Articles

All photos from the article

For many people, a bathhouse is not only a means of personal hygiene, but also a place to relieve stress or even relax with friends. In this case, of course, it should be quite spacious and comfortable, but what to do if there is limited free space on the site, and besides, the budget allocated for construction requires savings? An excellent solution in this case are compact, but at the same time quite roomy baths made of 6x4 m timber, the design of which is the subject of this article.

Below we will look at the most common layout options, as well as the main points that need to be taken into account when designing a bathhouse measuring 6x4 m.

Timber bath 4x6 m

Buy cannot be built

Build a bathhouse yourself? Why not, if you have a talent for construction, the necessary equipment and a lot of effort. Buy? This option is also good, since you get a ready-made bath complex. But will everything really work out?

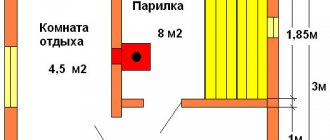

Whether you build it yourself or order a ready-made building, you will need a 6x4 bathhouse project. We offer several photos with dimensions and internal layout. This way you can visually imagine where you and your guests will steam, shower, change clothes and relax.

There can be one plan for the bathhouse, but several design options, depending on the material for building the walls. And if something doesn’t suit you, you can make additions to the project in the form of a veranda or terrace below or an attic above.

Bathhouse layout 6x4 meters

What should be in the bathhouse besides the steam room itself and the entryway? Let us forget the dark and cramped village buildings as bathing rooms. Today, a sauna is a place of relaxation, so the plan for a 6x4 sauna should be well thought out. What to include?

- Steam room. There is a stove here, and there are benches with sun loungers. Typically, the steam room occupies the second largest room and is usually located in the corner of the building.

- Shower room. The sink and steam room are located separately, otherwise either the steam room will cool down or the shower will not bring the desired relief.

- The dressing room is a place where you can leave things.

- The rest room is the largest room in area. There are comfortable sofas, armchairs and a table, and a TV. Using your imagination, you can decorate your room with fresh flowers and an indoor waterfall.

The relaxation room inside the bathhouse itself is a great place to spend winter time. In summer it will be pleasant to sit on the open terrace, and in the off-season - on the glassed-in veranda. It is worth considering this point and designing a 6x4 bathhouse plan with a terrace or veranda. We will help you with photos of such options.

Do you want to have a swimming pool in your bathhouse in addition to the standard rooms? A 6x4 bathhouse layout can take this into account as well. In this case, you will need a second floor or attic. You can equip them with locker rooms, a relaxation room or a shower, and leave a steam room or swimming pool below. Get inspired by photo ideas.

More details about the premises

The classic 6x4 sauna has three rooms.

Rest room, steam room and shower

Waiting room

Here guests undress, coal or firewood for the stove are stored in drawers, and brooms are on the shelves.

To save space, the dressing room is often combined with the guest room, placing furniture here, installing a TV and other appliances, and setting the table.

Its ideal area is 1.3 sq.m per person + space for storing bath accessories and things.

Important! The rest room should have a window.

Steam room

There is a stove in the room - natural, gas or electric. Shelves are attached to the walls. Here the requirements are different - at least 1 meter for each + stove + distance from the stove to the walls and passages.

The ideal height is 2-2.1 meters. If the ceilings are higher, the steam will take up extra, unused space. If it is lower, accumulating, the hot air will need an outlet, and it will evaporate into the ventilation. The width of the shelves is 40-90 cm.

Important! The door should open not into the steam room, but from it, that is, into the relaxation room. Otherwise, there will be high temperature and humidity in the waiting room.

How guests and hosts can steam in a steam room is shown in the diagram below.

How to steam properly

Shower room

Depending on the size of the room, you can install a shower stall, a toilet, or mount a shower into the wall.

The shower room can be heated by the same stove as the steam room (if they have an adjacent wall).

Having chosen a layout taking into account the necessary premises in the bathhouse and their size, you need to decide on the material from which the complex will be built.

Construction works

In order for the service life of the bath to be long, the norms and requirements must be observed during construction. The whole process consists of several stages:

- Selecting a location and marking the site.

- Purchase of building materials.

- Construction of the foundation.

- Walling.

- Installation of doors and windows.

- Roof and roof installation.

- Finishing facilities.

Choosing the location of the bath

The ease of use and service life of the steam room depend on the correct choice of place for construction. There are several features:

- A bathhouse with your own hands should be built on a hill. If it is not there, then it is recommended to erect an artificial hill. In this case, it takes a year for the soil to settle.

- Water pipes. The best option for quickly drawing water into the steam room is a well.

- Delivery and storage of fuel materials. Storage space should be selected at the planning stage.

Selecting materials for the foundation, walls and roof

The foundation should be arranged taking into account the building material chosen for the walls:

- For log, timber and frame buildings, a pile or columnar foundation is suitable.

- For heavier buildings made of bricks and blocks, a strip is required.

Corrugated sheets or metal tiles can be used as roofing material.

Marking and foundation

When the bathhouse diagram according to the drawings is ready, you can begin marking the site. To do this, in strict accordance with the project, pegs with a taut rope are installed in the corners. If you plan to install a pile or columnar foundation, then in this case it is necessary to install pegs in all places where the supports will stand.

In the case of a strip foundation, a trench is dug taking into account the depth of soil freezing. To prevent swelling, the bottom of the trench is filled 10 cm with a “cushion” of gravel and sand.

After installing the formwork, the trench is filled with concrete and reinforcement elements.

Professionals warn: with such dimensions, the baths with a relaxation room are a five-wall structure. For this reason, the partition is laid at the foundation stage.

Walling. Windows and doors

The first stage of brickwork, foam blocks or crown (when erecting a building from logs and timber) is considered extremely important. The entire further course of work depends on the correctness of its implementation. After finishing the laying of the first row, it is worth checking it using a level. If there is a distortion, it is better to redo it right away. The second row begins to be laid from the corner.

Already at this stage, the location of windows and doorways is noted. You need to remember: frames and doors can only be installed in a finished building. These elements for steam rooms are best made of wood.

Roof of the bathhouse

After the walls are erected, the roof must be installed. This work can also be done without the involvement of specialists:

- After the walls are built, ceiling beams are laid and covered with boards.

- The next stage is the installation of the rafter system and sheathing.

- The roof can be represented by corrugated sheets or tiles.

- The final stage of installation includes installing a drain.

Floors

Floors in a Russian bathhouse are installed in several stages:

- Rough floor.

- Waterproofing layer. With its help, they block moisture from entering from below.

- Insulation. This layer is required in all rooms except the washing room and steam room. Mineral wool can be used for this purpose.

- Another layer of hydro- and vapor barrier is laid on top of the thermal insulation.

- The final stage is laying the finished floor.

Log sauna

A log sauna is a classic. And the most popular are rounded logs. Village steam rooms were built from logs.

The beauty of such complexes is that wood is a healthy, environmentally friendly material. Such a bathhouse is being built in record time. If the logs are processed mechanically rather than manually, their cost is low. You can also save on interior decoration - wood itself is beautiful. And for fire safety and resistance to fungi, logs are treated with special solutions.

Disadvantages will appear if the company that volunteered to install the bathhouse did not dry the logs, so after a while the building will “lead”, or if the tree was chosen incorrectly: conifers “cry”, oak can crack from the heat.

Advice: aspen baths have proven themselves well. This is a durable, beautiful tree, which also has aromatherapy qualities.

Do-it-yourself 6x4 sauna. Projects and their implementation

Despite the external simplicity of this building, its construction should be approached extremely responsibly. This is especially true for the choice of building material. Experienced professionals advise choosing one of the following options:

- wood (timber or log);

- frame;

- brick;

- foam blocks.

Each material has advantages and disadvantages. In addition, the speed of construction of the building and the final cost of the project depend on the choice of construction technology. The choice of material must be made before the start of the project, thanks to this it is possible to make adjustments to the drawing of the bathhouse.

Bathhouse made of logs or timber

In modern construction, more than a dozen materials are used to construct buildings, but wood occupies a leading position, as it did many centuries ago.

A log or timber bathhouse has several features:

- Environmental friendliness. Wood is a 100% natural material and therefore has no harmful effects on human health. In addition, steam rooms made of logs have always been in demand in Russian villages.

- Construction speed. When using already processed logs or timber, you can build a bathhouse in a short time.

- Savings on finishing. A wooden bathhouse looks aesthetically pleasing and does not need finishing.

The cost of such building material is relatively high, but a 6x4 bathhouse is small in size and will not require large financial costs.

If the choice is made in favor of natural wood, then aspen, linden, and alder are best suited for building a steam room. When heated, conifers release resin and emit an intrusive odor that not everyone will like. Oak, despite its durability, has disadvantages - high cost and susceptibility to elevated temperatures. Birch is relatively inexpensive, but when in contact with water it quickly loses its quality.

In terms of technical characteristics, timber and logs have no differences. In this case, the log has a round shape, and the timber has a square shape. This affects the appearance of the building. In addition, when using timber, a more precise fit is achieved, which reduces costs.

Frame-based sauna

A frame steam room can be a cheaper alternative to a bathhouse made of timber or logs. The peculiarity of this structure is that a frame made of wooden blocks is first installed on the foundation. After this, the base is sheathed with a “pie”, which consists of internal and external cladding, insulation, and a waterproofing layer.

This technology has several advantages:

- Saving on foundation. The light weight of the structure allows the bathhouse to be erected on stilts.

- Effective heat retention. This point is only possible with good thermal insulation.

- Short construction time. You can completely build a 4 by 6 steam room along with the foundation in 3-4 days.

- Low cost. Compared to wood, frame technology requires less costs.

One of the disadvantages is the shrinkage of the frame. In this case, cracks and deformed areas appear on the sheathing panels.

Brick bath

For the construction of steam rooms, brick is in less demand than wood, but its features are also worth studying. There are several advantages of using this:

- Fire safety. Brick has increased fire resistance compared to solid wood and frame buildings.

- Duration of operation. Brick buildings do not require repairs for up to 50 years.

- Environmental friendliness. The composition contains components that are safe for human health.

- Wide choice of architectural solutions. 4x6 baths can be not only 4-corner boxes, but also have a complex shape.

The disadvantages of brickwork include the following features:

- Increased heat capacity. Heating such a room will require more time and resources than heating a log or frame building.

- Moisture absorption. Bricks are a hygroscopic material, so they need increased insulation.

- The need to lay a strip foundation. This increases construction costs.

- High price for bricks.

Bathhouse made of blocks

A steam room made of foam blocks is well suited for DIY construction. This can be explained by several advantages of this building material:

- Construction speed. 1 foam block is equal in size to 13 bricks, so the laying process takes less time. With the optimal size of the bathhouse, construction can be completed in 1-1.5 weeks.

- Possibility to use immediately after construction. The blocks do not shrink.

- No harmful chemicals in the composition.

- Energy intensity. Premises of this type retain heat for a long time.

- Increased fire safety.

- Resistant to mold and parasites (unlike wood).

The disadvantage of this material when building a bathhouse is its hygroscopicity. To prevent moisture absorption, the walls must be treated with a waterproofing agent.

Bathhouse made of timber

A bathhouse made of timber is practically no different from a log bathhouse. Wooden beams are also environmentally friendly and, due to their natural aesthetics, do not require either internal or external finishing.

The differences between timber and log house are in the method of processing the material. The log is round when cut, and the timber is square. The fit of the timber is more precise, the material consumption is less, which somewhat reduces the cost of construction.

Bathhouse made of modern materials

Yes, wooden baths are great, natural and rustic. But along with baths made of logs or timber, other materials are also in demand.

- Frame bath. It is built in production to adjust the material and find out whether all the details are taken into account. Then the bathhouse is dismantled and delivered to the place of order. The construction is light and can be erected quickly. It does not require a reinforced foundation. The only negative is that it is undesirable to build a two-story bathhouse or make a bathhouse with an attic, especially a residential one. And the issue of additional space will be solved by the plan of a bathhouse with a veranda, which can be glazed and heating equipment installed in it.

- A bathhouse made of foam blocks is suitable for cottage areas designed in a modern style. This is an environmentally friendly material that perfectly retains heat, does not burn, does not smoke and does not emit toxins when heated. For beauty and comfort, the inside walls can be decorated with wooden lining. Here you can already build a bath-sauna on two floors with an attic or a full second floor. The internal layout will increase and give more room for imagination: steam room and shower room, relaxation room and billiard room, swimming pool, kitchen, dressing room and everything that can fit into a 6x4 meter bathhouse.

The bathhouse is considered a simple building to construct. However, the internal layout and material must be thought out. Then the wish “enjoy your steam” will be sincere and pleasant.

Finally, we suggest you see what a completed bathhouse project made from 6 by 4 timber might look like.

( 5 votes, rating: 3.40 out of 5)

Design Features

During the design process, it is necessary to decide not only on the layout, but also on a number of other points, such as:

- foundation type;

- roof structure;

- material and its quantity.

Below we will take a closer look at all the design nuances.

Columnar foundation

Foundation

In order for a self-built bathhouse made from 6x4 timber to be durable, it is necessary to competently approach the arrangement of the foundation.

Since the structure is not heavy, the base can have the following design:

- columnar - pillars are erected from concrete blocks or even bricks under load-bearing walls and under the building itself. This type of foundation is suitable for stable soil types. At the top, all the pillars are united by a grillage, on which the building is erected;

- pile-screw - metal screw piles are screwed into the ground, which are also connected with a grillage. The advantage of this foundation is the high speed of construction. However, like a columnar base, it is not suitable for all types of soil;

- Shallow strip - is a closed circuit on which external walls are erected. To equip it, trenches are dug to a depth of about 50 cm, then a sand-crushed stone cushion is filled in, formwork is installed and concrete is poured. The foundation must first be reinforced with metal rods;

This type of base is the most expensive, but at the same time the most durable, which allows it to be used on different types of soil.

The choice of foundation type should be made by specialists, since it depends primarily on the characteristics of the soil. However, you can focus on the foundations of other similar wooden buildings located nearby.

Mansard roof design

Roof

The roof structure of a timber bathhouse does not have any special features. Most often, a gable frame is made, the main one of which is trusses formed by two rafter legs. From below, the rafter legs rest on the Mauerlat, and from above they are connected to each other in a ridge unit.

A mansard roof with “broken” rafters has a more complex design. However, having familiarized yourself with the principles of its assembly, making the frame yourself will also not be difficult.

The only thing is that you first need to draw up a drawing of all the roof elements and indicate the dimensions of the parts. This will simplify your work in the future and avoid mistakes.

In the photo - profiled timber made of solid wood

Material

The timber from which a bathhouse can be built comes in several types:

- made from solid wood - can be planed and profiled;

- glued - can also be smooth or profiled.

It should be noted that laminated veneer lumber is a more durable material that is resistant to negative environmental influences. However, its cost is significantly higher than solid timber.

Note! The walls of the steam room should be made of linden timber, since this tree does not release resin when exposed to high temperature.

In addition to the type of material, it is also important to determine its cross-section, which depends on the purpose of the bath. If it will be used only in the summer, a beam with a section of 150x150 mm is sufficient. Otherwise, you should use 200x200 mm timber.

Glued profiled timber of different sections

Having decided on the type and cross-section of the material, you can calculate how many cubes of timber are needed for a 6x4 m bathhouse.

This is done as follows:

- First of all, you need to find out how many beams are in one wall. For example, the height of the wall is 3 meters, and the section of the beam is 150x150 mm. In this case, you need to perform the following action - 3: 0.15 = 20 pcs.;

- Now you can find out the volume of one beam - 0.15x0.15 x 6 = 0.13 m3. Hence, one wall will require 0.13x20 = 2.6 m3.

- Now the resulting value must be multiplied by four 2.6x4 = 10.4 m3. As a result, you will get the volume of the beam with a small margin, since the two walls have a size of 4 m, not 6. To obtain a more accurate value, you can use the same scheme to calculate the volume of the beam for a four-meter wall.

That's all the instructions for calculating the volume of timber. Now that the project has been drawn up and the amount of materials has been calculated, you can purchase them and begin construction.