Layout features

A detached house, unlike an apartment, has its own characteristics. This applies to general provisions that must be taken into account during construction, and to the zoning of the premises.

General principles:

You cannot go directly from the street into a warm room. This will lead to increased heating costs. And in the cold season, cold air entering when opening the door will create inconvenience. To prevent this from happening, it is necessary to make a vestibule. Moreover, it is better if it is part of the main house, and not attached as a separate room. If you plan to allocate part of the space for a covered veranda, then a vestibule is not required.

The living room should occupy a central place. It is often combined with a kitchen to increase space. Then the zoning of the room will come to the fore.

Each family member must have a separate sleeping place. If this is a country house, then you can divide the bedrooms into adults and children (separately for boys and separately for girls).

For a house size of 8x10 sq. m, one bathroom and a bathroom are enough. Whether they will be combined or separate depends only on your desire. An alternative to a bath is a shower stall, which will save space. If the housing is supposed to be two-story, then such a room is also needed on the second tier.

Zoning

First you need to decide where on the site your home will be located. The layout and better location of the windows and entrance will depend on this. It is better when the windows in the bedroom face east, in the living room to the south, and in the kitchen to the west.

Next, calculate how many people the plan should be designed for. Based on this, the specialist will calculate the required number of bedrooms. Don't forget about a guest bedroom if you often have family and friends staying overnight. At your request, the architect can design a building with isolated rooms or with a minimum of partitions.

The latter will allow you to increase the space and give it some lightness and freedom. This is especially true if you plan to use the room as a country house.

An important issue will be the number of storeys of the house. More often it is a one-story or two-story building. You can consider the option with a basement or attic.

Deciding on the number and placement of bedrooms

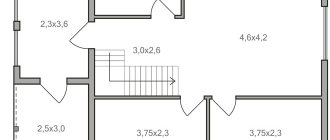

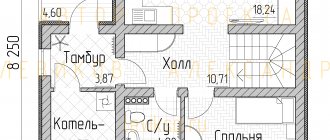

Since a one-story house with dimensions of 8x10 does not have a large area, the principle of compactness is important. However, despite the limited possibilities, you can approach the layout of the interior space creatively and create an interesting design.

For example, make the kitchen and living room combined, as is now fashionable. In this case, a bar counter serving as a table or a wide arch can delimit the zones.

This technique visually enlarges the room and creates coziness. A hood above the kitchen hob will remove the smell of cooking food from the room. An area of 10-12 m² is quite enough for this. It is advisable to place 2 rooms, one of which can serve as a bedroom, and the second as a nursery, on the opposite side of the house, away from the active zone.

Between the two zones there should be utility rooms that act as a buffer and soundproofing layer. If you make the bathroom combined, you can free up a couple more meters. A shower stall takes up much less space, but the choice depends on the owner’s decision. The remaining meters can be used for a pantry, boiler room, dressing room and hallway.

Do not forget about the possibilities of the basement floor - its construction will almost completely solve the problem of shortage of space on the ground floor.

For example, it is possible to transfer all the technical premises there: a heating boiler, a bathroom, which can already be made separate, a storage room, etc. While working on a house project, it is necessary to draw all the locations of communications, furnishings, etc. Completing this point will save from many difficulties in building a house.

Project A45-90.2

River cruise and passengerList of all types and projects

·

All photographs of the vessels of this project.

The delivery dates of the vessels and the construction number are given according to the competition documentation (2 vessels are planned in the series). Approximate characteristics of the vessel (changes are possible during the construction process in accordance with the terms of the current contract): overall length - 99 m maximum length - 98.3 m waterline length - 96.7 m maximum beam - 14.6 m side height - 4.2 m draft along the vertical line - 2.0 m passenger capacity - 220-245 people. crew - 41 people. number of cabins: four-bed — 47 double — 16 luxury — 7 for people with disabilities (persons with disabilities) — 1 block cabins — 2 single cabins — 13 double — 15 hull material — steel superstructure material — aluminum alloy Main power plant 3 diesel-geared unit Characteristics of the unit: diesel Mitsubishi S6R2-T2MPTK in-line, 6 cylinders maximum power - 480 kW (652.62 hp) at 1350 rpm supercharging - gas turbine, with charge air cooling fuel supply to the cylinders - Common Rail system Cooling system Main engine - double-circuit Main engine start - from an electric starter gearbox: type - ZF3000 gear ratio - 2.773 connection to the engine - through an elastic coupling maximum propeller thrust, kN - 60 At a specific operating speed of the vessel of 20 km/h, the required engine power is about 220 kW at rotational speed about 1020 rpm With a specific operating speed of the vessel of 23 km/h, the required engine power is about 300-340 kW at a rotation speed of about 1100-1200 rpm Auxiliary power plant (WPP): diesel generator (DG) - 3 emergency diesel -generator (ADG) - 1 hot water boiler - 4 characteristics of DG as part of DG: Rigas Diezelis EM340BL (made in the Republic of Latvia) number of phases - 3 type of current - variable frequency, Hz - 50 rated power, kW - 340 diesel type - Baudouin 6M26.2 (brand country - French Republic) power, kW - 440 at 1500 rpm number of cylinders - 6 arrangement - in-line generator as part of a diesel generator: Leroy Somer LSAM 47.2S5 (brand country - French Republic) brushless, synchronous, air cooled , with built-in voltage regulator, with anti-condensation heating of windings, with parallel operation transformer Power, kW (kVA) - 340 (425) Voltage, V - 400 number of phases - 3 frequency, Hz - 50 speed, rpm - 1500 insulation class /temperature - H/H degree of protection - IP23 Characteristics of the ADF: Rigas Diezelis E90BL-M (made in the Republic of Latvia) number of phases - 3 type of current - variable frequency, Hz - 50 rated power, kW - 90 diesel included in the ADF: type diesel engine - Baudouin 6W105 (brand country - French Republic) power, kW - 128 at 1500 rpm number of cylinders - 6 arrangement - in-line generator as part of the ADG: Leroy Somer LSA M 44.3 M6 (brand country - French Republic) brushless, synchronous, air-cooled, with built-in voltage regulator, with anti-condensation heating of windings Power, kW — 90 Voltage, V — 400 number of phases — 3 frequency, Hz — 50 speed, rpm — 1500 insulation class/temperature — H/H degree of protection — IP23 power of anti-condensation heater, W at supply voltage, V - 800 at 220 according to the design ADH is located on the second deck Water heating boilers: Total thermal power, kW - 500 fuel - diesel

List of all types and projects

·

All photos of the vessels of this project

Table of project vessels

Sort by: Date of construction

· Place of construction · Year and place of construction · Modifications · Last title · First title · Editorial sorting

| 716 | Andrey Dubensky | (Russia) | State transport leasing company |

| 717 | Victor Astafiev | (Russia) | State transport leasing company |

Simple view of the list of vessels (records according to registration data)

List of all types and projects

·

All photographs of vessels of this project

Report any inaccuracies in the description or name of the type/project

Advantages and disadvantages

The main advantage of 8x10 houses remains their versatility. The buildings are quite compact, but with proper planning they are very ergonomic. The cottages fit perfectly into a suburban area and look great in the city.

Among the advantages of such a choice are not too high construction costs: such a house does not need an expensive strip foundation, the weight of the structure allows you to use columnar or pile technology.

And:

- the costs of paying construction workers and purchasing building materials are minimized;

- the speed of construction increases significantly, which is a significant argument for families living in rented living space;

- the relatively small size ensures lower energy and heating costs.

Among the disadvantages, the same small dimensions are noted, depriving individual family members of the opportunity to have a spacious room, although the presence of an attic will help solve this problem. Moreover, the area can be increased due to the basement or basement floor, but this will automatically negate such an advantage as savings on construction and utility bills.

The decision to build a house must include the following criteria: reliability, quality, comfort for all family members. Fulfillment of these requirements largely depends on the correct layout of the house.

A competent design is a big part of a successful solution. The layout of an 8 by 10 house should include not only spacious rooms, a kitchen and a wardrobe, but also a bathroom and various outbuildings.

Single-story 8x10 houses will be much more spacious if you equip an attic, the arrangement of which will cost much less than the construction of a full second floor. When drawing up a drawing of the interior, the number of future residents and the rooms they need must be taken into account.

A very important factor influencing the planning is the properly organized space:

- division into active and passive zones;

- placement of the stairs, if there is an attic or basement - to save space, they can be placed in the corner or the basement stairs can be moved outside.

A good solution may be to organize sliding screen partitions - this allows you to change the purpose of the space. The ground floor unloads the layout of the first floor - the boiler room, kitchen, and bathroom can be moved there.

Additional design information

The table below provides information regarding certain aspects of residential design.

House shape

Houses with a rectangular shape in projection are considered the most convenient, as they make it possible to get a house of a fairly large area. Moreover, you can build such a house yourself if it does not have any complex architectural elements.

Availability of a veranda

Not every home needs a porch. It is not recommended to install it immediately. The same applies to balconies, and in small houses an 8x10 balcony can look completely inorganic. If you want to have a veranda, then it is better to add it some time after the construction of the house. This recommendation is related to the possibility of shrinkage of the house after construction.

Ladder

The staircase, if the house is two-story and is intended for permanent residence, must be located inside the house. If this is a country house, then it can be placed outside.

Bathroom

One bathroom is enough for an 8x10 house with one floor. If there are two floors, then there should be two bathrooms, one on each floor.

Utility premises

Do not neglect utility rooms - they should be there. Often they are not thought about when designing, and then it turns out that there is nowhere to store a number of things that are periodically needed in a private home.

Material purchase

In most cases, it makes sense to consult a specialist about the characteristics of the brick you are purchasing.

However, you can take into account the recommendations below. It is best to buy different bricks (facing and ordinary) that have approximately the same characteristics, which will make it possible to create a structure with uniform properties.

It is better to purchase bricks to build a house in one batch. Keep in mind that prices are usually lower in winter, but it may be difficult to organize brick storage on site.

Please also note that there are no defects upon purchase. High quality bricks ring when struck and have a richer core color.

It is necessary to ensure against purchasing bricks that are not fully fired, which have a characteristic mustard color and make a dull sound when struck.

By purchasing such bricks cheaply in the winter, by the time construction begins, you risk getting a mountain of brick chips, suitable only for sprinkling dirt paths. Attention! When choosing a project, you should remember that brick, cellular concrete and warm ceramics are usually interchangeable materials. Therefore, you can expand your choice by also considering cottage projects made of cellular concrete as if they were made of brick.

How to design a house?

Step 1. The first step is to choose an approximate version of the house in which you would like to live. So, to do this, you can visit house exhibitions, showrooms, and also just walk around the villages and see what houses others live in. Perhaps this is how you will be able to find your dream home and decide on a project.

Step 2. As a rule, visiting your neighbors often helps you find inspiration or at least decide on the type of home you want to have. So it is advisable, without delay, to pay a visit to those neighbors whose houses you really like.

Step 3. Don’t be shy to take pictures of the options you like or save projects that interest you to your library. Then, from all the sorted options, it will be easier to choose your dream home.

Step 4. It is recommended to keep a notebook in which you will keep notes about what kind of house you like, what should be in the house, what budget is expected to be allocated for building the house, what materials can be used to build the house, etc.

Step 5. Next you need to choose the place where the house will be built. It can influence the design process. For example, the close occurrence of groundwater will not make it possible to equip the basement. Or maybe its presence is the owner’s dream?

Step 6. It is recommended to entrust the creation of the project to experienced specialists who will take into account all wishes. But sometimes you can do the design yourself, while periodically resorting to the advice of architects.

Step 7. The first rough plan of the house can be sketched simply by hand. Then you should definitely detail everything, indicating all the sizes of the rooms, locations of communications, etc.

Step 8. It is better to make a full-fledged house plan in some special program on a computer. In this case, it will be easier to identify any errors at the design stage. It is important to understand that there should be no mistakes in the project right before building a house, otherwise the desired version of the house may not be realized later.

Cost of construction of a turnkey SIP house*:

| Domokomplekt | №1 LUX | №2 PREMIUM | №3 STANDARD | No. 4 GARANT | |||

| Cost of a house kit (factory-ready house with porch and veranda) | 580 370 | 544 001 | – | 418 687 | |||

| Warranty and production | |||||||

| Warranty for house kit* | 10 years | ||||||

| The house kit is made from three-layer SIP panels produced using SIPWALL (EKOPAN) technology at our own factory located in the city of Shuya, Ivanovo region. When manufacturing a prefabricated panel-frame house, only planed, chamber-dried lumber is used, treated with the fire-bioprotective composition “Wood Shield” in the factory. All SIP panels of the house kit are manufactured in accordance with the design design documentation developed by the SIPWALL company’s own design department, and covered with dry planed lumber. When leaving the SEEPWALL factory, the house kit is 99% complete. | |||||||

| Working documentation | |||||||

| Sketch design (DS) of a house (standard/individual) | X | X | X | X | |||

| Constructive documentation (CD) for the assembly of a house kit, developed taking into account the strength calculations of load-bearing structures. | X | X | X | X | |||

| Foundation piping | |||||||

| Wooden grillage 200 x 150 | X | X | X | X | |||

| Overlap at mark +0.000 | |||||||

| Three-layer reinforced SIP panel SIPwall 224U/174U mm (OSB-3 12 mm “Kalevala” Russia/EGGER*, facade self-extinguishing polystyrene foam PPS 14 200/150 mm, Russia), sewn-in structural lumber, kiln-dried, planed, treated with fire-bioprotective composition “Wood Shield” » in factory conditions. | X | X | X | X | |||

| External walls | |||||||

| Three-layer SIP panel SIPwall 174 mm (OSB-3 12 mm “Kalevala” Russia/EGGER*, façade self-extinguishing polystyrene foam PPS 14 150 mm, Russia), sewn-in structural lumber, chamber-dried, planed, treated with fire-bioprotective composition “Wood Shield” in the factory. | X | X | X | X | |||

| Internal walls - interior, load-bearing | |||||||

| Three-layer SIP panel SIPwall 174 mm (OSB-3 12 mm “Kalevala” Russia/EGGER*, façade self-extinguishing polystyrene foam PPS 14 150 mm, Russia), sewn-in structural lumber, chamber-dried, planed, treated with fire-bioprotective composition “Wood Shield” in the factory. | X | ||||||

| Wooden frame with a cross-section of posts 37x147 (kiln-dried lumber, planed, treated with the fire-bioprotective composition “Wood Shield” in the factory). | X | X | X | ||||

| Internal walls - interior, non-load-bearing | |||||||

| Three-layer SIP panel SIPwall 124 mm (OSB-3 12 mm “Kalevala” Russia/EGGER*, façade self-extinguishing polystyrene foam PPS 14 100 mm, Russia), sewn-in structural lumber, chamber-dried, planed, treated with fire-bioprotective composition “Wood Shield” in the factory. | X | ||||||

| Wooden frame with a cross-section of posts 37x97 (kiln-dried lumber, planed, treated with the fire-bioprotective composition “Wood Shield” in the factory). | X | X | X | ||||

| Interfloor ceiling | |||||||

| Three-layer reinforced SIP panel SIPwall 224U/174U mm (OSB-3 12 mm “Kalevala” Russia/EGGER*, facade self-extinguishing polystyrene foam PPS 14 200/150 mm, Russia), sewn-in structural lumber, kiln-dried, planed, treated with fire-bioprotective composition “Wood Shield” » in factory conditions. | X | X | |||||

| Wooden beams with OSB-3 subfloor covering 22 mm thick (kiln-dried lumber, planed, treated with the fire-bioprotective composition “Wood Shield” in the factory). | X | X | |||||

| Second floor ceilings and/or attic roof | |||||||

| Three-layer reinforced SIP panel SIPwall 224U/174U mm (OSB-3 12 mm “Kalevala” Russia/EGGER*, facade self-extinguishing polystyrene foam PPS 14 200/150 mm, Russia), sewn-in structural lumber, kiln-dried, planed, treated with fire-bioprotective composition “Wood Shield” » in factory conditions. | X | X | X | ||||

| Wooden beams/rafter system for insulation. | X | ||||||

| Beams - load-bearing structures | |||||||

| Set of beams, racks (stitched/glued). (kiln-dried lumber, planed, treated with the fire-bioprotective composition “Wood Shield” in the factory). | X | X | X | X | |||

| Porch, terrace, canopy, balcony | |||||||

| Lumber necessary for the manufacture of the structure. | X | X | X | X | |||

What to build an 8 by 10 house from

We have a detailed article for each material. We will provide links so you can learn more about the option you are interested in.

Next, we will briefly describe everything important. Just the basic tips for building a comfortable, warm and reliable one-story 8 by 10 house.

Concrete blocks

There are many of them produced and they use different technologies. We have already described: sibit - especially durable and reliable; foam blocks - in which bubbles are formed due to additives; aerated concrete - cavities in it arise due to a chemical reaction. Each block has its own characteristics. But there are also many general pros and cons.

The advantages of concrete blocks are lightness, better insulation, low weight, and good sound insulation. It is easier to build a house from them; you can do without special equipment. They are easy to cut to shape, groove channels, and round corners. By themselves, they retain heat well and protect rooms from noise.

The disadvantages of concrete blocks are low tensile strength and absorption of large amounts of water. Therefore, they need a monolithic foundation, which is more expensive than piles, and good waterproofing. Otherwise, the house will stand without cracks for a maximum of 5 years.

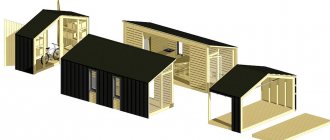

Frame

For fast and cheap construction. In frame houses, a skeleton is first made of wood and metal, which is then filled with insulation and covered with wood wall panels. The result is a warm and reliable sandwich.

The technology has two approaches to construction.

- The first is to make a construction kit at the factory and bring it to the construction site. This approach is used for SIP panels. At the factory, wall panels are made from wood and insulation between them, and the frame is cut. Then all this is delivered along with instructions and you can assemble the house in 2 months.

- The second option is to do everything separately. First, they install the frame, fill all the cavities, and cover them with wall panels. If you want some special insulation or non-standard fastening of corners for better thermal insulation, this is your option.

On average, frame houses are light, simple and cheap to build, and warm. The exact pros and cons depend on the materials chosen.

Tree

The choice for building a home in traditional and modern style. It all depends on the choice of material.

- Log house - for lovers of naturalness. These are logs in which they made bowls for stacking on top of each other. Virtually no additional processing - only impregnation after construction.

- Warm log house

- It doesn't require any additional sheathing so you can heat your home cheaply. It is important to choose the correct log diameter for the region. This is the only way the walls will cope without insulation.

- The log house will shrink. The house needs to be given approximately 6 months to take its final shape. After that, caulk the cracks, install windows and you can move in.

- Timber is for modern houses. The wood is cut into equal blocks, dried, packaged and sent to the construction site. The exact features and production technology depend on the type of timber.

- Profiled timber is simply cut and dried wood. No special characteristics. Requires insulation and time for shrinkage.

- Glued laminated timber is wood plates that are glued together. They arrive at the construction site with optimal humidity, so there will be no shrinkage. Remember, modern adhesives are safe and wood does not emit harmful substances.

- Double timber - wood on the outside and insulation on the inside. This is a combined material that looks like a frame. Lovers of natural finishes will like it and will additionally insulate the house.

Regardless of the type of wood chosen, it needs regular treatment with bio- and fire protection. It must be updated according to the recommendations of the manufacturers. Usually once every 10-20 years. Without impregnation, the wood will rot faster and lose its quality.

Brick

For the construction of a reliable one-story house 8 by 10. The most classic building material, but quite expensive.

It is important to choose the right type of brick in terms of strength - this is the letter M in the characteristics, and frost resistance - the letter F. For load-bearing walls you need an indicator of M-150 and F-150, for internal walls - M-125 and any F.

Pay attention to the additional brick parameters. Options with increased fire resistance are needed for the construction of a fireplace area. Additional water resistance will be useful in the sauna and bathhouse.

Brick necessarily needs hydro- and thermal insulation. Without them, the house will be very cold in winter.

1958 April 22

Enlisted in the lists of Navy ships;

1958 December 20

Laid down on the slipway of the shipbuilding plant named after.

Lenin Komsomol in Komsomolsk-on-Amur as the lead cruising submarine of Project 659 .

The crew, after formation and training, is subordinated to the 80th BrSPL Pacific Fleet; 1960 May 12

Launched;

1960 June 1 - September 18

Factory mooring tests have been carried out. Since 10.9, comprehensive tests were carried out, during which the nuclear power plant was brought to 60% power, then the reactors were cooled down, identified defects were eliminated and the ship was placed in a transport dock;

1960 September 25 - 29

Transferred in a transport dock along the Amur River from the plant to Chikhachev Bay. After leaving the dock, the submarine anchored to prepare for the launch of the reactors;

1960 September 29 - October 2

Factory sea trials have been carried out. At 0.05 on September 30, after the launch of the nuclear power plants on both sides, it began moving under its own power to the bay. Pavlovsky. The transition took 48 hours at an average speed of 14.6 knots, while the reactor power did not exceed 35%. The voyage was carried out with unfinished adjustment of the ship's ventilation, unfinished work with the TA and torpedo-loading device, and missile containers. During the mooring tests of the AB with a ventilation system, some operating modes of the NPP were not accepted. Despite this, during the transition it was possible to check and accept the full speed mode in the surface position, the operation of the rudders and anchor device, echo sounder, log, and determine the diameter of the circulation. At 0.13 on October 2, the first nuclear-powered icebreaker built in the Far East arrived at the outfitting base of plant No. 199. During the transition, 270 defects and comments were identified;

1960 October 2

Became part of the 9th Submarine Submarine (from 06/15/1961 - 26th Divisional Submarine) Pacific Fleet, based in the bay of Pavlovsk Bay Strelok (Fokino village);

1960 November 19 - 1961 June 28

The state sea trials program has been completed.

On the first trip to sea (11/19-11/27), we were able to test the nuclear power plant in all modes, obtaining a surface speed of 15 knots. and underwater 24 knots. The Nichrome and Albatros systems were tested and accepted. The ship was controlled well (a smaller circulation diameter than planned was obtained). The emergency blowing time from the periscope position was 70 s (instead of 200 s according to the specification). However, there were also shortcomings: more than 400 comments were identified regarding the operation of the equipment, the main of which were a leak in the 1st circuit with an intensity of 15 l/h and failure of both vacuum compressors. When going out to sea, we had to change the filters four times. On January 2, 1961, the KrPL carried out missile firing, which revealed design flaws in the hydraulic system, gas outlets, container heating system and in the Sever-A659U firing control system. March 1, during a deep-sea dive in the b. Valentina, sea water began to flow into the central air and compartment VI. It was also found in the air pressure system, which led to water hammer and damage to the system. After the KrPL surfaced, water also appeared in missile container No. 1. On April 16 and 26, rocket firing was repeated, but again without success. The unsatisfactory design of the gas outlets of the middle and aft containers led to the fact that the main engines stalled at the moment of launch, and the rockets fell in the launch area. In addition, the seals on the rear lids of the containers were torn out of their sockets. The disconnection of the side connectors was not carried out reliably, and systematic cases of deviation of the missile impact points to the left were noted. On May 24, the P-5 complex was tested by firing 4 missiles. The tests were successful. In total, during the test, the K-45 carried out four missile firings of the 13th missile launcher.

The launch of seven missiles had to be cancelled, which corresponded to a launch failure rate of more than 50%. 400-mm caliber TAs were tested by shooting with water, because There were no torpedoes of this caliber available. Tests of the MG-10 sonar were carried out according to Project 56 EM. The detection distance of an NK traveling at a speed of 18 knots with a nuclear submarine speed of 4.5 knots was 75 cables in the noise direction finding mode. The means of communication were accepted by the commission (with the exception of the Iskra radio transmitter). When testing the ship, the nuclear power plants on the starboard and port sides worked for 1700 and 1630 hours, respectively. At the same time, for 18 hours the reactors operated at 80% of the nominal power. The final data on the organization of tests of the first nuclear submarine of the Pacific Fleet show that the duration of factory sea trials was only two sea days, and the total duration of State tests was 222 days. Of these, only 34 were operational, during which the KrPL covered 3,840 miles in a surface position in 445 hours, and 2,560 miles in a submerged position in 223 hours. It took 140 days to eliminate defects in the missile system. The control exit took place on May 29. Eliminating the identified issues took almost the entire next month; 1961 June 28

The acceptance certificate has been signed. Came into operation. Responsible deliverer - Yu.I. Khvalin, Chairman of the State Commission - Rear Adm. Ivanov;

1962 May - 1964 January

Was under warranty repair;

1963 May

The 185th crew of the KrPL

Project 658 was reorganized into the crew of the KrPL Project 659 for the KrPL K-45 ;

1964 November 4

Became part of the Pacific Fleet;

1964 December

Transferred to the 45th DiPL of the 15th Special Submarine of the Pacific Fleet KchVFl, based at Krasheninnikov Bay (Vilyuchinsk);

1964 - 1966

Made 2 autonomous trips to the BS with a total duration of 90 days;

1966

Worked on BP tasks, tested new equipment, trained new crews;

1966 September

Transferred to the 26th DiPL KTOF based at Pavlovsky Bay in Strelok Bay (Fokino village);

1966 (probably)

The 185th crew of the KrPL

Project 659 was reorganized into the crew of the KrPL Project 658 for the KrPL K-16 ;

1966 October - 1970 September

She underwent repairs and re-equipment into a torpedo submarine according to Project

659T at the Zvezda Shipyard in the village.

Bolshoi Kamen (Primorsky Territory). According to other sources, repairs took place from December 31, 1966 to September 12, 1968. The crew was subordinate to the 72nd OBrSRPL KTOF; 1970 September 30

The acceptance certificate was signed and it was put into operation. Responsible deliverer - Rybak V.A., Chairman of the State Commission - Cap. 1r. Lemin. Upon completion of the modernization, it was returned to the 26th DiPL (from November 30, 1978 - 4th FPL) KTOF;

1970 October 20

Assigned to Project

659T ;

1971 August 19

At the control exit to the sea of the submarine

S-222 K-45 of project 659T , which was on the surface . S-222 submarine received holes in the starboard main tank Nos. 1, 2 and 3; all four tubes were bent, three of which contained live torpedoes.

There were no casualties; 1972 May 9 - June

Together with

K-184 and K-57, it was deployed on alert in the Gulf of Thin in the South China Sea to monitor US aircraft carrier forces. K-45 was

later 1972 - 1974

Made an autonomous trip to the BS lasting 48 days;

1975 December 27 - 1976 February 15

Completed autonomous BS tasks in the Philippine and South China Seas for 51 days;

1976 November 20 - 1977 May 1

Completed the tasks of an autonomous BS (commander - Capt. 2nd R. Zavarukhin G.M.) in the Indian Ocean for a duration of 163 days (of which 89 running days) with resupply in the Berbera (Somalia) PMTO. During the BS in the Indian Ocean, it was subordinate to the 8th OpEsk;

1977 July 25

Reclassified as a large submarine;

1977 May - 1978 May

It was undergoing ongoing repairs at the Zvezda plant in Bolshoi Kamen. The crew was subordinate to the 72nd OBrSRPL KTOF;

1979 December 16

At sea, an increase in gas activity in the nasal apparatus baffle to 49 MAC was detected. PPU LB was withdrawn from action. However, the cause of the leak could not be found at sea. And only on April 14-15, 1980, it was established that there was a leak in the 1st circuit in the LB reactor cover due to a violation of the liner density;

1981

The reactor cores at SRZ-30 in Chazhma Bay were recharged (according to other sources, the recharge was carried out during repairs in 1977-1978). The crew is subordinate to the 52nd ODnRPL 4th FPL KTOF;

1981 September 10

The submarine went to sea (commander - Capt. 2nd Rank. Konev A.V., senior on board - KD Capt. 1st Rank. Samoilov Yu.M (A?).) to conduct a deep-sea dive in the area of Kit Bay.

During the transition to the combat training area, the ship's commander was on the bridge. Wind with a direction of 165° (5 m/sec) and sea state of about 1 point with full night visibility did not cause difficulties in controlling the submarine. By order of the operational duty officer of the Pacific Fleet, the submarine set a heading of 0° and followed at a speed of 12.5 knots. The radiometrist reported on three clusters of fishing vessels and the boat commander decided to switch to electric motors to facilitate maneuvering. The division commander ignored this decision of the commander and ordered to leave the previous mode of movement. While approaching groups of surface targets, the submarine made several course changes within 5-6 minutes (by 05.39). The submarine did not take safety measures appropriate to the situation of approaching an area constrained by navigation. Combat readiness was not increased, the combat information post was not functioning, and the officer on watch was sent by the commander to the radio room for the next radio communication session. The commander believed that all detected targets were drifting and did not take any action even after the radiometrician’s report about the unchanged bearing and the reduction in distance. Meanwhile, R was quickly approaching the submarine, against the backdrop of the ships’ lights, this RTMS maneuver was not noticeable. At 06.03 the distance was already less than 5 cables and the trawler suddenly turned sharply to the left. The submarine commander suddenly discovered the red side light of an unknown vessel and ordered the signalman to fire a red flare and flash a series of spotlights in the direction of the approaching vessel. Command “Left aboard!” and “Reverse!” were late and at 06.05 the submarine K-45 collided with the trawler, ramming it with its bow.

A hole measuring 3.5 m x 6.0 m was formed on the side of the trawler, and severe damage to the bow of the light hull and hydroacoustic stations was noted on the submarine. None of the crews on the submarine or RTMS were injured. Samoilova Yu.M (Ah?). removed from his post and transferred to the reserve. RTMS and KrPL were put in for repair; 1981 October 15 - 1982 February 20

Passed emergency repairs;

1983 June 1

It was relocated to Postovaya Bay (Sovetskaya Gavan village) and transferred to the 28th DiPL of the Sakhalin FlRS (from 07/01/1990 - 60th BrPL of the reserve of the Sovgavan Naval Base) KTOF;

1983

Completed combat service tasks lasting 53 days;

1984

The crew confirmed the title of “excellent”;

1984 - 1985

She made an autonomous trip to the BS for a total duration of 257 days, covering 1,226 miles over water and 17,747 miles under water. Made a call at Cam Ranh (NRT);

1986 - 1988

After 9 months of combat service, she was undergoing mid-term repairs at the Zvezda plant in Bolshoy Kamen with inspection of the PPU, replacement of pipelines of the hot water pressure and third circuit systems. The crew was subordinate to the 72nd OBrSRPL KTOF;

1989 May 30

Expelled from the Navy in connection with the surrender to the OFI and in Chazhma Bay (Danube village) laid up (for unloading spent nuclear fuel) as part of the 52nd ODnRPL 4th FlPL KTOF (from 1992 - 8th OBrRPL Pacific Fleet), later transferred for storage to Pavlovsky Bay as part of the 26th DiPL of the 4th FlPL (from 01.08.1994 - 3rd EskPL, from 01.11.1996 - PrFlRS) Pacific Fleet;

1992 April 28

Possibly renamed

B-45 ;

1995

Work was completed to prepare for long-term storage afloat at the base;

1999 (approx.)

Disposed of at the Zvezda Shipyard in Bolshoy Kamen with the formation of a reactor block, which was left afloat in Razboinik Bay for temporary storage.

In total, since its construction, the K-45 has traveled 197,894 miles in 24,907 running hours.

Interior style

With a wide variety of layouts for residential buildings measuring 8 by 10 square meters. m, these days there are many options for styles of both interior and exterior decoration:

- For country houses, finishing made from natural materials such as wood and stone is suitable. You can cover all the walls with clapboard, imitation timber or block house. In addition to the fact that this option will look natural, it will also be very environmentally friendly. If your house is made of logs, then the walls can not be finished with anything, but the logs can be coated with special compounds. To this interior, you can add a fireplace in the living room, and the comfort of your home is guaranteed.

- For lovers of modern designs, Scandinavian style or minimalism is suitable. Then, most likely, the building will be built of brick, and the interior finishing options will be no different from apartment ones. Remember that light walls always visually enlarge the space, while dark walls “eat up” it.

- Panoramic floor-to-ceiling windows will bring a lot of light into the room. You can make windows and doors opening onto the veranda. It will be not only functional and convenient, but also beautiful.

- If you want a house in a classical, baroque or rococo style, then it is better to consider a two-story building with a basement, because these styles will require more space for both wall decoration and furniture.

- An English-style interior is perfect for a private home. A fireplace, rocking chair, bookshelves, a sofa upholstered in dark leather - all this will create coziness in your home. And the abundance of natural materials will add environmental friendliness.

Remember that the correct shape of the house will cost you less, and the curvature of the walls will make the structure more unusual and interesting.

Types and brands of bricks

It is important to clearly distinguish between facing and ordinary bricks.

Ordinary is mainly used for internal masonry and in the construction of load-bearing structures. Its surface is embossed. Facing bricks often have a more uniform shade of finishing surfaces (“spoons” and “pokes”), and they may be hollow. When choosing a brick, it is advisable to carefully choose its brand and pay attention to its frost-resistant characteristics. To build a multi-story building, you need brick grade M150 or higher. The material must withstand a load of up to 150 kg per square centimeter. And for the construction of a two or three-story house, “weaving” (M100) is also suitable. The resistance of bricks to frost is measured in cycles and designated as “Mrz”. This characteristic is determined by testing the brick under special conditions. In the middle zone of our country, it is advisable to construct an external wall from frost-resistant bricks (more than 35 cycles). Their width must be at least 85 mm. Open areas of walls exposed to strong external factors should be constructed from wider bricks.

Briefly about the main thing

- Houses 8 by 10 are universal. They are suitable for singles who want a country house. Those who like to invite guests. Married couples. There are a lot of layout options.

- The ideal layout is the one you like. Think about what you usually do around the house. Imagine the optimal set of rooms. This is the only way to choose a suitable project.

- Experiment. Don't be afraid to make rooms unique. Separate gym, children's entertainment center, billiard room. Focus on your convenience.

- Communicate with the architect. The most important advice. Always talk to the architect. Tell us what you want to get in the end. Perhaps he will be able to offer interesting options for redesigning the layout.