Advantages of spiral staircases

The choice of such an interior detail indicates that you are not only the owner of good taste, but also a pragmatist. Screw structures are characterized by a number of advantages:

- Space saving. This is especially true for small spaces. Even 1.5 m² is enough to install a ladder. It is located around a special support and seems to hover in the air. It is this design property that allows you to save usable space.

- Visually increases the height of low rooms. The construction of spiral staircases will be significantly lower in price than marching staircases. This is due to the relatively small amount of consumables during the production of the product and low labor costs during its installation.

- The simple manufacturing process and simple installation allow you to make a staircase without the help of specialists. Screw structures are perfect for a private house or apartment, as there is no excessive traffic there.

When building a spiral staircase at home, you should not forget about safety precautions. If the structure is steep and the steps are not wide enough, carelessness and fast walking can lead to injury. But this drawback can be easily eliminated due to strong handrails. In addition, it is important to correctly calculate the size of the structure, including winder steps and tread width.

Pros and cons of spiral structures

You should not rush and purchase all the building materials to create a spiral staircase; first you should familiarize yourself with the advantages and disadvantages of such structures. Unfortunately, there are practically no ideal things, and even knowing how to make a spiral staircase, the owner of a house or apartment must learn all the pros and cons of such structures.

Pros:

- Small sizes. Which is most convenient, for example, if the area of a private house is small. At the same time, by installing the required number of steps and correctly calculating all the dimensions, a do-it-yourself spiral staircase will become much more practical to use than an ordinary marching structure. It also simplifies the calculation.

- An attractive design that allows any owner of a private home to awaken the designer in themselves. When creating screw structures, you can choose such an unusual appearance that it will become a real work of art.

- Affordable price. Of course, if you do not make the steps from stained wood or mahogany, then the cost of a standard spiral staircase may “pleasantly” surprise the owner of the house. The most expensive element will be the metal frame and its welding; the rest of the calculation (consumables, wood for steps, etc.) has an average cost.

Minuses:

- After the construction is completed, it is quite problematic to lift or lower any cargo along the spiral staircase (this could be furniture, household appliances, or other bulky things). Therefore, all large items should be moved to the second floor or lowered from it in advance.

- Lack of convenience. It takes some skill to quickly ascend or descend a screw structure. This becomes especially difficult if the number of steps and their sizes are incorrectly calculated.

Otherwise, spiral staircases to the second floor are no less popular than marching structures; it does not take much time to make them yourself.

Video from YouTube:

What materials can be used

In the production of spiral staircases, various raw materials are used, on which their quality and service life directly depend.

A metal pipe or wooden pole most often serves as a load-bearing structural element. Often the support is made of stone, brick, concrete and even asbestos cement. The steps are attached to the finished load-bearing element in several ways: welding, bolts or couplings.

Railings are typically made from metal, hardwood, or a combination of these materials. As for the steps, the traditional options made of beech, oak and ash have been replaced by glass and plastic products.

Plywood is also used to make spiral staircases. Both individual elements and the entire structure as a whole can be made from this material. A spiral staircase made of plywood is distinguished by its environmental friendliness and low cost.

You can use plywood for the stairs: as elements or as a complete structure

Materials and tools used

You can build a reliable, beautiful staircase from cast iron or steel. Cast iron construction can decorate any room and give a majestic look. But its creation will require significantly more material and labor resources. Typically, less expensive steel is chosen for spiral staircases, and the components are made of aluminum.

Since you have to work with metal, you need to choose how this material will be processed:

- welding;

- forging;

- casting

The simplest of these is welding. Even if you don’t have the appropriate skills, you can easily find a specialist in this field or figure out for yourself how to weld several metal elements together.

Varieties of design

Spiral staircases have several modifications, differing from each other in design features and methods of fastening the steps. However, regardless of their type, the steps are always installed radially with a slight rotation of each of them. In this position, they resemble the threads of a screw, which is why this model of stairs received the appropriate name.

Types of spiral staircases

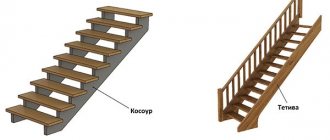

Thus, the following types of spiral staircase designs are distinguished:

- With the steps supported on an internal pillar and one or two walls located around the perimeter. Such structures are built in a narrow niche or in the corner of a room.

- With cantilever pinching of steps on the supporting element.

- With fastening steps to curved bowstrings.

These are the most common types of screw devices that a self-taught craftsman can build. Other varieties are considered more complex, so it is better to entrust their production and installation to real professionals.

Distinctive features of spiral staircase structures

Like all elements present in the interior of a room, radial staircase systems can also have advantages,

and disadvantages, each of which you need to know about when choosing exactly this option for installation in a particular room.

The main feature of spiral staircases is their unusual shape, design and installation methods.

Externally, this structure looks like a petal with rounded edges,

which, after installation, can occupy an area of only 1 m2 and still provide a comfortable transition between floors,

living quarters and attic. This is where all the advantages of using spiral staircases come from:

- Compactness is a determining factor that influences the choice of stairs for small spaces. They do not clutter up the space, and if the room also has low ceilings, then the screw model will help make it visually slightly higher;

- saving space. Most often, a spiral staircase to the second floor is placed in a vertical position around a special support frame, suspended in the air; it does not have inclined straight steps, therefore it takes up little space and does not limit the space in the room;

- ease of installation. Their compact size does not require the creation of a large ceiling opening, which saves floor space on the second floor, attic or attic. In addition, it is possible to install a spiral staircase with your own hands without the use of complex tools;

- availability. The cost of spiral staircase structures is slightly lower than the price of constructing traditional staircases. This is due to the fact that their creation requires fewer consumables;

- versatility. If the spiral staircase is made of durable materials that are resistant to adverse environmental factors, then it can be used on the outside of the building as an additional one. In addition, such a model can be installed either in the center of the room, or against a wall or in a corner of the room;

- originality. A circular staircase is stylish, modern and exclusive, which allows you to add some “zest” to any interior. Which for many owners of private houses is a predetermining factor.

In addition, you can build a spiral staircase with your own hands and not overpay.

It can be made from any material without resorting to the services of professionals,

and the installation of such structures with appropriate preparation lasts no more than one day.

But for this you need to carefully study the drawings of spiral staircases,

get acquainted with the simple principle of their manufacture and understand the nuances of their design and installation.

Despite such an impressive list of advantages of spiral staircases,

they also have a number of disadvantages that must be taken into account when choosing and purchasing for a specific room. For example:

- a spiral staircase can be installed to the attic, attic, or basement in private houses, cottages or apartments, that is, in places with low human traffic;

- not convenient for small children and elderly people;

- The steps of the spiral staircase are not wide enough for the feet of an adult and during a steep climb can become a source of increased injury risk. Therefore, it is impossible to quickly go up and down such stairs, and you will have to be extremely careful all the time. This disadvantage can be compensated for by installing reliable handrails and wider steps;

- each spiral staircase has a trapezoidal shape of steps, which are different in size for the right and left legs, which interferes with normal movement and can also cause injury;

- Regardless of the type of fencing, be it metal or wooden railings, it will not allow large objects to be climbed up the spiral staircase;

- Frequently going up and down a spiral wooden, metal or concrete staircase several times a day can cause slight malaise, dizziness, and nausea. Therefore, on the second floor, attic or attic, to which such a flight will lead, it is better to equip a bedroom or an infrequently used room.

To reduce the risk of injury when using a spiral staircase,

When manufacturing it, it is necessary to strictly adhere to the developed project, comply with all the requirements of GOST and the rules for its installation.

This is the only way you will get a convenient, practical and safe product.

Screw design elements

Before we begin making a wooden spiral staircase with our own hands, let’s look at the following issues:

- what elements it should consist of;

- location of components;

- methods of fastening elements.

The staircase structure has the following components:

- steps;

- final platform located on top;

- a post designed to support railings and balustrades;

- the main load-bearing element, which is the basis of the structure;

- cylinders that make up the support column;

- balusters supporting the railings;

- jumpers;

- screw-shaped railings;

- barrier on the top floor.

Diagram of structural elements

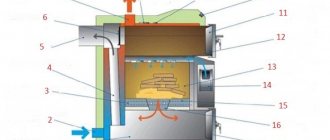

The above components form a single device by connecting them at nodes:

- Node "A". Here the supporting post or pipe is connected to the barrier on the upper floor. To do this, a bolt or screw is fixed in the rear part of the post or pipe, onto which a handrail is placed through a through hole. A decorative cover is screwed on top to secure it.

- Node “B” is the place where the support post and the bushing, which is installed in the hole of the step, are connected.

- Node "B". In this section, washers and a sleeve are attached to the support, performing decorative and pressing functions.

- Node “G” is the place where the support and base installed in the floor are attached.

Connecting nodes

Fencing device

The railings on a spiral staircase, like on a regular staircase, serve to protect a person from falling from the stairs and provide support during ascent and descent.

The railings include:

- Balusters. These are the support posts on which the handrail is attached. Their purpose is to perform a load-bearing and decorative role;

- Placeholders . Such elements are necessary to fill the gap between the balusters. They serve as a decoration for the structure and increase safety when moving. Such elements are not always used, but if there are children in the house, fillers are installed without fail;

- Handrails . This support element for the hands when moving. Installed on one side or, if necessary, on both sides of a spiral staircase. Handrails are attached to balusters, or directly to the wall, as in the photo.

Types of Fence Infills

There are several types of structures to fill the space between racks. You can get acquainted with them from the table:

| Type of aggregates | Peculiarities |

| They consist of racks located vertically or at an angle. Such elements can have different shapes, which gives them decorative functions. |

| In this case, the fence consists of solid sheets installed between the steps and the handrail. |

| Their peculiarity is the connection of the support posts with each other by horizontal elements installed parallel to the handrails. Such designs are most often used in modern railings. |

| This is the most beautiful handrail for a spiral staircase; the space between the handrail and the staircase itself is filled with all sorts of patterns. |

In addition, the fencing can be made by analogy with the bowstrings of a spiral staircase; spiral staircases with a support pillar without fencing can be manufactured.

Materials for making fencing

Before you make a railing for a spiral staircase, you should get acquainted with the materials for their manufacture.

Tip: When choosing a design and material for railings, you should pay attention to their combination with the style of the staircase and the entire interior of the room.

Stair railings can be made from the following materials:

- Glass. The price of such structures is the highest. The fence is difficult to install due to the need to bend the material, which can only be done in the factory. It is preferable to use glass for fencing in office premises, for residential buildings in interiors made in high-tech and minimalist styles.

Tip: When ordering glass panels from a company to enclose a spiral staircase, you must specify their bending radius; some organizations cannot produce a small radius due to the complexity of the process technology.

- Iron railings for a spiral staircase. The cost of the fence is more economical, and the appearance is almost the same as glass. For production, metal pipes and rods of square and round cross-section are used, bent into the desired pattern. After this, the elements are welded together, the joints are cleaned and painted in the desired color. Metal railings can have a wide variety of shapes and colors, without restrictions in application;

- Of stainless steel. The technology of their manufacture is similar to that of ordinary metal, the difference is in the appearance after completion of the work. Stainless steel looks more presentable and stylish. Such railings can be installed in wet rooms, outdoors. Stainless steel allows you to create original and very beautiful external spiral staircases.

- Tree. These are economical and beautiful handrails for spiral staircases, which can fit perfectly into any interior from classic to high-tech, which depends on the finishing of the structure.

Tip: When making a wooden fence, you need to choose high-quality wood with minimal moisture. This will prevent cracking and deformation of the structure during operation.

After careful polishing and varnishing of all surfaces, the design will become pleasant to the touch and very beautiful. Wood is always warm, unlike metal.

Making handrails for a spiral staircase from wood is especially recommended in rooms where there are children. The designs look very elegant, but they take up quite a lot of space; they are best used in residential buildings and premises with a large area.

- Stone. This is the most expensive option and is used very rarely in homes. Stone is difficult to combine with many interior styles. Such structures are used for fencing spiral staircases in castles, palaces and similar majestic buildings;

- Plastic. Most often it is used to imitate materials such as stone or wood. PVC railings are low cost, have a long service life, look aesthetically pleasing, and are safe to use.

- Combining materials. The options can be very different: wood with metal, glass with metal, metal with wood. They are appropriate to use in different styles from modern and classic to high-tech (see Staircase in high-tech style: how it works) and minimalism.

Tip: When using a combination of materials for railings, you should pay attention to the quality of processing of the joints during installation. During operation, deformation of various parts may occur due to improper adhesion of materials to each other.

The most common options for making railings are metal and wood. Making a handrail for a spiral staircase with your own hands from such materials is quite simple; you just need to have the desire and a little construction skills.

Spiral staircase, wooden railings

Metal railings with wooden handrail

Calculation of spiral staircase parameters

The process of manufacturing the components of a structure begins, first of all, with calculations. Moreover, the accuracy of their implementation is directly proportional to the level of safety of the staircase as a whole.

To understand how the calculations are performed, it is proposed to take a specific example with average statistical indicators for clarity. Let's assume that the width of the staircase is 90 cm (as a rule, its dimensions vary from 70 to 100 cm), the height is 270 cm, and the diameter of the support is 30 cm.

Further calculations are made according to the following scheme:

We determine the diameter of the spiral staircase, that is, the top view in projection. To do this, double the width of the staircase and add the diameter of the central pillar to the resulting figure:

(90×2)+30=210 cm

We make a drawing of the future structure. Correctly executed drawings of a spiral staircase made of wood are a guarantee of obtaining a good result.

On a piece of paper we draw a circle, the diameter of which we obtained in the previous paragraph (210 cm). For convenience, it is recommended to use a scale of 1:10. Thus, the diameter of the circle in the drawing will be 21 cm.

To display in the figure the trajectory of a person moving along the stairs, another circle is drawn inside. Its radius is equal to the sum of the radius of the support and the width of the stairs, divided by 2.

(90+15)/2=52.5cm

We calculate the number of steps in each turn. To obtain this parameter, an average step width is required. Considering that the usual width of this part of the structure is 40–45 for the external fence, then for the calculation we take approximately the middle (trajectory of a person’s movement) - 25 cm.

To obtain the exact number of steps, divide the circumference, which reflects the trajectory of movement, by the average width of the step.

(2×3,14×52,5)/25=13,18

Rounding, we get the result of 13 steps. Find the height of the steps. Divide the first circle into 15 parts of the same size. It should be taken into account that the distance between the first and last step is approximately equal to the height of a tall person. For example, 1m 90 cm. To this indicator, a 10 cm reserve and a step thickness of 3 cm are added on top.

190+10+3=203 cm

We determine the height of each individual step. To do this, the height of the coil is divided by the number of steps:

203/13=15,61

To calculate how many steps there will be in the staircase, you need to divide the height of the entire structure by the height of the step.

270/15=18

Based on available calculations, we can calculate how many revolutions the staircase structure makes during the entire ascent:

18/13=1,38

Important nuances during calculations and installation

Even small errors made during calculations, manufacturing or installation of the structure can make the ladder unsafe when ascending and descending. Therefore, in the process of work, it is not recommended to neglect the rules and recommendations of professionals:

- the middle of the step is the place where a person’s foot most often steps when ascending and descending; for a confident step, its width should be at least 20 cm.

- The minimum diameter of the support is 5 cm.

- a spiral staircase and risers are not the best combination; they prevent you from fully placing your foot, which is dangerous due to the foot slipping and resulting injury.

- There must be at least 11 steps in one turn of the stairs.

- the height of the coil is determined based on the height of the tallest family member plus a margin of up to 20 cm; If you ignore this recommendation, then when lifting and lowering you will have to bend over in some places to avoid getting a head injury.

Drawings and calculations - their development

Perhaps one of the most difficult moments in working on a spiral staircase project is creating a drawing. Experts advise developing a drawing of a spiral staircase only after creating a detailed plan of the first floor.

The installation location of the screw structure must be indicated there. The plan also indicates the exact dimensions of the opening, taking into account the scale of the floor plan.

The drawing of the spiral staircase indicates in detail all the parameters of the product. These include the width of the tilt plane of the structure and the thickness of the material.

Drawing with dimensions of a spiral staircase

On their basis, all calculations necessary for the subsequent installation and installation of the stairs are performed. Calculations of details must be done carefully, thinking through everything to the smallest detail. Otherwise, errors can lead to both unreliability of the product and the possibility of injury when using the ladder.

It is important to take into account the following points in the calculations:

- Selecting a suitable area for staircase construction and developing drawings. The staircase entrance to the 2nd floor is at least 2 square meters. meters. Access to it is necessary to assemble the structure.

- Calculation of the number and location of steps.

Diagram of a spiral staircase with a central post.

Often, spiral staircases do not have risers. Because of this, it is necessary to make a slight overlap of the steps on each other in the places where they narrow. - Calculation of the most convenient step width for going up and down stairs. This is necessary to avoid stumbling over adjacent steps when walking. As a rule, only 12 steps are enough to climb to the second floor.

- Increasing the size of the minimum staircase width. According to the standard, the width of such a staircase is 120 cm. The degree of slope is 45 degrees.

Manufacturing of structural elements

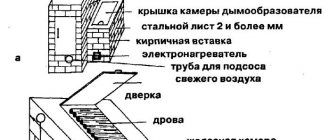

support pillar

To make the support, metal pipes with a diameter of at least 5 cm are used, as well as pillars made of materials such as concrete, brick and wood. Their diameter can vary from 15 to 50 cm, and in some cases more.

The central pillar is the main load-bearing element of the structure

Metal, concrete or brick supports are the most difficult to work with. To fix the steps on it, welding, bolts, and couplings are used. Elements can be attached to a wooden post without much difficulty using any method. These can be metal corners or wooden blocks, which are installed in a vertical position in the inter-stage gaps.

Since the central pillar is the main load-bearing element, it must be highly durable and withstand not only the total load of the entire structure, but also the weight of a person and luggage.

steps

The most common materials for their manufacture are wood species such as oak and beech. Unlike pine or spruce, they have a dense structure and are able to withstand the load placed on them.

The thickness of the steps depends on the height of the structure. If the staircase is no higher than two meters, then it is at least 5 cm. For taller structures it should exceed 6 cm.

When choosing material for steps, pay attention to the degree of drying and processing. According to experts, it is better to buy planed boards. Unevenly dried wood will begin to lose moisture over time and change its original shape. As a result of this, further replacement of the step will be required, otherwise the strength of the entire staircase structure may be compromised.

Experienced craftsmen recommend using laminated wood for steps, which is easy to make yourself. The length of the panel of bars is equal to the length of the step, and the width should be such that it can accommodate two steps placed in different directions.

To produce laminated wood, you must perform the following steps:

- Assemble the bars into a panel so that in closely spaced parts the structural pattern is directed in different directions.

- Coat the component elements of the panel with glue, tighten them with clamps and wait for the product to dry completely.

Scheme for manufacturing laminated wood

To save time and effort, you need to prepare in advance a template of the steps according to which they will be laid out. It is prepared based on previously made calculations and taking into account an allowance of 0.5 cm.

When transferring the contours of the template to the block panel, you need to be extremely careful. It is important to accurately display the dimensions of the wide edge of the part and the hole provided for the stand.

The upper stage of the structure deserves special attention. It is a platform connecting the stairs to the floor on the top floor. It is larger in size than other steps. In addition, the length of this element is sometimes deliberately made even greater in order to strengthen the staircase structure.

Making the upper stage

At the end of the work done, the manufactured steps are stacked and firmly fixed to each other on both sides. This “batch” method is used to make holes for the support post.

Fences and railings

The next step is to make the balusters. For this purpose, you will need laminated veneer lumber with a minimum cross-section of 5×5 cm and a lathe. If you are unable to make these elements yourself, you can buy them.

To ensure structural rigidity, the outer racks are shaped so that they can simultaneously connect two steps. This will prevent them from turning on the center support.

There are different methods for attaching baluster posts:

- by gluing them into the holes made;

- fixation to the steps using special fasteners;

- gluing using cuts made at the bottom of the posts.

Marking the railing posts and their installation diagram

The final stage is marking and sawing off the tops of the balusters at an angle depending on the inclinations and turns of the staircase structure. Curved wooden railings give a beautiful look to spiral staircases.

They are made using several methods:

- cutting out the components of the railing from a single piece of wood and their further assembly;

- cutting handrails from laminated wood;

- joining an element made of not very dense wood veneer.

Method for precision manufacturing of railings

Diagram of a twisted wooden railing.

Any of these manufacturing methods is quite complex. For these purposes, you will need appropriate material and special tools. Experts recommend purchasing ready-made handrails to order from a specialized company. Your task will only be to install them, although this work can be entrusted to a master of his craft.

As for the assortment, the market offers a wide selection of handrails that differ from each other in appearance, material and price. Those who prefer palace luxury can buy carved railings for the spiral wooden staircases to the second floor. And for more economical customers, there are plastic railings with an imitation of textured wood.

Making steps

You take the blanks, give them the desired shape, and process them completely.

- To connect the steps to the stand, you need to install special bushings on them.

- Cover the steps with varnish or paint;

- Mount bushings and treads on the rack, fan them out, give the structure the correct position

- Install the brackets between the wide tread elements;

- After installing the last bushing, decorate it with a beautiful decorative head;

- Install all steps using fasteners;

- Fasten the balusters, they can be straight or curly;

- Install handrails pre-made from plastic or wood.

- The final work is finishing the spiral staircase. It is best to paint a wooden staircase. If you used wood with a pronounced structure, then it is best to coat the structure with varnish, through which the natural beauty of the wood will be clearly visible.

Varnished

Before finishing, thoroughly clean all wooden elements, then cover them with stain and several layers of clear varnish.

For wooden parts that do not have a good structure, simply paint them with oil paint or use nitro enamel. After completing all the above work, you will have an excellent spiral staircase in your home.

Assembling a spiral staircase

Before you begin installing the structure, you need to decide on its location and whether it will be in contact with the wall. Having completed this task, you can begin to follow the step-by-step instructions:

- Apply markings on the ceiling, establishing the center of the circle.

- Using a plumb line, project the center of the circle drawn on the ceiling onto the floor. This will be the location where the support pillar will be installed.

The center of the circle drawn on the ceiling is where the support post will be installed

- Cut out a circle of the required shape in the ceiling and make a decorative frame around the edges.

Cutting and framing the opening

Further actions depend on the characteristics of the support post:

- If you purchase a ready-made set of spiral staircases, then the support, consisting of separate parts, is assembled simultaneously with the steps.

- If a monolithic concrete or brick support is used, then marks are placed on it where the brackets will be attached in the future. They serve for laying and fixing steps.

- The steps are attached to a large-diameter wooden support post using bars, the height of which is equal to the distance between the steps. Bars with a cross section of 3×5 cm or 5×5 cm are attached to the places marked on the post with self-tapping screws.

- When laying the first step, you can place a large wooden block on its wide side.

- The upper step is attached to the floor of the second floor.

- After setting all the steps, it is necessary to install balusters. They can be secured only after their tops have been cut off at an angle depending on the slope and turns of the stairs.

- The railings are installed and secured with self-tapping screws. To avoid damaging the racks, it is recommended to pre-make channels for screws.

- Then the plinth is attached, if provided for by the project.

Having carefully followed the instructions for installing a spiral staircase, proceed to the final finishing. Choose a suitable paint, stain or regular clear varnish for the design.

Screw structures are an excellent design solution for your home or cottage. And regardless of whether you chose an expensive option or an economy class, the result will please you in any case.

What to remember?

Any spiral staircase device is convenient to use and performs an aesthetic function.

At the same time, it should be easy to use and multifunctional, harmoniously combined with the overall style of the house.

Fully meet the requirements of future users and comply with all safety regulations, especially

if small children and elderly people live in the house.

And since this type of flight of stairs is a complex engineering structure and requires the presence of two or more flights,

which must be separated by turning platforms or steps.

In their production, a preliminary calculation of the overall dimensions of the staircase itself, the dimensions of its winder steps and the tread width are required.

In addition, in order to achieve maximum service life, reliability and safety of operation of the twisted staircase,

When making it, you should adhere to the following recommendations:

- a design with a free inner edge of the horizontal plane of the steps helps reduce injuries due to foot slipping during ascent or descent along their narrow part. This method of installing a spiral staircase makes it safer to use;

- The most affordable, more reliable and safe option for a spiral staircase is considered to be a model in which the steps are fixed to a load-bearing support and have spiral guards. Other types, which have handrails of a bent-adhesive type and steps fixed without support, are significantly more expensive to manufacture and require complex installation;

- since when moving along stairs, only their middle is most often used, it is better to make it wider - about 20 centimeters, and already at a distance of 15 cm from the central support, the width of the steps can be reduced to a width of 10 cm;

- Remember that narrow steps are inconvenient and unsafe to use!

- when making a purlin, it must be taken into account that the minimum step length should be 15 cm, and the distance between two steps should be 30 cm;

- The manufacture of its steps depends on the purpose of the staircase. If the steps are rarely used, then they can be up to 60 cm long with a diameter of the span itself of 1.4 m. The optimal size is a step length of 80 cm and a diameter of 2 m;

- It is not recommended to make steps on turning stairs, because they can interfere with the full placement of a person’s foot on its surface. And this can lead to your foot slipping and falling;

- when calculating the dimensions of the staircase and drawing up its design, one should take into account the optimal height of the passage, which will ensure comfortable movement of a person along a spiral up to 2 m wide. Therefore, the dimensions of the spiral staircase should be convenient for all its users: both adults and children;

- each of the full turns of the circular staircase must contain at least 11-12 steps;

- The angle of inclination of the stairs itself is also important. And the larger it is, the less space in the room a spiral staircase made of wood or metal will occupy. Acceptable tilt values are considered to be an angle ranging from 23 to 45 degrees. The most convenient to use angle is considered to be from 25 to 35 degrees. If it is more than 45 degrees, then it will be possible to climb such stairs only backwards. And with a slope of less than 23 degrees, nothing will be better than making a spiral staircase in the form of a ramp yourself - without steps;

- a thick-walled round metal pipe with a diameter of about 5 cm is optimally suited as a central support. Even such a minimum diameter will provide the finished structure with the necessary strength. But to create a vintage staircase, you can take a larger pipe, but with fairly thick walls. Such a support will be installed vertically, so the place where it comes into contact with the floor must withstand a colossal load;

- If the installation of a spiral staircase is carried out on a wooden floor, then its vertical post must be secured to the base using anchor bolts and fasteners. You can also secure the base of the structure by pouring concrete using tie rods.

Manufacturing of parts

In order to make the steps, hardwoods such as oak or beech are usually used. Wood that is not suitable for such purposes is pine or spruce, since in this case the ladder will be fragile and will not be able to withstand heavy loads. If metal will be used in this situation, before choosing the parts, you must remember that they should not be less than 50 mm, but only if the staircase is higher than 2 meters.

Next, you can begin sawing and drilling holes for installing balusters. Basically, people prefer to purchase ready-made products and not turn them themselves. As for the manufacture of railings for stairs, such work will not be possible for a person who does not have the skills of a highly qualified specialist.

At this stage, there are several ways in which these structural elements can be implemented:

- Sawing out railings from bars that are glued together.

- Cutting out individual elements from a single piece of wood with further assembly.

- Gluing wood veneer elements.

Calculations and algorithms - example

The first step to making a staircase is choosing your design option. A wooden spiral staircase, the drawing of which was developed and compiled by outside specialists, requires verification and clarification of the calculation results. Moreover, each specific solution will have its own individual construction conditions. So, when using a staircase with a side support, you will need to equip a “well”, the steps of which will be rigidly built into the side planes. The “well” is a technically complex mechanism, and you can make it yourself, but it is preferable to go with the option with a load-bearing beam on the main rod.

Screw-mounted design

As an example, we can provide an independent calculation of a screw model, in which the support beam is a metal pipe with a wall thickness of 5 mm, the Ø of the main pipe is 48 cm. The metal corners will serve as fastening of the consoles by welding, the steps will be made of solid wood. An ideal screw design is a regular circle with a diameter equal to the dimensions of the entrance opening to the room. A simple but accurate formula to calculate the circumference of a staircase:

L = 2πR x n; or L=2πR x (γ / 360);

Where:

- R – radius of the circle of the structure;

- R1 – internal radius of the stairs (pipe diameter);

- γ – stair turn, the value reflects the difference in height between the steps of the stairs;

- L – circumference.

The practical implementation of the model calculated using this formula showed that comfortable movement along such stairs will be complicated by tight openings, therefore the radius of movement should be 2R / 3. The final and working formula:

L = 2π x 2R/3 x n = 4πR / 3 x n

Data for calculating a spiral staircase

From the comparative diagram above it is clear that a staircase with a spiral design differs from a straight model by a different, more specific shape of steps. The console of a spiral product is a petal with a rounded end and with specific characteristics and meanings:

- h is the length of one tread, reflecting the difference between R and R1. If the length of one step is chosen to be less than 1 m, then the console can be made of hard wood without a frame;

- W1 – tread width;

- W2 – step width;

- Α – stage rotation angle.

Calculation of the number of steps

To find out the total number of steps, it is necessary to divide the height of the opening by the rise, the standard and comfortable value of which is taken to be 15-30 cm. The angle is calculated by

- α= γ / number of steps;

Having the calculated width and angle values, you can calculate the maximum tread width:

- W1 = R x sinα

The average tread width will be:

- W = R x sinα= (2R x sinα) / 3

Important! It is recommended to make drawings in horizontal and vertical projections and in two scans.

Types of spiral staircases

The screw model is not a necessary solution. It is equipped if there is not enough space in the room for a marching structure. The design of such products can be absolutely anything - from classic to modern or high-tech. For example, a wrought iron staircase is suitable for any interior if individual parts and elements are finished with wood or stone. Spiral models also work as auxiliary structures - attics, basements, etc.

Different staircase designs

Disadvantages of screw spiral designs of internal stairs:

- It is more difficult to climb on a helical surface than on a marching surface - due to the cramped and circular design, there is a danger of injury, children and the elderly are especially at risk;

- It is inconvenient to lift/lower pieces of furniture and other bulky items using a screw product;

- The complex geometry of the steps makes it difficult to quickly move along the steps, since the steps for the left and right legs will have different sizes;

But the appearance of such a model most often outweighs all its shortcomings - the design looks light and airy, although it is very durable and reliable. Rotary staircase systems are also considered screw, as they have winder steps in the device. Turning stairs are as follows:

- Curvilinear complex design;

- Half-turn rotary models;

- Quarter turn devices;

- Curved models.

Calculation of a quarter-turn model

When assembling and installing a rotary model, it is strengthened along the load-bearing wall, with a handrail on the outside. The disadvantage of such structures is considered to be an uncomfortable climb up the steps.

Features of installation of a spiral staircase

The assembly of spiral staircases is carried out in a certain sequence, violation of which can weaken the structure:

- Calculation of parameters for specific operating conditions;

- Selecting a place for support, installing the support bottom flange;

- Fastening the first step to the floor with a flange;

- A set of bushings for the support post, fastening the remaining steps;

- Fastening the entire frame to the wall, or mounting the structure to the ceiling using the top step;

- Fastening the upper end of the support;

- Selecting the design and design of railings and other protective elements.

¾ turn staircase

To calculate where to install the supporting metal rod, on the second floor, two construction cords are pulled diagonally at the location where the staircase is installed. At the intersection of the cords, a plumb line is attached, and on the first floor the center of the axis is marked, which will be the main axis of the staircase. The tube for the rod should be ≈ 50 mm in diameter if it is metal. The wooden post should be at least twice as thick.

For safe operation of a spiral staircase to the second floor, attic or attic, it is recommended to fill the support with concrete - for this purpose a separate concrete pad is installed. The support can be secured to concrete using anchor bolts or turboprops through a metal flange with mounting holes.

The steps on the main support are mounted at a smaller size. The height of the riser should be equal to the height of the sleeve minus the thickness of the washer, which is inserted between the bushings and the tread. The washers must be metal to minimize their wear during operation.

Angle of inclination and elevation

If desired, parts made from other decorative durable materials - glass, stone, plastic, marble, etc. - can be inserted into the elements of wooden spiral staircases. The lifespan of the staircase and the degree of its strength depend on the material from which the main supporting rod is made. Therefore, preference is given to building materials such as asbestos cement, concrete or metal. The steps are attached in different ways: to asbestos cement or concrete - with bolts or anchors, to metal - by welding or threaded connections. Sometimes a brick, wood or stone column is used as the main support.

What is a spiral staircase to the second floor?

The spiral staircase has a complex spiral shape that attracts the attention of others. It consists of railings, supporting elements, as well as wedge-shaped winder steps located under a certain radius.

For a screw lift, the following can serve as support:

- rack;

- central pillar;

- bowstrings;

- bearing wall;

- loaches;

- spiral stringers.

Calculations

Let's calculate a spiral staircase, in which the support will be a steel tube 5 mm thick, with a diameter of 6-8 cm. We use a steel corner for welding consoles, and we will use solid wood to arrange the steps.

You must understand that the spiral staircase to the second floor is a regular circle, its diameter corresponds to the size of the opening.

R – outer radius of the console (circle).

R1 is the internal radius of the opening (diameter and thickness of the support pipe).

γ is the revolution of the structure, an angular value demonstrating the difference in height between steps.

L – circumference.

Formula for calculating circumference:

L=2πR*n or L=2πR* (γ/360).

In practice, this is not enough for normal movement along steps, and therefore 2R/3 is taken as the radius of movement. As a result, the formula takes the following form:

l=2π*2R/3*n=4πR/3*n

Conclusion

The economic component of making a screw structure yourself is quite attractive. The price of work, materials, fittings is quite low and allows everything to be done at minimal cost.

However, it is worth mentioning that this is a rather complex process that requires precise calculations, some knowledge of geometry, and the ability to work with wood. Drawings and assembly diagrams, of course, will help in many ways, but the rest depends only on perseverance and attentiveness. And in the video presented in this article you will find additional information on this topic.

Economy spiral staircase in a private house, design and railings

The simplest stairs that can be successfully assembled with your own hands and used both in the country and in a large cottage are simple welded economy-class structures. As a rule, such stairs are assembled around a main pillar, which is rigidly fixed in the stairwell. This design is assembled from ready-made elements, and the elements themselves can be prepared and made in convenient conditions, and when installing the structure it will be enough to assemble them together. We presented several such structures in the photo.

The simplest option is a prefabricated pillar, which is formed as the steps are strengthened, and the design of the railings and strength elements is determined by the choice of the owner; here the choice is extremely large. Thus, for very little money and with your own hands, you can make a simple spiral staircase for your summer house, which, nevertheless, will meet all the parameters of safety and comfort.

Material

The material for making stairs can be anything: from stone to plastic. The choice of material is determined by the functional purpose of the staircase and its operating conditions.

Metal spiral staircase

Options for stairs made of different materials:

- rope;

- plastic;

- wooden;

- from natural and artificial materials (tiles, porcelain tiles, marble, granite, etc.);

- metal and steel (copper, steel alloys, aluminum alloys are used; artistic forging is often used in the manufacture of metal stairs);

- brick;

- concrete (reinforced concrete);

- glass (often combined).

White and brown spiral staircase in the interior

Often stairs are made of wood, metal alloy or glass. Less often - marble and concrete. Designers create various options for the layout of materials (railings and staircase bases); combinations of glass and metal, stone and wood, glass and stone, wood and glass, etc. are often found.

Spiral staircase made of wood and metal

The choice of material depends on the style of the interior. Wood is an almost universal material, because... Suitable for use in various conditions (indoors and outdoors). Wood combines well with other materials, so it will not be difficult to combine wooden steps and clear glass railings, create concrete steps and beautiful wrought iron railings and railings.

Small spiral staircase made of wood and metal

Beige and black spiral staircase

Beige and gray spiral staircase

Black metal spiral staircase

Beautiful view from the spiral staircase in the house

Beautiful wrought iron spiral staircase

Brown and black spiral staircase

Staircase shape

Projects sometimes include a pattern configuration that involves the use of winder steps and has different radii or offset turns. Winder steps can be screw or rotary. The first option is also used in the construction of spiral staircases, and sometimes a closed spiral is converted into an open branch. Stairs of this type have a perfectly round space between the steps; an oval layout is rare. Spiral stairs are included in the category of curved stairs, the main feature of which is the absence of a central support. The classic spiral staircase has such a stand. Compass ladders are also classified as curvilinear. In rounded staircases, the steps are sometimes “diluted” with small platforms. As for the turning steps, they are necessary to design a bend with a right or acute angle. Such turns gave the rectangular spiral staircase its name. The latter consists of a large number of marches, at least three per level.

Construction installation rules

Installation of this design is as follows:

- Initially, an accurate calculation is made to ensure that the staircase complies with safety standards.

- Then comes the selection of the staircase location point. The lower support flange is being installed.

- The very first step must be mounted to the floor and installed in a flange.

- The rod must be strictly vertical. To do this, use a level.

- Bushings are attached to the main support. And the steps are installed according to the manufacturer's recommendations. It is advisable to involve an assistant in the work, or even better, a friend who is knowledgeable in this area.

- The spiral staircase must be fixed along the load-bearing wall and attached to the floor of the second floor using the last step.

- The main post is finally fixed at the very top.

- Then the railings with protective grille are installed.

- Solid wood or other decorative material is applied to the steps.