comparative characteristics of various bimetallic radiators

StroyConsul comments: All the tests given in the article were carried out by specialists in the accredited laboratory of heating devices of the Federal State Unitary Enterprise NIIsantekhnika (the main institute of the Russian Federation for the development and testing of heating devices) and in Vitaterm LLC and were published on the City of Masters website. Our website publishes abbreviated versions of tests containing only the most important consumer indicators of the heating devices being tested. Full versions of these tests (containing all the technical details of the tests) can be found on the City of Masters website

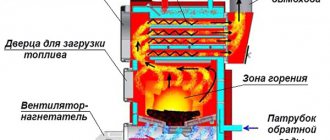

The idea of using two materials with complementary properties is widely used in technology. The same is true with heating equipment. One of the main positions among radiators and convectors of domestic and foreign production presented on the market is occupied by bimetallic models. Thanks to the strength of the steel that reinforces the structure, these devices can withstand the high operating pressure typical of Russian heating systems. And the steel filling is “calmer” than others regarding the alkalinity of water - the pH value.

Aluminum, in turn, has high thermal conductivity, therefore it significantly improves the heat transfer of the heating device and reduces its inertia, that is, the radiator heats up faster and cools accordingly. In addition, this material is high-tech, it can be given any shape, and fins of complex configuration can be cast. Based on the totality of indicators, “bimetal” is the optimal choice for extreme Russian conditions. The heat transfer of “combined” models is 1.5-2 times higher than that of the best steel ones of the same dimensions. Moreover, they are lighter and more elegant. And the design is no worse than aluminum, and the strength is several times greater. All this is true, but it turns out that “bimetal” is different from “bimetal”...

"BIMETALLIC" CLASSIFICATION

Radiators and convectors. Both are bimetallic. Let us remember that these devices differ in their operating principles. A simplified diagram of a convector - a pipe with fins. The air passing from bottom to top between the fins is heated and rises upward due to convection. Actually, the device is named so because its main heat flow is convection. The heat flow transmitted by the radiator has not only a convection component, but also a large radiant component (up to 45%), so heat emanates from it both upward and to the sides.

"Bimetal" and "semi-bimetal". The role of the steel core in a bimetallic radiator is to strengthen the vertical channels. After all, it is precisely the place where they are connected to the collectors that is the “weak link” in aluminum devices that cannot withstand high pressure. There are two ways to solve this problem. The first is to make a steel frame and fill it with aluminum. We will call such devices “fully” bimetallic. Their horizontal collectors and vertical channels are a welded steel structure, and water is in contact only with steel, so a steel-aluminum galvanic couple cannot occur. The second is to reinforce only the vertical channels with steel tubes, so to speak, solving the problem halfway. Let’s call these devices conventionally “semi-bimetallic”, although manufacturers also call them “bimetallic”. In principle, this technical solution is quite justified: the thickness of the walls of the aluminum manifold is sufficient to withstand high pressure. The problem of galvanic couples, according to experts from the Scientific Research Institute of Plumbing, is not as acute as they say. With this design, the main thing is to ensure the immobility of the steel tabs in the aluminum “shirt”, to “glue” them securely, so that they do not inadvertently “fall out” due to different thermal expansion of the two metals and block the cross-section of the lower collector.

For all their attractiveness, bimetallic heating devices are also far from ideal. First of all, steel and aluminum have different thermal expansion. This means that the “core” and the “shirt” do not always fit tightly to each other, which affects the stability of thermal performance. Therefore, during operation (especially in the first year of operation), bimetallic “batteries” of all types crackle. For devices with aluminum heads, in which the steel tube is simply “pressed” into the shell, during operation there is a risk of water leaking into the gap between the two metals. This will not reduce the strength at all, but just like a loose fit, it will lead to instability of heat transfer. And finally, heating devices where aluminum is in contact with the coolant “cannot tolerate” alkaline water: hydrogen is actively released, and if it is not vented in a timely manner, the device may simply crack. In this regard, “bimetal” with aluminum collectors is, as a rule, recommended to be installed in heating systems with an independent connection circuit.

Connection methods

Side method . The pipe through which hot water is supplied is attached to the upper pipe, the return pipe to the lower one. The pipe is located on one side of the radiator. This connection method is only effective for a battery consisting of 15 sections .

Diagonal method . The coolant pipe is mounted on top on one side of the radiator, the return pipe is mounted on the bottom on the opposite side. The coolant is evenly distributed throughout the battery, ensuring high efficiency.

The bottom connection is used when pipes need to be hidden so that they do not spoil the interior. In this case, efficiency is reduced by 20% .

"Santekhprom BM" RBS-500

Price: about per section (about per kilowatt)

Sectional bimetallic radiator (Russia)

PURPOSE: installation in heating systems of high-rise buildings with operating pressure up to 16 atm.

TECHNICAL PARAMETERS (according to the manufacturer)

- SECTION DIMENSIONS (HxDxD): 560x80x100 mm; center distance - 500 mm. Weight: 3 kg.

- SECTION CAPACITY: 0.217 l.

- HEAT TRANSFER OF SECTION: 195 W.

- PRESSURE: working - 16 atm., test - 24 atm., destructive - over 60 atm.

- COOLANT TEMPERATURE: up to +130 degrees Celsius. pH value 8.3-9.5.

TEST RESULTS: A factory-assembled 5-section bimetallic radiator with a thermal power of about 1 kW was selected for testing.

STRENGTH: the operating and test pressure declared by the manufacturer for Santekhprom BM is slightly less than that of its analogues (16 and 24 atmospheres). However, even at 48 (three times the operating pressure) and even at 60 atmospheres, the device did not collapse and did not undergo visible changes. Apparently, the developers, with the typical Russian craving for reliability, simply played it safe. In any case, a device with a working pressure of 16 atmospheres can be safely installed in heating systems of high-rise buildings and structures.

INSTALLATION: Santekhprom BM radiators are mounted in the same way as steel heating devices, observing the general requirements of SNiP 3.05.01-85 for sectional radiators. Optimal installation distances: at least 3 cm from the wall and at least 10 cm from the floor and window sill.

OPERATION: the radiator is installed in heating systems with steel, copper and plastic pipes, with water as a coolant or antifreeze. In this case, you must adhere to the requirements of RD 34.20.501-95 for its parameters.

LABORATORY CONCLUSION: the main advantages of the Santekhprom BM radiator (Russia) are reliability, increased strength, high heat transfer, hygiene, modern appearance and long service life.

The heating device is characterized by stable thermal performance and high power (195 W). It is used in systems with coolant temperatures up to 130 degrees Celsius. Due to the large thickness of the walls of the steel pipes, the bimetallic radiator will be used in heating systems with a working pressure of up to 16 atmospheres and is suitable for installation both in apartments of multi-storey buildings and in private construction.

What are vertical heating radiators?

In apartments and private houses with a classic layout, it is customary to install batteries under the window sills. This is due to the fact that most radiators have a section height from 380 to 750 mm. To increase productivity (heat transfer), the number of sections is increased, increasing the effective surface.

Agree, it doesn’t look harmonious.

Recently, designers have been using new layout schemes, for example, panoramic glazing with minimal openings between windows. It is difficult to install convectors in such cases, and the appearance of the structure is not suitable for residential premises.

Another thing is the vertical design.

The situation can be corrected by installing high vertical radiators, which have a larger surface area and, therefore, more productivity.

Vertical radiators are usually called radiators whose height of sections significantly exceeds the width of the device.

Photos of classic and design solutions in the interior of the house

Zehnder Charleston 2180.

ZEHNDER 2180.

Purmo Delta 1500x200.

GUARDO PILON S4H.

Bimex 500

Price: about per section (about per kilowatt)

Sectional bimetallic radiator (Czech Republic)

PURPOSE: installation in heating systems of high-rise buildings with operating pressure up to 25 atm.

TECHNICAL PARAMETERS (according to the manufacturer)

- SECTION DIMENSIONS (HxLxD): 540x80x102 mm; center distance - 500 mm. Weight: 3.07 kg.

- SECTION CAPACITY: 0.23 l.

- SECTION HEAT TRANSFER: 201 W.

- PRESSURE: working - 25 atm., test - 40 atm.

- COOLANT TEMPERATURE: up to +110 degrees Celsius. pH value 7-8.

TEST RESULTS: A factory-assembled 5-section bimetallic radiator with a thermal power of about 1 kW was selected for testing.

STRENGTH: the radiator was tested in operation at a coolant pressure of 25 and 40 atmospheres (working and test). They tried to destroy it by exposing it to 60 atmospheres, but it didn’t work, there wasn’t even a leak. But at this level of operating pressure, 75 atmospheres would be destructive, which could not be verified at the RP-50 stand. However, judging by the design, Bimex is a reliable device and is designed with a large margin of safety.

INSTALLATION: like other bimetallic radiators with a solid steel core, Bimex is installed according to the rules for steel heating devices. Thanks to the design feature - symmetry in relation to the front-rear and top-bottom - the installation of the radiator is significantly simplified: twist and turn it over as you like. If you accidentally scratched or damaged the fins of one of the sections, you can always hide the defect - turn the flaw towards the wall, and, if necessary, even rearrange the sections that are connected to each other with steel nipples. Only for this you need to use branded gaskets.

For more efficient heat transfer, when installing the device, you should comply with the general requirements for sectional radiators, regulated by SNiP 3.05.01-85 “Internal sanitary systems”, and, in particular, the optimal installation distances: from the wall - at least 3 cm, from the floor and window sill - at least 10 cm.

OPERATION: the device is capable of operating both in a water heating system and with low-freezing coolants, as well as in contact with pipelines made of various materials (using appropriate adapters). Pay attention to the pH value of the coolant. For some reason, the manufacturer suggests using a radiator in heating systems with a pH value of 7-8, which is recommended for aluminum appliances, while a steel core, according to specialists from the Scientific Research Institute of Plumbing, is more suitable for a pH value of 8.3-9.5.

LABORATORY CONCLUSION: Bimex radiators (Czech Republic) have a modern design, good thermal performance and high strength characteristics. Symmetrical shapes simplify installation. The nominal heat flux of the section is 194 W, standard for this size (within 200 W), optimal in terms of size, weight, material consumption and price. The high test pressure of 40 atmospheres makes it possible to use bimetallic radiators in heating networks with an operating excess pressure of up to 25 atmospheres, typical of high-rise buildings. Bimex is distinguished by high quality workmanship, reliability and durability.

How to calculate the number of battery sections for an insulated room

If you are too lazy to delve into all the intricacies of calculating the heat loss of a room, then you can use average values and not take into account the difference in materials.

For an insulated private house, the average figure is approximately 75 W/sq.m. for multi-apartment 100 W/sq.m.

To find out the area of the room, you need to multiply the width by the length. We multiply the resulting figure by the average loss rate and divide by the power of one section, which we take from the technical characteristics indicated on the radiator packaging.

An example of calculating the number of sections of a bimetallic battery:

A room in a private house is 5 by 5 meters: 5x5x75/180 = 10.4 sections, rounded up and we get 11 sections by 25 squares. This is an approximate amount. The rule here is that it is better to take one or two sections more than to freeze later. In addition, there is usually a window for ventilation. For an apartment building, it is considered the same, only we use the number 100 instead of 75. But it is best to contact specialists who will select the optimal dimensions of the heater.

Global Style 500

Price: about .5 per section (about per kilowatt)

Sectional bimetallic radiator (Italy)

PURPOSE: installation in heating systems of buildings and structures of any number of floors with a working pressure of up to 35 atm.

- SECTION DIMENSIONS (HxLxD): 575x80x80 mm; center distance - 500 mm. Weight: 1.97 kg.

- SECTION CAPACITY: 0.2 l.

- HEAT TRANSFER OF THE SECTION: 168 W at a temperature difference of the coolant and air in the heated room of 70 degrees Celsius.

- PRESSURE: working - 35 atm., test - 52.5 atm., destructive - over 110 atm.

- COOLANT TEMPERATURE: up to +110 degrees Celsius. pH value 7-9.5.

TEST RESULTS: A factory-assembled 6-section bimetallic radiator with a thermal power of about 1 kW was selected for testing.

STRENGTH: the model being tested belongs to the second generation of Global bimetallic devices, which were developed specifically for Russia, taking into account the recommendations of the Scientific Research Institute of Plumbing (the first were designed for 15 atmospheres). Today, the Global Style radiator has the highest declared operating pressure in its class - 35 atmospheres. (It is not possible to check the safety factor on the RP-50 stand, which should be at least 105 atmospheres.)

INSTALLATION: bimetallic radiators with an all-steel core are installed in heating systems like steel appliances. However, the mechanical properties of aluminum fins should be taken into account and protected from damage. The radiator sections are connected to each other using steel nipples. For this purpose, the manifolds are equipped with a 1-inch pipe thread. When regrouping, only branded gaskets should be used. To achieve the calculated heat transfer, when installing Global Style, you must maintain optimal distances: at least 3 cm from the wall behind the radiator, at least 10 cm from the floor and window sill.

OPERATION: it is advisable to strictly adhere to the requirements of RD 34.20.501-95 for coolant parameters. The radiator can be installed in heating systems with steel, copper and plastic pipes, as well as with low-freezing coolant (antifreeze).

LABORATORY CONCLUSION: Global Style radiators (Italy) have a modern design (according to experts, the best in their class of devices), compact dimensions, light weight, stable thermal performance and high strength characteristics. The relatively small value of the section’s nominal heat flux (168 W) allows you to more accurately select the required thermal power of the heating device. The high test pressure of 52.5 atmospheres allows you to increase the permissible operating excess pressure of the coolant to 35 atmospheres and install bimetallic radiators in the heating systems of any high-rise buildings and structures. Global Style devices are distinguished by high quality materials, workmanship, reliability and durability.

Comparison table of characteristics

In order to more clearly compare the models presented above, we use a comparative table of characteristics.

| Model | Heat dissipation (W) | Number of sections | Working Pressure (Bar) | Weight, kg) | Price, rub) |

| Royal Thermo PianoForte Tower | 1610 | 18 | 30 | 40.3 | from 33155 to 36900 |

| ATM Metallo 500/80 | 552 | 6 | 25 | 15 | from 3288 to 4500 |

| Royal Thermo Revolution Bimetall 350 | 968 | 8 | 30 | 10.8 | from 6760 to 8000 |

| Royal Thermo Vittoria 500 | 1575 | 9 | 30 | 16.7 | from 4899 to 6769 |

| Royal Thermo Indigo Super 500 | 1110 | 6 | 30 | 11.58 | from 6090 to 8900 |

| Rifar SUPReMO 500 | 1212 | 6 | 30 | 13.2 | from 8220 to 11880 |

| Royal Thermo Vittoria 350 | 708 | 6 | 30 | 7.92 | from 6360 to 7840 |

| Rifar Monolit 350 | 536 | 4 | 10 | 6 | from 4680 to 7680 |

| Heating device BR1-500 | 780 | 4 | 20 | 27.2 | from 3420 to 5000 |

| Global STYLE 500 | 168 | 10 | 35 | 18.7 | from 990 to 3000 |

| Halsen BS 500/100 | 816 | 4 | 25 | 10.2 | from 3189 to 5000 |

| STI BM 500 | 2280 | 4 | 24 | 21.6 | from 3210 to 5697 |

| Royal Thermo BiLiner 500 | 760 | 4 | 24 | 21 | from 2264 to 3600 |

| Rifar Monolit 500 | 1960 | 10 | 24 | 10 | from 1007 to 2999 |

| Bilux Plus R300 | 952 | 8 | 20 | 10.32 | from 5407 to 7564 |

Biradus 500

Price: retail (Moscow) - per column (June 2003).

Block bimetallic radiator (Armatmetal, Czech Republic)

PURPOSE: installation in high-rise buildings in heating systems with an independent connection circuit with a working pressure of up to 15 atm.

TECHNICAL PARAMETERS (according to the manufacturer)

- COLUMN DIMENSIONS (HxLxD): 540x75x80 mm; center distance - 500 mm. Weight: 1.32 kg.

- SECTION CAPACITY: 0.43 l.

- HEAT TRANSFER OF SECTION: 191 W.

- PRESSURE: working - 15 atm., test - 22.5 atm.

- COOLANT TEMPERATURE: up to 110 degrees Celsius. pH value is 6.5-9.5.

TEST RESULTS: A factory-assembled bimetallic radiator with a thermal power of about 0.87 kW, consisting of two blocks of 2 and 3 columns, was selected for testing.

STRENGTH: the radiator was tested in operation at a coolant pressure of 15 and 22.5 atmospheres (working and test). They tried to destroy it by first exposing it to the prescribed (at working 15 atm.) 45, and then to all 60 atmospheres - there was not even a leak. Tests have confirmed that Biradus is a reliable device, designed with a large margin of safety.

INSTALLATION: like other bimetallic radiators with aluminum collectors, Biradus is installed with special precautions according to the rules for aluminum devices. Aluminum is a fairly soft metal, and the blocks are connected to each other by steel nipples, therefore, for example, when eliminating misalignment of heat supply pipes or passage plugs, a force of more than 50 Nm cannot be applied. The radiator is mounted on brackets. For optimal heat transfer, you need to maintain installation distances: 10-15 cm from the floor and 10 cm from the window sill. Thanks to the design feature - symmetry in relation to the front-rear and top-bottom - the installation of the radiator is significantly simplified: twist and turn it over as you like. If you accidentally scratched or damaged the fins of one of the sections, you can always hide the defect by turning it towards the wall, and, if necessary, even rearranging the blocks. Only for this you need to use branded gaskets.

OPERATION: bimetallic radiators with aluminum collectors are very demanding on the quality of water treatment. The point is not only about the possibility of the formation of a galvanic steel-aluminum couple, but also about the formation of gases when alkaline water comes into contact with an aluminum alloy. And although the manufacturer recommends coolant parameters - temperature - up to +110 degrees Celsius, pH - from 6.5 to 9.5 - it is better to adhere to more stringent standards - pH within 7-8.5. Especially considering that during a month and a half of testing the samples, traces of corrosion were found on the steel tubes.

For proper operation of the device, an air vent valve and two shut-off valves must be installed on the supply and discharge pipes. Do not leave water in the radiator when both taps are closed, otherwise it may lose its seal. But you should also not drain the coolant for a long period of time (more than two weeks) due to the risk of corrosion of thin-walled pipes.

LABORATORY CONCLUSION: Biradus heating devices have a modern design, high strength characteristics and excellent installation properties, however, they require clarification of thermal indicators. Radiators can be used in heating systems with an independent connection diagram in medium- and high-rise buildings with an operating pressure of up to 15 atmospheres

Which is better: a model made of several sections or a one-piece one?

The bulk of bimetallic radiators consists of sections. There are usually an even number of them. These factory-made elements are combined into one common radiator. The joints between all sections have sealed gaskets secured with nipples.

This option is convenient because you can always subtract or add the required number of sections - an experienced craftsman can easily handle this.

The monolithic design is good because it can cope with enormous pressure - up to 100 atmospheres. After all, inside it there is a monolithic steel core, the strength of which is higher than that of a sectional one. The steel pipes are covered with an aluminum shell on top. Although less common than the previous type, such models are also found in stores.

When choosing here, you need to look in the direction of what operating pressure you need; if your centralized network contains powerful water hammers, then choose monolithic devices. But they will be more expensive, so in all other cases it is better to go with sectional ones.

Rovall Metall 80 - 500

Price: retail - .3 per column (June 2003).

Block bimetallic radiator (Italy)

PURPOSE: installation in high-rise buildings in heating systems with operating pressure up to 20 atm.

TECHNICAL PARAMETERS (according to the manufacturer)

- SECTION DIMENSIONS (HxDxD): 542x80x80 mm; center distance - 500 mm. Weight: 1.23 kg.

- SECTION CAPACITY: 0.25 l.

- HEAT TRANSFER OF THE SECTION: 161 W at a temperature difference of the coolant and air in the heated room of 70 degrees Celsius.

- PRESSURE: working - 20 atm., test - 30 atm.

- COOLANT TEMPERATURE: up to 110 degrees Celsius. pH value is 6.5-9.

TEST RESULTS: A factory-assembled 6-column bimetallic radiator with a thermal power of approximately 0.97 kW was selected for testing. By the way, for those who are not in the know: the Rovall plant is part of the Sira Group corporation.

STRENGTH: a welded structure is always more capricious compared to a solid cast one. It is known that seams are a potential weak point. However, the minimum number of mechanical connections in a block radiator provides it with high tightness and reliability. The tested samples withstood an excess pressure of 60 atmospheres (more than three times the worker's reserve) without destruction. True, one device had its plugs knocked out at a pressure of 41 atmospheres, which, however, has nothing to do with the strength of the radiator itself.

INSTALLATION: Metall 80 is installed in heating systems, like other bimetallic devices with aluminum heads. The blocks are connected to each other with steel nipples. To avoid damaging the threads in rather soft aluminum manifolds, it is recommended to carry out installation using torque wrenches. For more efficient heat transfer, when installing the device, you must maintain optimal installation distances: at least 3 cm from the wall, 10 cm from the window sill and 12 cm from the floor.

OPERATION: in Metall 80 radiators, the coolant flows through aluminum collectors. When water (especially alkaline) comes into contact with aluminum, its accelerated decomposition occurs with the formation of hydrogen. Therefore, when using bimetallic radiators with aluminum heads in heating systems, special attention must be paid to the quality of water treatment or the use of antifreeze - a low-freezing coolant. Metall 80 bimetallic radiators can be mounted with any heat pipe using the appropriate adapters.

LABORATORY CONCLUSION: Metall 80 radiators are durable, have an excellent design, stable thermal characteristics and an optimal nomenclature step, allowing to minimize the overconsumption of heating devices when designing heating systems. Thermal indicators require adjustment.

Design and arrangement of flat radiators

Panel radiators are made of steel plates with a flat or perforated profile. These elements are made from sheet metal by pressing with a certain step, so that after welding the mirror elements, vertical and horizontal channels for the coolant are formed inside. Next comes the automatic painting and packaging process. Their biggest advantage is fast heating and high inertness.

To improve air circulation, “U” or trapezoidal sheets up to 0.5 mm thick can be welded to steel panels. The air between them will rise when heated, and its place will be replaced by a cold flow. However, this will transfer more dust masses, and the air in the room will be drier.

Steel radiator type 11, implies one panel with coolant and one row of convection fins at the rear.

Flat steel heaters can be connected to the heating system in four ways:

- Lateral - “supply” and “return” are located on one of the sides of the device.

- Diagonal - “supply” and “return” are located on different sides and at different levels of the heater.

- Bottom - “supply” and “return” are located next to each other on the bottom panel.

- Saddle (cross) - “feed” and “return” are located on different sides of the device at the bottom or on its side and bottom panels.

Sira Bimetal CF 500

Price: retail (Moscow) - .5 per section (June 2003).

Sectional bimetallic radiator (Italy)

PURPOSE: installation in high-rise buildings in heating systems with operating pressure up to 25 atm.

TECHNICAL PARAMETERS (according to the manufacturer)

- SECTION DIMENSIONS (HxLxD): 580x75x110 mm; center distance - 500 mm. Weight: 1.9 kg.

- SECTION CAPACITY: 0.21 l.

- HEAT TRANSFER OF THE SECTION: 199 W at a temperature difference of the coolant and air in the heated room of 70 degrees Celsius.

- PRESSURE: working - 25 atm., test - 37.5 atm.

- COOLANT TEMPERATURE: up to 110 degrees Celsius. pH value is 5-11.

TEST RESULTS: A factory-assembled 5-section bimetallic radiator with a thermal power of about 1 kW was selected for testing.

STRENGTH: the high strength of the Sira bimetallic structure is ensured by the absence of welds and original assembly components. To check the tightness of devices at the factory, they are tested with air: after casting, each section is “purged” under a pressure of 10 atmospheres, and then the radiator assembly is exposed to 25 A so that no drops accidentally remain inside, so that before installation in the heating system the devices are not at risk of corrosion susceptible). Strength tests with water carried out at the Scientific Research Institute of Plumbing showed that the tightness is maintained even at 60 atmospheres, which can be “squeezed out” from the RP-50 test unit. True, at a working pressure level of 25 atmospheres, the destructive pressure should be at least 75, which, unfortunately, could not be verified at the stand. But, according to the manufacturer, destruction occurs when excess coolant pressure exceeds 170 atmospheres.

The reliability of Sira bimetallic devices is confirmed not only by strength tests, but also by 9 years of operating experience in Moscow residential buildings.

INSTALLATION: bimetallic radiators with aluminum collectors are installed in heating systems, like aluminum appliances. The radiator sections are connected to each other by steel nipples, for which a 1-inch pipe thread is provided in the manifolds. To “not tear it off” (after all, aluminum is a relatively soft metal), special torque wrenches and gaskets are recommended. The symmetry of the sections greatly facilitates grouping and installation. By the way, Sira also supplies its dealers with spray cans to touch up damaged enamel after rearranging the elements. It must be remembered that the calculated heat transfer can be achieved by observing the optimal installation distances: 3-5 cm from the wall behind the radiator and 7-10 cm from the floor, with a gap of 8-12 cm between the top of the radiator and the bottom of the window sill.

OPERATION: bimetallic devices, in which aluminum is in contact with the coolant, are very sensitive to the quality of water treatment. For such models, the Scientific Research Institute of Plumbing recommends a pH from 7 to 8.5, and the Italian laboratory recommends a pH in the range of 5-11, which, in principle, has not been refuted by many years of operating experience in Russian conditions. Since there is a risk of hydrogen formation in bimetallic radiators with aluminum collectors, a gas vent such as a Mayevsky valve is needed to bleed off the gas. It is cut into the top plug on the opposite side of the liner. To reduce the risk of corrosion and gas formation, it is not recommended to empty the heating system with such devices for more than 15 days a year. In private heating systems, Sira devices work effectively with antifreeze (low-freezing coolant). Taking into account the properties of the construction materials and enamel, the maximum coolant temperature is 110 degrees Celsius.

LABORATORY CONCLUSION: Sira Bimetal CF radiator is one of the few bimetallic devices with aluminum collectors that can be used in heating systems connected in a dependent circuit. Modern design, quality workmanship, excellent installation properties and high reliability allow it to be used in high-rise buildings

Selecting the distance between the axes

The functionality of different models of bimetal radiators is usually equivalent. But they differ in the distance between the axes of the collectors.

There are models with both standard values (50 and 35 centimeters) and non-standard ones. For example, if radiators of minimum or maximum height are suitable for your purposes, then keep in mind the following points:

- A small distance between the axles (20 centimeters) is found only in models from BiLUX, RIFAR and Sira.

- A large distance between the axles (about 80 centimeters) occurs only in models made by the Italian company Sira.

We can note some advantages of the products of our manufacturer – RIFAR. He makes a line of RIFAR MONOLIT radiators, which have a solid core. Another line - RIFAR FLEX - can be rounded in accordance with the wishes of the customer.

This is convenient in an apartment where the corners are not straight, but rounded. Such a radiator will fit into the design most optimally and will fit perfectly into the wiring.

STALL 500

Price: retail (Moscow) - per section (June 2003).

Sectional bimetallic radiator (“Tsvetlit”, Russia)

PURPOSE: installation in high-rise buildings in heating systems with operating pressure up to 15 atm.

TECHNICAL PARAMETERS (according to the manufacturer)

- COLUMN DIMENSIONS (HxLxD): 580x75x100 mm; center distance - 500 mm. Weight: 2.43 kg.

- SECTION CAPACITY: 0.21 l.

- HEAT TRANSFER OF SECTION: 186 W.

- PRESSURE: working - 15 atm., test - 22.5 atm.

- COOLANT TEMPERATURE: up to 110 degrees Celsius.

TEST RESULTS: A factory-assembled 5-section bimetallic radiator with a thermal power of about 0.93 kW was selected for testing.

STRENGTH: the operating and test pressure declared by the manufacturer for “STALL” is 15 and 22.5 atmospheres. However, even at 45 (three times the operating pressure) and even at 60 atmospheres, the device did not collapse and did not undergo visible changes. Apparently, the developers, with the typical Russian craving for reliability, simply played it safe. In any case, a device with a working pressure of 15 atmospheres can be safely installed in heating systems of high-rise buildings and structures.

INSTALLATION: “STEEL” installation is carried out according to the rules for installing devices made of aluminum alloys, taking into account the mechanical properties of the material. The sections are connected to each other by 1-inch steel nipples. To ensure the tightness of the connection when screeding, ring gaskets are needed. To avoid stripping the threads in the manifold, a force of more than 50 Nm cannot be applied. Therefore, when rearranging sections, it is advisable to use a torque wrench. The symmetry of the sections relative to the top and bottom simplifies installation work. For more efficient heat transfer, when installing the device, you should maintain optimal installation distances: from the wall - at least 3 cm, from the floor and window sill - at least 10 cm.

OPERATION: bimetallic radiators with aluminum collectors are demanding on the quality of water treatment. The hydrogen index of the coolant, recommended by specialists from the Scientific Research Institute of Plumbing for devices of this type, is pH 7-9. To avoid airing of the sections (occurrence of gas locks), an air vent such as a Mayevsky tap must be inserted into the upper “STALL” plug on the opposite side of the liner. To reduce the risk of corrosion and gas formation, it is not recommended to empty the heating system with such devices for more than 15 days a year.

LABORATORY CONCLUSION: the bimetallic radiator “STALL” has a durable structure and improved design. Thanks to the symmetrical design of the sections, the technology for its installation in heating systems has been simplified. However, heat transfer and some other specifications of the device require clarification.

Distinctive features

The main feature of bimetallic heating radiators is their design. It combines the use of two metals: copper and aluminum.

The use of these materials ensures:

- resistance to water composition;

- are not subject to pressure changes and are able to withstand high pressure in heating (40 atm.);

- Convenient connection to standard pipeline.

The bimetallic radiator system also includes steel pipes and aluminum plates. Thanks to this combination, heat loss in the room is minimal, and heat transfer is significantly increased.