Can't find the instructions? Did the recommendations in the brochure not help you? You have the opportunity to read our article about setting up boilers. If you don't know how to handle gas equipment, you need a specialist. But you must admit, it doesn’t hurt to save time and money over and over again thanks to knowledge of the basic settings. Effectively adjusting a gas boiler is much simpler than it might seem.

From the article you will understand the principles of adjusting pressure, thrust and power during operation of the device. Find out the probable causes of problems along with options for eliminating them. If you need to tune the boiler, use our materials. Do not forget about the safety rules, and you will successfully configure the device and fix minor problems.

You should be interested in the settings of a gas boiler long before purchasing, taking into account your needs and various features. We have written which parameters can or should be changed in the device you are using. The new device should be configured and prepared for operation, and some undesirable aspects can be corrected.

flame Setting the gas burner

In order to properly set up the burner of a gas boiler, you must first of all follow the operating instructions for the gas appliance. Let's talk further about how to properly start and set up a gas burner, and in what cases flame adjustment is necessary. But first things first.

Features of the boiler settings burner

It is recommended to adjust the flame using a burner gas analyzer. It shows information about the amount of air mixed with gas, namely the level of oxygen involved in the process, and the amount of CO.

As a rule, CO should be no more than 50 ppm, oxygen concentration should be approximately 3 to 5%. If it is less, then most likely the gas will not have time to burn, as a result of which a lot of soot will accumulate, the CO2 level will be higher than the efficiency, and equipment standards will decrease.

If there is more air than normal, then the temperature of the household gas burner of the boiler will be too high, and this can lead to tragic consequences, including an explosion.

To ensure maximum equipment performance, ensure that the gas burner flame is blue. If it is yellow, blue or orange, it means that it is necessary to do the opposite; in this case, the gas will burn without leaving a lot of soot. This in turn will lead to damage to the device.

The flame in the gas burner should be blue. If you find that the color has an orange tint, try it, which means reducing the amount of gas. Reduce until the color becomes blue (color). This color is a sign of optimal gas operation of the device. The main thing is not to reduce the fuel supply until the moment when the flame becomes almost colorless. In this case, it will go out very quickly.

Setting the starting gas supply is only necessary during ignition and does not affect the performance of the device. But depending on the need, it is possible to adjust For. its beginning, the starting fuel supply should be reduced. Reduce until the burner stops turning on. After this, you can turn the regulator until the ignition is no more. will resume in detail about setting the flame of a household gas burner, you can watch in the video at the end of this article.

We also recommend that you familiarize yourself with the intricacies of gas boiler adjustment.

When adjustment is necessary Gas

flame? An atmospheric burner, which does not have a built-in fan, very often fails; a turbocharged burner breaks down much less often. During long-term operation of the device, its components may break or stop working at full capacity.

A floor-standing gas boiler takes up useful space in your room, so such heating systems are suitable for private homes more often. In all houses, a special room is allocated for such devices - a boiler room, in which wall-mounted units are installed. boiler boilers save space, so they are installed preferably in apartments or houses with small For example

area, the efficiency indicators of a gas boiler may decrease or a decrease may be observed.

And the flame may occur for the following reasons:

- power Large burner installed for equipment intended for less powerful burners. In this case, there is not enough space for proper combustion of fuel, the fuel burns unevenly, which leads to soot quickly accumulating on equipment parts.

- A lot of soot in the chimney can have a bad effect on the draft of a gas boiler. Because of this, the output of subsequent combustion products is very weak, little air enters, and the flame becomes yellow.

- The color of the burner defects is one of the reasons for the efficiency of the boiler, but in this case, the adjustment will help the flame not to correct the problem.

- Gas supply pressure differences can also contribute to the formation of soot and deposits, and this will significantly reduce equipment productivity.

All these reasons can affect the temperature of the flame in the gas burner, in which case repairs will be required.

Wall-mounted heating boilers and gas water heaters are installed, most often, in apartment buildings. But at home they may need to adjust the flame. Recommendations

Circulation pump

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will display a corresponding error).

To do this, you need to remove the front panel of the housing, unscrew the central bolt on the pump and use a straight-bladed screwdriver to turn the shaft in the direction indicated by the arrow.

An air vent is installed above the pump. You need to pull the bright lid up and let the air escape.

Floor-standing boilers are usually more powerful than wall-mounted ones. If you need to heat a large room, it is better to choose this option. — overview of design options and models.

Conclusion

At first, the system may make gurgling sounds, all because during startup it is impossible to bleed air down to the last atom. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the operating range.

Temperature adjustment and other boiler settings are described in the instructions for each model.

GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1. An employee who is at least 18 years old, who has undergone a medical examination and has no contraindications for health reasons, who has the necessary theoretical and practical training, who has completed introductory and initial workplace safety briefings and training according to a special program, and who is certified, is allowed to perform work using a gas burner. qualification commission and received permission to work independently. 1.2. An employee who performs work using a gas burner (hereinafter referred to as the employee) must periodically, at least once a year, undergo training and testing of knowledge of labor protection requirements and receive permission to perform high-risk work. 1.3. An employee, regardless of qualifications and work experience, must undergo repeated training on labor protection at least once every three months; If an employee violates labor safety requirements, as well as during a break in work for more than 30 calendar days, he must undergo an unscheduled briefing. 1.4. An employee who has not undergone timely instructions and testing of knowledge of labor protection requirements is not allowed to work independently. 1.5. An employee performing work using a gas burner, who is allowed to work independently, must know: safety measures when using gas cylinders and burners. Rules, regulations and instructions for labor protection and fire safety. Rules for the use of primary fire extinguishing agents. Methods of providing first aid in case of accidents. Internal labor regulations of the organization. 1.6. An employee sent to participate in work unusual for his profession must undergo targeted training on the safe performance of the upcoming work. 1.7. An employee is prohibited from using tools, devices and equipment that he has not been trained in the safe handling of. 1.8. When performing work using a gas burner, an employee may be exposed mainly to the following dangerous and harmful production factors: - the possibility of a fire when using a gas burner; — the possibility of a gas cylinder explosion; — gas burner surfaces heated to high temperatures; - uncomfortable working position. 1.9. An employee performing work using a gas burner must be aware that during work, the most likely cause of injury may be burns from the open flame of a gas burner. 1.10. To protect against the effects of dangerous and harmful production factors, the employee must use special clothing, safety shoes and other personal protective equipment. 1.11. To prevent the possibility of a fire, the employee must comply with fire safety requirements himself and prevent other employees from violating these requirements; Smoking is permitted only in designated areas. 1.12. The employee is obliged to comply with labor and production discipline, internal labor regulations; It should be remembered that drinking alcohol usually leads to accidents. 1.13. If an accident occurs with one of the employees, the victim must be given first aid, report the incident to the manager and maintain the situation of the incident, if this does not create a danger to others. 1.14. The employee, if necessary, must be able to provide first aid and use a first aid kit. 1.15. To prevent the possibility of illness, employees should observe personal hygiene rules, including thoroughly washing their hands with soap before eating. 1.16. It is not allowed to perform work while intoxicated or in a state caused by the consumption of narcotic drugs, psychotropic, toxic or other intoxicating substances, as well as drink alcoholic beverages, use narcotic drugs, psychotropic, toxic or other intoxicating substances at the workplace or during work. time. 1.17. An employee who violates or fails to comply with the requirements of labor safety instructions is considered a violator of industrial discipline and may be subject to disciplinary liability, and, depending on the consequences, to criminal liability; if the violation is associated with causing material damage, then the perpetrator may be held financially liable in the prescribed manner.

Installation of a gas burner in a heating furnace

We remind you that it is prohibited to install gas equipment yourself. However, it won’t hurt to familiarize yourself with the nuances of installing a gas burner in a stove.

So, installation of a gas burner is permissible in furnaces in which the length, shape, nature and temperature of the flame can be adapted to the nature of the material of the combustion chamber. The flame should not touch the walls, but should be freely located in the combustion space. If it is a brick wall, then the firebox should be made of refractory bricks.

Before installation, check the walls of the stove for cracks, voids, and unsealed seams through which combustion products can enter the room. The room into which the firebox door opens must have an opening window, a ventilation duct and a gap in the door for air to enter from below.

Gas burners of any type are characterized by the creation of high temperatures - more than 1000 °C in the combustion chamber. When installing a gas burner in the oven, you must ensure that the flame does not touch the walls.

The installation process itself is not complicated and is carried out in the following sequence:

- Remove the firebox door.

- A burner is placed in the combustion chamber.

- The shield is secured in the door frame.

- Connect the automation according to the manufacturer's instructions.

At the end of installation, connect the burner to a hose, the other end of which is connected to a gas source.

Installing a burner using the example of an AGG gas burner device: the stage of installing a gas burner block in a furnace with dismantling the ash pan

The system is launched by a master from the gas service, he checks the operation of the nozzles, the automatic control and safety systems, configures and tests the response of the sensors.

Installation of a gas burner in an industrial furnace using the example of an AGG gas burner device. Connecting automation, placing the remote control and thermal cylinder

Another step is to check the tightness of all connections and the presence of traction. After successful startup of the system, the gas installer must issue a completed control certificate for the installation of the burner.

When starting the heating, you should first select the minimum thermal power, heating the stove continuously and little by little or, if there is no power adjustment, cyclically, turning the burner on and off

This is especially important for a brick kiln - strong continuous heating of a cooled brick can lead to cracking.

Burner design and its types

All heating boilers differ from each other in the type of fuel they use. The most affordable, of course, is gas. This type of fuel is the most common and produces the least combustion waste. At the same time, the efficiency level is quite high.

A standard gas burner is the main element in the heating system, which supplies and ignites fuel in a gas boiler. We will talk in detail about the design and principle of operation of the burner further.

How does a gas burner work and work?

The gas burner is designed to supply a combustible mixture along with air, then these components are mixed in the combustion chamber. The further process is to maintain even combustion of the fuel.

The principle of operation is supposed to be divided into the following stages:

So, first, all the necessary components of the combustible mixture undergo a preparatory process. They gain a certain speed, temperature and the desired direction of particle movement. Next, the fuel is combined with air and enters the fuel combustion chamber. After this, it ignites.

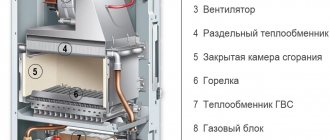

The main structural elements of a gas burner are discussed in the diagram below.

As for possible burner breakdowns and the safety of using gas equipment, boiler manufacturers did not forget to take this point into account. Thus, all modern boilers have additional structural elements that ensure safer operation and automatic shutdown in the event of a burner breakdown or other emergency situations.

When some elements of the equipment fail, in the event of their breakdown, the device turns itself off.

There are models in which ignition occurs by supplying a spark from an electric piezoelectric element. But such boilers also have components that can ensure the safety of using the equipment in the event of a gas burner failure or other malfunctions.

To avoid problems when igniting the burner, it is important to carry out maintenance in a timely manner. Mandatory inspection and maintenance of the gas boiler must be performed before the heating season, but at least once a year

Main types of burners for a gas boiler

For maximum efficiency of the heating system in a private house, a burner is installed in a gas boiler. Such equipment facilitates the regulation of combustion processes in the system. As a result, the fuel burns evenly.

Based on their operating principle, burners are divided into:

- injection;

- turbocharged;

- combined.

Injection (injection) type of gas burners is an integral part of a gas boiler. It works in such a way that air enters the work area by injection. To evenly maintain the combustion process, the oxidizer enters the tank under a certain pressure and mixes with gaseous fuel.

This type of appliance is designed exclusively for use with natural gas. For another type of gas, for example liquefied, it is necessary to install additional elements.

The second type of burner (turbocharged) works on a different principle. Here, air enters the work area and is mixed with combustible fuel using a fan. Thanks to the control system, it is possible to regulate the speed of rotation of the blades, thereby regulating the supply of oxidizer. This device allows you to qualitatively increase the efficiency of the boiler.

Despite the noise that comes from the fan, such devices are quite effective, and unwanted sounds can be eliminated by installing additional noise-reducing devices. They are more productive. But, as you know, turbines often fail if operating rules are not followed.

But, there are also combination type burners. They are also designed for boilers and operate not only on gas, but also on other types of fuel. Such heating systems do not require additional structural elements, since they are installed initially. These types of equipment are much more expensive.

Burners are also divided into industrial and household. There is practically no difference between their operating principles.

But, despite the differences in the design of gas burners, they are all designed for high-quality fuel combustion.

Possible startup problems

- The gas boiler slams when the main burner starts.

The most common problem, the cause of which is most often clogging of the igniter (dust, combustion products, etc.). It is recommended to call a specialist to clean it.

The reason may also be that the pilot flame is too low: below the main burner. When using electrode ignition, the electrode may be clogged or faulty. In rare cases, the cause may be excess gas pressure in the line. It is important to understand that slight, barely audible pops are characteristic of most models of gas boilers that do not have a sound insulation layer.

- Only the wick is lit and cannot light the main burner.

The reason may be the same clogging of the igniter or its incorrect installation, when the flame simply does not reach the main burner. Clean the pilot nozzle (it is advisable to entrust this to a specialist) and check the operation: its flame should reach the main burner and simultaneously “wash” the thermocouple. Sometimes the reason lies in a malfunction of the thermocouple, which does not open the gas supply.

Gas boilersInstructionsBoilers

Ignition type

All burners can be divided according to the type of ignition:

- Electronic type. They do not have a constantly working igniter. Requires electricity to operate. Electric ignition is one of the most convenient inventions for modern heating units. Thanks to him, the operation of the stoves has become as comfortable as possible. Electric ignition makes it possible to light the burner flame safely, without using available wicks or lighters.

- Burners with piezo ignition. No electricity needed.

Sometimes special working conditions are required, for example, burners are placed in a sauna stove, which must distribute the flame well. These are dividers or ordinary distribution tubes. This is how kitchen gas ovens work.

The fuel consumption passing through the burner can vary widely and depend on its design.

Gas burners for your furnace should be safe and energy efficient. This can be achieved if all technical requirements are met. Self-indulgence in this matter can only do harm. Therefore, the installation of gas burners must be carried out by specialists.

source

Check before first start

If the equipment is new, then there is no need to check the deposits on combustion products; it is advisable to inspect the ventilation and remove excess debris from the chimney pipe. In these elements, I often noticed the accumulation of various insects, both small and large individuals, they can affect the productivity of the unit.

Open the chimney damper to the limit and check the draft. If you carry out the manipulations as carefully as possible, problems should not arise. But it is better to do all the work sequentially and devote the required amount of time to each moment, do all the work carefully and scrupulously, because safety directly depends on this.

Types of gas burners for heating furnaces: device options and methods of installation in the furnace

Converting a brick or metal stove to gas processing is a difficult process that requires a serious analysis of all components. It is imperative to find out which types of gas burners are ideal for furnaces and which ones should not be installed. After all, the result must meet exactly your requirements.

It would seem that the choice of model can be entrusted to gas workers; they can also be entrusted with reworking the burner block and installing the burner itself. But where is the guarantee that the equipment that you will be offered to install will have the necessary operating parameters and desired functionality?

In this article we will tell you how to independently understand the types of gas burners, the basic rules for their installation and operation, so that you can consciously choose which device to install in your heating stove.

Homemade units

There are craftsmen who remake heating systems with their own hands. On the Internet you can even find the necessary diagrams for changing the devices of gas burners, their installation and adjustment.

Typically, metal is used as a material for the manufacture of heating systems. A cast iron firebox would be much more reliable. However, it is not possible to use it at home.

An excellent option for manual work is to order the system from specialists. They will be able to manufacture the device in accordance with all the customer’s wishes. However, the possibility of defects in the boilers cannot be ruled out, which may appear after some time.

Why do you need homemade heating units? The fact is that the marked options have a lower cost. They are made mainly because of the desire to save money. At the same time, these options are inferior to their factory counterparts in efficiency.

Usually only solid fuel and electric units are manufactured. Making a gas or diesel boiler is extremely dangerous. In addition, their installation in the house is strictly prohibited.

According to the principle of operation, a homemade product is no different from a purchased version. It will burn fuel and heat the coolant filled with water.

The main disadvantage of this unit is the lack of warranty. Factory equipment will work and perform its functions. Even if the buyer stumbles upon a defect, he will be able to exchange the product for another.

It is better to use pellets, firewood, and coal as fuel in self-made units. These materials are less dangerous than gas. It is impossible to make heating devices based on the latter.

Simple solid fuel units are the most popular and widespread homemade devices. They are simple, and their design is in many ways similar to a conventional stove. In addition, they are versatile.

Like a conventional stove, these systems can operate on any solid fuel. The main thing is that it burns.

Main parts of a gas boiler.

The efficiency of homemade equipment is significantly lower than factory equipment. It is influenced by many factors.

Among them:

- thermal insulation;

- combustion completeness;

- the correctness of the conclusions.

The efficiency of the unit directly depends on the combustion temperature. The higher it is, the lower the efficiency. In high-quality systems, the temperature in the firebox is maintained at 120–150°C. Higher values reduce the safety of pipes. This in turn significantly reduces the durability of the unit.

When manufacturing heating boilers with a burner, it is better to protect yourself as much as possible from the possible consequences of its operation. Therefore, you should consider a separate purchase of an automatic gas burner, which will be installed in an atmospheric or blown boiler.

You can also make electric heating units with your own hands. Their design may vary. It all depends on the person’s needs. The simplest option is to install a heating element directly into the heating system. In this case, there is no need to make a boiler.

The pipe with the heater must have a sufficiently large diameter. It should be easily removable for repairs and cleaning.

Systems without a heater deserve special attention. Its role is played by water itself. A current is passed through it, and heating occurs due to the movement of water ions. The liquid itself must contain salt.

It is extremely difficult to make such a device. Electric current passes directly through the coolant, so the entire system must be reliably insulated.

One of the dangers of this device is electrical breakdown. Essentially the same as a short circuit. Gas may also accumulate in the system. As a result, heating efficiency will decrease.

From all of the above, the best option is a solid fuel unit. Its body can be assembled from heat-resistant steel. It is characterized by increased strength, less wear and high resistance to thermal influences.

However, heat-resistant steel is expensive and in practice is rarely used in homemade boilers. Another option is cast iron: this material tolerates heat well, although it is difficult to work with. Equipment for the manufacture of cast iron stoves is available only at specialized enterprises.

It is important to understand that without the proper experience and skills, it is better not to make a heating system yourself. Safety must come first

It is enough to make even one inaccuracy, and this can lead to disastrous consequences.

What temperatures do different types produce?

Most burners are now used together with gas cartridges. They are attached to the cans as attachments. Let us consider the main types of such devices in more detail.

- The cheapest household models provide temperatures from 700 to 1000 degrees. A typical representative of such devices can be called tourist burners. They are convenient and can be used to fix a variety of problems. Typically, the fuel mixture in this case is propane and butane.

- More expensive models can heat up to 1200 degrees. A canister filled with liquid natural gas with an ejector burner can raise the temperature to 1600 degrees. Mostly, such devices are used by craftsmen involved in metal processing. Also, devices of this type have high accuracy of adjustable temperature and are able to solder with a clear contour. The majority of such devices are also filled with a mixture of propane and butane. This also includes the so-called collet gas cartridges with burners. They can heat up to 1500 degrees. They got their name because of the method of attaching the burner to the can.

- The highest flame temperature that a gas can can produce is 2400 degrees. The burner cannot raise the heating level to such a value, so this can only be achieved thanks to the special filling of the canister - methyl acetylene propadiene gas. Such torches are used for soldering high-carbon steels and other similar metals. The highest temperature that can be obtained by burning gas on a burner is 3000 degrees. It is achieved by burning acetylene. However, such a mixture is rarely used. Most products do not need such a high temperature to process them. More specifically, it can be noted that the high or low flame temperature during combustion of a mixture is determined by its calorific properties.

Of course, there are other types of burners. In general, it can be noted that primitive products of this kind have a similar design and flame temperature. More expensive models are more equipped and have a higher flame temperature. A device designed for processing metals is a blowtorch. The temperature of its flame, like that of hand-held gas cans, can reach up to 2000 degrees.

Interesting fact. The flame temperature in a regular home burner reaches only 700 degrees. This temperature is achieved due to the fact that the fuel is a gas consisting of 97% methane.

Recommendations for storage and disassembly

All gas appliances require careful handling and compliance with safe operation rules. Therefore, it is not recommended to repair malfunctions without permission or disassemble the burner and the gas boiler itself.

In order to avoid emergency situations, as well as to ensure the correct and efficient operation of the device, it is best to contact the gas company with which you have a maintenance agreement. Calling a specialist will be the most reasonable decision, because the price of your life and the lives of the people around you is much higher than calling a specialist.

As for storing household gas burners, everything is simple. They must be stored in a dry and ventilated area to avoid corrosion of metal parts.

Make sure that there is no moisture inside your boiler's heating system; if the outlets are rusty, then most likely there is moisture present. If you plan to leave the gas boiler in a garage or other unheated room for the winter, then make sure that these entrances are not closed. What is needed for the natural evaporation of water

To store the boiler itself, you need to make sure that there are no plugs at the outlets for connecting the heating pipes.

You also need to make sure that there is no water inside. If you do not drain the water, the tank will rust and the boiler will be unusable.

Filling with coolant

The only sure way to turn on a Danko gas boiler or analogs from other manufacturers is to strictly follow all the rules of connection technology. The first thing to do, when all the equipment has been assembled and checked, is to fill the system with coolant - most often water.

Connecting the unit to the water supply Source strojdvor.ru

The procedure is performed according to the following algorithm:

- The valve of the pipe, designed to supply coolant to the system, opens. This unit is usually located at the bottom of the unit, but some models may have a different device. Therefore, before starting filling, it is necessary to check the technical documentation.

- The circuit, pipeline, tank and batteries are filled with coolant over a certain period of time.

- As the system fills, the pressure is monitored using a pressure gauge. The indicator must comply with the manufacturer's recommendations. Typically, its value varies between 1.5-3 atm, but not higher than the maximum level.

- When the required pressure in the system is reached, the supply of coolant stops - the valve closes.

Monitoring pressure parameters in the system Source termopaneli59.ru

Note! If the system is open, it is better to fill it through the expansion tank. However, you need to know in advance how much coolant will be required. Therefore, the preliminary task of solving the question of how to turn on the boiler should be the correct calculation of the total volume of liquid being poured. Its value consists of the capacity of the heating circuit, expansion tank, pipes, batteries, boiler and other consumers.

Pros and cons of using a burner for heating

A gas burner is a device that, by mixing air with natural or liquefied gas and supplying the mixture to the outlet, forms a torch and distributes the flame. It ensures efficient combustion of fuel and regulation of the combustion process.

Advantages of using gas burners for heating stoves:

- Ease of use. Gas burners greatly simplify the process of heating furnaces, eliminating the need to prepare solid fuel and constantly maintain combustion.

- Controllability of the heating process. Simple models, without automation, need to be turned off independently as soon as the temperature reaches the required level, leaving only the wick lit. Burners with a control panel make life much easier by more accurately setting the temperature.

- Security. Automatic nozzles have overheating protection functions and turn off the gas supply in case of poor draft or lack of flame.

- Minimal contamination of the chimney duct. A scheduled inspection of the chimney is carried out once a year, mainly for prevention - little soot is formed from the combustion of gases.

The transition from solid fuel equipment to heating with gas burners greatly simplifies life, freeing up a lot of time for more interesting and useful activities.

Gas burners are intended for heating private houses, baths, industrial buildings - the purpose must be taken into account when choosing the type of equipment

The main disadvantage of converting a stove by installing a gas block is that the energy efficiency is not very high. High fuel consumption is especially noticeable if the gas heating system in a country house is designed by an amateur.

In addition, it is not always possible to obtain permission to install a gas burner - if the stove is outdated, the chimney is of incorrect design, or the room parameters do not meet fire safety standards.

Gas burns red

Carbon monoxide is a byproduct of the combustion of absolutely any type of fuel. Gas equipment produces a safe level of gas if the gas produces a blue flame when burned. If the flame turns red or orange, this may indicate increased carbon monoxide emissions. If you experience nausea, headache, or dizziness, these may be signs of carbon monoxide poisoning.

Carbon monoxide, as everyone knows, is colorless and odorless, so the color of the flame must be controlled. If the gas water heater begins to go out and the gas burns red, then it is necessary to clean the equipment. To do this, it is better to call a specialist.

In the past, when there was no gas control system, many people died from carbon monoxide poisoning. Therefore, at the first suspicion of a carbon monoxide leak, you must urgently call the appropriate specialists.

Characteristic

An acetylene welding torch is a special device into which a special gas (acetylene) is supplied for combustion. It is used more often than other devices for gas welding. The reasons for its popularity are quite obvious:

suitability for work even with a limited set of equipment;

high efficiency of application (justified even at nuclear and other critical facilities).

The combustion temperature of acetylene is higher than that of any other welding gas. It reaches 3200 degrees. The reason is that the acetylene combustion reaction is endothermic, while other gases absorb heat during the decomposition process. Complete combustion of 1 cu. m of this gas will require the use of 2.5 cubic meters. m. air. These are the calculations carried out by chemists based on the formulas of the reacting substances.

However, in practice, acetylene burns only incompletely in a flame, so during real welding the air consumption does not exceed 1-1.2 cubic meters. m. Because of this, the total useful heat productivity, instead of the theoretically calculated 13500 kcal per 1 m3, is only 5120 kcal per 1 m3. In practice, an oxygen-acetylene mixture is most often used, in which 55% is acetylene, and the remaining 45% of the mass is oxygen.

It is also useful to understand how an acetylene torch differs from a propane torch in practice. The first type is mainly used for working with relatively thin (no more than 6 mm) metal. The tips of the burner devices contain, in addition to the injector, also a mouthpiece and a tube. The proportions of the holes in the mouthpieces and injectors are calculated strictly individually for each gas used. Therefore, to replace the gas, you have to use a different tip, preferably from the same manufacturer.

Adjustment

The cleanliness of the cut depends on the correct flame setting . Oxygen treatment is carried out with a slightly oxidized or normal torch. The carefully adjusted flame of cutters with concentric nozzles is surrounded by a cutting stream of oxygen. The core of the torch in each section should be symmetrical and not differ in brightness.

Cutting with a torch with the mouthpiece moved cannot be carried out, as this will lead to heating of the edge, which will negatively affect the quality of the cut. The use of self-centering mouthpieces increases the ease of use of such equipment, because the device makes the flame symmetrical.

Sometimes the movement of the gas mixture is hampered due to clogging of the channel, which divides the torch into streams and leads to loss of stability. Such a product not only reduces the quality of processing, but also reduces productivity. Flame adjustment is based on creating a symmetrical flame of the required power in relation to the oxygen cutting jet.

A normal flame is ensured with the valves slightly open, which makes it possible to make adjustments during operation. When acetylene and oxygen are fully open, an excessive amount of the former is observed. Smooth closing of the acetylene valve leads to stabilization of the process.

Criterias of choice

Important requirements for gas welding equipment are lightness and compactness. If these points are not provided, it will be more difficult to move the devices. When choosing the acetylene torches themselves, you should immediately take into account that they are divided into 2 types: one is designed for welding, and the other is for cutting metal. The difference between burner devices in terms of power is also relevant. There are 4 main classes:

low-power (with tips 1-4, for metal from 0.3 to 7 mm);

intermediate level (tips 5-7, work with products with a thickness of 7-30 mm);

GAO-2 (used in cleaning surfaces);

non-injector (main application is welding with pressure 0.01-0.08 MPa).

Bypass valve

If the batteries in the room warm up unevenly, then it is necessary to increase the speed of the coolant. To do this, the bypass screw is turned clockwise.

If, when the heating is turned on, the liquid in the radiators begins to make noise, this is a signal to reduce the speed of the coolant. This is done by rotating the screw in the opposite direction. To set up and measure, you need to use a pressure gauge or digital differential pressure gauge. It will indicate the nominal pressure, which should not be more than 0.2-0.4 Bar.

Selection of gas equipment - main criteria

You need to decide on the settings of a gas boiler before purchasing it. We recommend starting with the power of the equipment. The features of your home matter a lot. The main condition for the normal and uninterrupted operation of such a unit is the presence of a centralized gas supply. Naturally, you can try to use imported gas cylinders, but this will significantly increase costs. In some cases, it is even cheaper to purchase electrical equipment for heating a building than to purchase gas cylinders.

For rooms larger than 300 m2, it is better to choose a floor-standing boiler

Heating boilers are single-circuit and double-circuit. In the first case, we recommend purchasing an additional indirect heating boiler. Only then can the unit be used to heat sanitary water. The best option is to purchase a double-circuit boiler, which has all the necessary functions for heating the building and water. Its key feature is the transfer of priority control over the operating mode to the hot water supply. In other words, after opening the hot water supply system, the heat supply to the main circuit, which also includes the heating system, stops.

There are some features of choosing a floor-standing and wall-mounted boiler. Wall-mounted equipment has less power, so it is not enough to heat rooms with a total area of over 300 square meters. In this case, you will need to either purchase another boiler or install a floor-standing gas boiler. In stores you can purchase floor-standing units of any power.

Removing air pockets

No matter how carefully the system is filled, air pockets will inevitably form in it. Therefore, the next stage in solving the question of how to ignite the boiler is bleeding the air. It is performed according to the following scheme:

- Air is sequentially bled from the radiators, starting from the top to the bottom. Special valves are opened one by one - as a rule, these are Mayevsky taps - until coolant begins to flow from them.

- Next, the procedure is transferred to the circulation pump.

- The panel on the front side is removed from the unit and a cylindrical element with a slot for a flat slot is found. The cover is loosened by turning the fasteners with a screwdriver.

Bleeding air from the circulation pump Source ytimg.com

- The boiler starts and heating is established - at the same time the pump should begin to emit a buzzing and hissing sound - indicating the presence of air pockets.

- When water begins to exit the cylindrical element, its lid tightens. Then the procedure is repeated 2-3 more times.

- Then it closes and the front panel is assembled.

Further, before starting the gas boiler, the system must be supplemented with coolant. Since during the procedure of bleeding the air plugs, its partial loss occurred.