Residents of multi-apartment buildings rarely encounter heating problems, since they are connected to a central system and do not think about whether to heat the house with wood, gas or electricity. But in private homes it is necessary to install boiler rooms, the financial costs of using and installing which can be reduced through the use of electric heating boilers. Thanks to it, the efficiency improves. Also, the water supply becomes uninterrupted, while its volumes increase.

How does an electric water heater for heating work?

As a rule, such devices are used exclusively for hot water supply. But modern technologies make it possible to use it as an additional thermal circuit for heating water in a heating system. Before using the water heater to prepare the coolant for heating devices, it is necessary to modernize its recharge circuit:

Create a forced coolant circulation circuit.

It is necessary to connect the heating circuit with the installation of protection and control devices: an expansion tank, a circulation pump and shut-off and control valves, a control and protection unit with primary sensors for temperature and pressure of the medium.

The originality of the idea, and its practical implementation, lies in the synchronous operation of the same source: for hot water supply and heating. For this reason, it is recommended to first select an electric pump of the required electrical power. It must be able to cover all hydraulic losses in the system and evenly distribute heat throughout the heating devices. Experts recommend installing water purification filters at the inlet in front of the boiler in simultaneous hot water and heating systems.

Storage tank and heating boiler

The storage tank is ultimately completely identical to a classic water heater. The difference lies in the internal coil, which is connected to the heating system.

A professionally organized heat supply system through a heat exchanger implies that this component will act as a thermal accumulator. The liquid medium in the tank receives heat through a coil heat exchanger connected to the in-house heating pipe system.

Indirect heating boiler

The optimal alternative for heating small rooms is to include an indirect heating boiler in the heat supply scheme. They can be universal, capable of operating on different types of energy carriers: gas, flue gases from the combustion of solid fuels and electricity.

Typically, such devices are installed in heat supply circuits to increase overall efficiency in the form of an additional heating source. The main one is the traditional heating boiler. For efficient operation of an indirect heating water heater, it must be installed before entering return network water into the boiler unit. In this way it is possible to create an optimal heating system.

Do-it-yourself electric boiler for the heating system

The price of industrial modifications of heating water heaters is very high - from 12,000 to 70,000 rubles. and higher. Therefore, their alternative can be a heater made in-house. For this case, it is allowed to use an arbitrary steel tank of increased strength, with parameters corresponding to the design ones.

To wire the heating circuits of a homemade water heater, you will need the following parts:

- Tank. It would be preferable to place an order from a specialized organization for a device made of non-corrosive steel or assemble it yourself. It is necessary to place holes on the body in order to solder the inlet/outlet pipes.

- Coil heating element, the best choice is copper. This metal has the best heat transfer coefficient and temperature elasticity.

- Fastening elements for piping heating and hot water systems.

- Automatic safety with primary sensors and protective devices in the form of an air vent and an expansion tank. The kit is purchased in a retail chain according to the parameters of the working tank.

- Thermal protection of the boiler from loss of thermal energy. To do this, a glass wool/basalt heat insulator of at least 5 cm is placed in the layer between the tank and the protective casing.

How to save energy using a boiler?

The question itself is basically absurd. We purchase a boiler, first of all, to make our home more comfortable. It is often used where it is not possible to obtain hot water for washing dishes and household needs. The same daily shower requires a considerable amount of both cold and hot water. A boiler is an electric device and therefore requires a certain consumption of electricity to heat water. Therefore, we just have to learn how to save electricity by heating water using a boiler.

Everyone knows that a boiler is a device for continuously maintaining water of a certain volume at a given temperature. Therefore, most often the boiler always remains on and switches off from the mains periodically and automatically. However, some thrifty people at print-craft.ru go further and turn it off themselves so as not to waste electricity.

Radiator location

For high-quality heating of a cottage, you need not only to choose the right heating scheme, but also to correctly position the radiators in the rooms. Installation of heating batteries in a private house is carried out on the basis of calculations made by specialists. The number of radiators and sections for each radiator is determined taking into account various factors:

- volume of premises;

- level of heat loss of the building;

- radiator insert diagram;

- at what height the batteries will be installed, and much more.

How to calculate the number of heating radiators

Installation of heating radiators

Instructions for starting the boiler for the first time

Boiler installed

Whether the installation work was carried out by specialists or the owner does not matter. In any case, you need to check the operation of the system

To do this, following the given tips, you need to start the heater for the first time.

We start by checking the correct connection of the systems that are responsible for heating the water. Fidelity, reliability of connection of phase and neutral wires, presence of grounding. The functionality of the circuit breaker should also be checked. To do this, use a device - a tester or a special electrician's screwdriver.

Next comes the search for leaks in the system. It would be useful to control the connection of underwater pipes. Presence and diagnostics of check valve operation.

Running water into the boiler

Attention, the correct sequence of actions for the first and subsequent starts of the system will be described in the next section. Repeated search for water leaks in pipe installation areas.

Diagnostics of heater operation. Turn on the device by pressing the power button.

Fixing the initial temperature sensor readings.

Recheck after 15 minutes

An increase in indicators indicates the correct connection of the heating elements.

Water heater maintenance

The list of maintenance work is not too lengthy:

- replacing the magnesium anode;

- descaling;

- checking the inlet check valve.

It should be noted that many boiler service technicians, in private conversations or in discussions on thematic forums, give the following advice: as long as the water heater is working normally, there is no need to disassemble it or change anything. There are cases where boilers worked properly for 10 years or more without any intervention - it all depends on the amount of salts in the water, that is, its hardness.

If the boiler is expensive and under warranty, it is better to change the anode with the help of service specialists

If the device has clearly become worse at heating water, and when the heater is operating, a hissing or crackling sound is heard inside, it means that the scale layer has developed a significant thickness and it is really time to change the magnesium anode

At the same time, the tank and heating element must be carefully cleaned of salt deposits

Those whose tap water has increased hardness are advised to take measures to soften it. There are two ways:

- Install a softening filter with a cartridge filled with ion exchange resin in front of the boiler. This substance replaces calcium and magnesium ions with harmless sodium. It is better to choose filters that can be regenerated (restored) at home.

- Installation of a hydromagnetic system (HMS). This device is non-volatile. It is equipped with a permanent magnet, the field of which causes crystallization of hardness salts, as a result of which they turn from solution into sludge - a suspension of small particles. The sludge is retained by a fine filter installed after the magnet.

Advantages and disadvantages of heating with an electric boiler

The main advantage of the scheme is simplicity. Almost any craftsman can assemble such a structure, since for this purpose neither special qualifications nor complex tools are required. Another advantage is the low price. Most often, electric water heaters for heating are sold at lower prices than electric boilers. Thanks to this, when creating a heat supply system for small objects, you can save significantly. In this case, you can get a very reliable, highly functional system that can be controlled via modern communication lines, for example, Wi-Fi. That is why it integrates well into the Smart Home program.

The disadvantages of using water heaters include:

- Low power.

- The heating element is constantly in working condition, which leads to rapid wear. To guarantee, you need to choose devices with 2 or more heating elements.

Instructions for starting a Thermex boiler

If installation of equipment is usually carried out by specialists, then the owners themselves have to deal with its startup at least once a year. Let's take a closer look at how to turn on a Termex water heater so as not to negatively affect its performance properties. After all, the duration of operation and frequency of maintenance largely depend on the correct execution of the process.

Work order

Turning on the boiler: The steps for starting the water heater and the settings may vary slightly. It all depends on whether a flow or storage device is used. However, despite the design differences, the order of their inclusion has the same principle. The universal instructions for starting a Termex boiler are as follows:

- Before turning on the water heater, the shut-off valve for supplying hot liquid from the common riser is closed.

This occurs even if a check valve is installed on the pipe. After all, if there is a slight malfunction, the device will heat the central water supply without blocking the channel. - Before connecting the Termex storage water heater to the network, it is filled with water. The outlet of the hot liquid device and the mixer open in turn, and after them the inlet of the cold flow. These manipulations are necessary to displace air from the system.

- After the water has flowed in an even stream, you can turn it off, turn on the unit to the power grid and, after setting the settings and waiting an hour or two, start using it.

The connection diagram for a Thermex water heater when using flow-type devices will be similar, except that the result will be felt immediately.

The next stage after switching on is checking the functionality. Before using the Thermex water heater you need to:

- Make sure that the power indicators light up when plugged in.

- Measure the temperature of the liquid supplied to the mixer.

- After 20 minutes, look at the equipment sensors; if the connection of the boiler with the touch panel is done correctly, the temperature indicator on the device should already increase. If there is no electronic panel, you must once again measure the degree of heating of the water at the outlet of the mixer.

What to do if Thermex does not turn on

The installation process of a Thermex instantaneous water heater or any other model requires the presence of serviceable network elements: sockets, circuit breakers, cables of sufficient thickness. The devices have very high power, so if they do not work, first of all, armed with a tester, you need to check the presence of electricity in the outlet, then the power terminals. Video instructions for installing a Termex water heater will help you find their location, and the tester will help you take readings. If the voltage is zero, then the cable of the electrical appliance is broken.

What to do if the Thermex water heater does not turn on, or rather, power is supplied, but it gives an error - the most popular question. In this case, you need to open the device instructions and look at the explanation corresponding to the code indicated on the display. If this option is not available, the causes of the problem may be the following:

The heating element has a damaged or burnt-out coil. A sign is often a breakdown of electricity on the housing, then the RCD automatically trips and cuts off the power supply. The only way to combat this is by replacing the heating element. The protection is triggered if the heating of the coolant rises above the set limit (usually more than 90 degrees), which occurs both when the control thermostat breaks down and when scale accumulates on the heating element, after which it overheats. The tank is not filled with water. How to turn on a Thermex ID 50V boiler or another model for the first time was discussed above, and if the requirements for removing air from the pipes are not met, a protective mechanism is triggered

Please note that this must be done even if the system is full but has not been used for a long time.

Maintenance: How long will it take to disassemble and clean?

Every year the anode in the water heater , since it no longer works longer. At least twice a year it is necessary to remove parts with complete depressurization of the entire system for cleaning . This is done manually and using special chemical solutions.

An electric water heater or heating boiler is an effective and affordable device for many consumers living in private homes. Of course, the boiler is better adapted for such purposes, but not everyone can afford such a system. For small private and country houses, a simpler and more profitable option is quite suitable. In addition, in some cases, with the right approach to installation, heating a living space from a water heater can be no less functional than boiler heating.

How to use the boiler?

Turn on the unit and set the desired hot water temperature. On most heaters, manufacturers provide 3 positions: 35, 55-57 and 75 ºС. Some models also have a fourth position – “anti-freeze”, then the temperature in the tank is maintained at 10 ºС. The actual operation is to set the temperature regulator to the desired position and use water. In this case, it is worth following these recommendations:

- never turn on the boiler if for some reason the unit’s tank is empty, this can lead to failure of the heating element. The inlet safety valve has a built-in check valve; its performance must be checked at least once a year;

- Although the boiler temperature is adjusted according to your wishes, you need to turn it on to maximum once every 2 weeks and maintain this mode for 2 hours. This is necessary so that harmful bacteria living in warm water do not multiply in the tank;

- There should be a strainer at the cold water inlet into the house. If the water is hard, then it is necessary to organize additional cleaning and desalting, otherwise all heating equipment, including the boiler, will not last long;

- Once every 2 years, clean the tank from scale, and also check the condition of the protective magnesium anode and, if necessary, change it.

Using an electric instantaneous water heater is also quite simple. The device turns on immediately after opening the tap, the water temperature is regulated by decreasing and increasing the pressure. When the water runs too hot, the pressure must be increased; if it is cold, then decrease. For these devices, water hardness is also important; the presence of a large amount of salts will cause scale inside the heating element. First, the heating intensity will drop, and then the element will fail.

Peculiarities

Unlike conventional water heating devices, this device has an inlet pipe (for cold water) mounted at the bottom of the storage tank, and an outlet pipe (for hot water) at the top .

Thus, the liquid must circulate in a closed heating circuit at a fixed temperature , which is achieved in the upper part of the tank.

Indirect heating boiler with connection to the boiler

The main difference between such a device and a conventional water heater for heating is the presence of an external source of heating the coolant. This could be solar panels, a boiler, central heating.

a coolant passes through a coil passing through the inside of the boiler, which, in turn, heats the liquid in the tank.

This system is protected by a thermal insulation layer.

Rules for using a water heater

Before using the boiler, you need to consider the following rules:

- Initially, the device needs to be installed. Proper installation will determine the service life of the device. When installing, you must comply with the manufacturer's requirements.

- Before turning on the heater, you must close the hot water riser. Then the boiler output is connected to it and the system is started. To disconnect, you need to perform the steps in the reverse order.

- When the homeowner leaves for an extended period of time, the heater is disconnected from the power supply.

- Maintenance of the device is required annually.

- The higher the water temperature is set, the more it can be diluted and the slower it will be consumed.

- When there are a large number of consumers in the house, the maximum temperature is set.

Solenoid valve for DHW system with water recirculation

Solenoid valve UNIPUMP BCX-20 3/4″ (normally closed)

Operating medium temperature range – 0…+120 ºС Operating pressure – 0.5…16 bar Power supply parameters – ~220 ±10% V, 50 Hz Protection degree – IP65 Normal closed 20 – DN (nominal diameter) in mm

A normally closed valve opens the way for liquid flow when voltage of ~220 V enters the valve coil (solenoid).

Boiler market overview

Today, there are many Russian and foreign manufacturers on the domestic water heater market, although the latter are predominantly dominant: MTS, Lorenzi Vasco and others.

Many manufacturers are opening full-cycle production in Russia, producing basic components. This allows us to reduce the price on the domestic market and increase the availability of products for a wide range of consumers. One of these developers is considered to be the Italian corporation Ariston, whose heaters have actually already become a domestic brand.

It has been successfully operating in the Russian market for a long period of time, opening its factories and providing Russians with high-quality heaters. The range of models includes various types of water heating equipment.

Ariston is one of the most recognizable brands of water heatersSource goods.ru

The prevalence of Ariston boilers among buyers is quite high due to the quality of the products and the regular introduction of innovative technologies.

Before using the Ariston water heater, let’s consider its technological and design features:

- the model range includes round and flat heaters of various sizes with a bright design;

- high-quality thermal insulation of boilers and automatic control of operating modes make it possible to save on electricity;

- heater tanks are made of special stainless steel with increased anti-corrosion resistance;

- different models use electronic and mechanical control, which makes it possible to control the water heating process;

- in instantaneous boilers, the heating module is made of copper, which increases its service life;

- In a number of boiler models, the internal coating of the tanks is covered with bioglass porcelain, which completely eliminates the occurrence of corrosion.

In addition, the product range includes electric heaters with a mixed water heating system.

Ariston water heater with touch controlSource santeh.ks.ua

Installation of a gas boiler with a boiler

- The instructions for installing a boiler say that when a boiler is used to heat a private house with indirect heating, the temperature in its heat exchanger increases from the boiler, the coolant is heated and enters the distribution of pipes and radiators (read: “How to install an indirect heating boiler - types of device and methods installation"). Thus, recirculation or, in other words, partial return of thermal energy occurs, since the liquid in the heat exchanger heats the coolant coming from the boiler. Then the water, having passed through the heating system, returns to the gas boiler with a built-in boiler.

- To ensure boiler heating of a private house for the purpose of normal coolant circulation in the system circuit, a circulation pump operating in automatic mode is used. Pumping is turned on when the water temperature drops to the level specified by the program. Typically, manufacturers install heating elements for additional heating.

- The boiler in the heating system is equipped with a gas heater or other boiler that runs on any fuel, which can be coal, wood, electricity, diesel fuel (read: “Heating boilers using diesel fuel - characteristics”). It is also allowed to use solar energy to heat the device, and then the amount of heated water can not be limited. In addition, the boiler heating system provides the ability to provide heating with two energy sources, although this will require another heat exchanger.

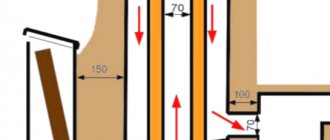

Pump insertion into the heating circuit

It is recommended to install the circulation pump on the return pipe, in which case the already cooled liquid will pass through the device. However, when using more modern models, which are made of heat-resistant materials, tapping into the supply line is not excluded. In any case, the installed equipment should not interfere with the circulation of the coolant.

There are several options for changing the gravitational scheme to a forced version:

- Installing the expansion tank at a higher level. This option can be called the simplest, but this will require a high attic space.

- The expansion tank is moved to the far riser. If you use this method to reconstruct an old system, it will require a lot of effort and time. If a new system is developed according to this scheme, it will not justify itself.

- Placing the riser of the expansion tank in close proximity to the elbow on which the pump is located. In this case, the pipe with the reservoir is cut out from the supply line and embedded in the return pipe behind the pump.

- Pump insertion into the supply line. This method is considered the most optimal option for reconstructing the heating circuit. However, it should be remembered that not every device can withstand high temperatures.

In order for a heating system with an open expansion tank and pump to work efficiently, it is important to choose the right circuit, calculate the parameters of all component elements, select the appropriate equipment and consistently carry out installation work.

Heating inertia

The rate of increase in water temperature in pipes for electric boilers is quite high. The average heating time from 25 degrees to 60 degrees is 15-20 minutes, depending on the volume of the system. In this regard, heating using a water heater is significantly inferior to traditional heating. In order for the volume of water in a boiler with a capacity of 150 liters to reach the desired temperature, you need to wait about an hour. The main criteria influencing this indicator are the power of heating elements, the volume of the tank and the entire system as a whole.

However, when the electric boiler stops working, the water in the pipes quickly cools down. At the same time, in a water heater system, a large volume of hot liquid is in the tank and will require several circulation cycles for it to cool. Those. In the event of an unexpected power outage, the coolant in the boiler system will remain hot for some time.

Summarizing these factors, we can determine the main conditions for using an electric water heater for heating:

- The area of the heated room should be relatively small. This is due to the ratio of 1 kW of thermal energy per 10 sq.m.;

- Good quality running water to preserve all heating elements;

- To fill the tank, it is necessary to create the same pressure as in the water supply - 4 atm. This applies only to those cases when a regular boiler is installed that is not intended for heating from a water heater. In specialized models, the minimum pressure value is much lower - from 1.5 atm.

You can use an electric water heater to heat a house with a small area of up to 80 square meters. First of all, this applies to country houses.

The second way to use an instantaneous water heater for heating is to install a heated floor system. But even in this case, you must carefully read the diagram for connecting the device to the pipeline.

Household models and their prices

Currently, there are a large number of heat exchange devices on the market, differing from each other in type of design, heating rate, tank volume and cost.

Lamellar

Here are some popular models:

R-012-10-19 PROMTECHSERVICE .

The plates of this model are made of steel. Between the plates there are thermal pads that effectively transfer heat from the carrier to the receiver.The strength of the structure is ensured by the corrugated surface. Approximate cost of the device: 14,000 rubles.

- KAORI Z. Soldered version model. The flows are directed diagonally. The plates have a large heat transfer area. Durable and reliable model. Cost from 32,000 rubles.

- Innovita DHW . Budget solution, installed on a gas boiler or heating network. The model is intended for use with Innovita boilers. Cost from 8000 rubles.

Shell and tube

Below are popular models of shell-type heat exchangers:

- TNG-1.6-M8/20G-2-2-I . A popular model, often used in industry and at home. It has tube sheets and a vertical heat compensator. Price – from 9000 rubles.

- Shell and tube heater TTAI . The design consists of two tubes with thin walls of different diameters, one nested inside the other. Thin walls promote more efficient heat transfer. The device is compact and easy to maintain. Price – from 7500 rubles.

- Bowman 190 kW . Premium device. Titanium tubes with anti-corrosion coating are suitable for interaction with chlorinated and sea water. Can work for both heating and cooling. Price from 120,000 rubles.

Pipe material for piping BKN

The thermohead regulator sets the desired water heating temperature no higher than the boiler supply temperature. Also in the passports are instructions for use.

The heating temperature and pressure on the pipes determine which material is preferable to use when piping: Cold water - a regular polypropylene pipe can be installed. The supply of coolant is regulated by a thermostat, which opens and closes depending on the temperature of the water in the tank. The BKN piping must solve several important problems: ensure continuous circulation of coolant from the boiler to the water heater; prevent hydraulic and thermal shock; maintain the set water heating temperature in automatic mode.

What is heating with priority Before installing an indirect heating boiler in the DHW system, you need to choose the principle of its connection: with or without priority. The thing is that the liquid constantly circulates around the ring and cools, so the boiler spends much more resources on constantly heating it.

In addition, the temperature reduction is enhanced by mixing different layers of liquid. If more intense heating is required, this can happen if the boiler usually operates in low temperature mode, then it is better to choose a model with a built-in heating element. The material is suitable for soldering the entire cold water supply system.

If the client turns off the boiler, then make sure that when the boiler is turned off, all systems and equipment are turned off. Also look for an electrical diagram for connecting the boiler to the boiler. Connecting an indirect heating boiler for this case is shown in the diagram below. In addition to installing and connecting the BKN, regular maintenance will be required.

Subscribe to receive new articles. To do this, we can shut off the heating circuit and leave only the indirect heating boiler running. The current load, as a rule, is not less than 10 A. Such devices are connected to heating systems that use boilers that are not equipped with automation. To connect, you will have to make the heating system in two circuits, the first - to generate heat in the house, the second, which has a higher priority, - for the boiler, that is, if the water temperature in the unit drops, the three-way valve will switch the hot water to the heating circuit until the desired one returns temperature.

Nuances of the piping device It is easier to do the wiring and piping if the KN boiler is installed together with the boiler, pumps and other equipment involved in the assembly of the hot water supply system. Let's take the simplest case, when the water heater already has automation. From experience we can say that it is better not to use a dry heating element. The first scheme of a heating system with an indirect heating boiler directs the entire volume of coolant to warm up the tank, which ensures very fast heating of water.

That is, steel pipes become overgrown. In this case, the boiler heats up faster, but then the heating stops completely and with prolonged inactivity, the temperature in the batteries can drop significantly. If the heating appliances are turned off for minutes, the temperature in the rooms is unlikely to drop in such a short period of time, but there will be enough heated water. Connecting an indirect heating boiler with recirculation The second option is to use models that do not have an input for connecting the recirculation circuit, but connect it using tees. That is, during DHW preparation, the heating circuit is switched off. Boiler room equipment. What elements does a modern boiler house consist of?

Types of forced circulation of coolant in heating

The use of forced circulation heating schemes in two-story houses is used due to the length of the system lines (more than 30 m). This method is carried out using a circulation pump that pumps the liquid from the circuit. It is mounted at the inlet of the heating device, where the coolant temperature is lowest.

In a closed circuit, the degree of pressure that the pump develops does not depend on the number of floors and area of the building. The speed of the water flow becomes greater, so when passing through the pipeline lines the coolant does not cool down much. This contributes to a more uniform distribution of heat throughout the system and the use of the heat generator in a gentle mode.

The expansion tank can be located not only at the highest point of the system, but also near the boiler. To perfect the circuit, the designers introduced an accelerating collector into it. Now, if the power goes out and the pump stops, the system will continue to operate in convection mode.

- with one pipe;

- two;

- collector

You can install each one yourself or invite specialists.

One-pipe circuit option

Shut-off valves are also installed at the entrance to the battery, which serves to regulate the temperature in the room, as well as necessary when replacing equipment. A valve is installed on top of the radiator to bleed air.

Valve for batteries

To increase the uniformity of heat distribution, radiators are installed along the bypass line. If you do not use this scheme, then you will need to select batteries of different capacities, taking into account the loss of coolant, that is, the further from the boiler, the more sections.

The use of shut-off valves is not necessary, but without them the maneuverability of the entire heating system is reduced. If necessary, you will not be able to disconnect the second or first floor from the network to save fuel.

To avoid uneven distribution of the coolant, circuits with two pipes are used.

- dead end;

- passing;

- collector

Options for dead-end and passing circuits

The associated option makes it easy to control the heat level, but it is necessary to increase the length of the pipeline.

The most effective is the collector circuit, which allows a separate pipe to be connected to each radiator. Heat flows evenly. There is one disadvantage - the high cost of the equipment, as the amount of consumables increases.

Scheme of collector horizontal heating

There are also vertical options for supplying the coolant, which are found with lower and upper wiring. In the first case, the drain with the supply of coolant passes through the floors, in the second, the riser goes up from the boiler to the attic, where pipes are routed to the heating elements.

Vertical scheme

Two-story houses can have a very different area, ranging from several tens to hundreds of square meters. They also differ in the location of the rooms, the presence of extensions and heated verandas, and their position to the cardinal points. Based on these and many other factors, you should decide on natural or forced coolant circulation.

A simple diagram of coolant circulation in a private house with a heating system with natural circulation.

Heating schemes with natural coolant circulation are distinguished by their simplicity. Here, the coolant moves through the pipes on its own, without the help of a circulation pump - under the influence of heat it rises, enters the pipes, is distributed among the radiators, cools down and enters the return pipe to return to the boiler. That is, the coolant moves by gravity, obeying the laws of physics.

Scheme of a closed two-pipe heating system for a two-story house with forced circulation

- More uniform heating of the entire household;

- Significantly large length of horizontal sections (depending on the power of the pump used, it can reach several hundred meters);

- Possibility of more efficient connection of radiators (for example, in a diagonal pattern);

- Possibility of installing additional fittings and bends without the risk of pressure dropping below the minimum limit.

Thus, in modern two-story houses it is best to use heating systems with forced circulation. It is also possible to install a bypass, which will help you choose between forced or natural circulation in order to select the most optimal option. We make a choice towards coercive systems as more effective.

https://www.youtube.com/watch?v=olrD9qxCAhM

Forced circulation has a couple of disadvantages - the need to purchase a circulation pump and the increased noise level associated with its operation.

Boiler selection

In the case of a flow-through boiler, select the power and size of the device itself. It’s also worth adding a power source here, because they are rarely gas - mostly electric instantaneous water heaters are sold in stores.

If we are talking about savings, then everything depends on the method of use and the size of the family. Boilers up to 15 liters are usually installed for regular washing.

It is important to understand that even for washing dishes, such a water heater may not be enough, depending on the amount of dishes. For a shower stall, a boiler of 50 liters is recommended, but this is for one person.

Next, you need to decide what the boiler will be powered from. Most often, the power source is electricity, but not always. In some cases, it makes more sense to connect the boiler to the boiler. There are a number of important reasons for this, which usually become relevant in individual cases and regions.

Most often, connecting a gas boiler is found in regions with high electricity costs and low gas prices. In this case, it would be financially wiser to use gas rather than electricity as an energy source.

Problems with the supply of electricity also motivate people to make their choice in favor of gas analogues - sometimes the electricity goes out for a day, or even more, and in this case it is especially unpleasant to be left without hot water.

For those who cannot decide on the type of storage water heater, there is also an option. In this case, we simply take and connect a double-circuit boiler, which is connected to two energy sources - gas and electric. Inside it there are two heating elements that can work either separately or together.

Specifications

A boiler for heating a private house, which is supposed to be included in the heating circuit, must operate in the temperature range of 60-70 C and have low thermal inertia of the system. The latter characteristic directly depends on the type of heat exchanger and the electrical power of the heating element. In containers up to 250 liters, heating is achieved in 1.5 – 2.5 hours. In addition, such water heating devices must operate from a 220 V household power supply, with a load not exceeding 30 - 40 A, so that a home craftsman can connect the device independently, without requiring special permission from the distribution zone.

Standard structural structure of a domestic water heater:

- A housing that protects functional elements from external interference.

- A storage tank located in the middle of the structure, isolated from it by a heat insulator. The best volume for autonomous heating is considered to be devices from 150 to 300 liters.

- The heating element is a heating element. It can be made in a variety of design forms: rod, spiral and round.

- An essential characteristic for such boilers is thermal power. It should be from 7 to 12 kW, which will allow heating a room up to 120 m2.

- Inlet/outlet pipes on the boiler for heating. The heating performance is determined by the rate of heat transfer, which depends on the diameter of the outlet pipes. In DHW boilers they usually have a cross-section of up to 20 mm, and for the heating function they need at least 32 mm. In this case, the larger the diameter, the more efficient the heating system functions. Of course, provided that the thermal power of the heating element is sufficient.

- Controlling primary temperature sensors of the coolant, integrated into the operation circuit of the circulation pump.

- Relay for monitoring the operation of the electrical network in order to protect the device from possible long-term overloads.

Boiler as a source of water heating

A classic boiler is a sealed container with an electric heating element inside. For connection to the water supply system, the design provides 2 couplers. Can a similar boiler be used in the heating system of a private home?

Alas, it does not have the proper characteristics necessary for organizing autonomous heat supply. For normal operation, a boiler for heating a private house must have very high power. On average, 10 m² of living space will require 1 kW of thermal energy. Those. To supply heat to a house of 100 m², you will need a boiler model with a minimum power value of 10 kW. Manufacturers simply do not produce such models.

If you use a boiler to heat a cottage with a small area, you may encounter the following problems:

- High rate of inertia. On average the tank is 100 liters. with a heating element power of 2 kW it will heat up to a temperature of +75°C in 1.5-2 hours. In this case, circulation will be impossible, since it will only increase the heating time;

- Large tank volume. In theory, it makes it possible to use a boiler for heating and hot water. However, constant intake of water and replenishment of the system from the outside will lead to uneven heating of the coolant;

- High energy consumption. Before making heating from a boiler, it is necessary to calculate its power. It should be borne in mind that using it in DHW will result in the heating elements being constantly turned on. This will increase energy costs.

So why are there increasingly schemes online in which heating is carried out using a boiler? After all, it is much more rational to use an electric boiler for this. It's all about the wrong terminology. In water heating, it is possible to install so-called indirect heating tanks, which are structurally similar to boilers. To avoid further confusion, we will also call them boilers.

If you want to install a classic boiler as the main heating element, there may be problems with the manufacturer’s warranty. This is due to malfunction of the device.

Calculation of the volume of the storage tank and the power of the heating element

The main element of the boiler, which serves to heat water from the heating system, is volume. It can be calculated using the following formula: V=T*N/(t1-t2), where:

- V—volume;

- T is the time spent heating water;

- N is power measured in kilowatts per hour;

- t1, t2 — thermal regime of the mechanism.

The heating element is a tubular electric heater and the main component of the mechanism. It looks like a spiral wrapped in metal. The system must be filled with dielectric. For example, sand can be used as it. This indicator is subtracted using the following formula: P=0.0011*m*(tk-tн)/T, where

- P—power;

- m is the mass of water to be heated;

- tk is the initial temperature;

- tn — final temperature;

- T is the time spent heating the liquid.

Schemes for connecting boilers to the network

Water heaters are very dependent on the quality of electrical wires, so it is advisable to use copper electrical cables with a cross-section of 2.5 mm or more. To ensure high-quality operation of the device, a fuse or special protection will be required. Any type of boiler must be equipped with an RCD (residual current device). For ease of switching, a three-phase moisture-resistant type socket with mandatory grounding is installed closer to the water heater. Only low-power models are allowed to be connected in this way. High power water heaters will heat up the outlet when operating. As a result, it will fail very quickly: this may be accompanied by sparking and even fire of plastic parts.

To avoid such troubles, it is recommended to connect the water heater with an individual cable of the required cross-section. It is connected directly to the electrical panel, which eliminates the need for additional sockets and branches. This type of switching makes it possible to turn off the device only through a special machine, the main task of which is to ensure the protection and safe operation of the water heater.

Having decided on the model of the water heater, you need to think through all the nuances of its installation in advance. When carrying out it yourself, first of all you should take care of safety precautions. If you have the slightest doubt, it is better not to skimp and call a specialist to connect the water heater.

Types of plumbing

Connection options for wall-mounted water heaters can vary greatly depending on the typical features of the plumbing. The reliability of the connection of polypropylene pipes is ensured by special end couplings and turns. Pipes must be stabilized, with an additional reinforcing layer in the form of aluminum foil.

Plumbing wiring diagrams for connecting a water heater

Connection to a metal water supply system is made using special clamps that can withstand significant loads and have a so-called “inset” in the form of a special pipe.

Particularly popular are lightweight and durable metal-plastic pipelines, easy to install and operate, which are installed using an open method.

What to do if the boiler produces less hot water

Don't worry if you notice that your heater is producing less hot water than usual.

If you decide to use a water heater (boiler) during the cold season, please note that the temperature of the water entering the water heater tank is significantly lower than in other seasons. Thus, the time required for heating increases, and accordingly, your waiting time also increases. Another reason for a decrease in the amount of hot water may be an unclosed riser

If you don't screw the faucet tightly and don't turn off the water, then all the neighbors in your house will also be able to enjoy a hot bath. Therefore, it is better to once again check how tightly the tap is closed, and whether the water supply is turned off

Another reason for a decrease in the amount of hot water may be an unclosed riser. If you don't screw the faucet tightly and don't turn off the water, then all the neighbors in your house will also be able to enjoy a hot bath. Therefore, it is better to once again check how tightly the tap is closed, and whether the water supply is turned off.

Using what criteria to choose?

There are 3 main criteria for this process:

- Volume . You should not set the device to the maximum value for this value. This may lead to financial difficulties in the future. Since a container of sufficient volume will use more water, the bill for its consumption will be higher. It is worth remembering that the larger the volume of the installation, the more it will come into contact with the coil, which can lead to heating of the coolant.

- Power . This criterion affects water heating. For a full heating process, a water heater with an indicator of 8-12 kW is suitable.

- Diameter _ This criterion depends on the area of the room where the device is installed.