advisable to increase the volume of the septic tank by 20%. Distribution of the required volume by sections: the first chamber - 75%, the second - 25%.

What are the disadvantages of aeration plants?

- Quite a high cost, especially for high-quality products.

- Relative complexity of the design: there are moving elements.

- Energy dependence. Although the energy consumption for VOC operation is relatively small, when the power is turned off, the installation quickly ceases to function normally.

- Unstable work under the condition of non-permanent residence in the house, which means uneven flow of wastewater.

- The need to preserve the installation for the winter if you do not intend to live in the house at this time of year.

- VOCs require regular maintenance (often 3-4 times a year), which can be a hassle for homeowners.

- Compared to septic tanks, aeration systems are not as “omnivorous”: there are serious restrictions on what can be discharged into the sewer. Most often, you cannot dispose of leftover vegetables and fruits, spoiled food, construction waste, filter rinses, large amounts of wastewater containing chlorine-containing products, etc. There, however, you can throw toilet paper, kitchen drains, and drains from dishwashers or washing machines there.

Sergey ShemaevCEO

When preserving an aeration plant for the winter, it is strictly forbidden to pump water out of it, otherwise the station may be deformed or squeezed out onto the surface of the earth. To avoid this, be sure to leave the unit filled with clean water.

Features of installing a septic tank made of concrete rings

The most common construction is a septic tank made of concrete rings, consisting of two sections. For production, standard concrete rings with a diameter of 100-200 cm are used, more often with a diameter of 100 cm. The second section is almost always made of 100 cm rings, and the first, depending on the required volume. The number of rings is determined from the calculated volume of the section.

Figure 1. Diagram of the first section of the septic tank.

The recommended structure of the first section is shown in Fig. 1. The following numbers are indicated on the diagram: 1. Hatch. 2. Air intake. 3. Concrete ring with a diameter of 70-80 cm. 4. Wooden cover. 5. Drain inlet. 6. Drain outlet. 7. Concrete rings with a diameter of 100-200 cm. 8. Bottom slab. 9. Concrete screed.

The second section is usually made in the form of a filter well. How to build such a well is shown in Fig. 2, where the numbers indicate the following: 1. Hatch. 2. Air intake. 3. Concrete ring with a diameter of 70-80 cm. 4. Wooden cover. 5. Drain inlet. 6. Holes in the bottom ring. 7. Concrete rings with a diameter of 100-200 cm. 8. Bumper. 9. Sand and gravel filter.

The choice of filter design depends on the above soil characteristics. It is recommended to build a septic tank with a filter well for loose soils and a groundwater depth of more than 3 m. For other soils, it is better to use a filtration field.

Construction stages

The VOC assembly process consists of the following steps:

- site marking;

- excavation work;

- preparing a nest, casting or installing a finished septic tank;

- installation of a well or filtration field;

- laying pipelines connecting the internal and external parts of the system;

- insulation, filling of sinuses.

The most complex procedures include assembling a septic tank. If ready-made concrete rings or collets are used, it is necessary to ensure the tightness of the bottom. In addition, all sections must be connected by an overflow system.

When installing a septic tank, it is necessary to ensure the required height difference between the points where the pipes exit the house and the inlet of the tank. This is an important point on which the normal operation of the system depends. In addition, it is necessary to ensure the specified depth of immersion into the ground of all elements of the system. If this is not possible, you will have to properly insulate the pipes and septic tank.

The recess under the tank must be made taking into account the thickness of the sand cushion and the concrete anchor. They add 4-0-50 cm to the overall depth of the nest. It is important to ensure that the container is installed level, without distortion or tilting. If there is groundwater on the site, the assembly process becomes more difficult. Many home owners postpone work until the winter so that the moisture freezes and does not fill the trench.

The sinuses are filled only after checking the tightness and insulation of the pipes. This is the last stage, after which it will be extremely difficult to fix anything. Therefore, it is necessary to carefully check the slope, connections, and install a heat insulator. There is no need to rush; all procedures must be performed carefully and efficiently.

DIY septic tank made of concrete rings

Figure 2. Diagram of the second section of the septic tank.

The construction of a two-section septic tank includes several stages. At the first stage, two pits are dug for sections and trenches for laying sewer pipes. Then a cushion of sand and crushed stone 40-50 cm thick is laid at the bottom of the first pit with a diameter of 2-2.5 m. A screed is made on top of the cushion by pouring cement mortar. A concrete slab with dimensions exceeding the diameter of the main concrete rings of the first section is laid on the screed. Along the edges, the gap between the slab and the ground is filled with cement mortar. Concrete rings are installed one by one on the slab using a crane.

At the bottom of the second pit, a sand and gravel filter with a thickness of at least 50 cm is made. The process of installing concrete rings on top is carried out, and the lower rings are secured by pouring mortar from the outside of the ring.

The rings are connected to each other with cement-sand mortar.

The joints of the concrete rings must be additionally sealed. It is best to use waterproof cement mortar “Aquabarrier”. The most commonly used method of waterproofing is coating joints with bitumen. Sometimes, to increase reliability, large-diameter polymer pipes are used, installed inside concrete rings. Inlet and outlet sewer pipes are installed in sections of concrete rings: the inlet drain is about 100 mm in diameter, the intermediate pipes are 50-60 mm. Pipe entries into sections are sealed.

The gap on the outside of the concrete rings is filled with soil. For additional waterproofing, it is advisable to add a clay composition. Next, the ceiling is completed, the vestibule is installed (for which concrete rings of smaller diameter are used) and the air intake is secured. A hatch is installed on top, preferably concrete. The question of how to make a septic tank from concrete rings has been completely resolved.

Necessary tool

To build a septic tank with your own hands from concrete rings, you will need the following tool:

- Bulgarian;

- perforator;

- Master OK;

- grater;

- shovel;

- putty knife;

- paint brush;

- knife;

- scissors;

- electric drill;

- sledgehammer;

- hammer;

- axe;

- roulette;

- meter ruler;

- level;

- plumb line;

- scrap.

A septic tank can provide a convenient local sewer system. Building a septic tank from concrete rings with your own hands according to all the rules will ensure the necessary living conditions without violating environmental purity.