In the material about polypropylene pipes, I briefly explained what these pipes are.

Now let's talk a little about soldering these pipes.

It is correct, of course, to say: “welding” or even “diffusion welding of pipes”, but we usually use simpler words: Dictionary diffusion welding, we call soldering Welding machine, we call it a soldering iron or even an iron Polypropylene we call “polycom” or “PPR”

We call the colors this way: White - Turk. (Although Valtek also makes white and the quality of the pipes is at a high level) Gray - Czech Green - German

Soldering

The average temperature of the welding machine should be set to 260 degrees.

Of course, for each diameter there are more subtle temperature settings and on expensive machines, the required temperature is inserted automatically if you specify the diameter of the pipe being welded.

We set the temperature to 260 degrees, put on the desired nozzle, and now all we have to do is remember the time during which we need to heat the pipe.

16th heat for 5 seconds. after which it must be fixed for 6-7 seconds so that the soldering is of high quality.

We heat the 20th for 5 seconds.

25th - 7 sec.

32nd - 8 sec.

40th - 12 sec.

Now more details.

We take the pipe with the coupling in our hands and try to connect them without heating. If this is possible, then there will not be a high-quality connection, replace the components and, if possible, use connectors from the same manufacturer in the same system.

After we have found out that you hold in your hands what you need and can be soldered, we first put the fitting on the nozzle of the welding machine (it is thicker) and then the pipe.

But this is a book example and it is very difficult to attach a fitting and a pipe separately to a soldering iron. Push in at the same time, but you can take out the pipe first, and then the connector.

This is what the heated fittings look like:

Now they need to be connected.

When heating, it is important to insert the pipe completely into the nozzle. To be sure, before soldering, you can make a mark on the pipe how long the pipe should go into the nozzle.

When heating, the elements cannot be twisted on a soldering iron . Although the manufacturer prohibits turns, I still do it, but the turns are very small, I would even say they are some kind of movements to make it easier to put on the pipe with the fitting. It happens that the corner fits very tightly onto the nozzle. This often happens with large diameters, for example 40 mm. In this case, the soldering iron can be moved back and forth a couple of degrees relative to the parts.

If you twist the parts or the soldering iron more than about 5 degrees, then parts of the plastic will remain on the nozzle which will then smoke, and the soldering may be of poor quality. So, if possible, it is better not to turn, and especially not to twist or turn .

After installing the elements completely, we begin the countdown at 5 seconds in the case of a 20 mm pipe. or 8 seconds in the case of the 32nd pipe.

After this time, we first remove the pipe, and then the fitting.

Quickly, but without fuss, we connect these two elements. After connection, you still have a couple of seconds to correct the alignment. After 2-3 seconds. Alignment adjustment must be stopped. Otherwise, the joint will leak.

After the joint, allow the product to cool for about 20 seconds, fixing the joint firmly.

If you are soldering the first joints, then strictly observe the heating and fixation time. In subsequent joints, take into account drafts and ambient temperature. If you are working in a draft and the temperature, for example, is below +10, then the heating time should be slightly increased by 1-3 seconds. depending on diameter. Otherwise, you risk not having time to dock the heated elements, or there is not a second left to correct the alignment.

Features of PPR pipes

Polypropylene today is only slightly inferior to polyethylene in terms of its consumption in the world. Not only pipes are made from it, but also containers, threads, sheets - this is the most popular plastic in industry. Pipes made from it have the following distinctive properties:

- they have high strength;

- resistant to alkaline environments;

- Acids have practically no effect on them;

- rust does not form in them;

- they have low electrical conductivity;

- withstands strong water hammer;

- you can bend them as much as you like;

- finally, they are now relatively inexpensive.

Specifications:

- can withstand temperatures down to – 15 degrees;

- have low thermal conductivity;

- material density 0.91 kg/cm2;

- strength – 35N/mm.

Polypropylene begins to soften at a temperature of 140 degrees, and melt at 170. Pipes from it are made of various diameters - from 10 to 125 mm. They are connected using special soldering, which makes the seam very durable if the work is done correctly.

What is needed for work

First, you will need tools and materials:

- tape measure or meter;

- marker or pencil;

- building level;

- pipe cutting scissors or hacksaw;

- soldering iron for plastic pipes;

- nozzles for the soldering iron corresponding to the diameter of the pipes;

- degreasing liquid and a rag for wiping before soldering;

- sharp knife.

Also, in addition to pipes, you will need couplings, fittings and angles to make the connection.

To install pipes you will need a soldering iron and several nozzles. Since the price of such a tool can be about 4 thousand rubles , it would be reasonable to decide whether to buy a soldering iron or not? It depends on how often it will be used. If you plan to use it only once in your life, then you should consider renting. All work with a soldering iron can be done within one day. In any case, before working with this tool, you should study the included instructions. It contains detailed instructions for use.

Required Tools

To carry out high-quality welding, you will need the following minimum set of tools and devices:

- a welding machine with a movable electric drive for diffuse welding (with a set of nozzles);

- a special cutter (or scissors) for cutting pipes;

- scraper;

- mounting device for welding elements with a diameter of over 50 mm;

- degreasing liquid (acetone, alcohol);

- marker;

- roulette;

- rags.

Video description

7 gross MISTAKES in welding POLYPROPYLENE pipes.

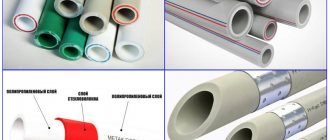

Particular attention should be paid to reinforced pipes, as in the photo above. Aluminum foil keeps polypropylene from deforming when hot water passes through it, that is, a hot water supply or heating circuit fixed on brackets at intervals of 80-120 cm will not bend. For the installation of plumbing and heating in the private sector, plumbers prefer to use the universal PN20, using it not only for heating and hot water piping, but also for the distribution of cold water. However, this depends more on the owner of the house and, if he wants to save money, then PN16 is installed for cold water. It should also be said about PN10 - at present, only irrigation systems for country gardens are made from such a thin-walled pipe and they refuse to use it in plumbing.

For centralized heating, PN25 pipes are suitable, which can withstand pressure up to 2.5 MPa or 25.5 atm. Such values are provided for a reason: when starting the system at the beginning of the heating period, the pressure is increased to check the integrity of the circuit and radiators. Thus, the pressure test in a nine-story building can reach 16 atm, but water hammer can cause one-time short-term surges of more than 20 atm. If the abbreviation PEX is present in PN25, then instead of aluminum foil, fiberglass is used for reinforcement, but this does not affect the strength.

The principle of the arrangement of layers on the walls of PN25 is the same as in PN20, but in the first case, the aluminum foil or fiberglass is located closer to the outer layer (almost under the top), so when the pipe melts in the matrix, the top coating goes away and the foil remains. It is clear that such welding will not have the required quality, so for PN25 they use a shaver, as in the photo above. This tool resembles a school pencil sharpener, only it cuts not to a cone, but in a flat plane, removing the foil. After this operation, the soldering turns out excellent.

PPR Welding Requirements

Look at this table first so that the explanations will be clearer later.

| D PPR, mm | Welding depth, mm | Time, sec | ||

| Warming up | Butt hold | Cooling | ||

| 20 | 12-14 | 5 | 4 | 3 |

| 25 | 14-16 | 7 | 4 | 3 |

| 32 | 18-20 | 9 | 4 | 4 |

| 40 | 20-22 | 12 | 6 | 4 |

| 50 | 22-23 | 18 | 6 | 5 |

| 63 | 23-25 | 24 | 6 | 6 |

| 75 | 27-29 | 30 | 8 | 8 |

| 90 | 33-35 | 40 | 8 | 10 |

| 110 | 37-39 | 50 | 10 | 10 |

Video description

How to solder polypropylene pipes

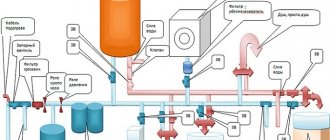

But in situations where reliability is required, steel clamps with a plastic dowel are used for fastening. There are rubber gaskets on the inside of both halves of the clamp. Clamps of this design secure not only polypropylene, but also polyvinyl chloride and metal pipes.

For the most part, PPR pipes are hidden under plaster, drywall or PVC/MDF panels, but for this they also need to be fixed somehow. Usually, a channel is cut for a water supply, and the pipe itself is secured with a perforated strip suspension to prevent it from falling out. This can also be done without a groove - simply press the PPR tape, like a clamp, pulling it on both sides with plastic dowels with self-tapping screws.

general information

The temperature regime for soldering polypropylene pipe products directly depends on the polymer used. In practice, 4 types of materials are used:

- PN10, used for the use of technical products at temperatures up to +40 C;

- PN16 for use at +60 C;

- PN20, used in water supply from +80 C to +95 C;

- PN25 for operating modes above +95 C.

In addition to maintaining temperature conditions, welding polypropylene pipes with your own hands depends on the pressure that pipe technical products of a specific marking can withstand.

The first type is used when laying technical products intended for cold water supply. Pipe products marked PN20 are considered universal and are intended for cold and hot water supply, but taking into account that the effect of +95 C is short-term. If the temperature is not maintained, then due to its action they will lose their tightness and become deformed.

Do not prepare the material before welding

In 90% of cases, do-it-yourself soldering of polypropylene pipes takes place at a facility under construction or during a major overhaul. Dirt, dust, cement, sand - this is the standard situation.

The workers don't pay attention to the dirt. They try to hand over the object faster, get paid and leave. As a result, the pipes are installed as follows: a fitting is taken, inserted into the welding machine, and connected to the pipe. However, a key point has been missed. Connections must be carefully prepared.

Pipes and fittings are on a dirty floor. On dusty shelves. Due to repairs, a large amount of construction dirt, dust, and cement accumulates on the pipes. Polypropylene must be cleaned before welding. Uncleaned connections may begin to leak. In a month, a year, two or five years.

Connection areas:

- wipe with a clean damp cloth;

- dried;

- degreased.

Cleaned parts are key to a proper installation. The treatment is recommended by the manufacturers themselves. Extra elements at the joints make the connection loose. Subsequently, cracks and leaks form.

Each future connection between pipe and fitting must be wiped down. It is advisable to do this with alcohol-containing rags or napkins.

Welding of connecting parts is carried out in a ventilated area. If working outdoors. The site is protected from precipitation: rain, snow, wind.

After cutting, check for burrs. Remove with specialized tools. Polishing and cutting. Chips inside are not allowed. The connection area must be free from damage.

Selecting a welding machine

Another name for the connection process is simply soldering pipes. It is performed using a special apparatus, which is called a device for welding polypropylene pipes, it is also called a welder or a welding iron.

It is not recommended to buy it if you only need to make a connection once. Since it is not economically profitable, it is easier to rent it. Most stores provide this service.

Nevertheless, if you decide to purchase a device for welding polypropylene pipes, then based on reviews, you can recommend Czech or Turkish devices. Chinese models are inferior in quality to the first two options. The cost of such a unit is proportional to its quality. High-quality devices are priced higher.