The manufacture of stairs has always been entrusted only to experienced carpenters, because such a design requires great skill. Every master must be an architect, designer and engineer at the same time. In addition, he needs to have enough practical knowledge and be able to make several types of stairs in order to select and manufacture the optimal option.

DIY wooden staircase

Construction of a wooden staircase

A wooden staircase for a private house most often consists of one or several flights (flights), which are located between floors or intermediate platforms.

Construction of a wooden staircase

The design of a flight of stairs is a combination of various components with different functional purposes:

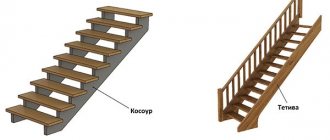

- Kosour. It is a load-bearing beam made of wood with a sawn comb. Risers with steps are fixed to it, so the part must be durable.

- Bowstring. In some cases, it becomes an alternative to a stringer, performing load-bearing functions (especially if one side of the structure is adjacent to the wall). Before installation, the string must be marked in detail so that the steps are located at a horizontal level.

- Step. The main element of any staircase, which is attached to one of the supporting beams. In addition to the usual ones, there are winder and radius steps. The winder elements have a non-standard shape and are mounted at the starting point of the march. Radius steps have a curved leading edge and can be semi-circular, wavy or with rounded corners.

- Riser. The part is optional, but it provides the staircase with high strength by supporting the step in the center. A spacer bushing is used to secure the riser. A radius type is installed under semicircular steps, and a curved version is mounted under the corresponding steps or under the landing between flights of stairs.

- Pillars for support. They are placed at the starting and ending points of the stairs, as well as along the edges of the inter-flight platforms. The elements increase the strength of the fence and serve as support for the handrails.

- Balusters. These are supporting posts for handrails, from which side railings are formed, and can have different configurations.

- Handrails. They are a required part. They rest on balusters and support posts. The main requirement for the element is a smooth surface.

- Distance sleeve. Such a stand is required for any structure with several flights (even when using stringers).

Building plan

Typically, a staircase drawing is part of a building or floor plan. We will begin by introducing the concept of a plan.

It is worth clarifying: of course, when manufacturing any complex structures, a detailed sketch is also drawn up, indicating those dimensions that are usually absent on the building plan. However, the staircase is in any case indicated on the general plan.

So, a plan is a projection of a horizontal section of a floor or an entire house onto a plane. What information does it contain?

- The location of all rooms on the floor, indicating their sizes.

- Location of staircases and flights.

- The location of window and door openings also depends on their dimensions, of course.

- Building structure (including location of supports and floor spans).

- Thickness of load-bearing walls and columns.

Drawing up plans is subject to certain rules:

- The main facade is at the bottom of the plan.

Cottage floor plan. The façade is below.

- If there are plans of several floors on one sheet, they are arranged in ascending order of the floor number from left to right or from top to bottom.

- The plan indicates the direction in which the doors will open.

- The drawing of a flight of stairs is supplemented with an arrow indicating the slope from bottom to top: the beginning of the arrow is always at the bottom of the flight.

Types of staircase designs

When choosing a staircase structure, the main factor is the size of the area required for its construction. In second place is the convenience and comfort of ascent and descent. Here you need to take into account the frequency of use, the presence of children and elderly people in the house.

Aesthetics is also an important criterion. The staircase should be combined with the interior of the room. In addition, it is necessary to take into account material possibilities: the production of wooden stairs with a complex configuration requires more time and financial costs than options that are simpler in form and execution.

Marching

Are the most popular. They got their name thanks to marches (flights) - a group of united steps. The staircase may have one or more flights.

There are straight structures (single-flight and double-flight, with a rest area). They can be free-standing or placed near the wall. But straight models require a lot of space, so in order to save useful space, two-flight options are provided with a rotation at an angle from 90 to 180 degrees.

The flight has a curved shape with an optimal angle of elevation, then rotary steps are used, which are also available in structures with two and three flights without platforms.

(function(w, d, n, s, t) { w[n] = w[n] || []; w[n].push(function() { Ya.Context.AdvManager.render({ blockId: "RA-510923-1", renderTo: "yandex_rtb_R-A-510923-1", async: true }); }); t = d.getElementsByTagName("script")[0]; s = d.createElement(" script"); s.type = "text/javascript"; s.src = "//an.yandex.ru/system/context.js"; s.async = true; t.parentNode.insertBefore(s, t) ; })(this, this.document, "yandexContextAsyncCallbacks");

The most popular types of wooden stairs for a country residential building are:

- Ordinary one-march ones. They have a simple design with a span in the center of the room or near the wall - the most durable with reliable support.

- Curvilinear single-flight. Installed in large rooms to emphasize spaciousness. They are distinguished by a smooth turn and steps widened on the outside.

- Marching with lower turning steps. Sometimes this option is provided for by the layout of the room and can support the chosen architectural style.

- A simple 2-flight system. A staircase with two flights and an interfloor turning platform can be mounted above the door and save space.

- 2-flight L-shaped design. It is located in a rectangular opening along perpendicular walls and saves space.

- 2-flight U-shaped staircase with an upper platform and turning steps. The design is installed in luxury mansions with a large hall.

- 3-flight system with two platforms. This type of staircase saves space, but requires a significant ceiling height.

To select a specific configuration, you must correctly calculate and measure the free area for installation and draw up a drawing. A detailed guide on how to do this will be below.

Screw

Screw-type structures are used less frequently, as a rule, with limited space or for aesthetic reasons by the owner of a private house. They are not as convenient as marching ones, and it is difficult to transport furniture on them. To install the ladder, you will need to perform complex calculations, since with a small error it may lose its functionality.

Spiral staircases sometimes serve simply a decorative function, especially with a fence made of artistic forging. The installation of such options is possible in almost any room, because they take up less space than rotating designs. The following types are distinguished:

- with cantilever pinching of steps on the internal pillar;

- with steps supported on the internal pillar and perimeter walls;

- with cantilever support of steps on the casing pipe;

- with support on the fence and bent bowstrings.

More complex options are modular spiral staircases. The structure is assembled from modules, folding them at an angle in a certain sequence. They come with a central stringer (the steps are attached to the modules, and the edges are connected by bolts) and a central column (rested on a stacked column, connected by bolts). Read more about wooden spiral staircases.

Spiral staircases save space

Ways to make a ladder on bowstrings with your own hands

There are several ways to install a ladder on strings. The most popular are free-standing and wall-mounted stair bows. A wall string for a staircase can only be seen from one side of the staircase, but a free string, otherwise called a light string, is visible from all sides.

It is these properties that need to be taken into account before making a ladder on a bowstring with your own hands and choosing any specific type of wood, as well as when processing the surface of wooden blanks.

Assembling a ladder on strings differs from installing a structure on stringers in the method of fastening. The steps of such stairs are inserted into the grooves of the supporting beams, which are called bowstrings. Sometimes only one string is used in a design. In this case, the second side of the steps is installed into the wall.

Stairs on bowstrings can be open or closed. Open staircases look lighter, and when creating closed structures, risers are used, making the staircase visually appear massive.

The most convenient and simplest to create are staircases on bowstrings with a straight flight, in which the steps are fastened between two straight beams - bowstrings. Such staircases can be single-flight or double-flight - depending on the size and design of the room. In addition, bowstring structures can be designed with an intermediate platform or winder steps. The shape of the landings (rectangular, square or rounded) directly depends on the chosen structure design.

One of the simplest designs of ladders made of wood on bowstrings, as well as ladders on stringers, which is suitable for novice craftsmen, is considered an extension (single-flight straight). The angle of inclination of the flight of stairs will depend on the amount of free space for the structure and on the height of the floor.

If there is not enough space, then it is recommended to build a two-flight straight staircase with winder steps or an intermediate platform. Thanks to this, you can save useful floor space. In addition, such a ladder is very convenient to use.

You can make your own bowstring stairs with risers, although the latter are rarely used in this type of structure. Due to the absence of these elements, the stairs look lighter and less massive.

As for the decor, in the stairs to the second floor, mounted on bowstrings, load-bearing beams, as well as stringers, may well act as decorative elements.

If desired, they can be decorated, for example, using artistic wood carving. A good decoration is forging metal, which is attached to a bowstring made of wood.

Fences play an important role in the design concept of a flight of stairs. They can be made of wood or wood with forged or stainless steel elements. The railings are usually light, so the staircase looks even more “transparent”.

Another distinctive feature of the design of staircases on bowstrings is the ability to place balusters in any order and at any frequency, which is problematic to do in staircases on stringers, where the order is more limited.

Do-it-yourself wooden ladders on bowstrings are reliable and easy to use. They are safe and durable, since, despite their apparent lightness, they are able to withstand significant loads.

The basic principles of constructing a staircase structure on bowstrings do not differ from constructing a staircase on stringers. Openings supporting bowstrings on the lower and upper beams are built according to the same principles as when installing stairs on stringers.

The main difference is in the way the steps are supported. In staircases on stringers, the steps rest on the boards on top, and in staircases on bowstrings, the steps are located between the boards (strings). When a vertical load is applied to a step, the tread bends down and then straightens. At the same time, a spacer is formed at its ends. To prevent the strings from moving apart, it is recommended to connect them with a metal rod with a diameter of 8-12 mm with threads at the ends and nuts. You can also use cords of other designs.

One of the common designs is a staircase with mortise steps. When erecting it, cutouts are made in the bowstring - grooves 15-20 mm deep into which treads and risers will be inserted. For a tight fit of the tread, the grooves of the bowstring must have even planes and the same depth.

Watch the video “String Ladder”, which shows various ways to install such structures:

https://youtube.com/watch?v=2YSwsjJWhiQ

Types of structures

Before making a wooden staircase, you should choose the best design option for your room.

The following popular types of structures exist:

- on two stringers;

- on one central stringer;

- on bowstrings;

- on pain;

- on the central post (screw);

The simplest is a straight staircase, which ensures linear movement along the flight.

Read more about this in the article about types of wooden staircase designs.

Let's look at making a wooden staircase with your own hands with clear step-by-step instructions in more detail. The process includes two main stages: design and installation.

Methods for obtaining a drawing

There are several ways to compile project documentation:

- On one's own. Many people can make calculations and draw a drawing of a staircase for simple structures (straight, rotary with a platform). More complex options are best left to professionals;

- Programs for designing stairs. They allow you to carry out detailed design, obtain visualization of the structure before installation and make adjustments. Using a 3D picture you can see how the staircase will fit into the surrounding interior. In this case, it may take several days to master the software;

- Ready-made solutions. Drawings of stairs presented on the Internet can be offered with or without detailed detailing. Such projects should be checked for compliance with calculations and building codes. You can contact professionals for advice.

Example of a finished drawing of a staircase

This will be much cheaper than making adjustments at the time of installation. Another subtlety - you should understand how the parameters of the ready-made solution will fit into the installation location; - Online calculators. Offered by some developers and manufacturers. Such software can calculate and automatically generate a drawing based on the entered data. The same programs display a list of recommendations for changing parameters if they do not meet technical standards. The disadvantage of calculators is that the design is not linked to the layout of a two-story house;

- Appeal to professionals. This method is considered the cheapest.

Because it is experience and professional skills that will allow you to perform competent calculations and drawings of the stairs, taking into account the features of the interior. The presented detailing and material recommendations can ensure the aesthetics, reliability, durability, comfort and safety of the finished structure.

Everyone chooses their own method of obtaining design documentation. If you have the strength and time, you can manually prepare a diagram and details of the staircase.

Calculations of staircase dimensions

Before you start designing, you need to make accurate calculations, draw a diagram and put all the data on it. If you are not sure of the correctness of the calculations, then it is better to entrust the work to professionals who will make a competent drawing, which will allow you to carry out the installation step by step without errors.

Total height of the stairs

The height can be determined by measuring the distance from the floor of the first to the second floor, taking into account the thickness of the ceiling. For example, if on the 1st floor the ceiling height is 2700 mm, and the thickness of the interfloor ceilings is 300 mm. As a result, the total height will be equal to 3000 mm.

If there is no finished floor, then its dimensions need to be approximate.

Number of steps

If the height of the staircase and riser are known, the number of steps in the structure can be determined. To do this, you need to divide one indicator by the second. For example, with a total staircase height of 3000 mm and a riser height of 175 mm, the calculation will be as follows: 3000: 175 = 171 mm.

After this, you need to round the value, the result will be 170 mm. The table shows an example of a calculation:

Dependence of the height of the steps on their number at a given floor height

Riser height

According to experts, the optimal riser height should be 150–180 mm, which is actually the size of a human step. This height can be 150–200 mm. Usually the average value according to the standard is 160-170 mm.

The optimal slope range for the stairs is highlighted in green.

Step width

To avoid injuries as a result of incorrectly selected width of steps, you need to calculate it correctly. Based on many years of practice, the width of the part should be in the range of 220 – 400 mm.

To determine a more accurate value, you can use a certain formula. You need to take the average width of a human step (600 - 640 mm) and subtract from it the height of the riser, multiplied by 2, i.e. 640 – 2x175 = 290 mm. This indicator will be optimal for moving.

March width

According to safety rules, for convenient movement of people, the span should be at least 80 cm wide, but it is better to take at least 90 cm. For convenient transportation of furniture, this figure for a private residential building should be 100 - 120 cm.

Plan length of the staircase

To calculate this parameter, you need to multiply the number of steps and the width of the tread. In our example, it will be 29x17 = 493 cm. That is, the staircase is quite long and when constructing one flight, a room of at least 6 meters will be required. In a small log house or country house, you will need to make 2 flights with a 90 or 180 degree turn.

A platform is installed between the flights or turning steps are installed. If you can’t perform the calculation yourself, you can use the special program presented below, which will clearly reflect the localization of the staircase parts.

Ceiling opening size

When building a staircase from solid wood, you need to remember to calculate the ceiling opening so that you don’t have to bend over when going up. This indicator will depend on the slope, which affects the ease of movement and is selected individually.

A slope of 23-36 degrees is considered optimal, but often it is not possible to maintain the required angle due to the small area of the room (the steeper the slope, the less area it will occupy).

The size of the opening in the ceiling area will depend on the angle of the flight of stairs. So, for a folding structure, a small opening will be required, and for a larger slope, a more significant one will be required (up to 2 m).

The size of the opening in the ceiling is determined based on the minimum permissible value for human passage

Stringer length

To determine the length of the stringer, the Pythagorean formula is used: (length of the staircase in plan)²+ (height of the staircase)²= (length of the stringer)².

Determining the length of the stringer

That is, with a length of 493 cm and a height of 300 cm, we get the following: L = √ (4932 + 3002) = 577 cm (the indicator is taken with a margin of 580 cm).

Online calculator for calculation

For your convenience, you can use a convenient and visual online calculator for calculating wooden stairs.

Standard dimensions

If the design involves the use of a large number of steps, then it is preferable to arrange special intermediate interfloor spaces. The optimal solution would be to create a wide platform. Its parameters are equal to the width of two flights with the addition of an additional 10-20 centimeters.

Various regulatory requirements affect the construction of stairs and prescribe certain parameters for them, for example, according to SNiP, the permissible norm varies from 80 to 140 centimeters in relation to the width of the steps.

For stairs used as evacuation stairs, there are separate parameters according to which the flight standards must be at least 90 centimeters.

Depending on the functionality of the stairs, the transfer of large objects is also taken into account

This is especially important to take into account on the so-called turning stairs. The useful width of such structures must be at least one meter, otherwise transporting things will be problematic

It is necessary to note such a parameter as the depth of the tread. Its peculiarity is that it varies depending on the length of the element: towards the inner part the tread narrows, creating something like an opening, and towards the outer part it expands. Based on this, the average value, that is, the central line, is always taken as a basis. This is what is taken into account in the design.

According to GOST, the minimum tread size should be 25. By substituting this parameter into the Blondel formula, you can calculate its height. It is 19.5 cm, and this is considered an ideal indicator. Of course, it is not necessary to observe exact values when arranging the staircase yourself in a private house. However, taking into account the standards will make the design as safe, convenient and comfortable to use as possible.

The optimal height of steps varies between 12-25 cm. In private houses with a height of more than two floors, this parameter should not be more than 20 cm.

Much attention should be paid to the distance between the balusters. The largest value reaches 15 centimeters

Otherwise, the stairs lose their original supporting function.

Since the staircase consists of individual modules, their dimensions also need to be taken into account. An indicator of these elements is the interaxial distance between the modules, which ranges from 225 to 300 mm, depending on whether the topmost step is taken into account.

Regulatory documents place the safety of the stepped structure at the forefront. It is considered safe only if the sum of the dimensions of the tread and riser is 46 cm, for example: 23 and 23, 28 and 18. Such calculations are called the “safety formula”, in which the best indicator is considered to be 29 and 17

However, it is not necessary to follow this parameter, it is only important to adhere to the number 46 cm, because in practice it is quite difficult to realize ideal indicators in individual projects

Material selection

After all the calculations have been completed, you need to purchase materials. This will require boards of different lengths and densities: for steps the thickness is 3-4 cm; for risers – 2-2.5 cm; for a bowstring or stringer, the thickness is 5 cm and the height is 150-250 mm. It is better to buy ready-made handrails and balusters, since their production will require a lathe and timber measuring 10x10, 15x15 cm. To fix the components, you will need screws and nails, as well as metal corners for reinforcement.

What do the standards say?

Elegant and beautiful structures leading to the second floor must be carried out in accordance with technical requirements and standards. Materials for construction are selected according to the criteria of strength, convenience and safety. A stepped product is constructive, decorative and utilitarian at the same time. It matches the interior of the space, does not overload it and is convenient to use.

Based on the current SNiPs, we can draw conclusions about the location of the stairs in a private house:

- from the end of the corridor to the flight of stairs there is a distance of at least 160 cm;

- the width of the steps is 105-120 cm;

- the ideal angle of the stairs is 45 degrees, which is the maximum slope of the flight;

- there are at least two lifts in one march;

- the optimal number of steps is from 13 to 18;

- The width of the steps is 25 cm and the height is at least 12 cm.

Manufacturing of parts and installation of stairs

The installation technology includes the manufacture and installation of all elements of the staircase structure in accordance with the drawing.

Assembling bowstrings or stringers

On the prepared boards you need to mark the length and saw off the excess. On the block, using a square, mark the height of the riser and the width of the tread with a decrease of 2-4 cm.

Marking a solid stringer

Option for making a stringer with fillies

Assembling a bowstring with stiffeners

The notches for the steps are cut out with a jigsaw or saw. Next, place the workpiece at the installation site so that the lower edge rests against the floor, and the upper edge against the ceiling. The cuts under the steps should be horizontal, without “blockages”. After this, it is recommended to sand the surface of the block and perform milling, rounding the outer edges.

For optimal rigidity, sometimes 2, 3 or 4 stringers may be required, the number of which is selected depending on the width of the stairs. Sometimes it’s easier to order a ready-made supporting frame, which will include all the elements with cutouts, designated by numbers for joining in accordance with the diagram.

Installation of steps and risers

The risers are mounted in the prepared cuts of the stringer, leveled and sanded. Fastening is done using self-tapping screws, which can then be puttied or covered with finishing material.

Methods for installing steps on a stringer

Options for attaching steps to the string

After fixing the risers, pre-milled steps are installed, the length of which should exceed the distance between the pair of outer stringers by 1-2 cm. The width of the elements should be 2-3 cm larger than the comb protrusion. The steps are fastened to the risers and stringers using self-tapping screws, the heads of which must be recessed into the wood.

Attaching the stringer to the upper ceiling. Methods of connecting staircase elements.

Attaching the stringer to the floor

Installation of fences

You can give the structure a complete look with the help of auxiliary parts. For this, carved, straight, figured wooden and metal fences can be used.

Fencing fastening scheme

Installing posts with balusters is considered a complex task, requiring precise markings and adjustments. In the step, the hole for the dowel is marked at a distance from the edge equal to ½ the width of the base of the baluster. Then holes are made on the steps and dowels are glued into them (they should protrude 1-1.5 cm from the surface).

Fastening balusters to dowels

After this, you need to make holes in the base of the posts and balusters according to the diameter of the dowel and coat them with glue. All elements are mounted on dowels with vertical level adjustment. Next, prepare the handrails by cutting the edges at the desired angle and milling them from the bottom. To connect to the supports, holes are drilled at the edge of the element. The handrail is installed on a dowel glued into the support post.

Fastening balusters with railings

Next, the balusters are coated with glue, and handrails are placed on top of them in the groove. And although fixation into the groove is quite reliable, it is recommended to fix the joint with thin self-tapping screws.

After the glue has dried, the stairs must be coated with an antiseptic primer, then the surface is treated with transparent varnish or paint. You can install a decorative plinth. In a spiral staircase, you can design it with an axial support in the form of a log or beam, or install a bent string to support the steps. The price of such a design will be high, since viscous flexible wood is used in production, but the final effect is worth it.

What type of wood to choose

The choice of wood type is an important issue. Many articles about stairs recommend choosing 50×100 mm timber. The working side is 50 mm. The other side will be enough to hold 200-250 kg. The steps can be purchased ready-made; the cross-section is selected in accordance with the calculations.

Important! When purchasing, you need to ensure that the material for the stairs is of high quality. It is advisable that the wood is stored in packaging rather than absorbing room humidity. Otherwise, after getting into the house, you will have to say goodbye to part of the steps, since they will dry out and burst.

Glued lumber is considered the most durable. At the same time, the greater the number of glued bars, the stronger the structure. Hardwoods are the best options for stairs to make them stronger.

The most economical option is considered to be a staircase made of pine or spruce.

They can be purchased anywhere you go. More durable and expensive options are larch, aspen or oak. These materials are the most popular, and most often you have to choose between them. Find out more: features of oak stairs.

The staircase must be made of quality material

Processing of the finished product

After the entire structure has been assembled, it is necessary to treat the wood with special means to protect it from insects, rot, etc.

Ideally, processing should be done on the structure in disassembled form.

In order to harmoniously fit the staircase into the interior of the room, it is necessary to use a varnish coating. It is also possible to tint the desired shade. To do this, you can use stain or colored varnish.

The painting process includes three stages: sanding, priming and varnishing.

Assembly steps

- First, a trial assembly is carried out with your own hands to eliminate possible defects in the stairs;

- After final fitting, the wooden parts are treated with a special antiseptic solution to protect the wood from damage by fungus and mold;

- The ends of the steps and the inner surface of the grooves are coated with glue and tightly fastened, as shown in the photo;

- To increase the level of reliability, the steps are additionally fixed with screws on the outside. In order not to spoil the aesthetic appearance of the stairs, it is better to recess the heads of the screws into the beam by 5-8 mm, and fill the resulting recesses with putty;

- Then the staircase undergoes finishing treatment - varnish or paint.

Let's sum it up

There are many design options for lifting products and materials used to equip them. The steps of the stairs, which are installed on a bowstring, look especially beautiful. And thanks to modern technologies, this design has become much stronger and stronger, which makes it possible to extend the service life of such a structure.

The width of stairs recommended by professionals in individual houses is 1300±200 mm.