Why do you need a pendulum stroke on a jigsaw?

The primary task of the pumping mechanism is to increase the cutting speed, due to a slight loss of quality.

The function is successfully used for a large volume of work with large products. Due to small vibrations, the pendulum stroke in the jigsaw increases the efficiency of the movements of the saw blade, causing it to “bite” into the material with force. In addition, such an amplitude contributes to the effective removal of sawdust from the sawn groove, which increases the immersion of the blade teeth, further speeding up the cut. The advantages of a pendulum motion come down not only to the speed of work, but also significantly reduce the heating and wear of the saw. This effect is most noticeable when cutting thick wooden pieces, more than 40 mm thick. In addition to preserving the saw blade, activated pumping reduces the heat of the tool itself, allowing it to work for a longer time. Thus, reciprocating movements, supplemented by a pendulum amplitude, will be able to saw through many times more material with one saw, while maintaining the working life of the engine than without it.

The main disadvantage of the function is definitely the low quality of the cutting line with increased chipping along the edges. The pump is absolutely not intended for figure sawing and working with ceramics, stone and hard metal alloys. If we say in a nutshell what the pendulum stroke of a jigsaw is, then we can give a fairly short and succinct answer. This is one of the most important additional functions, used in large volumes of work to perform fast but rough cuts with minimal wear on the saw blade.

On average, on modern models of jigsaws there are 4 levels of pumping, where 0 is its complete absence and 3 is maximum fluctuations. Each value is designed to perform specific types of work.

Why is it needed and what is it?

The pendulum stroke, or as it is also called, “pumping the jigsaw,” is an internal mechanism for increasing the amplitude of movement of the saw blade relative to the cutting line.

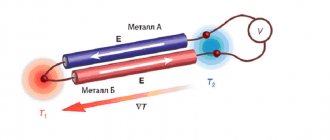

In this case, the cutting blade produces oscillatory movements due to the influence of the support roller. The main source is the balancer, and at the bottom of it is a thin plate of iron. During rotation of the gearbox, oscillations from the pump, that is, the pendulum, are triggered, and this leads to the transfer of impulse to the rod. This will mean that the file is able to change the course of movement, as if biting into the surface of the material. After turning off the function, the electric jigsaw makes standard movements, and thanks to this, it is possible to achieve uniform cutting. When the pendulum stroke starts, it becomes possible to work with larger and softer materials, as well as to make the most complex cuts.

Why is pumping adjustment required?

Why do you need a pendulum in a jigsaw? It is this, or rather the pendulum stroke itself in an electric jigsaw that makes it possible to change the oscillation and mode of motion of the sawing device. Most modern models have from 1 to 4 levels of pumping for different types of work or material densities. The most common modes are the following:

- The pendulum stroke will not start or even operate at minimum power. It is perfect for making straight and curved cuts. It is most often used for hard metal, as well as wood blanks with a thickness of up to 3 cm.

- Minimum level of pendulum stroke. This mode is perfect for working with soft wood, as well as aluminum and copper (i.e. soft metals).

- A medium level of vibration is required in order to cut plastic and wood with a thickness of 40 mm or more.

- High or maximum swap mode. It is required to roughly saw wooden surfaces, as well as to work with large-sized products.

Running the pendulum on an electric jigsaw will increase wear on the saw blade. When working with a large volume of materials, where a neat cut is needed, the cutting surface will wear out two to three times faster.

Please note that the blade for an electric jigsaw should be selected taking into account the material of the workpiece. Files for plastic, metal and wood differ in the size of the teeth, as well as the degree of sharpening

Advantages of use

More and more manufacturing companies are releasing device models with a paging function. It increases the number of options for operating the device.

The advantages of such devices are as follows:

- Very high speed of the cutting blade.

- Ability to cut plastic, as well as different types of wood, foam and steel sheets.

- Quick removal of emerging sawdust.

- The blades heat up less during sawing.

Due to the fact that the pendulum stroke has become very popular, an electric tool such as a jigsaw is practically no different in cost from simple electric jigsaws. This function will be very useful for both professional tasks and everyday tasks.

Disadvantages of use

Despite the many advantages of using a pendulum stroke, there are also certain disadvantages.

Let's consider the following disadvantages of models with a pendulum:

- Chips appear at the edges of the lines, and there are also uneven cuts.

- It cannot be used for figure sawing.

- The pendulum stroke will not work when cutting ceramic tiles or hard metals.

Manufacturers advise choosing a device model taking into account the specific tasks you set for the tool. Each device with a pendulum has the ability to turn it off, and this increases the variability of use of the electrical device.

Please note that when choosing a model, you should pay attention to how smoothly the swap mode switches. This will make it possible to avoid various damage to the cutting line during work.

The principle of operation of a pendulum

A convenient and definitely useful function, it has a very simple and yet reliable device. The pendulum stroke of the jigsaw works on the principle of swinging, for which it is often called “pumping”. The movements that cause the end of the file to perform pendulum oscillations come from the support roller. The source of such movements is a massive balancer, at the bottom of which there is a thin metal plate. As the gearbox rotates, the balancing element, together with the rod, perform reciprocating actions, and if the latter transmits them to the saw, the former exerts pressure on the pumping mechanism. To take a closer look at how the pendulum stroke of a jigsaw works and understand what it is, the following photos and video will help you.

In the material presented above, the paging function is not active. In this case, the movement of the balancer with a metal plate is quite clearly visible, which can rest against the cylindrical element when it is tilted. Thus, when the inclination of the part increases, by switching modes on the tool body, it will be in the path of movement of the metal plate, which will push this part and the support roller connected to it. Return to the original position is accomplished using a conventional spring.

Mechanical problems

Difficulties that arise during long-term operation of a jigsaw can be divided into planned and emergency. The first includes, first of all, normal wear of the graphite brushes of the engine. Emergencies include a wide variety of breakdowns of tool components or parts thereof. Let's look at some typical cases.

The saw moves to the side, the cutting line is not straight

Most often, this problem occurs among inexperienced users. They violate two basic rules of operation. The first is obvious. The saw must be sharp, have a tooth configuration appropriate for the material, and be properly secured in the clamp. Not everyone knows the second rule of work. The body of the jigsaw should be positioned in the direction of the cut. Similarly, efforts are made for its forward movement. And the latter should ideally be minimal. That is, you cannot put pressure on the instrument. A straight line and an angle of 90 degrees between the cutting planes will be obtained by themselves if the saw manages to remove the material being processed without effort.

There are also mechanical reasons for saw deflection. It is necessary to check the backlash of the support roller. If it is significant, the part or assembly is replaced entirely. The saw fixation block on the rod is also examined. He must bring the latter close to the support roller and maintain the perpendicularity of the web to its axis.

If the saw moves to the side, it is worth checking the support roller

The most serious problem is wear of the rod or its horizontal displacement limiters. Damage to parts can only be determined after disassembling the housing. If removing contaminants in the pendulum block does not solve the problem, the rod must be replaced.

Vibration and noise

If the tool is difficult to hold in your hands or is abnormally noisy, you should begin your inspection with the worm gear unit. This is the large gear or connecting rod of the pendulum mechanism, a bushing with spiral projections on the motor shaft. Vibrations and noise occur when teeth are chipped or there is excessive accumulation of dirt mixed with old lubricant. If there is no visible damage to the worm gear components, the tool may need cleaning and lubrication.

Sharp shocks

When a jigsaw literally hits the palm of your hand when working, this is a clear indication of problems with the pendulum assembly. The cause is most likely a damaged worm gear. Rarely, runout occurs due to deformation of the connecting rods. And even less often due to dirt accumulation. However, the latter must be removed first. Especially on the worm gear mechanism.

Contamination in the worm gear assembly can cause tool malfunctions

Blade holder faults

Many modern jigsaws are equipped with bells and whistles, which are their weak points. For example, some models often require repair of the saw blade mount due to the presence of such functions.

- A quick clamp that does everything for the tool owner: just move the lever, place the blade and work. Over time, the structure becomes loose and fastening parts become unusable. Unfortunately, most of these clamps cannot be repaired; they must be completely replaced.

- Lightweight screw fastening is a real problem for owners of cheap and mid-price tools. The rod attachment, made of weak alloys, has low strength, breaks, and the bolts break the seats. Repair consists only in the handicraft production of the appropriate product from durable steel, since each line of cheap tools often has its own saw blade holder configuration.

If the jigsaw has a classic screw fastening of the file, then repairing it will not be difficult. This is a durable and time-tested design; you can use bolts for a Phillips screwdriver or a wrench. The clamping blocks are standard; finding a replacement for an extremely worn part is not difficult. There is a problem with thread wear, but in this case a new one can be cut.

Device

A hand jigsaw is a technically simple tool. It consists of a metal arc. A sawing mechanism is attached between its tips. A handle is attached to one of the ends of the arc, by which the jigsaw can be held while working. The main element of a manual jigsaw is the saw blade, because the efficiency of the entire sawing process will depend on its quality and sharpness.

The main mechanism in an electric jigsaw is the file. It can produce back-and-forth movements with great frequency. The file is driven by an electric motor, which is located in a housing with a handle. The handle is necessary to regulate the cutting directions. The metal base in a jigsaw is used as a support during the cutting process.

The sole is the most important part of a jigsaw

The sole is made depending on the purpose of the tool - household or professional. It is important to decide on the required type of sole, since choosing a jigsaw with a cast platform is more profitable than with a stamped one. It provides better cutting if the following conditions are met:

- anti-splinter liner installed,

- the canvas is selected and secured correctly.

The alloy of the cast sole consists of aluminum with the addition of elements that increase its strength. If a particular model does not have an anti-splinter liner, there should be a function to move the “ski” back. In both cases, the likelihood of chipping is reduced, which makes working with metal easier. The insert is a plexiglass plate in which the file is located. You can make it yourself, taking into account the thickness and width of the canvas.

Files: different types and methods of fastening

A competent choice of a jigsaw file is a guarantee of a high-quality cut. They are divided according to the type of material being processed. Depending on it, they have different following parameters:

- tooth pitch and shape,

- geometry and width of the canvas,

- file thickness.

For wood processing, saw blades with a tooth pitch of 1.2-3 mm are used. Metal and plastic are sawn with a wavy blade, the teeth of which deviate alternately to the left/right. For cutting leather, cardboard, polystyrene foam, and rubber, a blade with a wavy sharpening is used. Also, the choice of file depends on the thickness of the material being processed.

For example, for sawing thin metal up to 1.5 mm thick, a wavy blade with a small tooth pitch is used. For processing metal up to 30 mm thick, choose a file with pointed teeth and a back angle. If the cutting element contains nails, use a blade with a rare pitch of teeth. The distance between them is 1.8-2.5 mm.

The methods for attaching the saw blade to a jigsaw depend on its model. The following varieties exist:

- slotted pads,

- quick clamping system.

Each of them affects the performance of the tool and the accuracy of the cut. It is important that changing the saw blade during operation is quick, comfortable and reliable. The slotted pads are clamped with two screws located at the front. The file is held in a clamped slot. Quick-clamping systems are easy to use and require the use of blades of a certain thickness. This limitation is not significant, since the retail chain offers a huge selection of them.

Jigsaw design

Ergonomics and ease of use also depend on the design of the tool. For example, the shape of the handle affects the quality of the cut if the jigsaw must be driven from below the material being processed. For the convenience of carrying out just such work, a jigsaw with a mushroom-shaped handle is produced.

There are also jigsaws with a transverse fastening of the blade, a protective screen, a laser sight, and a flashlight for illumination.

The cost of a jigsaw is influenced by the number of additional functions, the shape of its body, as well as its purpose: household or professional. The household one has fewer speeds (standard 6-8), low power, and the most necessary functions. Intended for occasional use, and its price is quite low.

Professional modern jigsaws are additionally equipped with a starting current limiting system, which guarantees a soft start. This is important when carrying out particularly precise, high-quality work. There are also battery-powered models, which accordingly have low performance and power.

Tips for use

Before you start using this tool, carefully read the following tips from experienced professionals.

- Do not put too much pressure on the tool while working. It is enough to simply hold the jigsaw firmly in your hand.

- To make an accurate cut, the workpiece must always be well secured.

- You can reduce vibration when processing thin sheets of metal by placing a sheet of plywood under it.

- If you stick tape along the marking line, the likelihood of chipping will be minimal.

- When sawing plastic, it is recommended to use the lowest speed of the tool.

- To properly cut plexiglass or non-ferrous metals, thoroughly treat the saw with machine oil.

Tool storage

In order for a tool to serve for a long time and properly, it is important not only to follow the rules of its operation, but also to store it correctly. The best option is to keep the jigsaw in a case from the manufacturer.

This suitcase is convenient both for storing spare parts and for transportation. But the instrument is not always sold with a case. In this case, you need to know that a jigsaw, like any power tool, is afraid of water and excess air humidity. Therefore, it must be stored in a dry, well-ventilated place. A cardboard or wooden box will serve as protection from mechanical damage. If the warehouse is unheated, then in the cold season, before starting work, the tool must “thaw” in a warm room for 20–25 minutes. During this time, the gearbox lubrication will become elastic again.

Standard case for storing and transporting a Makita jigsaw

When using a jigsaw at home, you should not neglect the rules of personal safety. While working, you cannot be distracted, talk on the phone or do other things. To protect your eyes and respiratory system, it is recommended to use a respirator and safety glasses. The use of homemade attachments is justified when they do not pose a health hazard and have successfully passed preliminary tests.

What is a pendulum stroke?

The pendulum stroke or so-called “pumping” increases the speed of cutting the material. It is especially effective when working with large-sized materials. Small vibrations during the pendulum stroke increase the efficiency of the saw’s movements and force it to “bite” into the surface. In addition, this amplitude removes sawdust well from the holes being cut. As a result, this increases the penetration of the teeth and speeds up the cut.

The pendulum stroke of the jigsaw is carried out according to the principle of swinging. The file produces pendulum vibrations under the action of the support roller. The source of these movements is a large balance beam, at the bottom of which there is a thin metal plate. As a result of rotation of the gearbox, the balancer and rod produce reciprocating movements. The balancer presses on pumping, and the rod transmits movement to the saw.

When the pendulum function is not turned on, the saw moves up and down and produces an even cut. Almost all models of jigsaws have adjustment of the amplitude of the stroke pendulum.

It is carried out by a special switch. This helps to select the optimal sawing mode for a particular material. A large number of control stages helps to more accurately select the correct tool setting and find a balance between speed and evenness of the cut.

How to choose?

To choose the right tool, you need to study its characteristics, properties, and also take into account a number of nuances. By following the advice of specialists - construction professionals, you can choose a convenient and suitable tool both for professional activities and for home.

All characteristics indicate the class of the device, so you first need to decide on the purpose of the tool: what and how it will be used.

Before choosing a manual jigsaw, you need to take into account its maximum cut size, as well as the tension of the blade. Taking into account the mass parameters, the performance is determined

The hand will get tired faster from a heavy tool. You should calculate and estimate how quickly the canvas is installed and how to attach it. Try to purchase embossed fasteners with inserts made of hardened metal - they are more reliable and will last longer. Please note that thin blades are good for making complex cuts, but require caution and skill, as it can be difficult to maintain direction. Try to purchase high-quality tools from proven and reliable manufacturers with a guarantee. A good tool cannot be cheap.

When purchasing a jigsaw, you should consider its parameters.

- A tool with high power will weigh many times heavier than its lightweight and low-power “colleagues”.

- The mushroom-shaped instrument requires a two-handed grip and, in turn, needs to be fixed. Therefore, it is advisable to use it in a professional capacity.

- Tools with a D-shaped handle are mobile and suitable for household use. You can easily work with them either with one hand or on your knee. They are convenient and indispensable when performing construction and repair work in a house, country house or garage.

- Devices with a pendulum stroke and stepwise speed adjustment are preferable, as they increase productivity.

- It is necessary to check the reliability of the sole fastening, as well as the presence of fixing elements, for example, a rubber gasket.

- Please note that a small number of lutes at the rod and roller contributes to cleaner operation.

- Some tools have a bolt as a lock, others have clamps. Often, quick clamps impose restrictions on the size of the blade. Therefore, it would be more correct to use a screw block.

- Power consumption directly affects the progress and quality of work. The weight and performance of the jigsaw depends on this indicator.

- Consider the number of approaches per minute. Some models can do up to 3200 per minute.

- The ability to quickly replace cutting elements is an important factor. It is clear that the working blade sooner or later fails and needs to be replaced.

Many stores and shopping centers that sell this type of product willingly allow test drives of tools. For this purpose, there are special niches where anyone can test this or that model of jigsaws before making a purchase.

To learn how to choose a jigsaw, watch the following video.

How to use the pumping adjustment?

It’s easy to guess that in jigsaws for professional use there are more levels of adjustment of the amplitude of the pendulum stroke than in ordinary household ones. The number of steps in professional jigsaws is usually four. Each speed corresponds to a specific type of cut.

- The zero mark is the complete absence of pumping.

- The first speed means turning off the pendulum motion. It is necessary for performing figured sawing, for manipulating hard metals, as well as thin wooden materials.

- The second speed means the lowest degree of pumping and is used for cutting wood and soft non-ferrous metals.

- At the third speed, with medium vibrations, plastic and thin wood are cut.

- The fourth maximum speed is needed for rough sawing of thick (more than 5 centimeters) wood.

Jigsaw. Selection rules

From school labor lessons, many are familiar with a jigsaw - a handle with an arc onto which a thin saw blade is attached. Now almost no one uses this, it has been replaced by a more efficient jigsaw. This is a small tool with an electric drive that allows you to make figured and straight cuts of profile or sheet materials. Thanks to a large selection of accessories and various operating modes, the tool can cut almost any material.

The basis of the mechanism is a file that performs reciprocating movements with high frequency. It is started by an electric motor enclosed in a housing with a handle, with the help of which the cutting direction is set. And the metal base serves as a support during work.

Jigsaws are presented in a large number of models in different price ranges. Here are the main indicators by which they differ:

Power

Power affects the depth of the cut, its quality, speed and possible duration of work. There are jigsaws with power ranging from 70 to 900 watts. This is the main characteristic that determines the class of the tool:

- Household . For home use, a 400-700 watt tool will be enough, and even less if you are not going to work with hard materials. Such devices are less powerful, have a small number of additional functions and limited continuous operation time. Allows you to cut wood up to 70 mm, steel up to 2-4 mm.

- Professional . They have a power above 700 watts and are able to withstand intense loads. They cut wood up to 135 mm, steel up to 10 mm, and aluminum and non-ferrous metals up to 20 mm.

Saw blade stroke

- Maximum stroke frequency . Affects the speed and quality of cutting. It happens from 1400 to 5000 per minute. Usually the indicator is indicated at idle; during operation it is lower. The higher the frequency, the more productive the tool, but the equipment also becomes unusable faster.

- Adjusting the stroke rate . A very important function if you are going to work with different materials. For harder ones, a smaller stroke is recommended. Also, do not use the high frequency mode on plastic, as it may start to melt.

- Stroke length . Affects the performance of the tool. It happens from 10 to 30 mm.

- Pendulum stroke . Jigsaws may have an additional saw blade stroke mode. With it, movements are made not only up and down, as with vertical, but also back and forth. In the pendulum mode, the speed of work increases, but the accuracy and quality of the cut decreases. For figured cutting, it is better to use only a vertical stroke. The amplitude of the pendulum stroke is regulated by a special switch.

Advantages of using a pendulum stroke

The positive aspects of using a pendulum stroke, of course, include the following:

- high speed;

- you can saw soft wood, foam plastic, plastic, plywood, chipboard, steel sheets;

- sawdust is removed well;

- Due to the high speed, heating and wear of the file are reduced, therefore, the service life of the tool increases.

Application benefits

More and more manufacturers are releasing models with a pumping function. It increases the variability of device operation. The advantages of such jigsaws:

- very high speed of the web;

- the ability to cut plastic, any type of wood, steel sheets and foam;

- quick removal of sawdust;

- less heating of the blade when sawing.

Due to the popularity of the pendulum stroke, such a tool is practically no different in price from simple electric jigsaws. Recommended for both professional and domestic purposes.

Disadvantages of using a pendulum stroke

But this wonderful mechanism also has its drawbacks. These include the following points:

- low quality of the cutting line and the appearance of chips along the edges;

- not suitable for figured cutting, can only be used for straight cuts;

- not recommended for working with ceramics, stone, hard metal alloys.

The presence of a pendulum mechanism in modern jigsaws helps to avoid excessive effort and increases the speed of work. Due to faster cutting, saw blade wear is significantly reduced. As a result of the blade deflecting downward, the cut is cleared. Thanks to all this, the productivity of the tool increases and the service life of the jigsaw increases.

For an overview of the pendulum jigsaw, see the video below.

If you constantly use electric jigsaws due to your work, or simply decided to carry out home renovations and major alterations, then you have probably noticed that modern models have a so-called pendulum installed. At first it is very difficult to understand why such a function might be needed on a device such as a jigsaw.

But if you understand the topic in more detail, you can understand the very essence of this purpose and figure out why the developers decided to equip the jigsaw with such outstanding technology.

Kinds

Jigsaws have a wide range of characteristics and parameters, so they are divided into groups for home and professional use. In turn, each of these types has its own characteristics. Popular are manual options, for figured cutting, with adjustable speeds, and tape.

A worthy option for a quality tool is a mini jigsaw. It is able to simplify precise sawing and sanding of the model due to the high rigidity of the working parts. This product can be used not only by professionals, but also by beginners. The jigsaw is easy to use and is an excellent option for sawing a variety of materials. Purchasing a tool will make it easier to make a tabletop or drawer.

Professional

Jigsaws with professional purposes meet high requirements, which are determined by high functionality, productivity, reliability, and ergonomics. Such a tool can withstand heavy loads and function continuously for 7 hours. Functionality of professional jigsaws:

- cutting wood material that has a thickness of 8 to 13.5 cm;

- steel billet with a thickness of up to 1 cm;

- aluminum plates – up to 2 cm.

The performance of such a tool is directly affected by the power reserve. The more powerful the engine the device has, the easier and faster the work is done. The reliability of professional jigsaws ensures their long service life and infrequent failures.

Domestic

An electric jigsaw for home use is considered inexpensive. It is quite easy to use, so it can be used to perform various functions at home and in the country. Experts note the good power of the device, so it is capable of performing all assigned tasks. Features of household jigsaws:

- low power;

- availability of a choice of additional functions;

- comfortable work with wood material that has a thickness of no more than 7 cm;

- high-quality cutting of steel with a thickness of up to 4 cm;

- the duration of operation should not be more than 20 hours per month;

- low cost of goods.

If you want to purchase an electric jigsaw, you first need to decide on the features of its use.

How to understand whether there is a pendulum stroke at all?

First you need to understand if your electric jigsaw has such a function at all. This can be done quite simply and it is not at all necessary to have an engineering education. If you take the jigsaw in your hand, you need to pay attention to its left side. There may be a small recess in the body, inside which the handle will be located. It can be red or any other color, but, as a rule, it differs significantly from the color of the body.

If there is such a switch, then you can congratulate yourself, because your electric jigsaw is equipped with a pendulum function. Often there are four travel positions. Moreover, the first digit will be zero, which only means that the pendulum function is disabled. Next there are three divisions to adjust the progress of this function.

Important functions of a jigsaw

The main parameters that ensure good tool performance:

- power,

- stroke frequency,

- adjusting the number of strokes,

- possibility of pendulum movement,

- method of fastening the saw blade,

- the presence of a scroller (device for turning the file).

The operating principle of a jigsaw is to convert the rotational movement of the shaft into the translational movement of the blade. The file is fixed in a rod, which is a round or oval-shaped plate or tube. Its durability depends on the profile of the rod, so it is advisable to choose a jigsaw with a thickened or round rod.

The cutting speed depends on the engine power. In household models powered from the network, it is 350-600 W. The output power, that is, supplied to the web, is always slightly less, since it is lost in the working units.

The stroke rate shows the number of up and down movements of the saw per unit time. Many tool models have an adjustable number of strokes. Single-speed jigsaws (without the possibility of adjustment) are used for processing wood. To work with metal, the stroke rate must be reduced, so the presence of this function becomes significant. The number of strokes in various models of jigsaws is 400-3500 strokes/min. The following regulation methods exist:

- pressing and holding the trigger button,

- fixed value switch.

It should be remembered that running at low speeds for a long time will overheat the engine. In this case, the instrument is stopped to allow it to cool.

How to control the pendulum stroke?

And so, we have already figured out that your electric jigsaw has such a function, so now you just need to understand what exactly it does and how you can use it.

In fact, everything is extremely simple. If you do not turn on the pendulum function, the jigsaw blade will only move up and down in translational movements. This is what allows us to cut wood, but unfortunately, not as quickly as we would like.

Now let’s imagine that you turned on, well, let’s say the first pendulum stroke on an electric jigsaw. The file will not only move up and down, but also bend to the side, against its cutting edge and back. Thus, the cut will no longer be at a straight angle, but at a sharper angle, which will slightly speed up the cutting process itself.

The higher the number on the pendulum adjuster, the sharper the angle of inclination of the cutting edge will be. Accordingly, the speed will increase significantly, since in one translational movement, the saw will be able to cut at least twice as much as in the standard mode without pendulum movement.

Jigsaws

Although some manufacturers clearly exaggerate the capabilities of their products, jigsaws are undoubtedly a versatile tool. They cut both artificial wood materials and solid wood quite well, but their main advantage is the ability to make curved cuts. When equipped with the appropriate saw blade - a file - the jigsaw will cut sheet metal and plastics.

How does it work

High-quality jigsaws are designed with electronics that ensure constant speed and perfectly balanced electric motors that provide minimal vibration. This type of jigsaw works relatively quietly and accurately, provided that a sharp file is used.

The simplest jigsaw moves the file strictly up and down. Jigsaws with pendulum (or orbital) action cut faster by moving the blade forward on the up stroke and retracting it on the down stroke, which cleans the cut. Vertical movement is achieved using a joint eccentrically mounted on a gear driven by an electric motor. At the same time, a separate vertically moving pin pumps the saw blade support roller, which in turn pumps the blade.

Most jigsaws have a cooling fan that blows air through an air duct to remove sawdust from the cutting line. Some models have a sawdust removal function: sawdust is removed from the work area using a flexible hose of a household vacuum cleaner connected to the back of the jigsaw.

A single-speed jigsaw cuts at a constant speed, but most jigsaws have infinitely variable speed adjustments to optimize work on different materials. With such jigsaws, the number of saw movement cycles is regulated by a trigger switch, which is also a switch-regulator.

Maximum efficiency of using a jigsaw

Saw blades should be replaced as soon as they become dull, let alone break. Dull saw blades cut poorly and put additional stress on the engine and gearbox.

There are special files for cutting various materials; Wood saws come in different tooth configurations: for fine, faster or cleaner cuts. When performing a job, be sure to use a file that matches it.

Check the manufacturer's recommendations for the optimal speed and pendulum action of the jigsaw for the material you are cutting.

From time to time, lubricate the blade support roller with a drop of light machine oil.

Rice. 2 Lubricate the support roller

CLEANING THE JIGSAW

Use a brush to sweep away dust from the ventilation holes and sawdust outlet and wipe the entire body. If you won't be using your jigsaw for a while, lightly lubricate the exposed metal parts to prevent corrosion. Be sure to wipe down these parts before using the jigsaw.

Rice. 3 Cleaning the jigsaw

JIGSAW LEAVES TO THE SIDE

Dull or bent saw blade

Don't hesitate to replace a dull or damaged saw blade.

Rice. 4 Change the file as soon as necessary

Blade support roller requires adjustment

On some models, the blade support roller can be adjusted forward and backward until it just touches the back edge of the blade. Sometimes the roller is attached to the base plate of the jigsaw, and to do this you need to loosen the fasteners and move it forward or backward. Don't forget to re-tighten all fasteners afterwards.

Rice. 5 Adjust the support roller

Incorrect sawing technique

Pressing the jigsaw in the direction of sawing can take it away from the desired path. Pull the tool back and gradually reach the desired cutting line, reducing the pushing force.

The short track can be extended by screwing a long piece of hardwood onto it.

Rice. 6 Extend the guide

RACK SUPPORT ROLLER SETTING

If you forget to lubricate the roller, it may jam. If lubrication does not solve the problem, try replacing the roller. For some jigsaws this may involve replacing the entire base plate. For other models, you will have to disassemble the housing to remove the damaged roller.

- Remove the file and place the jigsaw on a table or workbench so that the two halves of the body can be separated. Mark the exact position of the parts and wires, being careful not to touch them unnecessarily.

Rice. 7 Carefully disassemble the case

- Slide the roller out of its recess and install a new one. Then reassemble the housing, ensuring that all components return to their original positions.

Rice. 8 Remove the roller from its recess

WOOD SPLITTING

As the blade cuts wood on its upward stroke, it tends to break off pieces of wood on either side of the cut on the top surface of the workpiece.

Turn the workpiece over so that the front side is facing down, or place the workpiece between two sheets of high-density fiberboard.

Some jigsaws come with anti-splinter inserts that “surround” the blade and hold the wood fibers on either side of the cut. Other jigsaws have a corresponding adjustment of the base plate gap to perform the same function.

Rice. 9 Adjust the base plate gap

WOOD IS BURNING

If the wood begins to char and smoke when sawing, then the file may be dull or twisted. Install a new file and do not press too hard on the jigsaw.

Increasing the pendulum stroke can prevent clogging of the cut with sawdust - look in the manual for recommendations on the optimal parameters for this function.

Rice. 10 Try increasing the pendulum stroke

THE JIGSAW SUDDENLY STOPPED

Cord cut

This is quite possible if the cord is in front of the jigsaw or is under the workpiece. The power cord can be connected to accessible screw terminals so you can replace it yourself. If the cut cord is long enough, strip its ends for connection. If not, buy a new cord of the same type. All double insulated instruments are connected with two-conductor cords.

Rice. 11 Replacing the cord

NOT WORKING AT ALL

No power supply

If other devices in the same circuit have stopped working, check the panel: there is a blown fuse or a tripped circuit breaker or RCD.

Advantages and disadvantages of a pendulum stroke on an electric jigsaw

Of course, if we talk about the advantages of such a function, then we can certainly immediately note the fact that your jigsaw will cut many times faster. The boards will fall to the floor at high speed, and the work will progress by leaps and bounds. It is also worth noting that the jigsaw blade, when working in a pendulum stroke, will last many times longer. It will not dull quickly and certainly will not break off if the hard wood gets bitten when cut.

But, as always, there is a negative side to such a cut. We have already found out that the stroke of the cutting edge increases the speed significantly, so many people simply do not take this into account. If you need to cut something perfectly straight, then you simply may not have time to hold the electric jigsaw evenly enough or, conversely, at the right angle, which will lead to the fact that the cut will not be straight all crooked, but certainly far from ideal. Therefore, this function will be convenient only for those who have already worked with a pendulum stroke more than once and know exactly in which cases it can be used.

Rating of the best jigsaws with a pendulum mechanism

There are quite a lot of jigsaws with a built-in pendulum on the market. Even inexpensive models are equipped with this popular mechanism, and it is installed almost without fail on units from the mid-price and professional categories.

DeWalt DWE349

A household jigsaw with three stages of pendulum adjustment has a low level of vibration during operation. The inclination of the unit sole can be adjusted without a key. The tool supports speed settings, provides sawdust blowing, and has a backlight. The handle is equipped with rubberized pads for increased grip comfort.

The price of the DeWalt DWE349 electric jigsaw starts at 7,100 rubles. Pros

- fixing the start button;

- there is adjustment of the inclination of the sole and the amplitude of the pendulum stroke;

- makes little noise.

Minuses

- no soft start;

- the price is above average.

Metabo STEB 65 Quick

A semi-professional jigsaw with a power of 450 W is designed for simple sawing work. It is lightweight and compact; a quick clamp is provided for changing blades. The number of revolutions is regulated by a special wheel, and the tool also has a four-stage pendulum stroke.

Attention! A vacuum cleaner can be connected to the Metabo STEB jigsaw to remove sawdust directly during the sawing process.

The price of the Metabo STEB 65 Quick jigsaw starts from 4,000 rubles

Pros

- pendulum stroke with four settings;

- long cord 2.5 m;

- compact dimensions;

- there is sawdust blowing.

Minuses

- no backlight;

- no laser;

- makes a lot of noise when working.

Makita JV100DWE

A cordless jigsaw with a three-stage pendulum stroke and a tilting sole is suitable for performing simple and figured cuts. The cutting speed is controlled by the force of pressing the start button, there is a lock against accidental start. A protective screen is provided to trap flying sawdust. The jigsaw is not designed for high loads, but remains very comfortable to use and also produces little noise.

You can buy a jigsaw with a pendulum stroke Makita JV100DWE from 7800 rubles

pros

- there is a pendulum adjustment and speed adjustment;

- does not make noise;

- low vibration level;

- anti-slip inserts on the handle.

Minuses

- no quick clamp for the file;

- The battery requires frequent recharging.