Heating » Premises » Apartment

Published December 14, 2014 at 1:58 am

As is known, the provision of heat to a significant portion of the housing stock is carried out centrally. And, despite the fact that in recent years more modern heat supply schemes have appeared and are being implemented, central heating remains in demand, if not among owners, then among developers of multi-apartment housing. However, it should be noted that many years of foreign and domestic experience in using this heating option have proven its effectiveness and right to exist in the future, subject to trouble-free and high-quality operation of all elements.

A distinctive feature of this scheme is the generation of heat outside the heated buildings, the delivery of which from the heat source is carried out through pipelines. In other words, centralized heating is a complex engineering system distributed over a large area, providing heat to a large number of objects at the same time.

Theoretical horseshoeing - how gravity flow works

The natural circulation of water in heating systems operates due to gravity. How does this happen:

- Take an open vessel, fill it with water and start heating it. The most primitive option is a saucepan on a gas stove.

- The temperature of the lower layer of liquid increases, the density decreases. The water becomes lighter.

- Under the influence of gravity, the upper heavier layer sinks to the bottom, displacing less dense hot water. Natural circulation of liquid begins, called convection.

Reference. The dependence of water density on temperature is not linear. The more the liquid heats up, the faster its density decreases, which is clearly visible on the graph.

Example: if you heat 1 m³ of water from 50 to 70 degrees, it will become 10.26 kg lighter (see below for a table of densities at different temperatures). If we continue heating to 90 °C, then the cube of liquid will already lose 12.47 kg, although the temperature delta remains the same - 20 °C. Conclusion: the closer the water is to the boiling point, the more active the circulation occurs.

In a similar way, the coolant circulates by gravity through the home heating network. The water heated by the boiler loses weight and is pushed upward by the cooled coolant returning from the radiators. The flow speed at a temperature difference of 20–25 °C is only 0.1…0.25 m/s versus 0.7…1 m/s in modern pumping systems.

Low speed of fluid movement through pipelines and heating devices causes the following consequences:

- The batteries have time to give off more heat, and the coolant has time to cool by 20–30 °C. In a conventional heating network with a pump and a membrane expansion tank, the temperature drops by 10–15 degrees.

- Accordingly, the boiler must produce more thermal energy after the burner starts. It is pointless to keep the generator at a temperature of 40 °C - the flow will slow down to the limit, the batteries will become cold.

- To deliver the required amount of heat to the radiators, it is necessary to increase the flow area of the pipes.

- Fittings and fittings with high hydraulic resistance can worsen or even stop gravity flow. This includes check valves, three-way valves, sharp 90° turns and pipe reductions.

- The roughness of the internal walls of pipelines does not play a big role (within reasonable limits). Low fluid speed means low frictional resistance.

- A solid fuel boiler + gravity heating system can safely operate without a heat accumulator and a mixing unit. Due to the slow flow of water, condensation does not form in the firebox.

As you can see, there are positive and negative aspects in the convection movement of the coolant. The former should be used, the latter should be minimized.

Design features

For a gravity system to work effectively, the following requirements must be met:

- the heat source is any non-volatile heat generator with outlet pipes with a diameter of 40-50 mm;

- at the outlet of a boiler or stove with a water circuit, an accelerating riser is immediately installed - a vertical pipe through which the heated coolant rises;

- the riser ends with an open-type expansion tank installed in the attic or under the ceiling of the upper floor (depending on the type of wiring and the design of the private house);

- tank capacity – 10% of the coolant volume;

- by gravity, it is advisable to choose heating devices with large internal channels - cast iron, aluminum, bimetallic;

- for better heat transfer, heating radiators are connected according to a versatile pattern - bottom or diagonal;

- special full-bore valves with thermal heads (supply) and balancing valves (return) are installed on the radiator connections;

- It is better to equip batteries with manual air vents - Mayevsky taps;

- replenishment of the heating network is organized at the lowest point - near the boiler;

- all horizontal sections of pipes are laid with slopes, the minimum is 2 mm per linear meter, the average is 5 mm/1 m.

On the left in the photo is the coolant supply riser from a floor-standing boiler with a pump on the bypass, on the right is the return line connection

Note. Slopes perform 2 functions - they help the coolant flow in the desired direction, and the air rises through the pipelines and leaves through the open expansion tank. A caveat regarding the radiators used: if the system is built correctly, steel panels also heat well.

Gravity heating systems are made open and operated at atmospheric pressure. But will gravity flow work in a closed circuit with a membrane tank? We answer: yes, natural circulation will continue, but the speed of the coolant will decrease and efficiency will drop.

It is not difficult to substantiate the answer; it is enough to mention the change in the physical properties of liquids under excess pressure. With a pressure in the system of 1.5 Bar, the boiling point of water will shift to 110 °C, and its density will also increase. The circulation will slow down due to the small difference in the masses of the hot and cooled flow.

Simplified gravity flow diagrams with an open and membrane expansion tank

What should be the performance indicators?

In this case, the indicator is determined from several values. Due to the presence of a circulation pump and additional elements in the heating (for example, an expansion membrane tank), dynamic pressure , and static pressure determines the vertical (altitude) level of the liquid column. The summation of these two indicators gives the final operating pressure of a closed heating system.

The norm for this parameter is a value of 1.5-2 atmospheres for houses consisting of 1 or 2 floors. The increase in pressure indicator directly depends on the increase in the number of storeys.

The upper peak value sets the weakest node in the heating circuit. This is what a hot water boiler is. Its limit is 3 atmospheres.

In multi-storey buildings, radiators and pipelines that can withstand powerful water hammer are widely used. In such systems, the pressure varies in the range from 20 to 100 atmospheres.

The role of return and its difference from supply

Sometimes, when carrying out plumbing work on their own, the user does not know how to identify the supply and return pipes when the battery is connected. If you are completely unfamiliar with the design, you can use a thermometer, identifying the supply and return pipelines by the temperature difference, if you know the circuits for discharging coolant to the heating radiators, consider the following options:

- With diagonal and side switching, the supply is always at the top and the outlet at the bottom.

- In the lower connection, the direction of movement of the input and output flows is sometimes indicated by arrows on the supply unit (binoculars).

- In Leningradka, the return pipe is considered to be the one coming from the last radiator in the row.

- In the manifold distribution, the supply combs are equipped with adjustable supply sensors in the form of fittings with transparent caps and indicators placed inside; the shut-off valves of the return comb are closed with threaded plugs. Also, the color marking of the forward feed is red, and the return feed is blue.

Rice. 3 Organization of heating systems using an open expansion tank

The return line plays no less important role than the direct line for supplying media to heat exchange devices or heated floors, its purpose and installation methods:

In gravity flow structures with an open storage tank. The movement of water in open circuits occurs due to the difference in hydrostatic pressures of the cooled and hot water columns due to the fact that the hot liquid has a lower density.

It follows from this that the greater the temperature difference between the cold and hot water column, the more significant the difference between the supply and return in pressure and, accordingly, the force that pushes the heated flow upward.

Therefore, the return line is designed and installed taking into account the following rules:

- Heat loss in the return must be quite significant to minimize the cooling of the water, that is, the batteries must have significant heat transfer.

- As the distance from the bottom point of the radiators to the boiler inlet pipes increases, the length of the low-temperature column increases and, accordingly, it more effectively displaces the heated coolant. The high location of the boiler from the battery lengthens the section with a cooled return, while simultaneously shortening the section of the high-temperature column - as a result, a large temperature difference shifts the working fluid much further up the circuit and heating occurs more efficiently.

- The upper installation of the boiler is contradicted by the condition under which it must be at a height below the level of the last batteries in the chain for the gravity flow of the carrier into it at an angle. If the boiler is installed low in the basement, to ensure normal circulation during installation, slopes towards the heating unit should be observed (2 - 3 mm per linear meter).

It should be noted that both of the above schemes are working (the latter is used more often) and their choice is related to the convenience of installing boiler equipment in the house.

Rice. 4 Closed heating system - diagram

It may be useful to read about Connecting the boiler to the heating system

In closed circuits with an electric pump. In multi-circuit heating with heated floors, circular pumps are installed that create the required pressure in the main; in many cases, two circular pumps are used - one pumps water throughout the system, and the second supplies coolant to the floors or radiator heaters.

Pre-launch maintenance in autumn

Annual inspection and maintenance events are traditionally scheduled for late summer or early fall, when the heating system is preparing for the new heating season. But even in operating mode, you can always arrange a planned shutdown, since the entire range of maintenance work and proper startup does not take much time.

When performing repair work or inspecting the internal parts of the equipment, the water is drained, so before starting the entire system is filled with a new portion of coolant. The quality of water used to “prime” the system is of key importance, especially for systems with metal pipes or aluminum radiators. Water must be softened and cleared of solid particles; in systems with a displacement of more than 400–500 liters, it is recommended to first displace dissolved oxygen from the water.

After filling the system, if it has a closed expansion tank, the standard pressure for the cold state is injected, and air is removed using Mayevsky taps and bleed valves. It is important that before draining the water, the fittings in the piping of the circulation pump located above the return line are closed - this will prevent it from airing. When the system is completely filled with water, the circulation equipment is turned on, after which the heating unit is put into operation.

When the supply and return pipes heat up, you need to immediately make sure that there is circulation; at the first stage, it is better to set the pump to maximum speed. Next, all pipelines and radiators are bypassed, the degree of their heating is checked, and adjustments are made if necessary. If individual batteries have been drained, they are filled through the lower supply pipe, bleeding the air through the Mayevsky valve, and after complete filling, the upper valve is also opened, starting circulation.

It is important to remember that pouring fresh water is accompanied by gas formation inside the system, so at first - about a week after startup - you need to check the operating pressure and its drop during cooling, or the water level in the open expansion tank. Gases released from the water also have to be vented from the radiators.

Causes of poor circulation

The circulation of water in the system is disrupted due to complete or partial blockage in the riser or in the supply to the heating device, airing of the main line, freezing of the network, or errors in pipe laying. This also leads to deregulation of the central heating system and the appearance of coolant leaks.

Poor pump performance

The purpose of the pump is to maintain the required water pressure in the heating circuit. A well-functioning pump must meet the following requirements:

- A necessary indicator of work productivity;

- Pressure;

- Device pressure;

- Compliance with the type of liquid;

- Matching pipe diameter;

- Dimensions of the device in accordance with the length of the line.

Check valves

Often, for normal circulation in the network, pumps alone become insufficient, then check valves are installed.

In this case, each circuit can operate independently of the others. Even in a branched radiator system with several circuits, where there are several pumps, it is better to install check valves. There is no need to skimp on installing them. The absence of these mechanisms leads to the slowing down of water movement in the system. This happens in situations where a network with several circuits is laid. To ensure that warm water flows along the circuit where the pump operates, and its movement occurs in the desired direction, check valves are used. These elements are not always installed, but only in situations where there are no other technical solutions. This is explained by the fact that these elements create high hydraulic resistance, depending on the design. Therefore, the installation of these valves in systems with natural circulation has its limitations, and the reason for the restrictions is the low water pressure in the main.

The actuator in the product is a spring that closes the valve when the normal operating conditions of the heating network change. For systems with different operating parameters, products with appropriate elasticity and spring mass are selected. Valves are a very important element; they ensure trouble-free operation of the central heating system, increase the efficiency of all equipment and improve circulation.

Small diameter, overgrown pipes

Old steel pipes become overgrown with rust and deposits from the inside, their throughput capacity decreases significantly over time, and there is only one solution - they need to be replaced with modern ones.

But even during installation, for the sake of economy, mistakes can be made with the choice of pipeline diameter - on mains, on groups of heating devices, diameters of 16 or 20 mm can be installed. The result is noise in the pipes, excessive consumption of electricity, and insufficient coolant flow. What pipe diameters should you choose?

A complex system

A type of bad design is an incorrectly designed complex heating system consisting of many heating circuits and several boilers. Here entire circuits will not work correctly if the work of one affects the neighboring one.

As a rule, one boiler (the backup one does not count) and three circuits - boiler, radiators, heated floors with their pumps are coordinated normally, and no questions arise. But if you connect another working boiler plus a circuit (for example, heating a garage and greenhouse), then the system will become complex. It is difficult to say how the coolant will circulate in it without equalizing the pressures at the connection points.

In complex systems, a competent design is important, installing a hydraulic arrow or an equal pressure ring; more information about the hydraulic separator can be found here

No balancing

Many home heating schemes involve balancing; balancing and control valves are installed in them. For example, between floors, between shoulders, and for each radiator. The taps cover the direction with less hydraulic resistance; accordingly, more coolant will flow to other points.

Children can play with the taps. Or the system is initially unbalanced. Setting up, as a rule, is no problem, you just need to find this tap... How to set up home heating

Neighbors don't provide heat

But complex heating project schemes are of little concern to residents of high-rise buildings, who have a separate riser for each radiator in the apartment. And if any radiator stops heating up normally, it means there is no circulation through the riser, therefore...

You need to contact the heating network, housing office (service organization) to adjust the power in the risers, and if this does not help, then with the requirement to check the neighbors.

Often, unauthorized connection or replacement of radiators and pipes in central heating systems leads to a redistribution of pressure, circulation through individual batteries decreases and disappears.

No circulation in gravity system

In gravity systems, the pressure difference is low; they are especially sensitive to air pockets, pipe diameters, and gaps in radiators.

In old circuits, gradual deposits occur in radiators and pipes; circulation may decrease over time, and the only cure for this is replacing everything with a more modern one.

You also need to pay attention to the correctness of the circuit itself - the middle heating line is below the cooling line (the boiler heat exchanger is below the radiators), and also - the hot feed rises up to the highest point, and from there it drops to the radiators... Read more about gravity flow circuits below

Various breakdowns in heating systems

- The taps and valves are closed - check that everything is open to ensure circulation.

- There is a leak in the system - there is not enough coolant, check the pressure, eliminate the leak.

- Installation with flexible pipes - the pipe is pinched.

- Failure of automatic equipment - thermal heads on mixing units, radiators, the mixing units themselves - silting, failure, it is necessary to check the correct operation. Also – electronic failure.

- Incorrect balancing on the distribution collector - in beam circuits, complex systems, collectors with balancing and tuning equipment can cause a lack of circulation anywhere due to breakdowns and incorrect settings.

- Low pressure, no air in the expansion tank - check the pressure in the pipes and the pumping of the tank; automated units will not work at all without the required pressure.

- Violation of the circuit, excess bypass - check that the installation complies with the design, the logic of the circuit, whether there are any short circuits in the jet, parallel branches to radiators and circuits.

System clogged

As already noted, if there is no water circulation in the riser and heating system, then the problem may be due to debris accumulated in the system. A coarse filter will help get rid of it.

Dirt that gets into the pipes is easier to remove by catching it in the filter. First of all, such a filter protects the pump. It is also recommended to install a filter at the boiler inlet.

Such a water filter should be placed in front of each plumbing fixture. When installing the device, you must pay attention to the filter housing.

There is an arrow on it that indicates which side to install the filter depending on the direction of movement of the coolant.

Temperature standards

It is quite difficult to regulate heating in a residential apartment building. Even if residents have access to the system and the ability to increase/decrease the heat supply, it is not always possible to find a common language with their neighbors. In this case, it is worth focusing on the current regulations.

Temperature standards are regulated in accordance with GOST R 51617-2000, approved. . According to this document, the minimum temperature in apartments during the heating season should be:

- in living rooms, toilets, and kitchens - at least 18˚С;

- in the bathroom - not lower than 25˚С;

- in corner rooms, regardless of purpose, as well as for families where disabled people live - 2˚C above the established norm.

If the readings in your apartment are lower, you can safely demand an increase in temperature.

Read more about what temperature standards are set in the apartment.

How to eliminate uneven heat transfer

Not all problems can be solved on your own. Poor heat transfer from the radiator may be a consequence of non-compliance with the slopes, indicating gross violations in the installation of the heating system. In this case, you will have to invite a specialist in heating systems.

Some heating problems can be fixed on your own.

- Air locks - air in the heating system is an inevitable consequence of filling pipes and radiators with coolant. A characteristic sign of the problem is that the radiator is warm at the bottom and cold at the top. If the section heats up unevenly, you can try to bleed air from the system using the Mayevsky valve. Some owners initially install an automatic air release valve.

Checks performed on heating systems in a private home

The easiest to maintain is the open system. Preventive measures when checking it are limited only to monitoring the level of water in the expansion tank. If the system is closed, there is a need for additional checks.

Place of expansion tank in water heating system

Closed water heating system: features of preventive measures and inspections

If water heating in a private house is of a closed type, then the quality of its operation can be ensured only if a greater number of actions and operations are performed. The sequence of actions may be as follows:

- First, the pressure in the expansion tank is checked, for which a pressure gauge mounted on the pipeline is used. The ideal pressure level is 1-1.5 Bar. If the level is lower, the volume of water in the tank should be increased and the probable cause of its leak determined (all connections are checked);

The pressure in the heating system should be about 1-1.5 Bar

- then air is removed from the system, for which all radiator taps are opened in turn. If water starts flowing from the taps, we can conclude that there is no more air in the system;

There is no air in the heating system if water starts flowing from the tap

- Next, the expansion tanks are checked by connecting a pump with a pressure gauge to the radiator valves. Low pressure requires pumping air into the tanks.

Checking the circulation pump of the water heating system

If water heating in a private house includes a circulation pump, it is necessary to ensure its serviceability and efficiency. The operation of the pump should be silent and there should be no excessive resistance during its operation. If there is any deviation, you should invite a specialist to determine the cause and solve the problem.

The circulation pump installed in the heating system should operate almost silently

The filter located in front of the pump may become clogged if it gets into it with wood chips, sawdust or other debris that may have been in the pipes before they were installed. The filter is cleaned after turning off the water. To do this, the filter is removed and washed under running water.

The filter at the inlet of the circulation pump must be cleaned regularly

By performing these simple and fairly few operations, you can ensure trouble-free operation of the water heating system and the necessary comfort in your home.

Heating systems with natural circulation

The natural circulation heating system became widespread in the pre-war period due to its efficiency, simplicity and reliability. Most often, this type of heating system is used in dachas, as well as in country houses due to frequent power outages at such facilities. Such systems are conventionally divided into two types - with bottom and top water supply. To determine the choice of the type of heating system, it is necessary to consider their differences, characteristics and scope of application.

Heating systems with top water supply

The coolant - in this case water - is heated and supplied to the upper part of the heating system through a pipeline. The pipe used to supply water must have a larger diameter compared to the pipes that are responsible for supplying water to the radiator. This is necessary to achieve the greatest resistance to heat exchange. Horizontal pipes must be installed with a minimum slope of one centimeter per adjusted meter.

The expansion tank must be installed at the top of the system: it will perform the function of receiving steam and excess heat - this is necessary due to the property of water to expand when heated and turn into steam. The tank must have a drain valve and a cap or valve at the top. After the water is heated, it is distributed through the supply pipe to the vertical risers and into the radiators.

Tip: if you are going to use a heating system with natural circulation of water, remember that radiators must be connected using a diagonal method

After direct heating of the room, the water passes into the boiler through a specialized pipe - the return. Here it is heated again and the cycle of water movement is repeated. The heating boiler is located in the lowest part of the system, under the radiators. Typically, these elements are installed in boiler rooms, for which basements are allocated.

What it is

If a system with forced circulation requires a pressure difference created by a circulation pump or provided by a connection to the heating main, then the picture is different. Natural circulation heating uses a simple physical effect - the expansion of a liquid when heated.

If we ignore the technical details, the principle of operation is as follows:

- The boiler heats a certain volume of water. So, of course, it expands and, due to its lower density, is forced upward by a colder mass of coolant.

- Having risen to the top point of the heating system, the water, gradually cooling, describes a circle by gravity through the heating system and returns to the boiler. At the same time, it gives off heat to the heating devices and by the time it reaches the heat exchanger again, it has a higher density than at the beginning. Then the cycle repeats.

Useful: of course, nothing prevents you from including a circulation pump in the circuit. In normal mode, it will provide faster circulation of water and uniform heating, and in the absence of electricity, the heating system will operate with natural circulation.

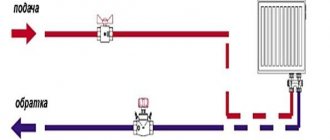

Pump operation in a natural circulation system.

The photo shows how the problem of interaction between the pump and the natural circulation system was solved. When the pump is running, the check valve is activated, and all the water flows through the pump. Once you turn it off, the valve opens and water circulates through the thicker pipe due to thermal expansion.

Heating systems with bottom water supply

A system in which coolant is supplied from below is usually used for heating houses where there is no attic space or access to it is closed. The main difference of the presented heating system is that the pipes are laid under the radiators. There is also an expansion tank, which is installed in the upper level of the system; Usually utility rooms are used for this purpose. If there is no water circulation in the heating system, which should occur naturally, then it is created by force.

Preventive measures

We figured out why air appears in the heating system and how to deal with this negative fact. It remains to be seen whether there are preventive measures that help avoid such problems. It turns out yes:

- when installing a heating system, it is necessary to provide for the installation of special devices that automatically remove air;

- Before adding water to the heating system, you should bleed the air;

- During operation, you should monitor the operation of the entire system by observing the readings of pressure gauges and from time to time monitoring the pressure in the pipes. In addition, it is recommended to monitor the level of coolant in the expansion tank, conduct a visual inspection of pipes and radiators, and check the uniformity of heat distribution along the circuit;

- The system should be periodically pumped to remove all blockages.

The implementation of this set of measures will extend the operational period of the entire heating network.

Heating systems with forced circulation

A standard forced circulation heating system operates using the same connection methods. The difference is that due to the large extent of this system or the lack of natural conditions to create an inclination of the pipes, it is necessary to include a pump in the system. The circulation pump is mounted to the main pipe - this helps to increase the service life of the heating system. Using a pump helps not only increase heating efficiency, but also reduce the number of lines. A forced circulation system has the ability to heat not just several rooms, but even a house with several floors.

In order to produce high-quality operation of this type of system, a continuous power supply is required. Installation of a circulation pump in the heating system is required in order to create forced circulation of water in a closed loop. In this type of system, the pump is the central component among the equipment. It should be noted that the circulation pump may not have significant performance: its power is only needed to direct the liquid into the supply pipe. The same pressure pushes the water in the opposite direction, since the system is closed.

The circulation pump is necessary to ensure uninterrupted operation of the heating system, therefore it must fully comply with the system into which it is installed. Due to its functionality, this type of pump can be widely used in a wide variety of pipelines.

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline. To completely avoid this, again, we don’t save on pennies, but install a coarse filter in front of each device:

Using a filter, catching dirt is easier than correcting the consequences of clogged pipelines or boiler heat exchangers.

Conclusion! We place coarse filters in front of each heating system device (pump, boiler, etc.) and in front of each plumbing fixture. We do NOT save pennies to “buy” problems. There are arrows stamped on the filter housing indicating the direction of movement of the coolant or water in the water supply...

Selecting a circulation pump for a heating system

In order to select a circulation pump for the heating system, it is necessary to make the appropriate calculations. Please note that within an hour, this element will drive three times more water than its total volume in the system. Thus, the total volume of a suitable amount of liquid is on average 10 liters per 1 kilowatt of heating boiler power. The required pump model for the heating system and its power are determined by pressure and flow parameters. The pressure must be equal to the hydraulic resistance of the heating system.

Do-it-yourself installation recommendations

To lay the main natural circulation lines, it is better to use polypropylene or steel pipes. The reason is the large diameter, polyethylene Ø40 mm and more is too expensive. We make radiator hoses from any convenient material.

Advice. When assembling a gravity heating network made of metal-plastic, do not install compression fittings - they greatly reduce the internal passage.

An example of installing a two-pipe wiring in a garage.

How to make the wiring correctly and withstand all slopes:

- Start with markings. Mark the locations for installing batteries, connection points for connections, and routes for highways.

- Mark the routes on the walls with a pencil, starting from the distant batteries. Adjust the amount of inclination using a long building level.

- Move from the outer radiators to the boiler room. When you draw all the routes, you will understand at what level to install the heat generator. The inlet pipe of the unit (for cooled coolant) must be located at the same level or below the return line.

- If the firebox floor level is too high, try moving all the heaters up. Horizontal pipelines will rise next. As a last resort, make a recess under the boiler.

Laying a return line in a furnace room with a parallel connection to two boilers.

After marking, punch holes in the partitions and cut grooves for a hidden gasket. Then check the routes again, make adjustments and proceed with installation. Follow the same order: first secure the batteries, then lay the pipes towards the combustion chamber. Install an expansion tank with a drain pipe.

The gravity pipeline network is filled without problems; Mayevsky’s taps do not need to be touched. Just slowly pump water through the fill valve at the lowest point, all the air will go into the open tank. If any radiator remains cold after warming up, use a manual air vent.

Is assembly required

If the radiators are supplied assembled, it is enough to install plugs and a Mayevsky tap. Most models have four holes located at the four corners of the body. They are used to connect heating lines. In this case, any scheme can be implemented.

Before installation of the system begins, it is necessary to close excess holes using special plugs or air vent valves. The batteries are supplied with adapters that must be screwed into the collectors of the product. In the future, various communications should be connected to these adapters.

Prefabricated models

Assembling batteries should begin by laying the entire product or its sections on a flat surface. Best on the floor. Before this stage, it is worth deciding how many sections will be installed. There are standards that allow you to determine the optimal amount.

The sections are connected using nipples having two external threads: right and left, as well as a turnkey lug. The nipples should be screwed into two blocks: at the top and at the bottom.

When assembling the radiator, be sure to use the gaskets supplied with the product.

It is necessary to ensure that the upper edges of the sections are correctly located - in the same plane. The tolerance is 3 mm.

Single-pipe and two-pipe heating schemes

When developing a heating scheme for a house with natural water circulation, it is possible to design one or several separate circuits. They may differ significantly from each other. Regardless of the length, number of radiators and other parameters, they are made according to a single-pipe or two-pipe scheme.

Circuit using one line

A heating system using the same pipe for sequential supply of water to the radiators is called single-pipe. The simplest single-pipe option is heating with metal pipes without the use of radiators.

This is the cheapest and least problematic way to heat a house when choosing natural coolant circulation. The only significant disadvantage is the appearance of bulky pipes.

With the most economical version of a single-pipe scheme with heating radiators, hot water flows sequentially through each device. A minimum number of pipes and shut-off valves is required here.

As the coolant passes through, it cools down, so subsequent radiators receive colder water, which must be taken into account when calculating the number of sections.

A simple one-pipe circuit (above) requires a minimum amount of installation work and investment. The more complex and expensive option below allows you to turn off radiators without stopping the entire system

The most effective way to connect heating devices to a single-pipe network is considered to be the diagonal option.

According to this scheme of heating circuits with a natural circulation type, hot water enters the radiator from above, and after cooling it is discharged through the pipe located below. When passing in this way, heated water gives off the maximum amount of heat.

When both the inlet and outlet pipes are connected to the battery at the bottom, the heat transfer is significantly reduced, because the heated coolant has to travel the longest possible path. Due to significant cooling, batteries with a large number of sections are not used in such circuits.

“Leningradka” is characterized by impressive heat losses, which must be taken into account when calculating the system. Its advantage is that when using shut-off valves on the inlet and outlet pipes, devices can be selectively turned off for repairs without stopping the heating cycle (+)

Heating circuits with radiators connected in this way are called “Leningradka”. Despite the noted heat losses, they are preferred in the arrangement of residential heating systems, which is due to the more aesthetic appearance of the pipeline.

A significant disadvantage of single-pipe networks is the inability to turn off one of the heating sections without stopping the circulation of water throughout the entire circuit.

Therefore, they usually use a modernization of the classic scheme with the installation of a “bypass” to bypass the radiator using a branch with two ball valves or a three-way valve. This allows you to regulate the water supply to the radiator, even turning it off completely.

For two or more storey buildings, variants of a single-pipe scheme with vertical risers are used. In this case, the distribution of hot water is more uniform than with horizontal risers. In addition, vertical risers are shorter and fit better into the interior of the house.

A single-pipe scheme with vertical wiring is successfully used when heating two-story rooms using natural circulation. An option has been presented with the ability to disable the upper radiators

Option using a return pipe

When one pipe is used to supply hot water to radiators, and the second to drain cooled water to a boiler or furnace, this heating scheme is called a two-pipe heating system. In the presence of heating radiators, such a system is used more often than a single-pipe system.

It is more expensive, as it requires the installation of an additional pipe, but has a number of significant advantages:

- more uniform temperature distribution of the coolant supplied to the radiators;

- it is easier to calculate the dependence of radiator parameters on the area of the heated room and the required temperature values;

- more efficient regulation of heat supply to each radiator.

Depending on the direction of movement of cooled water relative to hot water, two-pipe systems are divided into associated and dead-end. In associated circuits, the movement of cooled water occurs in the same direction as hot water, so the cycle length for the entire circuit is the same.

In dead-end circuits, cooled water moves towards hot water, so for different radiators the lengths of coolant circulation cycles differ. Since the speed in the system is low, the heating time can vary significantly. Those radiators whose water cycle cycle length is shorter will heat up faster.

When choosing dead-end and associated heating schemes, they proceed primarily from the convenience of installing the return pipe

There are two types of location of the liner relative to the heating radiators: upper and lower. With the top connection, the pipe supplying hot water is located above the heating radiators, and with the bottom connection, it is below.

With a bottom connection, it is possible to remove air through radiators and there is no need to run pipes from above, which is good from the point of view of room design.

However, without an acceleration manifold, the pressure drop will be much less than when using the top line. Therefore, the bottom liner is practically not used when heating premises according to the principle of natural circulation.

Natural and forced circulation - what's the difference?

Natural is built on the physical process of heated water rising upward. The density of hot water is less than that of cold water, so warm layers are displaced by less heated layers. This phenomenon occurs without human participation, you just need to create the conditions to start the process.

However, natural circulation is unstable, without the necessary pressure. The speed of movement of layers of water is low; it cannot push the flow through the pipeline. In addition, it is almost impossible to regulate the natural process, just start or stop it.

Forced is the movement of water using special pumping equipment. The process occurs evenly, it can be adjusted, flow parameters changed or stopped as needed. The pump creates pressure that allows water to move through a branched, extended system.

The natural process is used where slow, ineffective mixing of layers of water at different temperatures is sufficient. As a rule, it is used in small water supply systems of a private home, when only a small exchange of layers is needed.