Underground installation of heating mains for industrial purposes is not uncommon, since it is often impossible to place large-diameter pipes above ground level, especially in urban areas. It is better to lay the heating pipeline of a private house, if the boiler room is located in a separate building, above the ground, but sometimes circumstances also force it to be done in a trench.

Laying heating pipes in the ground deprives the consumer of the opportunity to visually monitor the condition of the pipeline, therefore, in this case, increased demands are placed on the quality of work performed. In addition, a heating pipe buried in the ground is affected by a number of additional, specific factors that must be taken into account. Let's consider these factors and the current rules for performing the necessary work in order to correctly lay heating pipes underground.

Classification

Cardiomyopathies are divided into primary (idiopathic) without an established cause and secondary with a known etiology.

Primary cardiomyopathies

- genetic: hypertrophic cardiomyopathy;

- arrhythmogenic right ventricular cardiomyopathy;

- non-compact myocardium of the left ventricle;

- Lenegre's disease;

- ion channelopathies.

- mixed: dilated cardiomyopathy;

- primary restrictive cardiomyopathy;

- acquired: inflammatory cardiomyopathy;

- stress-induced cardiomyopathy (tako-tsubo syndrome);

- postpartum cardiomyopathy.

Secondary cardiomyopathies

The group of secondary cardiomyopathies is extensive and includes myocardial lesions in various diseases and pathological conditions. Among secondary cardiomyopathies, the most common are alcoholic cardiomyopathy, thyrotoxic cardiomyopathy, diabetic cardiomyopathy, autoimmune cardiomyopathy, etc.

Materials

It is also important to consider the method in which the insulation will be installed. On the modern market, materials are presented in three varieties, depending on this factor:

- roll Used for wrapping pipes. Their advantage is that they can be used on elements of any diameter;

- cylindrical. In accordance with the name, they are a cylinder. It can be either solid or with a cut. In the first case, the pipe is inserted inside the element; in the second, the insulation can be put on after the pipeline has been assembled. It is clear that in this case the diameter of the segments is very important, since the cylinders have certain dimensions. They must cover the pipe without any gaps, otherwise heat will escape through the latter;

- semi-cylindrical. In principle, this is the same cylinder, but divided lengthwise into two halves. One is installed on the top of the pipe, the second on the bottom. The disadvantage here is the same as that of the previous version - it is tied to the diameter of the pipeline. In addition, it should be noted that half-cylinders, also called “shells,” can be hard or soft. The former can only be used on straight sections of the pipeline, since the material does not bend. If you need to insulate a bend in a highway, then you need to use a softer option.

Fiber wool

These are the well-known mineral wool and glass wool. They are rolled varieties of materials, which makes them quite convenient for installation. The thermal insulation characteristics of both wools are simply excellent - both retain heat perfectly.

But there is a drawback that can cover all the advantages - it is unstable to moisture. With glass wool this is even more or less the case, but mineral wool not only instantly absorbs water, but also almost completely loses its insulating properties when wet. In addition, over time it is compressed, as a result of which it also begins to insulate worse than initially.

Glass wool does not have such problems, but there are others. Over time, it begins to disintegrate, releasing tiny particles of glass into the air. Naturally, if inhaled, this can seriously harm health, so such material is usually not used in a residential building.

If you decide to use cotton insulation, then the best option would be to combine them. Sections of the pipeline located on the street can be wrapped with glass wool - there it will not harm anyone, and moisture will not interfere with it. And insulate those segments that are located in the attic or basement using mineral wool. It is safe for people, and its location indoors will protect it from exposure to precipitation. However, it is better to make an additional protective layer of steel tape on top - this way you will definitely protect the material from getting wet.

Foamed polymers

This variety includes foamed polyethylene, polystyrene foam, polyurethane foam and rubber. The first is a roll material, the rest are semi-cylindrical. The main advantage of all foamed polymers is excellent resistance to moisture. They can be safely placed outdoors.

In addition, they all have a long service life, ranging from 30 to 50 years. The only drawback of the materials is their high level of flammability. Moreover, they not only ignite, but also emit very acrid smoke.

Therefore, when deciding to use these particular insulation materials, it is necessary to pay increased attention to fire safety issues.

Painted and sprayed insulation

With this approach, the insulation layer turns out to be monolithic; it, as it were, becomes another shell of the pipe, and therefore reliably protects the pipeline. However, it is worth considering that it is almost impossible to remove it.

In addition, polyurethane foam is damaged by the sun's rays, so when placing it outdoors it is necessary to provide protection. Paint does not have this problem, but it insulates worse. It is better to use it in regions that do not experience cold winters.

Dear readers, based on today’s article you will be able to decide exactly what and how to properly insulate the heating pipeline in your home. Do not neglect this procedure, because in the end you will receive significant cost savings and also protect the system from possible breakdowns. Good luck!

Rules for installing chimney systems

Before moving on to a review of insulation materials and the rules for working with them, you need to understand the requirements that must be met when installing a chimney. This point is very important, since violation of the standards can lead to the inability to operate the equipment.

Compliance with the standards and requirements for the installation of gas chimneys ensures their reliable and safe operation

Chimney ducts must comply with the requirements of DBN V.2.5-20-2001 and SNiP 2.04.05-91. The basic requirements are as follows:

- The internal diameter of the chimney pipe must be larger than the diameter of the outlet pipe of the gas boiler;

- The main pipe cannot have curved or tapering sections, must be located vertically, a slope of no more than 30 degrees is allowed;

- The diversion main can have no more than three turns;

- The distance from the outer surface of the pipe to walls made of combustible materials is 25 cm, to walls made of non-combustible materials – 5 cm;

- The insulation of the connections of the chimney elements must ensure complete tightness of the joint;

- No connections are allowed within the roof passage (this part of the chimney pipe must be solid);

- In places of turns, inspection hatches must be installed;

- The lower part of the chimney pipe must be equipped with a structure for collecting condensate;

- The upper part should rise above the roof ridge by no less than 50 cm, and the length of the chimney itself should provide high-quality draft.

Compliance with the standards and requirements for the installation of gas chimneys not only improves the operating efficiency of the equipment, extends the service life of the chimney, but also guarantees fire safety and eliminates the threat of smoke in the room.

The need for insulation

Now look: you invest in paying for resources, but the heat is released not only into the house, but also outside, into the basement, into the attic, etc. Do you need these expenses? Hardly. Agree, spending money on heating your yard during the cold winter is perhaps the most useless investment of all.

This is why it is so important to insulate pipes. This prevents heat from escaping to places where it is not needed.

Non-residential premises and the street are areas where the pipeline must be protected. Inside the house - in its residential parts - this does not need to be done for obvious reasons, heat transfer should occur there anyway.

In addition, there are other advantages that insulation of heating pipeline segments provides:

protection against condensation and freezing

As long as the heated coolant circulates through the pipes, even if not insulated, critical situations do not arise - if you do not pay attention to heat loss, then everything is in order. But there are times when a heating system malfunctions for some reason.

For example, an accident occurs and the house is left without light - as a result, both the electric heating boiler and the circulation pump stop. That is, heating of the coolant and its forced circulation through the pipes stops. What happens in this case? That's right, the liquid inside the pipeline is cooling. If it happens in the summer, there is no problem. If in winter, then first condensation forms on the pipe, which in itself is not a very useful phenomenon, and then the cooled liquid begins to freeze. It also depends on what kind of coolant you use. Antifreeze, for example, will obediently turn into a gel and wait until the system is restored to functionality. But the water will turn into ice, expand and can do a lot of damage to the pipeline, especially at the junction of the segments. Thus, breakthroughs may subsequently occur, and the restoration of the heating system will take a long time. Agree, in winter a house without heat is terrible. Of course, insulation on the pipes will not completely solve the problem, but it will prolong the cooling of the coolant for a long time, thereby giving you a considerable amount of time to troubleshoot problems in the system;

Possibility of underground pipe laying. Not everyone wants to look at the pipeline located in the yard. It is much more aesthetically pleasing to hide it underground. But, as you know, the temperature there is usually lower than on the surface. Therefore, insulation in this case is an absolutely necessary protection of the pipeline from freezing.

As you can see, pipe insulation is necessary both to save your money and to extend the life of the heating system. A nice bonus is that you can easily perform the procedure yourself, even without special skills. You just need to figure out what material to use for the job. But let's talk about this in more detail.

How and with what to insulate a heating boiler so that the water remains hot for as long as possible

Fortunately, such expenses can be avoided if you know how to insulate a heating boiler. In principle, any such equipment is usually made of materials that retain heat well. Some of them also have an internal insulating layer. However, additional protection against heat loss will always come in handy. The better it is, the less resources you will spend on heating the coolant.

So, let's figure out how this operation can be carried out and what materials are best used.

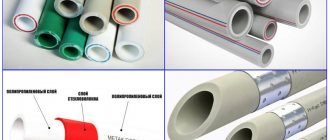

Polymer products

Modern thermal insulation materials made from foamed polymers have become widespread.

All of them retain the properties of the original materials:

- high resistance to moisture and low water permeability,

- ability to withstand the effects of aggressive chemicals,

- biological decomposition.

Thermal insulation properties are due to the cellular structure obtained during foaming and hardening of the material.

Due to this, excellent sound insulation performance is achieved. Insulation made from foamed polymers is used during the installation of a heating system with polypropylene pipes (the procedure is described here) in apartments or private houses.

The mechanical characteristics of materials and heat resistance are determined both by the properties of the original polymers and by the manufacturing technology.

The most widely used insulation materials are:

- polyurethane foam;

- foamed polyethylene and materials based on it;

- expanded polystyrene (used for thermal insulation of heat accumulators for electric heating boilers - written in this article).

Polyurethane foam

High strength and rigidity allows the material to be used on pipelines subject to significant mechanical stress.

The insulation is non-toxic and has the resistance to chemical and biological influences and moisture resistance common to polymers.

Available in the form of half-cylinders (thermal insulating shell), easy to install.

Foamed polyethylene

The material has excellent resistance to various influences and elasticity.

Universal in use - can be used in various conditions, for example, in the basement, for thermal insulation of a heat accumulator (read how to do it yourself here).

Limitations are imposed by the heat resistance of the material (for samples made from cross-linked polyethylene it is higher) and susceptibility to ultraviolet radiation, which requires additional protective measures.

Insulation made of foamed polyethylene is used for pipes and thermal insulation of household communications (split cylinders of various diameters produced by manufacturers are convenient for this).

Consumers are offered materials based on polyethylene foam, such as penofol, which has protective reflective coatings of aluminum foil on one or both sides.

Expanded polystyrene

Low thermal conductivity and water permeability, long service life, excellent heat resistance allow the material to be widely used both for thermal insulation of household networks and for industrial needs.

It is produced in the form of halves of cylinders, simply mounted and dismantled.

On its basis, such universal insulation as penoizol is produced, which provides excellent performance characteristics.

Other insulation materials

Among other foam insulation materials, foam glass deserves special attention - a durable, waterproof, heat-resistant material that is inert to any impact.

It also became the basis for progressive coatings, such as heat-insulating paint.

A material containing foam glass, ceramic microspheres and perlite allows for effective protection of pipeline surfaces, while having excellent thermal insulation properties.

A layer of heat-insulating paint, a couple of mm thick, gives the same effect as several layers of conventional insulation - mineral wool or polystyrene.

The release form in the form of aerosols simplifies the use, and absolute safety and performance properties allow use both for household communications and in harsh industrial conditions.

Watch the video below to see what thermal insulation for heating pipes looks like.

How to insulate a solid fuel boiler

The insulation process is almost the same for boilers of different types. In this case, the result largely depends on the materials used. We have already written above how to insulate a solid fuel boiler, but now we will consider suitable materials for electric and gas boilers:

- Mineral wool. It has low thermal conductivity and is easy to fix. The disadvantage of wool is its high hygroscopicity, which significantly worsens the thermal insulation characteristics of the material. Sold in rolls and in the form of mats.

- Glass wool. Its thermal insulation characteristics are not inferior to mineral wool. The main advantage is that the material is not hygroscopic. When working with glass wool, you should use goggles, protective clothing and gloves.

Insulation using polyurethane, which is applied using special equipment, is very popular. In terms of its thermal insulation and performance characteristics, polyurethane foam is significantly superior to glass wool and mineral wool.

Choosing insulation

Let's try to figure out which insulation to choose for external sewer pipes.

Let's conduct a small comparative analysis of the two most popular options for heat-insulating materials: mineral wool and polystyrene foam:

| Mineral wool | Styrofoam |

| The composition includes phenol-formaldehyde resin, which is harmful to human health. | Environmentally friendly. |

| Short-lived. | Durable. |

| Under the influence of mechanical loads, it “shrinks”, which can lead to the appearance of “cold bridges” on the pipes. | Maintains constant dimensions during operation. |

| Quite a high moisture absorption rate. Additional insulation required. Cannot be used in high humidity conditions. | Does not absorb water. Can work at any humidity level. |

Insulation of pipes with mineral wool requires the mandatory use of additional waterproofing material

As an insulation material, mineral wool can be successfully used if certain safety requirements are met when working with it, in dry conditions and with the obligatory additional waterproofing layer. However, foam plastic thermal protection, due to its excellent performance characteristics, is pushing it out of practice in modern realities.

Styrofoam

Modern insulation for sewer pipes is a foam shell. It consists of two or even three parts, on the sides of which there are locks equipped with a simple device for fastening. Shells selected according to the diameter of the pipe are simply put on it and snapped into place.

Don’t forget to allow for overlaps when putting on the shell. Their overlap in length relative to each other should be at least 20 cm.

The service life of foam shells is more than 50 years. They can be used in any climate zone.

Foam shell - effective in use and easy to install

Expanded polystyrene

This material can be characterized as follows:

- Excellent thermal protection is provided for pipes located both in the ground and on the surface.

- The affordable price of heat-insulating material is important for the consumer.

- Expanded polystyrene protection can be used repeatedly.

- The elasticity of the material due to the porous structure makes it possible to carry out work not only on straight sections of the pipeline, but also on bends.

- Expanded polystyrene shells are installed quite simply:

- two halves of the required diameter, which when assembled form a “casing” for the pipe, are combined around it;

- The coating is additionally secured with construction tape.

- Installation of such a thermal shell can be easily done with your own hands.

Foamed polyethylene

Modern insulation materials: polystyrene foam and polyethylene foam

The thermal insulating properties of this material are ensured by its unique structure - air bubbles in a polyethylene shell. Foamed polyethylene has the following operational and other properties:

- good heat retention;

- providing protection against condensation and fogging;

- resistance to mechanical damage;

- resistance to oil, gasoline, cement, lime;

- high elasticity and flexibility;

- durability;

- maintaining characteristics throughout the entire service life;

- environmental Safety.

The thickness of the protective polyethylene foam coating varies depending on the outer diameter of the pipes (7–114 mm) made of steel, copper or plastic, and can be from 6 to 20 mm.

Thermal insulation of large-diameter sewer pipes, connecting parts and pipes with a non-circular cross-section is made using sheets of foamed polyethylene coated with foil.

Staples, glue or reinforced adhesive tape are used to hold the insulation together.

Foam rubber

This flexible synthetic material provides high quality and effective insulation due to its properties:

- good elasticity;

- low thermal conductivity;

- resistance to moisture absorption;

- durability;

- fire resistance;

- ability to operate in a wide temperature range: from –200 °C to +175 °C;

- good noise absorption;

- environmental friendliness;

- non-toxic;

- efficiency.

Installation of synthetic rubber insulation is possible on pipes of any type (steel, plastic, copper). The outer diameter of the insulated pipes (6–160 mm) determines the thickness of the material layer: 6–32 mm.

Rubber has all the advantages necessary for insulation

Backfilling the trench

Backfilling of the trench begins after checking the heating system in operation - if pressure testing of the circuit reveals defects in its tightness, it will be necessary to eliminate them.

Backfilling a trench is a critical stage of work, the correct execution of which determines the uniform distribution of loads and the durability of the pipeline section in the ground.

Backfilling of the trench begins with laying soft plastic soil on the sides of the pipe (in the grooves). This is done evenly along the entire length of the pipeline, preventing it from moving to the sides. The soil laid on the sides is thoroughly compacted, after which the pipeline is backfilled from the same material with a protective layer of at least 15 cm along the entire width and length of the trench in accordance with the requirements of SNiP. Compaction of this layer is carried out to a lesser extent - this is a necessary condition for the formation of a strong protective arch of soil over the pipe, resting largely on the sinuses on the sides of the pipe.

After compaction of the protective layer is completed, the trench is completely filled with soil removed during digging, removing large stones from it. Backfilling must be carried out evenly along the entire length of the trench, avoiding the formation of pipe sections with a large difference in the vertical load from the soil.

The evenly growing load from the backfill will be taken up to a greater extent by the protective soil arch above the pipe, and the residual compressive force for the pipe is not terrible - it is designed for it.

If the trench is filled in separate sections, then the difference in the vertical load on the buried and open segments of the pipeline will lead to tensile forces, which the pipe resists less well.

What do angiography indicators mean?

The amount of radiation that will penetrate the veins and other brain tissue is determined by their density. It is expressed in various color shades. The bone in the image will be white, and the cerebrospinal fluid will practically not appear on the resulting images. Other brain substances have different colors and densities. Using them, doctors evaluate the internal structure. The doctor will provide a detailed transcript of the received images.

Methods for insulating water pipes

To prevent frost from damaging water pipes in a private house/dacha/cottage, you need to worry about their thermal insulation in advance.

It is important, even at the stage of laying communications, to consider options for insulating pipes, and not only water pipes. If this is done in a timely manner, the costs will be minimal.

There are quite a lot of options for insulation for pipes - it is important to choose high-quality material among the mass of proposals, without focusing too much on price. The cheapest option is wasted money. Among the methods of insulating a pipeline for supplying water to a house, the most popular among homeowners are:

Among the methods of insulating a pipeline for supplying water to a house, the most popular among homeowners are:

- extend the pipeline 0.5 m below the freezing level;

- use a heating cable;

- insulate with heat-insulating material;

- provide an air gap;

- buy a ready-made factory pipe;

- apply several methods at once.

Most often, more than one method is used. So, if the water pipes are deep, then the area responsible for the entrance to the house still needs insulation. Therefore, the most optimal option is selected for it in order to protect the local water supply system.

The depth of the pipeline depends on the region. To find out, you can use special lookup tables by finding your region or check it empirically

The heating cable has become widespread due to its ease of installation and high-quality performance of its functions.

Depending on the type of installation, there are 2 types of cable:

- outer;

- interior.

The first is mounted on top of the water pipe, and the second - inside. It is reliably insulated and made of safe materials. It is connected via a heat-shrinkable sleeve to a regular cable with a plug or to a machine. Read more about heating cable for water supply below.

The heating cable comes in different capacities. Most often found from 10 to 20 W

There are a great variety of thermal insulation materials on the market. They all differ in their properties, quality, price, installation difficulties and service life.

Which one to choose depends on the specific situation.

Among insulation materials, polyethylene and polyurethane foam half-cylinders - shells - are particularly easy to install.

The method of providing an air gap is also often used. It consists of a water pipe placed inside a cheap, smooth plastic or larger diameter corrugated pipe.

Inside there is free space for the circulation of warm air coming from an insulated basement or heated in another way.

Warm air perfectly protects the water pipe from freezing. Although it is often additionally insulated with polypropylene or other material

Another option is to purchase ready-made insulated pipes of factory origin. They are sold completely ready for installation.

They consist of 2 pipes of different diameters placed inside each other. Between them there is a layer of insulation. This insulation method is often called pre-insulation.

The option with ready-made pipes does not always satisfy the needs of a particular user - diameter, type of material and cost can become a real problem for purchasing them

The use of several methods of thermal insulation of pipes is due to the fact that all methods are imperfect and it will not be possible to apply them in all cases. Conditions of use in various households located in all regions of the country are radically different from each other. Therefore, you have to choose the option that suits your specific requirements.

Criteria for choosing a heat insulator

When giving preference to one type of insulation, the following nuances are taken into account:

- Method of laying a water supply system. It is important to understand here that depending on the installation location: underground or on the surface, different insulation methods and materials used are used.

- Permanent or seasonal use of the plumbing structure. If the water supply is made in the country, then insulation will be required to prevent the pipes from bursting or to install a receiver. For permanent residence, serious thermal insulation of the entire pipeline system will be required.

- The thermal conductivity coefficient of the material from which the pipes are made. Plastic retains heat longer, metal heats up stronger and faster.

- Resistance of the material to UV rays, heat, moisture, combustion. These technical indicators are taken into account when understanding what protection the pipeline requires.

- Durability. This criterion affects the frequency with which the insulation material will have to be changed.

- Price.

In conclusion, it must be said that when working on insulating water pipes, there are no trifles. Every nuance is important here. The quality of operation of the water supply system as a whole will depend on this.

Alternative thermal insulation options

There are alternative methods of thermal insulation that prevent adverse consequences. They do not apply in all cases. First, you can remove all the water from the system - no water, no problem. This method is applicable for houses not used in winter. It will help protect the system from damage if water pipes freeze.

Secondly, you can ensure constant movement of water in the pipeline by opening the tap a little. This is not difficult to do if you live permanently. But the option is dangerous - suddenly you will have to leave home for a couple of days, and upon return you will be surprised in the form of a damaged water supply.

The insulation helps get rid of condensation, which has a positive effect on extending the service life of metal pipes

In addition to holding the tap slightly open, there are other ways to ensure constant pressure in the pipeline. For example, use a special pump to increase the water pressure in the system or add another element - a receiver. It should be cut into the pipe immediately near the pump. The operation of the receiver will maintain constant pressure, which will protect the system from freezing.