Buyers are increasingly choosing polypropylene-based pipes.

The products are in high demand, providing performance characteristics, no installation problems, and an affordable cost.

Manufacturers say they last at least 50 years. Minimal skills are enough to do a job such as laying a water supply system from polypropylene pipes in the ground.

We dismantle the old water supply system

The first step in any installation of a plumbing system is to dismantle sections of the old pipeline. Steel products most often require complete replacement.

Installation using a grinder is the most convenient and simplest solution. After this, we begin laying polypropylene pipes for the new water supply system.

We suggest you read the article on how to independently lay a drainage pipeline at the entrance to a site

Possible difficulties

Experts note a number of problems that everyone may encounter:

- The main mistake is the wrong choice of pipes. Steel rusts. Too simple and cheap ones become deformed. It is better to focus on a proven model of the required parameters.

Water pipes

- The soil is hard to yield and it is impossible to dig to the required depth. The advice of craftsmen on this matter is this: dig as much as possible, as deep as possible. But be sure to provide good thermal insulation to the pipes.

- Neglecting a heating cable always ends badly. They are necessary for the normal functioning of your water supply system, no matter how expensive and difficult its installation may be.

- Many residents of warm regions neglect trench depth standards and lay the pipe almost below the surface of the earth. Yes, it will not freeze in the south of the country even in winter, but it will be mechanically damaged so quickly that it will soon need to be replaced.

If you follow all the rules and advice from the experts, the system will serve you for many years.

Rules for laying in the ground with your own hands

GOST says that for laying in the ground, pipes must have a diameter of at least 32 millimeters. For convenient and quick installation, a set of fittings is purchased.

This sequence of actions is performed when installing polypropylene pipes with your own hands.

- First, a trench is dug in the ground. Standards indicate that the depth of the trenches must exceed the freezing level of the soil. It is better to use special tables to determine the freezing level specifically for your region. 0.5 meters is the optimal width for the seam.

- We compact the trench - the bottom and also the walls.

- They create a cushion that provides shock absorption. For it, it is enough to pour a layer of, for example, sand gravel or sand of about 10 - 15 cm.

- It is mandatory to wrap the water supply pipe with a heat-insulating layer. Then the products are laid in a ditch and connected using fittings.

- We fill the pipeline with sand. The main thing is that the highest point is 5 centimeters higher than the pipeline itself.

- We cover the place where the water supply is located with tiles. In this case, broken bricks and tiles will become indispensable assistants.

- We fill the trench with earth. It is easy to understand that installing polypropylene pipes in the ground is not such a complicated process.

Initial stage of work

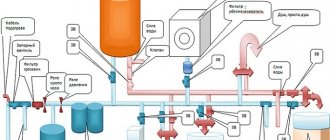

Any installation of water pipes begins with drawing up a project. The scheme must be well designed, otherwise the pipeline system will not be able to function properly. This does not mean that the project should become a miracle of engineering - the main thing is that you can easily navigate the finished circuit, so that if errors arise during the work, you can easily figure it out and quickly solve them.

The project must contain the following information:

- Soil properties - its type, whether it is loose, rocky or sandy.

- The area of land over which the pipe will be laid. It is necessary to calculate so that you can always consider the number of forks and entrances.

Remember that the laying of water supply pipes must pass along a pre-leveled area. Ignoring this nuance may lead to unexpected bad consequences in the near future.

Regulatory documents: conditions and requirements for pipeline construction

The standards determine the laying of any pipeline, regardless of what material it is made of. Many technical issues are regulated in the so-called SNiPs.

They ensure safety and allow any work to be carried out efficiently. Here are a number of requirements that must be met for installation in the ground.

- Accounting is required for the point at which the soil freezes. Its level is often 1.4 meters. In winter, the water inside the water supply will simply freeze if it is located lower. The operation of the water supply will become impossible.

- The laying and its method may vary depending on what structures and structures are already present on the territory. And from the presence of highways, communication networks, highways. It is better to contact specialized companies if you are not completely sure about where to carry out the installation.

- The characteristics of the soil and topography are important for those who lay underground water pipes.

Watch the video

Water supply from well to house

Why is thermal insulation needed?

Insulation of pipes is a necessary condition for their proper operation. If for some reason you were unable to install the pipeline at a depth of 1.4-1.6 meters, then thermal insulation will protect the fittings from low-temperature damage.

Important! Even if your region has warm, mild winters, you should not neglect thermal insulation. It is impossible to predict weather anomalies, and a sudden frost can cause a serious accident on the pipeline.

Mineral wool in rolls is used as thermal insulation for pipes, as well as special covers made of foamed polystyrene, polystyrene foam and rubber, which are placed over the pipes before welding. Insulating materials can also be supplied in the form of so-called. a shell consisting of two halves of a circle. When installing such insulation, it is fixed with special tape.

Possible problems

Sometimes it happens that the structure of the soil does not allow digging to the required depth. Or ground freezing of the ground occurs with such force that the water supply is damaged.

But a way out can always be found. For example, make a puncture if the ground is too loose. First, a steel pipe is laid in the hole, and a polypropylene pipeline is installed inside it.

Additional protection against freezing - heating cables located along the entire length. But such work is associated with additional costs.

Trenchless installation methods are finally a great solution for those who are faced with an obstacle that cannot be bypassed.

The most common mistakes made when laying underground pipes

The underground installation of communications, of course, largely depends on the type of soil in a particular location. And, often, many difficulties arise with it during work, since the composition of the soil may simply not make it possible to deepen the pipes to the distance specified in SNiP. In particular, the soil may be very compact, rocky or boggy, so that you simply cannot get to the desired depth. In this case, many difficulties can arise in winter.

However, even in this case, there is a way out - insulating water supply pipes in a private house in various ways. In this case, a reasonable option would be to dig a trench as deep as possible and insulate the pipes well.

Features of trenchless laying

Trenchless installation provides owners with several advantages.

- There is no need to destroy buildings or plants that stand in the way.

- The harm caused to the environment is minimized.

- Time and financial costs are reduced.

There is more than one method.

- Sanitation. This means that old pipes are replaced with new ones. The work is carried out in two ways:

- Relining. New polypropylene pipes are laid inside the old pipes. The main thing is to inspect the existing pipeline in advance. The main thing is to make sure there are no foreign objects or debris. It is also important that the diameters match each other.

- Renovation. A new pipeline is being laid and the old one is being destroyed simultaneously. It is carried out in situations where the initial diameter is insufficient.

- Piercing. Relevant for diameters over 150 millimeters. The work has several stages.

- Two pits are being dug on both sides of the object under which we will conduct communications.

- Placing a hydraulic jack on one side. He pushes a polypropylene pipe with a steel tip inside.

- The pipe gradually increases in volume, and then polypropylene products are introduced into it.

- Connection to all systems.

But the latter method is suitable only for those who are interested in laying short sections of water pipelines.

Technical Preface

In order to mentally (and not only) prepare for work, of course, you need to learn a little general theory.

There are two ways to lay a water pipeline: on the surface and underground. In this article we will look at the latter option.

Laying water pipes

The pipeline is laid using one of three methods:

- An excavator digs a trench; the rest of the work is done manually. A lot of special equipment is required.

- Horizontal drilling (HDD), trenchless technology. Piercing the earth.

- Shield gasket - this method is called collector. Construction of tunnels for communications.

The technology is different in each case; in this article we will look at a method that you can do it yourself (a shovel instead of an excavator, drilling).

What about insulation?

Water will not freeze if you choose the right type of pipes and the depth of their installation. But additional protection is often required for external installation.

For this, for example, special cases are used. The existing water supply is laid inside another pipe with a small diameter. This contributes to the formation of an air cushion between the walls of different products. Thanks to this, the heat of the water is retained.

Video

Heating of water pipes with a self-regulating heating cable

Or the pipeline is simply poured using polystyrene concrete or foam concrete. This is a monolithic layer, with a base in the form of concrete with low weight and a porous structure.

The water supply is sometimes wrapped with insulation. Or a heating cable. The latter is laid both inside and outside the structure. It is recommended to carry out the gasket in two available ways:

- Two lines parallel to each other.

- In a spiral shape, around the water pipe.

Not every system is designed so that pressure increases without problems. But this method of protection can boast of effectiveness.

When high pressure remains inside, the liquid does not freeze. Even if there is no physical thermal insulation.

When installing external non-pressure types of sewerage, the so-called socket connection is used. The main thing is that there is no contamination on the plastic, then the connections will become highly sealed. Silicone or liquid soap is used to lubricate the parts that require connection.

Treatment with a sealant will provide additional protection during work such as laying water pipes from polypropylene pipes in the ground.

Only compliance with all requirements and technologies will allow you to obtain a water supply system that will function for a long time. And it will help reduce operating costs.

We are installing filters

If there is no scale or sand in the water, then elements such as fittings on toilet tanks, automatic washing machines, and ceramic faucets will last much longer.

It is enough to install the simplest filters, with rough cleaning. Without water purification filters, it is not advisable to lay polypropylene pipes yourself.

You should not give preference to filters that are disassembled manually. Inside such structures there are rubber seals, whose durability leaves much to be desired.

The preparation process depends on what type of pipes you have chosen. If it is galvanized, then we use a grinder to cut blanks of the sizes we need with our own hands. This can also be done using a hacksaw.

It is more convenient to cut metal-plastic or polypropylene products right on the spot. Even small errors in size will not be terrible.

When connecting, preference is given to two methods. For example, through a collector, which plays the role of wiring for individual devices, when each of them has its own fittings. Or through a simple tee.

We work with steel products

If you have the appropriate tools at hand, for example, such as welding, it is used to connect a metal structure.

It is easy to use to weld threads. Or bends that were bent on a special machine, the so-called pipe bender.

You can use dies or holders and do the work manually. Threaded connections are made in the same way as in the case of valves.

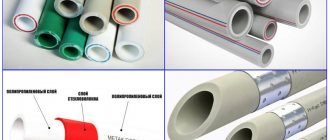

About metal-plastic pipes

In this case, the connection is made using fittings, which are equipped with union nuts. After cutting off the pipe section, proceed to chamfering from the inside using a knife. The union nut is put on the pipe along with a split ring.

We place the fitting from the fitting inside the pipe. The main thing is to act carefully, otherwise the rings with sealing characteristics will move. The nut is tightened just as carefully, without sudden movements.

Products with a polypropylene base

To get the job done, it will be enough to purchase an inexpensive soldering iron. We apply heat to the inner fitting surface by selecting the desired nozzle.

We do the same with the end where the polypropylene pipe is located. We insert one part into another, wait until everything cools down.

Stainless steel and copper

A serious problem with metal can be the appearance of corrosion on the surface during prolonged use without waterproofing. That is why they began to produce versions made of copper and stainless steel. They are reliable and durable, and can be used for supplying cold and warm water, as well as draining wastewater. They are often chosen by people who do not want to save money on water supply or drainage work.

Despite a fairly large number of advantages, the pipes in question are used extremely rarely today. This is due to the following points:

- There is a high probability of deposits and plaque appearing on the walls.

- When carrying out installation work, welding work is required.

- High cost, especially copper options.

- Heavy weight, which makes it difficult to carry out delivery and installation work.

- High requirements for insulation to eliminate the possibility of water crystallization when the soil freezes, which leads to a breakthrough of the system due to expansion of the liquid.

For a summer cottage, it is recommended to use such pipes only with careful insulation of the main line. The cost of insulation, the complexity of the work carried out, the cost of the materials used determine that a system of stainless and copper pipes is a very expensive investment.

Is it possible to use polypropylene pipes for gas?

In Western countries, metal pipes are used only for the assembly of industrial pipelines. In the manufacture of water and gas supply systems, plastic elements are used. This is due to the performance characteristics of the material. Gas flows through a plastic pipe without any difficulty. Before putting the gas pipeline into operation, it is necessary to check the tightness of the connections of individual elements in order to prevent violation of the integrity of the system.

You can figure out which is better – a pipeline made of metal or plastic – by comparing these two materials. Differences:

- Weight - plastic pipes weigh less than metal parts. Thanks to this, they are easier to install; they do not require additional fastenings on vertical surfaces.

- Versatility - There are more factors to consider when choosing metal pipes than when using plastic parts.

- Price - tubes made from polymers are cheaper than metal ones.

Metal tubes are superior to plastic ones in terms of strength, durability, and resistance to mechanical stress.

Advantages of using polypropylene pipes

Polypropylene pipes are optimal for laying sewer systems for summer cottages, supplying water for domestic needs, watering gardens, and greenhouses.

The use of polypropylene pipes today is justified in many areas, from water supply to sewerage. Among the advantages of using such pipes are:

- resistance to corrosion and various mechanical influences;

- ease of installation (trench method), which does not take much time;

- the possibility of using polypropylene pipes for supplying drinking water;

- reliability and strength.

Such pipes are optimal for laying sewer systems for summer cottages, supplying water for domestic needs, watering gardens, and greenhouses. In this case, all work is completed quickly, and the pipes themselves do not require complex and expensive maintenance.

Characteristics

The technical characteristics of the material determine the scope of its application. When making a gas pipeline, you can use different types of plastic pipes. Each of them has its own technical characteristics.

Metal-plastic parameters:

- High chemical resistance.

- The material is not subject to oxidation.

- The maximum coolant temperature is up to 95 degrees.

- The maximum permissible pressure is up to 25 bar. If the temperature is high, the permissible pressure is reduced to 10 bar.

- The thickness of the metal layer between the plastic is up to 0.3 mm.

Characteristics of polyethylene:

- outer diameter of tubes - 10–110 mm;

- maximum coolant temperature - up to 95 degrees;

- at high temperatures the maximum pressure is up to 10 bar.

Polypropylene parameters:

- maximum coolant temperature - 90 degrees;

- permissible pressure at maximum temperature - up to 10 bar.

Polypropylene pipes can withstand short-term overheating up to 110 degrees.

Diameter of plastic pipes