If the family uses their own water supply, then they will need a caisson for the well. This is a structure that forms a special chamber in water and the adjacent wet soil, impervious to moisture. It helps protect against freezing and runoff. This is especially important for areas where there is no central water supply. Every home owner faces the task of preparing for the use of all systems. We recommend that you arrange everything correctly so that you don’t have to redo or repair it in the future.

General information

Considering the caisson, what it is in construction, the structure can be defined as a hollow sealed chamber, mostly round in shape with a diameter of approximately 1 m, which is installed on top of the well pump.

Most often, the caisson is placed in a hole dug in a circle around the casing, with the casing's mouth located at a depth of 1-5 m. At the bottom of the device there is a hole for the well, at the top it is closed with a hatch for insulation. A ladder must be installed inside, which allows you to descend to the downhole equipment.

The ladder allows you to conveniently descend for installation, repair or routine maintenance of equipment Source eurolos.ru

Why a caisson is needed for a well is to protect the pumping station from bad weather conditions, seasonal temperature fluctuations, and the penetration of underground, waste and melt water.

Plastic caisson

Plastic is considered a popular material for making caissons. The camera material has many positive characteristics.

All devices can have different geometric shapes.

The advantages of the products are:

1.low cost compared to analogues made of steel and reinforced concrete.

2.light weight of the caisson, making installation and transportation easy.

3.long service life, because corrosion does not form on the surface, there is no need to insulate the chamber.

4.high thermal insulation of plastic allows you to maintain the temperature of the liquid inside the container above five degrees, thus the water in the caisson does not freeze.

5.high level of waterproofing.

The big and only drawback is considered to be the low rigidity of the structure, so it can deform and break the equipment. In this case, backfilling the well around the perimeter, cement mortar is used to strengthen the walls. The cement layer should be eighty millimeters.

Functions of the caisson

At low temperatures, water turns into ice. As a rule, groundwater is located below the soil freezing level, but pumping equipment is installed on the surface and it is strongly exposed to the negative effects of low temperatures: the water in the system freezes, the hoses burst, the pump fails, and the water supply system stops working.

Therefore, when considering a caisson for a well, what it is and why it is needed, we can briefly say that it is an insulated room that does not allow downhole equipment to freeze. The following is installed inside the structure:

- pump for water intake;

- filter installation;

- shut-off valves;

- battery;

- pressure gauge;

- automation device;

- expansion tank.

To install a caisson, it is best to contact specialists; it is almost impossible to carry out the installation work yourself

. Source provodoprovod.ru The installation of a caisson for a well is not required only if the equipment is located near the heated room. In this case, you can get free access to all elements of the pumping system, but the strong noise of the devices brings some discomfort.

In the process of organizing a well, a water pipe is installed in a caisson to a depth of 1-2 m. This allows you to create effective protection from low temperatures.

General installation recommendations

When installing a caisson, several general recommendations should be followed to make its operation more efficient.

- Chamber depth. To effectively protect the well and the water supply equipment installed inside the caisson from the cold, its depth must exceed the soil freezing level. This indicator is different for different geographical areas: in the Moscow region it is 0.8-1.1 m, in the Kuban - about 0.5 m, and in Siberia it can exceed 1.5 meters.

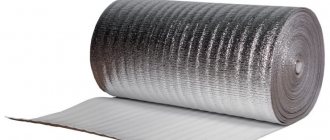

- To avoid freezing of the well, it is also recommended to properly insulate the chamber walls. External water pipelines connecting the well to the house can be additionally insulated with a self-heating cable.

- Caisson dimensions. You can decide what kind of caisson you need in terms of internal dimensions based on its specific purpose. If it is planned to accommodate pumping equipment and plumbing devices (shut-off valves, wiring systems), then it is better to make the chamber more spacious. In cramped spaces it will be difficult to maintain and repair equipment. If only the end of the casing with the head is placed inside, you can install a small caisson. This will save time, effort and money.

- Installation of a drainage cushion at the bottom. In this case, there is no clear opinion: some experts recommend concreting the bottom of the chamber, others advise filling it with coarse gravel. In the first case, if it is necessary to emergencyly discharge water from the system, or when condensation appears, water from the pit can be removed using a pump. In the case of a gravel bottom, it should sink into the soil on its own. But this will not happen on clay or loamy soil: water will accumulate in the pit.

Main types

Caissons for wells come in various geometric shapes, but cylindrical and round designs are the most popular. Sometimes you can find combined caissons; they have the shape of a rectangle at the bottom and a circle at the top.

Taking into account the material, the following protective systems are distinguished:

- plastic;

- iron;

- reinforced concrete.

In rare cases, brick is used for construction.

The materials used to make the caisson determine its performance. They all have their pros and cons.

Caissons come in different shapes, but mostly round ones are installed Source lider-skvajin.ru

Plastic

The most popular are plastic products. This material has excellent tightness, caissons made of plastic are easy to install, the surface is strong, durable, while it is absolutely not subject to corrosive processes and is inexpensive.

The structures are made from a solid cylinder or polymer sheet material 6-35 mm thick, taking into account GOST regulations; the material usually contains plasticized polyvinyl chloride, polyethylene, fiberglass, and polypropylene.

Main advantages:

- The material retains its characteristics for a long time, it is not exposed to rust and does not rot.

- The service life of plastic products is about 30 years (taking into account the wall thickness).

- The surface allows for excellent tightness and waterproofing.

This is what classic plastic caissons look like Source ytimg.com

- The low weight of the product facilitates the delivery and installation process. The medium-sized structure can be mounted without the use of special equipment.

- Plastic has excellent thermal insulation properties, due to which an additional insulating layer is not required in areas with moderate climatic conditions.

With all the described advantages, plastic structures are relatively inexpensive.

Flaws:

- Due to its low mass, during floods, a plastic product can rise from the ground. Therefore, a cement-sand cushion is poured into the base of the tank, this leads to an increase in the cost of the caisson.

- There is a possibility of surface deformation due to soil compression. This problem is partly solved by installing stiffeners.

Metal

The metal caisson for the well is not so popular. These products are characterized by high strength and maintainability. Taking into account GOST regulations, iron structures are made of steel with a thickness of 5-10 mm.

Insulation of the metal caisson is mandatory, but this can serve as part of the landscape design Source strojdvor.ru

Carrying out anti-corrosion, hydro- and thermal insulation work during installation is a mandatory requirement, in particular for products that are made of stainless steel.

Attention! The ideal shape is round, since this design has a minimum of connections.

Main advantages:

- Long service time. When all conditions of installation and further operation are met, iron structures last about 50 years, this can be compared with the service period of a directly dug well.

- Increased strength. Steel can better withstand pressure, unlike plastic products, this significantly reduces the possibility of cracks forming on the surface during soil heaving.

- Much easier to install, unlike reinforced concrete products.

- Good sealing. If there are no cracks in the joints, then the iron structure is guaranteed to be able to protect the installed equipment from the penetration of groundwater.

- Sustainable location. The relatively large weight does not allow the caisson to rise during floods.

But if the installation technology is not followed, the sealed metal caisson may float up Source domkesson.ru

See also: Catalog of companies that specialize in water supply, sewerage and related work

Flaws:

- The main disadvantage of metal structures is their susceptibility to the development of corrosion processes. The need for waterproofing leads to additional costs.

- A factory-made iron caisson for a well (especially one made of stainless steel) is much more expensive, unlike plastic products.

- The relatively large mass, which prevents swelling, sometimes creates certain difficulties during installation. Most often, during installation it is necessary to use special equipment.

- Low thermal conductivity. To prevent freezing, iron structures must be insulated; this also increases the cost of the caisson.

Reinforced concrete

Considering what a caisson for wells is and the materials for its manufacture, it is necessary to note reinforced concrete structures, which are not very popular.

Concrete rings are difficult to install and impractical to operate Source beton-house.com

There are several options for these products:

- The structure is made by pouring concrete into the formwork with reinforcement in it. Filling wells come in any shape.

- During installation, reinforced concrete rings are laid on top of each other on a previously prepared foundation. The individual elements are connected using a waterproofing compound. When the caisson reaches the required height, a slab with a hatch is installed on top.

A caisson for a well made using the first method is characterized by high strength, but it also has many shortcomings. The main ones are low hygroscopicity and large mass, because of this the caisson can sink into the ground.

Attention! Due to the large number of shortcomings, reinforced concrete structures must strictly comply with the GOST 8020-90 regulations: in terms of water permeability, frost resistance, actual strength, corrosion protection, concrete layer thickness, steel grades for reinforcement.

When installing concrete rings you cannot do without special equipment Source ytimg.com

Main advantages:

- Long service time. If the technological process and subsequent operating conditions are observed, reinforced concrete caissons last up to 100 years.

- Increased strength. Even serious ground displacement will not damage the integrity of the product.

- Relatively inexpensive cost of manufactured reinforced concrete chambers.

- The large weight successfully prevents the structure from floating up during an increase in groundwater levels.

Flaws:

- The main disadvantage of reinforced concrete products is the connections between the installed caisson elements; this is the most vulnerable link.

- Poor waterproofing. Concrete surfaces are hygroscopic; water that gets inside over time destroys the walls of the rings and causes corrosion in the reinforcement frame.

- Very large weight often leads to subsidence of the well into the ground, which sometimes leads to disruption of the operation of downhole equipment. The significant mass also creates certain difficulties during transportation and installation.

- Poor thermal insulation. Concrete surfaces must be insulated.

If you install it yourself, there is a high risk of leaks Source provodoprovod.ru

How to make a caisson without costs or helpers

Some varieties can be created without professional help and the purchase of expensive components. It’s worth trying to assemble a brick or concrete container; some specialists will even be able to weld a product from sheet iron. But at home, the quality is often worse than in production. How this is done is described below.

Warm brick option

This is one of the most budget-friendly and easiest ways to create protection for your water supply. To build it, you will need building materials of almost any quality left over from the construction of a house or other outbuildings. You will also need some concrete and sand.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Subsequence:

- a pit is dug taking into account all parameters;

- a concrete pad is poured;

- a wooden box is assembled to provide an even frame and protect against soil pressure;

- dilute the cement mortar in a ratio of 1:4;

- installation is in progress - it is important not to forget to insert the sleeves in certain places;

- so that the walls fit most tightly to the insulation, spacers are placed inside;

- a square steel sheet with the center on the side is often used as a cover;

- After complete drying, the inside of the container should be treated with waterproofing.

Warm method from concrete pouring

This method of obtaining a container for equipment and a well requires much more work, but it is also possible to do it yourself. It’s easier to do it if you turn on the concrete mixer or order the required amount of ready-made mortar. Mixing by hand is long and difficult.

Subsequence:

- dig a hole of a suitable size;

- compact the bottom, lay an insulating film, fill with the mixture;

- cut sheets of insulation according to the dimensions of the cube;

- Weld the mesh on the outside, put the formwork on the inside;

- to build the walls, you will need boards or panels tightly fitted to one another, which are fixed to the timber;

- pour concrete, preferably using a concrete mixer or machine;

- bayonet, tap or otherwise get rid of bubbles and unevenness in the mass;

- cover with cellophane so that everything dries without cracks;

- use a finished slab as a lid or fill it in a similar way;

- After all actions are completed and the surfaces have completely dried, everything needs to be treated with waterproofing.

Installation Features

The installation process is almost the same for any type of protective boxes, but there are certain nuances. The hole for the caisson is dug at least 50 cm larger than the structure being installed. This allows you to accurately level the product and adjust the alignment of the pipes. This will also help to insulate the walls or secure them if it is a plastic caisson device.

The well casing is cut to the height of the structure floor. Sand is poured into the bottom of the hole in a layer of 25-35 cm and watered to compact it. A reinforced concrete slab is laid on top.

Attention! You can pre-install fasteners for the caisson on the slab. But there is a big risk of making a mistake. Therefore, it is best to first put the product in place, and then make holes for fastening. Today there are many expanding fastening methods, so there will be no problems with the choice.

During the installation of any caisson, it is imperative to follow the technological process Source burenie-m.ru

Metal caisson

The metal camera is also very popular among consumers.

The advantages of the products include:

1.completely sealed structure, so electrical equipment can be installed.

2.easy installation.

3.high strength, does not deform from external influences.

4.strong fixation in the soil, the structure will not float when flooded.

A caisson made of this material has a service life of up to 50 years.

Important! In order for the caisson to serve for many years, the internal walls should be treated with a special anti-corrosion agent, and water should be drained correctly.

Design disadvantages:

1.heavy weight of the device.

2.Welding is required when installing.

3.formation of corrosion on the surface.

Video description

The features of installing a concrete caisson are described in detail in this video:

Installation of a metal structure

Installation of an iron structure will necessarily require a concrete slab as a foundation. Before fastening the structure from the outside, it is finished with waterproofing, and the inside is coated with a primer. This is a mandatory requirement even for stainless steel. Insulation is also necessary.

Step-by-step instructions on how to make a caisson for a well:

- a hole is dug.

- The foundation is prepared - a sand and gravel cushion, and a reinforced concrete slab is installed on top.

- The well casing is cut to height.

Casing pipes must be selected taking into account the diameter of the pressure pipeline Source ytimg.com

- A caisson is installed on top of the pit on metal supports, and the pipes of the sleeve and the well must coincide.

- additional trenches are dug to bring the pipeline to the house.

- All communication systems are installed.

- thermal insulation is attached.

- the structure is covered with earth.

When considering a caisson for a well, what kind of product it is and how it will be used, it is necessary to take into account differences in the design, therefore the installation diagram sometimes changes taking into account specific tasks and conditions. But it is recommended to dig trenches for connecting communications after attaching the caisson - simply jumping over various ditches at this time is not very convenient.

Learn more about installation and connection procedures

The task is similar for all varieties, but there are some features that we will discuss below.

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

First, you should prepare a pit - at least 30 cm larger than the caisson itself. This will make it more convenient to install, place pipes, adjust them if necessary, and combine sleeves for passages. This will also make additional insulation and strengthening possible.

The bottom of the pit is covered with a sand cushion of 20-30 cm (this must also be taken into account when calculating the volume of required digging). Later, this backfill is spilled with water to make it denser. A concrete slab with steel reinforcement is already cast above it.

We do not recommend placing anchor bolts in advance - the chance of making a mistake is too high. In this case you will have to re-drill. It is better to install the equipment first and then secure it.

Users often wonder: what is kison, while making a mistake in spelling the name. We examined the principle of operation of the product and its essence, and talked about general recommendations. And now we suggest delving into the topic of correct installation on the territory, because its feasibility often depends on this.

If the rings are made of concrete

Here the system is the same as when creating a well. The main difference is in depth - in this case it will be much less.

It is better to fasten the parts together with steel plates. This will help protect the structure if the soil shifts. It is advisable to additionally fill the seams with cement mortar, without adding sand or other particles.

It is worth noting that concrete, unfortunately, allows moisture to pass through, albeit in small quantities. Therefore, he will need waterproofing and insulation to protect him in the cold.

In addition, a base under the rings is required, since the support area is too small. We recommend approaching the equipment with the principle that everything will last for decades, which means it must be done with high quality.

If metal products

Here you will also need a cast plate for the base and anchors. Even before installation in place, the container should be covered and treated with insulation, and the inside should also be primed. Even for stainless steel this is a prerequisite. You also cannot do without insulation.

The casing pipe is simply lowered into a sleeve hermetically welded to the bottom. Other inputs are welded with special bushings. Fittings will be screwed into them to set up the main line and supply the power cable for the electric pump.

If plastic tanks are installed

Working with this material is reminiscent of manipulating metal. The only difference is that instead of welding, glue will be used, and the tubes will be passed through couplings, and not through bushings. They can be closed with sealing lids if they are not needed.

There is no need for insulation or waterproofing here, but protection is required so that the equipment is not crushed by the soil. It’s easy to comply with this condition; just fill the gap between the wall and the pit with a solution and fillers. Moreover, it is allowed to take only one part of the cement. Sand and crushed stone are suitable as impurities.

This must be done even if stiffening ribs are visible on the surface. With proper protection, it can last for decades.

Video description

Why the caisson was compressed is shown in this video:

Attention! In this case, hydro- and thermal insulation will not be required, but protection against compression by soil is required.

Filling a plastic caisson with concrete is mandatory. Source moikolodets.ru

To do this, the gap between the walls of the pit and the box is filled with concrete. High-strength mixture quality is not necessary in this case. As a rule, the solution is mixed in a proportion of 5 parts sand and 1 part concrete. This procedure is mandatory, even if there are stiffening ribs on the plastic box.

Features of installing a caisson made of plastic

The main feature is the sealing of the joint between the sleeve and the casing pipe. To do this, they do not use welding, but special glue.

Pipes must enter the chamber through couplings, which are covered with lids for sealing.

A plastic caisson does not require waterproofing or insulation, but requires protection from deformation by soil. In this case, the gap between the pit and the chamber is filled with cement, which is diluted 1 to 5 (cement and sand mixture).

If there are stiffening ribs on the structure, the caisson should still be strengthened.

Video description

To see what errors can occur when installing a caisson, watch this video:

Also, the diameter of the installed casing tube must be 500 mm larger than the cross-section of the pressure pipe, the height of the caisson itself is at least 2400 cm, while the upper chamber must be above ground level, to prevent rainwater from entering it. For the same reason, the hatch must be sealed.

An installed caisson on the territory of a private house should not disturb residents Source strojdvor.ru

Summarizing

Installing a caisson simultaneously solves many problems. The water supply at home immediately becomes safer; owners do not have to worry about being without water when frost sets in. At the dacha, this device can be used as a warehouse or cellar, equipping it with a reliable lock.

Now you can buy a durable, ready-made plastic or metal caisson, or make it yourself. The choice is up to you. The main thing is not to forget that without this equipment, normal operation of the well is simply impossible.

Briefly about the main thing

A caisson is a sealed chamber of a round, rectangular or square shape that isolates the wellhead to protect it from groundwater. This allows you to protect against the penetration of dirty water into your home water supply.

After determining what a caisson is and what types it comes in, the problem becomes which material is better to choose:

- If the well is located on calm soil with little ground movement and low groundwater, the best option is to install a plastic structure. The goal of saving money on organizing a caisson made of plastic is justified, but it is not recommended to purchase very cheap models; it is worth taking a closer look at products made of high-density polyethylene and stiffeners.

- Installation of heavier iron boxes is advisable in unstable soil with high groundwater levels. Metal is more reliable than plastic, and repairs to steel products are much cheaper, unlike polymer ones. It is recommended to choose stainless steel caissons, but they are more expensive.

- Reinforced concrete rings can only be recommended with a stretch, since concrete, due to its hygroscopicity, is poorly suited for these structures.

Organizing a caisson allows you to solve many problems. The supply of water to the house immediately becomes much safer; the owners will not worry that they will be left without water when frost sets in. In a summer cottage, this structure is often used as a cellar.

Ratings 0

Types of caissons and their characteristics

Caissons for wells play the role of protection from adverse external influences. First of all, these are temperature changes and precipitation. Year-round water supply to housing requires mandatory insulation of all elements of the system located outside the building. It is also necessary to protect the well from penetration of rain and melt water. Getting into it, along the pit channel, surface runoff carries with it mechanical and chemical pollution.

Also, when equipping a water intake source, it is important to find a place to install the pumping equipment so that it is convenient to use, perform routine maintenance and repairs. If the owners do not live permanently on the property, an important task is also to protect equipment from theft and vandalism. This entire set of problems can be solved by installing a caisson on a well. However, such a technical device is quite suitable for a well, providing the necessary level of protection from cold and debris.

In general terms, a caisson is a chamber buried in the ground located around the top end of a casing. To improve its protective functions, it is sealed and insulated as much as possible to prevent cold air and precipitation from penetrating inside. There are several design options for caissons, differing in material, shape and size.

Today, the most commonly used materials for the construction of caissons are:

- Monolithic reinforced concrete.

- Ready-made concrete structural elements (rings).

- Brick and similar masonry materials (cinder blocks, aerated concrete).

- Plastic (for ready-made factory caisson chambers).

- Metal.

Previously, wood was also widely used as a building material. But today, log houses or beams are used less and less to protect wells. This is due to the complexity of construction and the low durability of wooden walls in conditions of constant dampness.

Option #1. Chamber made of concrete rings or bricks

The design, consisting of stacked reinforced concrete rings with a lid on top, is today the most common option for arranging caisson chambers. This is due to the high speed and ease of installation, as well as the durability of the structure. Concrete, provided good waterproofing is provided, can last for decades. Installing the rings will not cause any particular difficulties, and the entire job will take less than an hour.

This design also has a number of disadvantages. To deliver concrete rings to the construction site and install them, you will need to use heavy special equipment. The joining seams between the individual rings should be carefully sealed with cement mortar to prevent melt and rainwater from penetrating into the chamber. This requires a certain amount of time and effort.

You also need to take care of the external waterproofing of the rings, since concrete has the property of being saturated with moisture and, under its influence, gradually deteriorating. All this fully applies to monolithic concrete pouring.

Brick, cinder block or aerated concrete caissons are built in a pre-prepared pit dug to the required size. This option may be more economical than constructing a caisson made of concrete rings. Especially if used materials are used for masonry, or materials left over from the construction of the house.

Option #2. Metal caisson

A metal borehole caisson is usually made of sheet steel. Its thickness should be approximately 4-5 mm. Their design can be of two options:

- Assembled on a frame. In this case, a frame of metal corners or channels is initially welded. It is then sheathed with sheets of steel cut to the required size.

- Welded from solid steel sheets. This option is simpler than a frame one, but has less rigidity. To achieve the required strength, the use of thicker steel sheets is required, which increases its overall cost. Therefore, a similar design is used for caissons of relatively small sizes.

Unlike concrete, metal caissons have sealed joints that do not require additional sealing. However, steel structures also require external waterproofing. Otherwise, under the influence of ground moisture, the steel will soon be corroded.

Among the advantages of this option it should be noted:

- Less weight than concrete caissons. However, in this case, the metal structures are quite massive, which makes it necessary to use lifting equipment for their installation.

- Faster installation. Since the metal caisson is manufactured as a one-piece structure, it is installed in the pit at one time. Unlike a precast concrete structure, it takes much less time.

In general, brick, concrete and metal caissons, due to their significant mass, better resist the forces of frost heaving. This is especially true if the groundwater level is high in the area.

Option #3. Plastic caisson

Plastic caissons became widely available relatively recently – a couple of decades ago. But they managed to earn a good reputation due to their manufacturability, resistance to moisture, low weight, and ease of installation.

It is made from various polymer materials:

- Polypropylene.

- Polyethylene.

- Polymer-sand composite materials.

Depending on this, plastic caissons may differ in their technical characteristics. Their design scheme also varies:

- Solid containers. Produced by rotational molding from molten material.

- Welded. They are made from several separately cast parts, then joined by extrusion welding.

- Prefabricated. They consist of individual elements mounted using tongue-and-groove fasteners. Polymer-sand caissons have this design, assembled from individual rings and covered on top with the included lid.

The main advantage of polymer caisson chambers is their low weight. Thanks to this, installation can be done on site without the involvement of lifting equipment. To lift and lower a plastic caisson into a prepared pit, several people are usually enough.

The most massive are polymer-sand structures, but thanks to the use of prefabricated technology, their installation will also not cause difficulties. Due to their resistance to moisture, the walls of the polymer chambers do not need to be treated with moisture-repellent compounds.

Among the disadvantages of plastic cameras are:

- Less rigidity than concrete or metal options.

- Low weight. This parameter is both a plus and a minus. Its negative properties appear on soils with high groundwater levels. In winter, the plastic structure can be squeezed out of the soil as a result of frost heaving of the soil.