Cork flooring is made from the bark of Quercus suber (cork oak), which grows in the countries of the Mediterranean region, more than 50% in Portugal, where forest lands are protected by law and the procurement of raw materials is strictly controlled. The valuable material is used in a variety of areas, but it is for cork floors and wall panels that the properties of cork are needed : the coatings are wear-resistant, warm, elastic, do not require special care and, most importantly, are environmentally friendly and absolutely safe! We offer a detailed review, expert recommendations on selection, photos of interiors!

Cork is a light and elastic, but durable material (specific gravity 2 kN/m3, less - only for the very expensive and rare balsa wood).

Unique properties of natural cork

The plant material has a honeycomb structure: approximately 40 million 14-sided compartments per cubic centimeter - each cell functions as a microscopic isolation chamber with walls impenetrable to liquids and gases! The raw material is 90% air, and the solid substance is a mixture of rare organic acids: 45% suberin (responsible for moisture resistance) and 27% lignin (responsible for loads and elasticity), which provide a unique combination of elasticity and strength.

The growing habitat of the evergreen cork oak is the Mediterranean countries, mainly Portugal (33% of the world's cork stock), Italy, France (south), Spain, the Maghreb states, Algeria, Morocco. In Portugal, which supplies half of the total cork supply, the trees are recognized as a national treasure and are protected by law from being cut down.

Interestingly, in Portugal the value of cork was realized at the beginning of the 13th century: in 1209, laws were passed to protect against deforestation. During the Age of Discovery on Portuguese ships, all elements exposed to atmospheric influences (especially rotting under the influence of moisture) were made from cork. In particular, masts and mast yards were made from magic wood.

Suberin is a complex fat-like substance in the integumentary tissue of oak bark. Phellonic acid glyceride provides water resistance and reduces the thermal conductivity of the material.

Flaws

Possible swelling of seams

May swell in high humidity. The reason is that the laminate is based on MDF, and it is not resistant to direct water flows. There is an option to apply varnish on top, but then you will have to do this constantly, and from a surface that is regularly exposed to stress, the varnish will peel off faster.

Deformation from severe dents

No deformation - does not concern strong dents that can be left by a hammer falling on the floor. Similar dents remain on wooden floors.

Roughness

Inconveniences may also be associated with the rough texture. In production, the material can be coated with different compounds for better smoothness and aesthetics. But sometimes roughness interferes - for example, it wears out the soles of house shoes or socks.

In general, as with any material, everything is relative. There are clear advantages that can immediately motivate you to buy and install it in your apartment. But against the advantages there are also disadvantages, and they cannot be ignored.

Instagram @parket_kazan

Instagram @parket_kazan

Cork floor production

Procurement of raw materials

Amazing material begins its journey from plantations in Portugal or Spain. The bark of mature trees (at least 40 years old), the third or later cut is used. Harvesting is carried out in the summer (the bark peels off spontaneously), with mandatory adherence to technology. The next stage is atmospheric drying for 5-6 months directly on the plantation (under canopies).

Quercus suber oaks live up to 250 years. On average, in 10 years the bark is completely restored and is ready for a new cut!

Factory processing

After the moisture evaporates under natural conditions, the raw materials are supplied to factories, where they undergo forced drying at high temperatures in special chambers. The prepared raw materials are crushed, undergo antiseptic treatment, and sorted by quality: primarily for elite wines, and the remainder for floor and wall coverings, substrates, and technical materials.

Production Features

The durability and comfort of use of all types of wooden floors depends on proper preparation - in this regard, cork oak bark requires a particularly careful approach. Trees have a unique property: cut bark is completely regenerated in about 9-10 years! For the production of cork, mature material is used, at least the third cut from trees over 25 years old (with an average life expectancy of 150-200 years).

The bark is removed after the trunk diameter reaches 70 centimeters, using a special technology, only in the summer: after this, the tree is processed and prepared for a long-term restoration process. For 6 months, the removed bark dries on the plantations under natural conditions, and after that for another six months in special chambers, already in factory conditions.

The prepared bark is converted into a suitable material by pressing at high temperatures. In this case, the binding element is a resin that is released when heated: no formaldehydes, plasticizers, glue or other chemical additives!

Origin of floor cork

Cork is obtained from the bark of the cork oak tree, which is most common in Portugal. The cork oak must be 25-30 years old before the bark can be removed from it without damaging the tree itself. In this regard, the cork oak is a very unique tree, as it is capable of regenerating its bark, so the bark can be removed from an individual tree every 7-9 years.

The process of removing cork oak bark

Then the resulting bark goes through a series of complex technological procedures: dried, processed, boiled. The basis of the material for the manufacture of floor coverings is crushed cork tree bark (cork granules). Basically, it is waste left over from the production of bottle caps, which is compressed under high pressure under certain temperature conditions and then turned into sheets.

Cork flooring

The birthplace and leading country of cork production is Portugal, but today Italy and Switzerland also have large production capacities. Raw materials come from the south of Europe and the north of the African continent.

Italian cork is rated higher than Portuguese, and there are several reasons for this. Firstly, the coating is more dense, about 8-12 mm, which is twice the thickness used by a competitor. Secondly, fashion trends play a significant role: each drawing is worked out by hand, using original design techniques.

Price records, however, are not attributed to the Italians at all - Swiss craftsmen rely on technological progress, applying the pattern using a unique “hot” method. With a standard thickness (4-6 mm), the material turns out to be much more durable and wear-resistant, adapts to maximum loads and goes beyond purely domestic use - it can be safely installed in public institutions.

Photo printing turns the floor almost into an object of art, so the buyer has every reason to claim an exclusive interior.

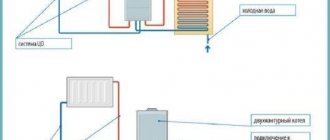

Typical structure

Cork flooring can be either click-type or adhesive-type: the fundamental difference lies in the structure. The interlocking version is installed without glue, using click locks, like a laminate: an HDF board is used as the middle layer, on which interlocking joints are cut. The adhesive type consists exclusively of natural raw materials: the middle layer is a pressed cork 5-6 mm; the top (decorative) layer is 0.5-1 mm veneer.

The illustration shows the structure of an interlocking and adhesive cork floor. The composition and thickness of layers may vary slightly among different manufacturers.

How to install a plug

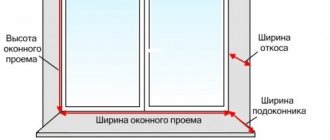

The main advantage of this coating is its ease of installation, so even a novice craftsman or amateur can easily complete the necessary work on his own. The unique properties of the material allow it to be used successfully even if there are minor errors during installation. Key points to pay attention to during installation:

- Before installation, the products must “get used” to the microclimate of the room where they will be permanently located. It is best to leave the slabs in the room for several days without opening the packaging.

- Installation of the material should be carried out at average temperatures and humidity.

- If the plug is located on a plank floor base, the slabs are placed across the floorboards.

- The seams between the floating floor slabs will be less noticeable if the panels are laid parallel to the sun's rays that enter the room from the most illuminated window opening.

- To compensate for horizontal temperature deformations near the walls, you need to leave a 1 cm thick seam. When the coating is completely ready, these places need to be covered with an ordinary plinth.

Pros and cons of cork flooring

pros

- Environmental friendliness. 100% natural material from renewable raw materials, recyclable. There are no synthetic additives in the structure, even a resin naturally released at high temperatures is used to glue the layers.

- Wear resistance. The floor plug can withstand mechanical or spot damage thanks to its wear-resistant coating with elastic varnish.

- Elasticity. Under pressure, the membranes elastically compress, and after the load is removed, they are restored. The elasticity of the structure is one of the unique properties and main advantages of cork flooring.

- Comfort when walking, reduction of stress when walking. The elastic floor covering is elastic enough so that the spine does not get tired when walking on it, but also moderately hard to relieve shock loads on the musculoskeletal system.

- Natural warmth. It is pleasant to walk on cork barefoot; there is no need to use additional heating systems: a comfortable room temperature of the surface is maintained due to the very low thermal conductivity of the material. Unlike, for example, porcelain stoneware and ceramic tiles, the floor is always warm and pleasant to the touch!

- Insulating properties. An ideal natural insulator: the material has low thermal conductivity, provides sound insulation in the room, and absorbs noise from footsteps. Pressed cork is a natural and effective insulator that is used in interior decoration.

- Moisture resistance. The material can withstand changes in humidity and even direct contact with water during flooding (true for adhesive plugs). In addition, laying end-to-end with walls and other objects is allowed: properly glued cork does not expand or dry out when exposed to moisture!

- Versatility. It is easy to choose an option based on characteristics and decor for any residential space, as well as for commercial facilities with medium or high loads.

- Variety of decors. The monotony of textures is diluted by the methods of laying veneer, tinting, as well as the use of photo printing technology: an endless number of decors for any interior!

Minuses

The disadvantages are very conditional - they are of the castle type:

- Applying a protective layer at the factory eliminates the need to adjust wear resistance (number of layers of varnish): if the wrong choice is made in the salon, the material will very quickly become unusable.

- The inevitable gaps between the boards widen over time, the edges turn black, the material delaminates - the minus is compensated by applying an additional layer of varnish, which prevents clogging of the joints.

- High-density HDF board is used as the middle layer, which provides simplified installation, however, you will have to pay for water resistance: fiberboard does not tolerate moisture well and delaminates when wet.

Accordingly, an adhesive cork floor is free from all of the listed disadvantages , but has its own disadvantages: during installation, more thorough preparation of the base is required and mandatory varnishing after completion of the work. In addition, the technology itself is quite complex: independent installation (if there is no experience) does not guarantee high-quality flooring .

The popularity of cork provokes the appearance of low-quality products on the market. Therefore, we recommend choosing cork flooring from the manufacturers Corkstyle, Corkart, Wicanders, Granorte and only in specialized showrooms that are official representatives and provide a guarantee from the manufacturer. In addition to quality control, experts will advise which cork floor to buy and offer professional installation, which determines how long and how long the coating will last.

Which room is better to do it in?

Laying a coating without a waterproof base is chosen for rooms where the heat and sound insulation properties of the material are important - in living rooms, children's rooms, bedrooms, corridors. Such a decision will be justified:

- extraneous sounds will not interfere with your rest;

- walking around barefoot will not lead to colds;

- Children’s games on the floor are safe, the elastic surface of the coating softens the impact of a fall;

- Warm shades create incredible comfort.

Designer color options provide opportunities to realize unique ideas. The cork floor in the photo of children's playrooms and living rooms fits into various interior styles.

When purchasing a cork floor for a kitchen or bathroom, you need to pay attention to the moisture-resistant protection of the lock or prefer an adhesive coating with a layer of varnish.

A non-slip surface in these rooms reduces the risk of injury. In sunny rooms, a tinted coating should be provided to protect against exposure to ultraviolet rays.

Cork floor in the hall

How to choose a cork floor

Floor adhesive plug

✔ Select adhesive cork flooring from the catalog.

The most practical is cork flooring installed with glue. The floor covering is two-layer: natural cork veneer or decorative film with a pattern is glued onto the agglomerate base. After installation, a wear-resistant varnish is applied, which makes it possible to finely adjust the thickness of the protective layer, taking into account the operational characteristics of the room.

Adhesive cork coating is the professional choice. Installation in rooms with high humidity and temperature changes is allowed: kitchen, bathroom . In addition, thanks to the application of protective varnish after installation, the edges of the sheets are reliably hidden: the ingress of dust and debris or the widening of cracks and delamination are excluded.

Locking plug for the floor

✔ Select interlocking cork laminate in the catalog.

The modern development of cork flooring is the interlocking version of the floor covering, which retains (with some nuances) the performance characteristics of cork, while ensuring easy and quick installation. The interlocking joints are cut on the HDF board, which is the middle layer of the floor covering. A cork agglomerate is glued to the top and a substrate to the bottom. The top layer is veneer or decorative film with a pattern (cork floors with photo printing).

Another remarkable feature of interlocking laminate: the protective varnish is applied at the factory, which ensures a high degree of readiness of the floor covering, but does not make it possible to adjust the wear resistance, as is the case with adhesive cork.

The locking plug is the choice for quick installation and immediate use. When choosing, you should take into account the restrictions on use: rooms with normal humidity without temperature changes, average or low traffic.

Description and features

In the manufacture of cork flooring, unique natural raw materials are used. Plants, namely cork oaks, grow mainly in Europe. The largest plantations (up to 33% of the world's reserves), well-established production are located in Portugal, as well as in Spain, the south of France, and Switzerland. Trees in some countries are protected by the authorities from unauthorized logging and are recognized as a state property.

Oak trees for processing must be 25 - 30 years old, then the trees will be able to restore the coating. The work of removing bark is carried out exclusively by hand; these are masterly manipulations of masters that do not harm the trees. Re-processing of trunks is possible after 8-9 years. Thus, with the right approach, raw materials are renewed.

Cork floor in the interior

Natural material is processed: crushed, granules heated in an oven, pressed. The result is a unique texture of cork sheets, similar to honeycombs. The mass called “suberin” contains crushed bark and air capsules. Increasing the additional height of the sheet increases the strength of the material. Varieties for decorative and other properties are obtained through many methods of further processing.

Cork flooring blends harmoniously with any style and does not lead to disappointment. The material retains its attractiveness and properties for 18 - 20 years. Doctors recommend sitting on a cork surface to get a healing effect on the skeletal and nervous system.

The eco-friendly coating retains heat and pleases with its original patterns. The top layer of veneer attracts with natural colors, conveys any pictures: imitates the pattern of stone, tiles, wood structure, pictures for children. Exclusive patterns and images are created using photo printing.

Cork floor thickness

The adhesive type is available in 2 versions: thickness 4 mm and 6 mm. Accordingly, prices for 4 mm thick plates are lower: a budget choice for premises where the priority is appearance and cost optimization, but not insulating properties (commercial applications). The classic thickness of 6 mm reveals all the advantages of cork: ideal for residential areas.

Multilayer interlocking laminate can be 10-11 mm thick - solely due to the middle HDF layer . If we take into account only the cork layers, the thickness of the interlocking coating will also be 4-6 mm .

Where does the cork come from?

If you carefully examine a wine cork, you can clearly see that it consists of crumbs carefully pressed together.

Cork is nothing more than the bark of wood, but not any kind, only oak. At a certain period of time, it is removed, and the tree produces the next material suitable for the production of products. As a rule, the oak species from which cork is obtained grows in Asia – where cork production is on stream.

Cork flooring decors

Natural cork veneer

Thinly sliced bark is arranged in various patterns, small, large or medium fragments are used. Depending on the installation, abstractions, tiles or stripes are obtained.

Tinting

To diversify the decors, the veneer is tinted before applying the varnish coating: the cork floor can be lightened, darkened or colored. Tinting emphasizes the texture of cork and saturates the flooring with new colors and shades.

Photo printing

Photo printing technology is a way to unlimitedly expand the choice of decors for a somewhat monotonous cork veneer floor. Images applied to cork imitate the texture of wood, natural stone or any other surface. Thanks to the use of modern industrial printers, incredible realism and richness of the picture is achieved.

Selection criteria: what you should pay attention to

The correct approach when choosing a cork is to focus on its performance characteristics. You have complete freedom in choosing products, but manufacturers help you make a choice by indicating the purpose of their products. It is more convenient to use specific types of cork as follows:

- Moisture resistance level. Moisture-resistant coatings are suitable for any room.

- In the living room. Not only strength is important here, but also appearance. Therefore, you can lay the floor with a decorative layer of varnished natural veneer. Photo printing is an option.

- In the bedroom. Comfort is important here. To make it pleasant for you to walk barefoot, soft tiles with minimal facial protection are suitable (you can choose the option without covering).

- In the nursery. Active games require significant load on the floor. You will need a soft, but at the same time quite strong cork; Floor coverings with such characteristics are easier to find among adhesive panels.

- Cork coated with polyurethane or ceramic varnish works well in the hallway or kitchen.

Natural flooring is a good choice for children's rooms Source yandex.net

Why experienced installers recommend adhesive plug

Interlocking cork laminate requires high factory readiness: the final varnish coating is applied during production. In combination with the technical features of cork, this does not allow for correct calculation of wear resistance, which leads to deformation of the flooring at the slightest damage: roller wheels, rearrangements, heels, sand and dirt.

In addition, even the highest quality interlocking laminate is not without gaps between the boards: over time, the gaps expand, dirt gets stuck in them, the edges delaminate and turn black. This is especially true for flooring in the hallway. This cannot happen with an adhesive cork floor: the varnish is applied after installation, creating a single film on the surface that prevents the penetration of dirt. Thanks to this, the floor plug installed with glue is durable, practical and wear-resistant, subject to professional selection of consumables and installation.

Price and reviews

The cost of cork flooring is determined by a number of factors:

- drawing (natural, tinted, with photo printing);

- manufacturing company;

- manufacturing difficulties.

Adhesive sheets are half the price of locking plates. The final price of a cork floor is adjusted by the purchase of glue and varnish, which accounts for approximately a third of the costs. Designer tiles will cost more – 1 sq.m. coating costs from 3 thousand rubles. The performance characteristics of the models are almost the same.

Owners of natural flooring in their homes most often leave positive reviews about cork floors. What consumers are most satisfied with is receiving a safe environment. Residents of apartment buildings note that they do not hear any extraneous noise, the surface is easy to care for, and the varnish layer can be renewed.

Installation and maintenance of flooring

The method of installing cork flooring depends on the type: interlocking laminate is installed using click locks, planks or tiles are connected to each other. To install the adhesive plug, a special water-based or solvent-based adhesive is used. The quality of installation is determined by the preparation of the base, the qualifications of the installers, and the selected accompanying materials. We offer detailed installation video instructions.

Video: laying adhesive flooring

Video: laying a lock plug

Care and renewal

Cork flooring has a stable structure, impact-resistant, and moisture-resistant: the floor covering does not require special care. Wet cleaning or cleaning with a washing vacuum cleaner is allowed. It is forbidden to use chemicals with solvents and abrasive particles to avoid scratching the surface and to prevent discolouration.

The surface of a cork floor under varnish or wax looks impressive and bright for 1-2 years, especially with heavy traffic. That is why flooring, just like parquet or parquet boards, needs regular updating . Old varnish or wax is removed with a grinding machine; a new protective layer is applied - the surface is like new again !

An air humidifier is not only an indispensable device for creating a healthy indoor climate, but also a simple solution for maintaining the performance characteristics of walls and floor coverings. Under natural conditions, Quercus suber oak grows at an average humidity level of 50%: dry air will lead to drying out, delamination, and brittleness.

Laying

In installation technology, one of the most important conditions is laying the cork floor on a level surface. A wooden, metal or concrete base or gypsum screed is suitable, which should be free of cracks and bumps.

General recommendations:

- after purchase, the material must be kept for about a day in the room where installation work is planned;

- if there is a pattern, you need to work in advance to adjust the pattern;

- Remains of glue and small debris should be removed immediately.

Laying different types of cork flooring has its own nuances.

Sheet covering

The process of gluing the plates must be carried out from the center to the walls. Determining the place to start working is easy with the help of threads if you stretch them along the diagonals of the room. After marking is completed, a thin layer of glue is applied first to the tile, then to the base. Further, according to the recommendations, you need to wait 20-40 minutes, and then connect the surfaces.

After gluing, the tiles are carefully tapped with a rubber hammer. It is more convenient to join sheets if you first bend the sheet in an arc and then press it to the base. When installing, maintain a 5 mm gap between the edge panels and the wall.

It is better to use moisture-resistant glue, especially for laying floors in wet rooms. Finally, 2-3 layers of varnish are applied to the coating, which protects it from damage and moisture.

Sheet cork covering

Castle coating

Laying does not require a strong connection to the base; if necessary, the floating floor can be disassembled. To improve the quality of the coating, use a substrate that protects against dampness and smoothes out unevenness.

The panels are installed from right to left. The ends are fixed at an angle of 30° to the laid sheet. It is recommended to start laying the second row with the panel located at the end of the first strip. A sealant is used to treat joints.

Interlocking cork covering

Technical substrate

Laying working cork requires maintaining 15 mm gaps between the wall and the tiles. It is allowed to use PVC film to protect the coating from moisture. The pieces are laid and secured with tape.

Technical cork backing

Table - comparison from NAFCD

The North American Flooring Distributors Association has conducted a number of studies comparing different types of materials. The results are collected in the table.

| Property | Adhesive cork floors | Lock plug | Carpet | Parquet board | Ceramic tile | Laminate |

| Thermal insulation | ●●●●● | ●●●●● | ●●●●● | ●●● | ●● | ●●● |

| The sound of footsteps | ●●●●● | ●●●●● | ●●●●● | ●●● | ●● | ●● |

| Durability | ●●●●● | ●●●●● | ●● | ●●●●● | ●●●●● | ●●●●● |

| Care, cleaning | ●●●●● | ●●●●● | ●●● | ●●●●● | ●●●●● | ●●●●● |

| Environmental friendliness | ●●●●● | ●●●●● | ●● | ●●●●● | ●●●● | ●●● |

| Depreciation | ●●●●● | ●●●●● | ●●●●● | ●●● | ●● | ●● |

| Mold resistance | ●●●●● | ●●●● | ●● | ●●● | ●●●●● | ●●● |

| Soundproofing | ●●●●● | ●●●●● | ●●●●● | ●●●● | ●● | ●● |

| Water resistance | ●●●●● | ●●● | ●●● | ●●● | ●●●●● | ●●● |

| Insect resistance | ●●●●● | ●●●● | ●●● | ●●●● | ●●●●● | ●●● |

| Fire resistance | ●●●●● | ●●●● | ●●● | ●● | ●●●●● | ●●● |

| Easy installation | ●●● | ●●●●● | ●●● | ●●●●● | ●● | ●●●●● |

| Maintainability | ●●●●● | ●●● | ●● | ●●● | ●●●● | ●●● |

| Scratch resistance | ●●●● | ●●●● | ●●● | ●●●● | ●●●●● | ●●●● |

| Final score | 4,8 | 4,4 | 3,3 | 3,7 | 3,8 | 3,3 |

What is the difference between cork flooring?

The main advantages of cork flooring are listed above. When arranging a private home, many doubts and questions arise about which flooring is best to choose. The following comparisons may help:

- Ceramic tiles and cork. Until now, tiles are considered the most popular material for flooring in bathrooms, toilets and kitchens. This is facilitated by absolute water resistance, resistance to aggressive liquids, and ease of cleaning. In terms of wear resistance and durability in these areas, it is superior to cork. However, cork has an important advantage - a warm surface on which it is comfortable to walk barefoot, without slipping. Falling heavy objects can break the ceramics and only push through the cork. Wax-impregnated cork is highly water-resistant, making it competitive with tiles.

- Cork floor and linoleum. This finishing material is rightly considered a practical option for non-humidified areas in the house. It combines low cost, sufficient wear resistance and attractive appearance. However, linoleum is clearly inferior to cork in terms of durability, mechanical strength and decorativeness. In particular, if liquid accidentally gets in, it warps and loses its attractiveness.

- Cork and laminate covering. Laminate flooring is increasingly used in private construction. It is characterized by high strength, durability and decorativeness. Among the disadvantages are the need for careful leveling of the base, excessive hardness of the coating, and the need for insulation. Cork in the form of a laminate is completely similar in appearance, but has such important advantages as optimal softness with a healing effect, and water resistance in the impregnated version. It is more resistant to accidental damage.

- Wooden floor or cork flooring. Boards on the floor in a private house have been used since ancient times. It is easy to install, has a fairly warm surface, and is repairable. The main disadvantage is the tendency to rot when exposed to moisture and insufficient decorativeness. According to these indicators, cork flooring has a clear advantage.

In general, many continue to consider cork flooring exotic. The reason for this is the high cost, at which it surpasses other coatings. It is the economic side that most often hinders its use.

We recommend reading: What to choose - linoleum or laminate?

Photos of interiors

Choose cork flooring in the online store and order inexpensive delivery throughout Russia. You can view samples and ask related questions in our showrooms. Welcome!

Proper care

This is a guarantee that the coverage will serve you for a maximum period. As we wrote above, care is quite simple and this is an advantage. Can be vacuumed and washed with a regular damp cloth. But sometimes persistent stains appear that cannot be removed with simple actions.

- It is necessary to take into account that hard metal brushes and abrasives with large fractions cannot be used.

- If the top layer has a vinyl finish, it will need to be coated periodically with mastic. The recommended interval is once every two years.

- To protect against scratches, it will be better if you cover the legs of the furniture with special pads - you can find them in any furniture store.

- And do not place rubber mats on the cork - marks will remain.

The video contains more information about cork laminate, as well as its installation technology.