A heated towel rail is a necessary attribute of any bathroom, ensuring the comfort of its use; without it it is impossible to imagine a modern apartment or country house. When carrying out construction or repair work yourself or moving the device to another location during reconstruction, it is important to know how to connect a heated towel rail to the heating system.

The task is complicated by the fact that there are different types of heated towel rails and ways to connect them; to choose the best option, it is useful to study the basic diagrams of their location. And studying the correct installation technology will allow you to avoid uneven heating or its absence, airing of the system and leaks, which are a fairly common occurrence among errors when installing the device.

Rice. 1 Heated towel rails for bathrooms - varieties

Connecting a water heated towel rail - features

A heated towel rail is an important attribute that creates increased convenience when using the bathroom, in which it performs the following functions:

- Drying towels that are wet after washing and washing clothes and shoes.

- Heating the bathroom for a comfortable stay in the room after taking a bath or shower.

- Combating dampness affecting finishing materials, electrical sockets and lamps, heating boilers and household appliances.

The heated towel rail is connected to the heating or hot water supply system by parallel or series connection to the pipeline through which hot water flows.

Any heated towel rail has an inlet and outlet pipe with a thread at the end for quick and convenient connection to pipes. In some schemes, the heated towel rail becomes part of the pipeline, placed in the gap in place of the cut section of the pipe. During installation, it is welded to pipes or installed on American-type threaded connections.

Rice. 2 Design and equipment of the ladder heated towel rail

Features of chrome parts

Chrome plating of metal parts is carried out by applying a thin layer of chromium to the surface. This layer protects the base metal from destruction.

Chrome plating serves several purposes:

- Improved appearance. Chrome plating of fittings transfers the connecting part from the category of plumbing to the category of interior design.

- Hide metal defects.

- Improve performance properties.

- Extend the life of fittings.

Chrome surfaces give the bathroom a special atmosphere of crystal-clear luxury. Their mirror-like shine and perfectly smooth surfaces are in harmony with tiles and sanitary ware and fit organically into the room.

We recommend that you read: Testing machines - main types and differences

Types of heated towel rails

Heated towel rails connected to the pipeline are divided into three main categories:

- Mermen. The main type in all apartment buildings and private buildings, they work on the principle of circulating water through a heated towel rail, and are a piece of curved pipe of various shapes or a ladder with threaded outlet pipes. In old houses, the element was often connected to heating pipes and it functioned only during the heating season; in modern residential high-rise buildings, the heated towel rail is connected to the hot water supply pipeline.

- Electrical. The device is a regular autonomous heating element not connected to water; it can be installed anywhere in the apartment: in the bathroom, in the kitchen, in the loggia. Although this device is a modern development, its use in the household is limited due to high energy consumption and additional financial costs for electricity.

- Combined. Such models combine water and electric heating of the heated towel rail, which is very convenient when connecting it to the heating system. In this case, during the heating season, the heated towel rail operates due to hot water passing through it, and when the heating is turned off, heating occurs due to electricity. This option is less popular due to its higher cost.

Rice. 3 Electric coil - modifications

Main materials of manufacture - comparison of characteristics

The main materials for the manufacture of heated towel rails are stainless steel and brass; in budget options, galvanized steel is used for installation in apartment buildings. When choosing, the buyer often gives preference to the widely advertised stainless steel, which has an aesthetic appearance. To determine which metal is better, their main characteristics should be compared in terms of efficiency as materials for heat exchange devices.

If we consider stainless steel, it is almost three times cheaper than brass or copper, can withstand temperatures of more than 450º C, and is slightly susceptible to corrosion in water. Although stainless steel is corrosion-resistant and is not afraid of the effects of solutions of most acids and alkalis, if the alloy is made poorly (violation of technology, structural defects, reduced content of the main alloying additives of chromium), corrosion processes can occur in the structure. The material has high strength and durability, is harmless throughout the entire period of operation, but non-ferrous metals are used much less frequently as parts of plumbing fittings.

Copper-based brass alloys have thermal conductivity 4 times higher than stainless steel, which is the main advantage when using the material as a heat exchanger. Brass has high corrosion resistance (its surface is covered with a protective film of oxides, which serves as a barrier against the penetration of oxygen into the pure metal). Non-ferrous metals, unlike steels, are not subject to electrochemical corrosion; when used, the maximum temperature of the flowing coolant should not exceed 260º C.

Rice. 4 Types of heated towel rails - U-shaped, M-shaped and ladder

What designs are there?

The main diameter of the pipe for a heated towel rail is 32 mm; if the body has a complex structure in the form of a ladder with welded pipe sections, their diameter is about 20 mm. On the market you can find other dimensional parameters of the main pipeline with an outer diameter of 26, 28, 50 mm.

All structures can be divided into two categories: single-pipe U-shaped or M-shaped and multi-pipe, consisting of two pipe sections of large diameter and small cross-section pipes located between them in the form of a ladder.

Some models provide for connection using special seals that allow the device to be rotated around its axis; in other modifications, a set of heated towel rails is possible from several fragments connected in series to each other. To connect the heated towel rail to the water riser, use a bottom, side or diagonal connection - this is how the inlet and outlet pipes are located in manufactured models.

Rice. 5 Single-pipe arrangement of a heated towel rail in the system

A little history, old types of PS

Just twenty years ago, the substation “from the developer” was a monolithic riser pipe, bent in the shape of the letter “P” or “M”.

Figure 1. U-shaped substation, which is part of the riser.

Figure 2. M-shaped substation, which is part of the riser.

Despite its unsightly appearance, this type of substation had undeniable advantages: it was constantly hot, did not introduce any noticeable hydraulic resistance and did not allow residents to disrupt the operation of the hot water supply (DHW) riser.

However, time passed, and residents in the old housing stock, making repairs, exchanged the old and ugly PS for a new and shiny one. In a good situation it turned out like this:

Figure 3. New PS, which is part of the riser, a competent replacement.

The diameter of the PS corresponds to the diameter of the riser, the connection is made without narrowing and without shut-off valves (taps).

If things go wrong, like this:

Figure 4. New substation, which is part of the riser, an illiterate replacement.

Four extra narrowings appeared in the riser from the fittings used:

Figure 5. Internal cross-section of a fitting for metal-polymer pipes.

But it can be much worse:

Figure 6. The new PS, which is part of the riser, is an absolutely ignorant replacement.

In addition to the narrowings already mentioned above, shut-off valves have been added. When any of them is blocked, the circulation in the riser stops completely, the pressure in the apartments following the supply direction drops down to zero (water can somehow flow from the return line), the riser cools down in the absence of water supply, and when opening the mixer it takes a long time to drain cold water .

Installation of shut-off and control valves (taps) on risers is strictly prohibited!

Where to connect and where to hang - recommendations

When installing heated towel rails, the following recommendations should be followed:

- The distance from the vertically located riser to the most remote section of the heated towel rail pipeline should not exceed 2 meters - if the device is located at a greater distance, due to the high hydraulic resistance of the resulting loop, water simply will not flow into it. In the bathroom, the heated towel rail is installed by direct connection to the tee adapters of the riser.

- It is more practical to choose more expensive products made from chrome-plated non-ferrous metals - they have four times better thermal conductivity compared to stainless steel and better corrosion resistance.

- To connect the heated towel rail, you should use the installation option using an American connection, which allows you to connect the fittings in a stationary position of the parts without turning around their axis.

- Before installation, it is better to replace the cheap rubber gaskets in the American union nut, which at constant high temperatures quickly lose their plasticity, with higher-quality fluoroplastic ones; you can install silicone and paronite rings or use a sandwich of soft and hard rings.

- If the heated towel rail is part of a common building riser of an old design, to replace it and carry out preventive maintenance, install a bypass and connect the device through ball valves, which are also secured using fittings.

- When connecting a heated towel rail to fittings, it does not hurt to maintain electrochemical compatibility, that is, to join products from the same material. A common mistake is contact between steel and brass, which creates a galvanic couple with accelerated corrosion.

- To seal the seal, it is more practical to use flax tow or plumbing thread; it is better to avoid using Fum tape - it is often cut with threads and assembled in the channel in parts, allowing water to penetrate between sections.

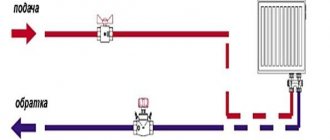

- If the heated towel rail is connected in a line parallel to the riser, it is useful to install shut-off ball valves in front of its inlet and outlet pipes for the convenience of carrying out preventive and repair work in the unit.

Rice. 6 Installing a heated towel rail in the bathroom - assembly diagram

Why doesn't the heated towel rail heat up?

• Works in any direction of supply in the riser.

• The ability to run pipes somewhere hidden under the bathroom, without stripping the walls.

• Requires bleeding of air through Mayevsky valves.

• Less efficient compared to side or diagonal connections.

• The upper outlet of the riser with an offset or narrowed bypass must be below the connection point to the substation. This guarantees the independence of the PS operation from the feed direction.

• The lower outlet must be below the substation in all variants of this scheme.

• The slope of the supply pipes must be observed (the direction is shown in the figure)

3 - 5 mm per meter.

• There should be no “humps” (completely unacceptable, air will accumulate in them and circulation will stop) or dips on horizontal routes (allowed only in

within small limits, deep “holes” will air the supply line to the substation).

• The diameter of the pipes to ensure maximum circulation is preferably at least 3/4” (32mm for PPR), ball valves – at least 3/4”. The use of pipes and taps of a smaller cross-section is allowed only when the length of pipes leading to the substation is short, but in this case uneven heating may become noticeable

PS - hotter on top, colder below.

• It is highly desirable to place the supply pipes in thermal insulation. Besides what it is

a prerequisite for embedding PPr pipes into walls, such insulation

improves circulation and the functioning of the PS.

It is strictly prohibited to install any taps on the bypass - this is vandalism and harm to yourself and your neighbors. Overlapping or excessive narrowing of the bypass:

a.) Slows down circulation throughout the riser (the temperature of hot water drops at the water intake points of apartments).

b.) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - even to the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as large.

c.) Does not significantly improve the efficiency of the above scheme.

Acceptable options for designing scheme No. 2

Figure 19: Bottom connection, example of acceptable design 1.

All bends are below the substation, no conditions are violated.

Figure 20: Bottom connection, example of permissible design 2.

The upper outlet is higher than the bottom of the substation.

Please note that this immediately imposes a restriction on the direction of feeding - only from above! With a bottom feed, this connection is unstable.

Scheme No. 3: lateral and diagonal connections with a narrowed or offset bypass.

The vast majority of plumbers believe that there must be a narrowing between the bends on the substation - otherwise nothing will work. Firstly, this is not true (see diagrams Nos. 1 and 2), and secondly, in the case of lower water supply in the riser and poor circulation, the narrowing prevents the heated towel rail from working until it cools completely, despite the seemingly normal connection. Therefore, whenever possible, it is worth striving to ensure that the diameter of the bypass is equal to the diameter of the riser.

Figure 21: Connection of a PS ladder, operating on a combination of forced and natural circulation, with a narrowing of the bypass. Lateral connection.

Figure 22: Connection of a PS ladder operating on a combination of forced and natural circulation, with a bypass offset. Lateral connection.

Figure 23: Connection of a PS ladder, operating on a combination of forced and natural circulation, with a narrowing of the bypass. Diagonal connection.

Figure 24: Connection of a PS ladder operating on a combination of forced and natural circulation, with a bypass offset. Diagonal connection.

Note that the supply direction in the riser is now clearly indicated as top. When using bottom feed, these options are strictly not recommended; the reasons will be described below.

Disadvantages of this scheme:

• Stable operation is guaranteed for top feed only.

The advantages of this scheme: • It works unambiguously and stably with the top supply in the riser. • There is no need to bleed air from the substation after turning off the water.

• The distance from the riser is arbitrarily large.

Conditions for the circuit to work:

• Let us remind you once again that with bottom feed, narrowing/displacement between the bends interferes with the operation of the PS up to its complete inoperability! With top supply, it is permissible to narrow the bypass by a maximum of 1 step from the diameter of the riser. Narrowing the biased bypass is never required.

• The lower outlet of the riser must be below the bottom of the substation, and the upper outlet of the riser must be above the top of the substation.

• It is necessary to observe the slope of the supply pipes (the direction is shown in the figure) of at least 3 mm per meter, but better than 30 mm per meter.

• There should be no “humps” (completely unacceptable, air will accumulate in them and circulation will stop) or dips on horizontal routes (allowed only within small limits, deep “holes” will interfere with circulation).

• The diameter of the pipes to ensure maximum circulation is preferably at least 3/4” (32mm for PPR), ball valves – at least 3/4”. The use of pipes and taps of a smaller cross-section is allowed only if the length of the pipes leading to the substation is short.

• It is advisable to place the supply pipes in thermal insulation. In addition to the fact that this is mandatory when embedding PPR pipes into the walls, such insulation will improve the performance of the substation in certain cases (sagging pipes or “holes” in them).

It is strictly prohibited to install any taps on the bypass - this is vandalism and harm to yourself and your neighbors. Overlapping or excessive narrowing of the bypass:

a.) Slows down the circulation throughout the riser (the temperature of the hot water drops).

b.) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - even to the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as large.

c.) Does not significantly improve the efficiency of the above scheme, and with a lower feed, even on the contrary, it interferes with the operation of the substation.

Why doesn't my PS work?

Let's look at typical PS connection errors (the section will be gradually updated with links to real examples).

Figure 25: Lateral connection, example of WRONG execution 1.

Figure 26: Bottom connection, example of WRONG execution 2.

The PS is located below the lower branch. The water that has cooled in the substation and dropped down ends up in a trap formed by the lower part of the substation and the pipe (the stagnant zone - from the bottom of the substation to the level of the lower outlet), and is not pushed back into the riser, because lighter hot water presses on it from above.

Technology for connecting a heated towel rail

It is clear that connecting a heated towel rail to the heating system is a bad option; in private homes it is installed in the hot water supply pipeline, for which many use modern plastic pipes to supply water. The pipeline can be placed in any convenient place, the liner can be made from sections of pipes not only of the same type, but also from any material used for hot water.

If the work is carried out in an apartment building, when repairing a bathroom, the riser located in the basement of two pipelines of the forward and return lines will have to be closed; the material of the old risers is always steel; if they were replaced, in most cases polypropylene was used.

When the pipe is steel, you can weld an outlet threaded fitting to it, cut it with further cutting of external or internal threads to connect adapter tees, or attach a clamp with a branch - all methods are quite complicated except for the last one, but this option is not very reliable. There is another modern innovative option for connecting transition fittings to a steel pipe, which will be discussed below.

If there is a polypropylene riser, a section is cut out of it and two tees are soldered in to connect pipes or the heated towel rail itself.

Rice. 12 Connecting a heated towel rail through the threads on the pipes

Hello! In this video and article I will show and tell you how to connect a heated towel rail in an apartment building and in a private house. Let's look at the connection diagrams, errors associated with the connection and the connection itself using fittings.

Nobody forbids you to install a heated towel rail of any shape. But if it concerns reliability against leaks, then it is better to install U-shaped or M-shaped ones for one simple reason. There are fewer joints between one pipe and another. The fewer joints, the higher the reliability against leaks.

There are heated towel rails made of two types of steel on the market – black steel, which rusts, and stainless steel.

Whether to choose black chrome-plated steel or stainless steel is an interesting question. Because there are cases when stainless steel is subject to destruction.

Stainless steel is a cross between black steel and non-ferrous metals to give them the property of being resistant to corrosion.

My answer regarding the choice of steel would be: I think if you have plastic pipes installed, then choose stainless steel. If you have risers made of black steel, then you can choose a heated towel rail made of black steel, but only with a good mesh thickness.

Black steel heated towel rails are the same rusting steel pipes from which the risers in apartment buildings are made. But these pipes are coated with chrome. These pipes are called water and gas pipes. Made from maximum wall thickness.

The wall thickness of the pipe for water supply and heating must be no less than the thickness specified in GOST 3262-75 for reinforced pipes with a maximum thickness. If the outer diameter of the heated towel rail is about 32mm. then the wall thickness should be at least 4 mm.

The thicker the pipe wall, the longer the pipe will last.

The outer diameter of the heated towel rail pipe is at least 32mm. Denoted as 1”=1 inch. The most common diameter. If your bathroom is cold, then you need to choose an M-shaped heated towel rail, and with the maximum diameter that you will find on the market.

As for stainless steel. They praise the steel grade: AISI-304

In stores, ask for a passport for the heated towel rail. If the passport does not indicate the steel grade, then ask for certificates and other documents that will indicate information about the steel grade. The wall thickness can be indicated in the passport of the heated towel rail.

Choose a wall thickness of a stainless steel heated towel rail of at least 2mm.

You can try to measure the thickness of the steel with a caliper.

I believe that stainless steel is not one hundred percent corrosion protection. There may be defective products, insufficient mixing of ferrous steel with non-ferrous metals. And therefore, the thicker the pipe wall, the longer the pipe will last.

Stainless steel can be tested with a magnet. A magnet is not attracted to stainless steel. Opposite to black steel. If there is no magnet, you can check with a napkin or your finger by touch. But this can only be determined by an experienced plumber who actually tried to compare the differences in materials from the inner wall of the pipe by touch. Therefore, go buy a heated towel rail with magnets and a caliper to measure the wall thickness.

If the inside surface is oiled or has a rough grain, then it is most likely rusting black steel.

Pipes can be seamed. That is, there is a seam along the length of the pipe. You can try to identify this seam by touch from the inside. That is, it is not advisable to use seam heated towel rails, because there is a high probability of pipe leakage at the seam joint. There are cases that seam heated towel rails leak in the seam areas.

Heated towel rail connection diagram

First, let's look at the connection in an apartment building.

For apartment buildings we connect heated towel rails with different heights. That is, we do not connect bottom-to-bottom.

Ladder heated towel rail can be connected from above and below

This arrangement can work well if the water flows from top to bottom.

If the water is running from bottom to top, then it may have some problems. I described the problem of this connection in a separate video:

The heated towel rail does not heat up

It is necessary to find out in which direction the hot water circulates from bottom to top or from top to bottom. If hot water circulates from top to bottom even with bypass without reducing the diameter.

If the flow is from bottom to top, then be sure to narrow the diameter and make bends in the pipeline to use kinetic energy in the tees towards the heated towel rail.

Usually, if the diameter of the riser is 40, then the jumper is 32. If it is 32, then the jumper is 25, and so on.

We slope the top pipe to get rid of air

The pipes going to the heated towel rail do not need to be narrowed too much, hoping for a narrowed bypass. A narrowed bypass may not provide good pressure towards the heated towel rail. Minimum internal diameter 20mm. It's better to use 25mm.

Heated towel rail connection errors

To understand why such connection schemes will not work, watch the video above entitled: The heated towel rail does not heat.

American connection for heated towel rail

Now regarding the connection fittings for the heated towel rail.

There are beautiful decorative union nut connections. I am categorically against such connections for U- and M-shaped heated towel rails. Why? Because the thread connection is pointed, and it cuts off the gasket. Roughly speaking, the connection is not flat with the gasket. The pressing area of the gasket is small.

In some cases, water circulation occurs naturally, and such connections have a narrowing internal diameter.

Experience has shown that leaks occur with such connections. See the picture above. Anything crossed out cannot be used. Anything that is not crossed out can be used.

The tap cannot be installed on the bypass!

If you have risers made of steel pipe, then we make the bypass itself from the steel pipe. That is, there is no need to install a plastic pipe. Dissolve the plastic after the taps.

If there is no welding, then try to make it with twisted steel pipes.

If you are a plumber and do not weld, you can hire a welder for a fee. You can take on the order yourself, but hire a third party to weld the riser through the bypass.

Connecting a heated towel rail in a private house diagram

In a private house, hot water supply is recirculated. recycling goes through the BKN. The BKN must have three inputs. The middle height is for heated towel rail recirculation.

In summer, the heating system can be switched off and the heated towel rail is powered by thermal energy from the hot water supply.

Recirculation allows you to maintain hot water in the pipes, so as not to wait for a long time for hot water to arrive from the BKN. That is, by opening the tap, hot water will come faster.

A thermostatic three-way valve can be installed in the DHW system to regulate the DHW temperature. When I worked for the company, we always implemented such systems for VIP clients. That is, the BKN must be connected according to this scheme.

Heat exchanger for heated towel rail

And finally, you can make a heat exchanger, as shown in the photo.

It's a pipe within a pipe. Water moves due to natural circulation. Cold water is heavier and it goes down, while warmer water is lighter and it rises.

Do not forget to install a safety valve in the heated towel rail circuit. Because there may be chemical reactions that release various gases that increase pressure. In practice, there are cases of increased pressure that can destroy the pipeline.

And in conclusion

If you are a plumber and are involved in water supply and heating, then I have programs for calculating water supply and heating. If you are interested in selecting a pump and diameters, then in the programs you can perform such a selection. The programs operate on the principle of simulation. That is, physical phenomena in the water supply and heating system are virtually played out, and you can find weak points in pipelines.

Program for calculating heating in three-dimensional realistic space:

More about the program

You can test your fictitious piping system. Before installing the systems, you can check how your system will work with the assigned hydraulic and thermal parameters. You can also test existing systems how they work in order to find weaknesses and change the system.

Program for calculating water supply and heating:

More about the program

If you do not want to fool your head with these calculations, then you can contact me for services in calculating pumps and diameters. I also develop schemes for your specific purposes.

In general, if you need a project or calculation of water supply and heating, please contact us

| Like |

| Share |

| Comments (+) [ Read / Add ] |

A series of video tutorials on a private house

Part 1. Where to drill a well?

Part 2. Construction of a water well Part 3. Laying a pipeline from the well to the house Part 4. Automatic water supply Water supply Water

supply for a private house.

Principle of operation. Connection diagram Self-priming surface pumps. Principle of operation. Connection diagram Calculation of a self-priming pump Calculation of diameters from a central water supply Water supply pumping station How to choose a pump for a well? Setting up a pressure switch Pressure switch electrical diagram Operating principle of a hydraulic accumulator Sewage slope of 1 meter SNIP Connecting a heated towel rail DHW recirculation diagram - the best solution! Heating schemes

Hydraulic calculation of a two-pipe heating system Hydraulic calculation of a two-pipe associated heating system Tichelman loop Hydraulic calculation of a single-pipe heating system Hydraulic calculation of radial distribution of a heating system Scheme with a heat pump and a solid fuel boiler - operating logic Three-way valve from Valtec + thermal head with remote sensor Why the heating radiator does not heat well in an apartment building How to connect a boiler to a boiler?

Options and connection diagrams DHW recirculation. Principle of operation and calculation You are not correctly calculating the hydraulic needle and collectors. Manual hydraulic calculation of heating. Calculation of a warm water floor and mixing units. Three-way valve with a servo drive for DHW. Calculation of DHW, BKN. We find the volume, power of the snake, warm-up time, etc. Water supply and heating designer

Bernoulli's equation Calculation of water supply for apartment buildings

Automation

How servos and three-way valves work Three-way valve to redirect the movement of coolant

Heating

Calculation of the thermal power of heating radiators Radiator section Overgrowth and deposits in pipes worsen the performance of the water supply and heating system New pumps work differently... Calculation infiltration Calculation of temperature in an unheated room Calculation of a floor based on the ground Calculation of a heat accumulator Calculation of a heat accumulator for a solid fuel boiler Calculation of a heat accumulator for storing thermal energy Where to connect the expansion tank in the heating system?

Boiler resistance Tichelman loop pipe diameter How to choose the diameter of a pipe for heating Heat transfer of a pipe Gravity heating from a polypropylene pipe Why don’t they like single-pipe heating? How to love her? Smart selection of diameters in a heating system Balancing heating radiators - a step-by-step guide Top 5 problems in designing heating systems Heat regulators

Room thermostat - operating principle

Mixing unit

What is a mixing unit?

Types of mixing units for heating Characteristics and parameters of systems

Local hydraulic resistance.

What is KMS? Bandwidth Kvs. What it is? Boiling water under pressure - what will happen? What is hysteresis in temperatures and pressures? What is infiltration? What are DN, Du and PN? Plumbers and engineers must know these parameters! Hydraulic meanings, concepts and calculation of heating system circuits. Flow coefficient in a single-pipe heating system. Hydraulic paradox in a heating system. Riddle No. 4 Video

Heating Automatic temperature control Simple replenishment of the heating system Heat engineering.

Walling. Warm water floor Combimix pump mixing unit Why choose underfloor heating? Water heated floor VALTEC. Video seminar Pipe for heated floors - what to choose? Warm water floor - theory, advantages and disadvantages Laying warm water floor - theory and rules Warm floors in a wooden house. Dry heated floor. Warm water floor cake - theory and calculation News for plumbers and engineers Plumbers Are you still doing hack work? The first results of the development of a new program with realistic three-dimensional graphics Thermal calculation program. The second result of the development of Teplo-Raschet 3D Program for thermal calculation of a house through enclosing structures Results of the development of a new program for hydraulic calculation Primary secondary rings of the heating system One pump for radiators and underfloor heating Calculation of heat loss at home - wall orientation? Regulatory documents

Regulatory requirements for the design of boiler houses Abbreviations

Terms and definitions

Basement, basement, floor Boiler houses

Documentary water supply

Sources of water supply Physical properties of natural water Chemical composition of natural water Bacterial contamination of water Requirements for water quality

Collection of questions

Is it possible to place a gas boiler room in the basement of a residential building ?

Is it possible to attach a boiler room to a residential building? Is it possible to place a gas boiler room on the roof of a residential building? How are boiler rooms classified according to their location? Personal experiences in hydraulics and heating engineering

Introduction and introduction.

Part 1 Hydraulic resistance of a thermostatic valve Hydraulic resistance of a filter flask Video course Calculation programs

Technotronic8 - Program for hydraulic and thermal calculations Auto-Snab 3D - Hydraulic calculation in three-dimensional space

Useful materials Useful literature

Hydrostatics and hydrodynamics

Problems in hydraulic calculations

Pressure loss along a straight section of a pipe How does head loss affect flow?

Miscellaneous

Do-it-yourself water supply for a private house Autonomous water supply Scheme of autonomous water supply Scheme of automatic water supply Scheme of water supply for a private house

Privacy Policy

Bends from steel hot water riser for heated towel rails

When installing a heated towel rail in multi-apartment residential buildings, the main problem is connecting to a steel riser pipeline, and several methods are considered:

Welding. To connect a directly installed heated towel rail to the pipeline, two holes are cut in the pipe and a threaded fitting is welded. The method requires a welding machine or gas torch, as well as the presence of a gas welding specialist; difficulties may arise in the case of an old pipeline with thin walls, which the device will burn through, making welding difficult or impossible.

Thread cutting. With this technique, the steel pipeline is cut, a thread is cut into the surface of the pipe using a die, and then the adapter tees are screwed on from steel to polypropylene. Then they connect to the riser sections of soldered polypropylene pipe with threaded fittings at the end, which are laid in the wall grooves.

In addition to complexity and labor-intensiveness, the method has significant drawbacks: it is rarely possible to cut a thread when placing the pipeline at a short distance from the wall; moreover, old steel pipes have thin walls, and additional weakening often leads to their breakage.

Rice. 13 Example of a clamp connection in a private house

Clamps. The method is quite simple and is carried out in the following way: a large diameter hole is drilled in the pipeline and a composite clamp with a sealing rubber gasket and a threaded outlet of the required diameter is installed at this point, both halves are connected using bolts.

The method is quite simple and does not involve large costs, it is easy to implement with your own hands, the disadvantages are a rubber gasket that is not intended for long-term work with hot pipes (it is better to use fluoroplastic) and the possibility of moving the assembly down when loosening the bolts.

Gebo couplings. Gebo cast iron couplings are compression fittings that are securely and tightly connected to the pipe through a slotted metal ring (cracker) and an O-ring. To connect, a section of pipe is cut out, Gebo tees with bends of the required diameter and a pipe section between them are inserted at the top and bottom. The connection is very reliable and surpasses the above technologies in practicality of use, working in nodes for 10 years or more.

Rice. 14 Gebo couplings

Necessary equipment and tools

Plumbing wrenches

When installing a bypass with your own hands, you should take care of the following equipment and tools in advance:

- welding machine (for welded connection of the jumper and independent insertion into the riser);

- a tool for cutting pipe threads (if there is none), a grinder (for cutting a pipe of the required size);

- adjustable and plumbing (gas) wrenches;

- spanners;

- screwdriver;

- pliers;

- hammer;

- paint brush;

- calipers.

Do-it-yourself preparatory work

When carrying out work on installing a heated towel rail with your own hands in a metal riser, depending on the chosen method, you will need different tools. To install the clamps, you need a drill with a metal drill and a hexagon of the required diameter; if the pipe is cut to attach the Gebo coupling, you will need a grinder with a metal disc to trim the riser and adjust the size of the pipe section between the couplings.

To fix the fasteners, you need a hammer drill with a concrete drill with a diameter of 6 mm. and dowels with screws.

To properly connect such a device, you will need a building level - it is recommended to connect the lower pipes to the heated towel rail with a slight slope to ensure spontaneous drainage of water from the heated towel rail pipeline in the absence of coolant (especially important when connecting the unit to the heating system).

Before carrying out work, disconnect the riser from the water supply to the heated towel rail pipeline and prepare two containers for continuously draining water from the system.

Rice. 16 Examples of installing an old heated towel rail in a single-pipe and two-pipe system

Reinstallation and maintenance

With the advent of modern technologies, the question of whether it is possible to connect a heated towel rail to heating in Khrushchev apartments has disappeared. Most often this is solved by dismantling the old heated towel rail and installing an electric one. To implement this solution, there is one serious condition: the remaining residents of the entrance must carry out a similar reinstallation in their apartments. Otherwise, you will have to straighten the pipe to ensure water supply to neighboring dwellings.

In addition, the relevant authorities must issue permission to carry out dismantling work: unauthorized reconstruction of heating circuits can entail serious fines. Much fewer problems arise when connecting a side-switched heated towel rail to a hot water supply.

Connection to the hot water supply system

To connect a heated towel rail to a riser located at a great distance, polypropylene pipes are used - compared to metal plastic and cross-linked polyethylene, they are produced in a large diameter, which is necessary to reduce hydraulic losses. The connection is made using a pipe soldering iron; the necessary fittings are soldered at the ends. The heated towel rail is connected in the following sequence:

- After completing the plastering work, mark the connection points on the wall where the heated towel rail is installed, make markings and knock out grooves in the wall through which the pipes will pass. Install the plastic pipeline by soldering, leaving the threaded fittings protruding from the wall so that the later laid tiles are flush with them.

- Temporarily screw the heated towel rail on, level it and fix it on the wall using telescopic fasteners on the body, then cover the pipes with gypsum binding solution, after the plaster has dried, remove the device, and screw plugs into the fittings.

Rice. 17 DIY installation of a heated towel rail - main steps

- Further work is carried out upon completion of finishing work on laying tiles. The manufacturer produces heated towel rails with a different set of components; American ones are often found that are screwed onto the outlet pipes of the device with a special key. For sealing, it is better to use flax tow complete with a special paste.

- After placing the American on the outlet pipes, the device is screwed to the pipes through eccentric adapter couplings, which are connected and sealed with flax - this allows you to adjust the position of the pipes in the absence of alignment.

- Then unscrew the telescopic fasteners on the pipe walls of the heated towel rail until it makes contact with the wall, mark the holes for the fasteners with a marker, after which the device is removed.

- Using a self-tapping screw or any sharp object, a small depression is punched into the tile to prevent the drill from sliding on its smooth surface, after which a hole is made in the tile in the drilling mode. Then switch the tool to perforation mode and drill a hole of the required depth in the concrete; upon completion of the work, hammer in the dowels with a rubber hammer to avoid damaging the tiles.

- Finally, install the heated towel rail in place using an adjustable wrench, if necessary, replacing the low-quality American rubber gasket with a fluoroplastic one, screw the mount with self-tapping screws to the dowels using a Phillips screwdriver or screwdriver.

When carrying out work, one important rule should be observed - place a rag under the adjustable wrench or insulate its jaws to avoid scratches on the chrome-plated clamping nuts.

Rice. 18 Models of heated towel rails with complex shapes

How to connect a heated towel rail to the heating system

In a private house, there are no problems connecting to the heating riser - this can be done at any convenient time by draining the coolant from the system; in an apartment building you will have to wait until the end of the heating season.

When carrying out installation work in a multi-storey building in the absence of coolant, the functionality and tightness of the unit cannot be checked before turning on the heating, so it is better to install the heated towel rail with the bypass and shut-off valves at the inlet and outlet turned on.

Let's talk about physics. Gravity pump in substation.

If the performance of the PS with a narrowed or displaced bypass still somehow fits into the heads of plumbers who think in terms of “it will push or not,” then a scheme without a displaced bypass and without narrowing the riser plunges them into complete stupor: “All the water passes by the towel! It won’t leak there! This can never work!

However, the PS works great with this connection! Its functionality is based on a “gravity pump”:

The coolant cooling in the substation tends downward, since it has a higher density (specific gravity) relative to the hotter coolant. As a result, from the lower point of the substation, the cooled coolant is pushed into the riser, and at the same time, a hotter coolant flows from the riser to the upper point of the substation. Which cools down again and goes down - we get a “gravitational pump”, the perpetual motion machine of which is cooled water.

Figure 10. Thermogram of a radiator operating exclusively on natural circulation.

Figure 11. Thermogram of a substation operating exclusively on natural circulation.

How to connect heated towel rails with complex shapes

The main difference between the operation of a heated towel rail made from a large number of elements and a simple one is its high hydraulic resistance, which leads to the fact that the volume of passing coolant will be less and, accordingly, the device will not be sufficiently warmed up. In this case, you should reduce the diameter of the jumper, if present, or abandon the bypass altogether and remove all shut-off valves, connecting the heated towel rail in series to the riser pipeline.

If a highly branched heated towel rail is located at a large distance from the riser and you do not want to remove the bypass, you should choose the diameter of the supply pipes equal to or greater than the cross-section of the riser.

Rice. 19 Combined heated towel rails

Device form

The shape of the heated towel rail affects the speed of water movement, the presence of airy places, and stagnant areas. The most effective are M-shaped (snake) and U-shaped “towels”, the insertion of which does not require bends and transitions. In such devices, water directed into the inlet of the end of the pipe passes freely through the entire volume of the dryer, without slowing down or stopping.

The most popular heated towel rails are made in the form of ladders or complex spatial structures made of stainless steel. They differ from standard dryers in having an increased area for placing linen and towels.

A little about installing a combined heated towel rail

A combined heated towel rail is a rather rare guest on the construction market, although its installation in a heating system is quite effective. During the heating season, the heated towel rail will be hot due to flowing hot water; if the heating is turned off, the coolant in the circuit will be heated by the built-in heating element.

Structurally, the device is made in the form of a conventional heated towel rail with the difference that one of the fittings at the bottom (the bottom connection is mainly used) is made in the form of a tee, into the lower outlet of which a heating element with a thermostat is screwed. The combined model is connected in the same way as its water counterparts - from below, from the side or diagonally, the thermostat is always located at the bottom, in the design the outlets are assembled with the possibility of right or left connection.

Rice. 20 Installing a heated towel rail in a combined type bathroom

Features of electric heated towel rails and their installation

An electric heated towel rail is an autonomous design that does not depend on the presence of water in the house; there are dry and wet modifications. The first includes an electric heating cable placed in a housing; the principle of operation is similar to the heated floor used for heating in many homes.

In wet devices, TEN heats the oil inside the housing; the product differs from common oil electric heaters only in the shape of the housing. The models of such devices offered on the market have the following features:

- Devices with a built-in heating cable quickly reach operating temperature and cool at the same speed, while oil-based devices heat up slowly and take a long time to cool down.

- Oil devices are more expensive than cable devices due to the labor-intensive technology of manufacturing a sealed housing and a more complex design, including temperature control of heating elements; cable devices usually do not have temperature settings.

- The power of oil heated towel rails is higher than that of cable ones, so they are installed in bathrooms to heat the room and dry things; cable ones are used only for drying.

- All products are produced in floor and wall versions, while oil ones, due to their large weight, require a professional approach to installation using special fittings, while cable ones can be hung on the wall by any homeowner without much difficulty.

When choosing to obtain better heat transfer, you should purchase products with a large number of tubes or an increased cross-sectional area; things are better held on arched pipes.

Rice. 21 Electric heated towel rail - device

The connection of the heated towel rail to the heating or hot water supply system is made using tee bends from the riser pipe; to supply coolant when located remotely, a polypropylene pipeline with fittings connected by soldering is most often used. Any home craftsman can attach the heated towel rail to ready-made outlets - the fittings are screwed on using an adjustable wrench; to secure the fasteners to the dowels, you will need a hammer drill and a 6 mm concrete drill.