The building material of the 21st century is a type of lightweight concrete - expanded clay concrete. Lightweight and durable expanded clay concrete blocks are used in the construction of external and internal walls of low-rise civil and industrial buildings and structures. Energy-saving technologies are combined with the characteristics of expanded clay concrete, which perfectly retains heat, allowing you to save on home heating.

Types of expanded clay blocks

Clay for the production of expanded clay is a material of natural origin, and blocks that also contain cement and sand (natural materials) are absolutely environmentally friendly; a house built from such blocks has a favorable microclimate, heat is retained in winter, and the walls do not warm up in summer from exposure to sunlight.

Composition, classification and production of expanded clay concrete

Building blocks are the result of mixing sand, expanded clay and cement in strict proportions. These building materials, after being diluted with water, are poured into molds and pressed using a vibration press. For some types of structures, plasticizers are added to the solution. Expanded clay concrete can be used not only in the construction of walls, partitions or other structural elements - it is often used as insulation and sound insulator.

Heat transfer indicators

[ads-pc-1] [ads-mob-2]

Expanded clay as a component of the solution is obtained by firing clay at high temperatures, and the result is oval, porous, durable granules. In addition to granules, expanded clay gravel is produced, which has an angular shape. All components of expanded clay blocks are of natural origin, so production is cheap, and the building material is light and warm.

Based on size, characteristics and composition, expanded clay blocks are divided into the following groups:

- Purpose: Structural type is the heaviest and most durable element. Used in the construction of free-standing building supports, overpasses and bridge structures. Specific gravity – 1400-1800 kg/m3;

- Structural and thermal insulation element - construction of single-row walls. Specific gravity – 600-1400 kg/m3;

- The thermal insulation type of blocks is used as insulation. This is the lightest type, containing the least amount of sand and Portland cement with a specific gravity of 350-600 kg/m3.

- For the construction of walls (marked with the letter “C”), as well as for external and internal masonry with varying degrees of load;

Solid elements are laid in places and structures with increased loads. Walls are usually built from hollow blocks so as not to add weight to the object. The reliability and strength of the structure does not suffer.

Wall products

[ads-pc-1] [ads-mob-2]

The most common block size is 190 x 188 x 390 mm. These figures are taken for a reason - the layer of cement-sand mortar is usually 10-15 mm, and the standard wall thickness of one brick is 200 mm. We add the thickness of the mortar layer to the thickness of the expanded clay block wall, and we get the same 200 mm. The thickness of the mortar between the bricks is taken into account when determining the dimensions of any large blocks. The most unpopular size is 230 x 188 x 390 mm, since few factories produce products with such unpopular dimensions. The element length of 390 mm is selected by manufacturers based on compliance with the masonry dimensions of one and a half times the size of a regular brick plus mortar. This type of masonry is usually used for basements and plinths.

- The construction term “block-thick wall” means that the wall thickness is 390 mm, and the expanded clay block is laid across. With such masonry, the strength of the structure increases noticeably;

- The term “half-block thick wall” means a wall thickness of 190 mm, with blocks laid longitudinally.

The importance of making the right choice

Choosing the appropriate sizes of expanded clay concrete can be compared to choosing shoes. Nobody buys shoes at random just because they are beautiful or leather. Firstly, choose shoes that are appropriate for the season. And secondly, it is taken according to the size of the person.

The situation is exactly the same with expanded clay concrete. Products must be selected depending on their purpose . There are wall, partition and ventilation elements, each of which has its own parameters.

Wall blocks are designed for load-bearing walls, which is why they are wider. Partition elements are thinner, and they are also inferior in strength to wall elements. Ventilation products are laid in places where future communications will be constructed and have different types of voids.

Depending on the size, the performance properties of the material also change.

Knowing the dimensions of expanded clay concrete, you can:

- Calculate material consumption.

- Calculate the optimal thickness of the walls of the future building.

- Select a suitable foundation for the given block sizes.

- Calculate the layout of the products.

- Decide on the amount of time and people that will be needed for the work. Laying 1 expanded clay concrete is approximately equal to laying 7 bricks.

- Calculate the location of construction nodes and communication networks.

- Ensure thermal insulation of the building and its safe operation.

- Find out the usable area in the finished building.

It is easier to work with standard blocks because they are lighter in weight and special equipment is not needed to unload, lay and carry them. However, the larger the size of the product, the faster the building can be erected and the less mortar will be required for their laying, and this significantly reduces heat loss through the seams.

Dimensions of expanded clay concrete blocks and semi-blocks for internal construction

For internal partitions and walls, the expanded clay concrete block has the following dimensions: 90 x 188 x 390 mm and 120 x 188 x 390 mm. Partitions in a house or apartment are non-load-bearing walls between rooms that do not experience external loads other than their own weight. The partitions are made 90 mm thick.

The elements used for the construction of internal partitions are called semi-blocks - based on the thickness of the element, which together with the mortar layer is equal to 1/2 the thickness of a standard block. Semi-blocks are produced both in front and in rows. The main difference between them is the range of shades and smooth front surface, while the strength of expanded clay brick remains the same.

[ads-pc-1] [ads-mob-3]

According to technical characteristics, expanded clay blocks are manufactured in accordance with GOST 6133-99. These regulatory documents define the characteristics and properties of the material, following which the quality of production is controlled, grades are established, the properties of raw materials for production are designated, and the conditions for transportation and storage of finished building materials are regulated. The table indicates the sizes of blocks and half-blocks for various uses in construction:

| Type | Length, cm | Width, cm | Height, cm |

| Expanded clay concrete wall product | 28,8 | 28,8 | 13,8 |

| 28,8 | 13,8 | 13,8 | |

| 39 | 19 | 18,8 | |

| 28,8-29 | 19 | 18,8 | |

| 19 | 19 | 18,8 | |

| 9 | 19 | 18,8 | |

| Partition product | 59 | 9 | 18,8 |

| 39 | 18,8 | ||

| 19 | 90 | 18,8 |

[ads-pc-1] [ads-mob-2]

The table regulates the permissible deviations from the standard sizes indicated in the table above:

| Options | Value, cm |

| Length, width/height of blocks | ±0.3mm/±0.4 |

| Thickness of partitions and walls | ± 0,3 |

| Deviation of an edge from a straight line and faces from a plane | ≤ 0,3 |

| Deviation of faces from perpendicular | ≤ 0,2 |

What factors can influence size deviation

Even in the conditions of a well-functioning production process, it is possible that the dimensions of the finished product may deviate from the dimensions prescribed by regulatory documentation. Typical factors influencing the occurrence of marriage are:

1. Physical wear of the walls of the matrix, trays, and pressing equipment. Fresh expanded clay concrete mixture has high abrasive properties. Even high-quality steel, when in contact with it, can wear out by 3-4 mm in 1-2 years, which invariably affects the increase in the dimensions of the finished product. The use of plywood leads to an even faster disruption of the geometry of the forms. Sometimes, under the regular influence of a hydraulic press, the vibrating platform is pushed through.

Mold for expanded clay concrete blocks.

2. Unjustified interference with the design structure of the matrix. Some manufacturers, in an effort to make their products lighter, increase the thickness of the void formers. An increase in the proportion of voids, in addition to a violation of the geometry, also leads to a noticeable deterioration in the strength characteristics of such blocks.

Mold for hollow expanded clay concrete blocks.

Dimensions of expanded clay concrete blocks

| Purpose | Size, cm |

| Wall masonry | 39 x 19 x 18.8 28.8 x 28.8 x 13.8 28.8 x 13.8 x 13.8 29 x 19 x 18.8 19 x 19 x 18.8 9 x 19 x 18.8 |

| Construction of partitions | 59 x 90 x 18.8 39 x 90 x 18.8 19 x 90 x 18.8 |

Knowing the standard sizes of blocks, you can calculate their number and volume of solution without involving designers. For expanded clay concrete blocks, the dimensions will be the same as for concrete, foam concrete and aerated concrete products. But the standard dimensions can be changed by ordering your original size and shape of the product from the manufacturer. The shape can be taken as a parallelepiped with flat ends, a parallelepiped with a tongue-and-groove system, a polyhedron, a semicircle, etc. In this case, the seller informs in the accompanying documentation that the products are manufactured in accordance with the specifications and have individual sizes that differ from the standards.

[ads-pc-1] [ads-mob-3]

Sizes of half blocks

[ads-pc-1] [ads-mob-3]

Technical and operational characteristics

- The area of use of expanded clay blocks is determined by the strength they have:

Type Strength value Thermal insulation element 0.05-0.35 t/cm2 Structural and thermal insulation block 0.35-0.1 t/cm2 Constructive 0.1-0.5 t/cm2 - Volumetric mass (volumetric weight) of the building element:

Type Meaning Thermal insulation element 0.35-0.6 kg/cm3 Structural and thermal insulation block 0.6-1.4 kg/cm3 Constructive 1.4-1.8 kg/cm3 - Standard thermal conductivity indicators are 0.14-0.65 W/(m/K). The coefficient depends on the volume of cement and sand in the solution. Hollow bricks have the highest thermal conductivity values;

- Resistance to low temperatures (frost resistance) depends on density and mass - the more an element weighs, the denser it is (there is less air in it), and the greater the number of freezing and thawing cycles it can withstand;

Type Cycles Thermal insulation element 15-50 Structural and thermal insulation block 150 Constructive 500 - Water resistance is set to 10% for standard sizes of expanded clay blocks. To increase this figure, plasticizers and improvers are added to the mixture;

- The greater the porosity of the material, the higher the vapor permeability coefficient. For standard elements it lies in the range of 0.3-0.9 mg/(m/h/Pa);

- Sound insulation properties depend on the degree of porosity and vapor permeability coefficients. The 90 mm thick internal partition blocks sounds up to 50 dB;

- Fire resistance. Expanded clay concrete can easily withstand three-hour exposure to temperatures of 10500C;

- Shrinkage - 0.25-0.55 mm/m;

- The blocks can be used to build multi-storey buildings - up to 12 floors in height.

GOST requirements

All construction work using porous lightweight concrete must be carried out in strict accordance with special requirements.

Main recommendations on GOSTs and SNiPs:

- The maximum height of the wall is determined only by calculation.

- The height and number of floors of buildings are strictly limited: buildings up to 5 floors and no more than 20 meters in height can be erected from autoclaved aerated concrete. If the buildings are nine-story, then the self-supporting walls should not be higher than 30 meters. Foam blocks are used to construct a building of three floors, subject to a maximum height of 10 meters.

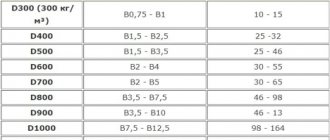

- It is important to observe strength indicators taking into account the floors: blocks of class B3.5 are used for 5-story buildings; blocks of classes B2 and B2.5 are suitable for 2-3-story buildings, respectively.

- For self-supporting walls, strength blocks of class B2-2.5 are used.

Application area

[ads-pc-1] [ads-mob-3]

This material is universal - its strength and thermal conductivity allow it to be used for the construction of objects for any purpose. For example, the foundation can be laid out from massive reinforced elements that can withstand heavy loads. The walls are built from special blocks designed to create an insulating layer, and their use is due only to the difference in the composition of the solution and the complexity of the design: load-bearing and supporting expanded clay bricks have increased mass and increased density, and insulating elements are characterized by increased porosity and low weight.

Parameters of expanded clay brick

Is it necessary to insulate aerated concrete walls?

, the idea that the walls of any house should be “insulated” has become widespread

That is, first build the walls, and then, additionally, supplement them with something else for “thermal insulation.”

The idea of the need for maximum “additional insulation” of walls is wrong. In order to save energy, it is often easier and cheaper to insulate other structures “to the maximum” - insulating walls is a very expensive undertaking . In addition, only 20-30% of the heat in the house is lost through the walls.

The successful combination of properties of aerated concrete - sufficient strength and low thermal conductivity, as well as reasonable cost, make it the best material for constructing a single-layer, uniform in thickness, durable and environmentally friendly stone wall.

Using aerated concrete as a structural material in two-layer walls with insulation is, as a rule, not profitable.

For double-layer walls with insulation, you can select structural materials and insulation materials with better technical and economic indicators than aerated concrete.

Advantages

- Standardization of sizes and other indicators allows blocks to be laid using the simplest technology, and the porosity of the material ensures good diffusion of the solution into the body of the element.

- Structures made of hollow blocks can be reinforced with reinforcement. To do this, reinforcement (rods, rods, metal corners) is inserted into the holes in the body of the product, taking on the properties of a reinforcing frame.

- Sufficiently large dimensions of the products allow you to save on mortar and reduce labor costs during the construction of objects of any complexity and number of floors.

- Low weight determines the type of foundation that can be made lightweight and therefore inexpensive.

- An opportunity to save money without additional insulation.

- “Breathing” walls allow you to maintain an optimal indoor climate without condensation.

- Expanded clay concrete surface can be finished with different building materials, and its structure will ensure reliable adhesion of the layers.

- Solid stones can withstand various hanging objects (cabinets, shelves, appliances).

- Minimal shrinkage will practically not affect the finish and integrity of the structures.

Block characteristics

[ads-pc-1] [ads-mob-3]

Builder reviews

How thick should the walls be?

Aerated concrete is considered an effective material for heat preservation, and is explained by its cellular structure.

To accurately determine what thickness of aerated block to choose, you must follow the following useful recommendations:

- In construction work, a special masonry mortar is used, which is applied to the block surface in a thin layer. This especially applies to people who constantly work with cement mortars. Thick seams will begin to let in cold, which will negatively affect the thermal insulation characteristics of the block;

- if construction is carried out in areas with cold climatic conditions, then the aerated concrete wall is insulated on both sides;

- strength calculations must take into account the additional mass created by thermal insulation materials.

In addition to official calculations, builders determine additional factors that help determine the thickness:

- Duration of use at home. If the option is a country house, then the thickness of the walls can be twenty centimeters. They will be able to withstand the weight of the roofing and protect from spring and autumn coolness. If you plan to stay all year, the thickness indicator doubles.

- Load-bearing walls should be ten to fifteen centimeters greater than the thickness of the internal walls made of aerated concrete.

- When increasing the height of the object, more durable gas blocks are used. If the object is one-story, then the wall can be from 25 cm, and in the case of multi-story construction this value reaches 300 - 400 mm.

- The duration of the cold season and the average daily temperature directly affect the strength of the walls. For Siberian regions this value is always higher.

- If you plan to use insulating materials, the thickness of the blocks can be reduced.

Flaws

- Compared to heavy concrete, expanded clay is less durable, therefore its use for foundations is possible only with low-rise construction and careful calculations.

- When constructing high-rise buildings, high-density blocks are required, which increases the load on the foundation and requires a more powerful structure, which can increase the cost of the project.

- It happens that expanded clay blocks have non-ideal dimensions due to their structure, so you have to be especially careful when laying them. But if deviations are within the limits allowed by GOST, no problems arise.