An unusual heating technology, fundamentally different from the usual systems with radiators under the windows, came to us from European countries recently, although it has been used there for more than twenty years. The name of the innovation speaks for itself - warm baseboard, the demand for it is growing due to its technical advantages and modern design.

You will learn everything about the types of baseboard heating and the features of its operation by reading the article we have proposed. We will talk about the design specifics and rules for constructing all types of baseboard heating systems. Here you will find out where heating baseboards are used and which models are popular among consumers.

Objectively about all the advantages and disadvantages

The ascending heat flow, according to Coanda's physical law, is pressed against the wall.

Without mixing with the rest of the air in the room, it heats the vertical surface. At a height of up to one and a half meters, the wall temperature is several degrees higher than in the room, and this creates thermal comfort for the people in it. During the heating season, the heating system is used for 6-8 hours every day. By multiplying the total power by the number of hours worked per month, we get the monthly energy consumption indicator.

The distribution manifold evenly distributes the coolant among the individual circuits. Its choice is determined by a number of factors - product material, comb throughput, pressure, energy consumption, possibility of further expansion

Do baseboard heaters really save energy resources due to the low temperature of the coolant?

The answer would be this example:

- Room area - 3.5m x 5m (17.5 sq. meters), perimeter - 17 m (minus the doorway - 16 m).

- Room volume with a ceiling height of 2.7 m: 17.5 * 2.7 = 47.25 cubic meters. meters

- The outside temperature in winter is on average -10 ºC.

- To maintain +20-22ºC in a room with normal thermal insulation, 1.5 kW/hour is required. The heating will operate 7 hours a day.

Taking into account 200 W per 1 meter of length when heating the coolant to 65 ºС (see above), we get 200 W * 16 m = 3200 W or 3.2 kW. Since this flow rate is twice as high (3.2 kW/1.5 kW = 2.1), it is possible to reduce the coolant temperature in the same proportion: 65 ºС / 2.1 = 31 ºС.

Let's calculate the monthly electricity consumption: 1.5 kW/hour * 7 hours. * 30 days = 315 kW. More reliable results are obtained by detailed thermal engineering calculations based on complete initial data on the object.

If we compare the efficiency of heated floors and baseboards, then we can argue, if only for the reason that convectors from the floor immediately heat the air, and part of the warm air from the baseboard is taken over by the outer wall, which is constantly fed by the cold outside.

The heat spent on constant heating of cold external walls is a kind of loss. Is their dryness, lack of mold, and dampness a compensation for this? There is also debate on this issue: some say yes, others point out that the humidity in the room is regulated by supply and exhaust ventilation, and not by heating.

If water radiators are connected in series, the coolant will cool while it goes around the entire perimeter. Therefore, the modules are combined in parallel, each pair of incoming and outgoing pipes is output to the collector separately

As for the appearance, the baseboard boxes that cover the heating really look beautiful in the interior, but when there is cabinet furniture in the room, problems arise - it is not possible to go around it in front, and behind it the warm air does not have freedom of movement.

And regarding the absolute absence of dust in the air, it is worth objecting - perhaps there is less of it than with air circulation in traditional heating systems, but it is there, since convection is present.

In general, we can conclude that baseboard heating radiators already have buyers, and over time their number will increase. The limiting factor is the excessively high cost of equipment, which is explained by the use of copper, brass, aluminum in production, i.e. expensive materials.

And installation, if you order it from professionals, is not cheap. Skirting pipe routing is the most complex of all available water heating circuits, but there are also many nuances in the assembly of electric baseboards.

Features of work

- The warm baseboard is mounted directly on the wall, where a regular decorative element is installed. Thus, it runs along the entire perimeter of the room.

- It is responsible not only for heating the air, but also the surface of the walls. And this significantly reduces heat loss from the walls themselves.

- Thanks to this movement of heat, the convention of air masses is significantly reduced. As a result, thermal energy is distributed evenly from floor to ceiling.

- The heated air rises very slowly. This means that it will not raise dust.

It is worth noting that the infrared baseboard can heat up to +70 degrees. Its minimum heating temperature level is +40 degrees. In this range you can look for the optimal temperature with which you will be comfortable. As a result, the air temperature will not be below +20 degrees. And this is considered the norm.

Many people are interested in where it is better to install a warm baseboard. But there are no restrictions when installing it. An excellent choice is to install this design in rooms with panoramic glazing. This is due to the fact that they can be cool. In addition, standard radiators cannot be installed under such windows. But they need a curtain of warmth.

Heating in baseboards: advantages and disadvantages

There are quite a lot of advantages of baseboard heating, and we have already mentioned a couple of very significant ones above. Now it remains to add a little to this list - as they say, to give it real outlines.

- Uniform heating of the room. It cannot be otherwise with this principle of arranging heaters. Moreover, the uniformity of heating also lies in the fact that throughout its entire height the air gap between the floor and the ceiling will have almost the same temperature.

- Rapid heating of the room due to the use of convector type heaters - they accelerate the air due to their special design. So to speak, accelerated air convection in the room.

- High aesthetic characteristics. The key point is that they are used “instead of baseboards.” This indicates not only the small size of the heating radiators, but also that they do not spoil the appearance of the room in any way - from a design point of view, these are the most attractive heating devices for residential premises.

- Economical in operation and maintenance. The question, of course, is controversial and largely depends on the type of baseboard heating system. If we talk about electric baseboard heating, it can hardly be called economical.

Naturally, baseboard heating distribution, or rather the system of such heating of a house itself, as they say, is not without its drawbacks, but this heating complex does not have many of them. Firstly, the high cost of the system, which will have to be paid for operational efficiency and simple maintenance - both the equipment itself and the installation work will be expensive. Secondly, baseboard heaters turn out to be ineffective behind furniture - in most cases, if not almost 100 percent of the time, they are not installed behind sofas and wardrobes, which not only reduces the efficiency of the system as a whole, but also creates some inconvenience. For example, if there is a need to rearrange the furniture, then you cannot do without altering the baseboard heating - so everything needs to be thought out in advance.

Scope of application

Baseboard heating is successfully used in residential premises, office buildings, and public institutions. They fit perfectly into the interior of catering establishments, country houses, and country houses.

Types and features of installation of baseboard heating

Baseboard heating can be either electric or water. Both are easy to install both in new and in used premises with existing heating.

Water baseboard heating

An autonomous water heating system consists of a boiler, distribution manifold, radiators and plastic pipes placed inside corrugated cross-linked polyethylene tubes. Supply pipes are laid from the distribution manifold to the baseboard installation areas along the floor or along the walls. Thanks to the corrugated outer pipe, which acts as a casing, replacement of failed supply pipes is carried out without dismantling and opening the floor screed.

The distribution manifold consists of a pair of steel pipes equipped with outlets and inlets, air vents and thermal valves. The top pipe is connected to the boiler and supply pipes leading to the radiators. The lower one is designed to return the cooled coolant.

The operating principle of the liquid system is no different from the usual design with traditional wall-mounted batteries. The heated coolant is supplied to the collector, from where it flows through pipes to the radiators. Skirting heating installations are much more efficient, simpler and more economical than “warm floors” and can be installed on any floor covering, including laminate and parquet.

Baseboard heating radiators consist of two copper tubes surrounded by metal plates that increase heat transfer. The elements are covered from above with decorative aluminum boxes, hiding the structure and evenly distributing heat. The standard height of the plinth is 14 cm with a thickness of about 3 cm. The color of the box is easy to match to the type and shade of the floor or wall.

In a liquid baseboard system with plastic pipes, any coolant can be used, but its temperature cannot exceed 80 degrees, and the pressure should not be higher than 3 atmospheres. In cases where the operating parameters exceed the declared values (which is often found in multi-storey buildings), it is necessary to install an additional heat exchanger in the apartment, which protects the central heating from overload. Another option is to install copper pipes instead of plastic ones.

The system is ready to connect

Electric warm baseboard

An electric baseboard heating system is practically no different in appearance from a liquid heating system, but instead of a coolant, the radiator tubes contain heating elements and power cables. The power of tubular electric heaters is 200 W per meter. The heaters are connected to the electrical network through a thermostat that regulates the set temperature in the room. To obtain maximum comfort, it is recommended to place temperature sensors at human height.

Installing an electric heated baseboard is much simpler than installing a water version. The system can be hung on any surface, including wooden walls and plasterboard partitions. The working elements are fixed on the walls at a distance of 4-6 cm from the floor, using special holders for fastenings. For safety reasons, it is recommended to use a residual current device.

The baseboard heating system does not have to be laid along the entire perimeter - the length of the heater is calculated depending on the volume of the room. In some cases, warm baseboards are used as auxiliary heaters in addition to underfloor heating or another type of heating.

Installing baseboard heating yourself can lead to serious breakdowns and accidents. It is better to entrust this difficult work to specialists who have the appropriate knowledge and experience in working with heating equipment.

Design, scope, price

Thin, elegant heaters that harmonize with the overall decor allow you to implement the most non-standard design ideas.

The peculiarity of the baseboard heating system is that it does not take away any free space from the room, and it can be placed next to furniture, antiques, household appliances, and musical instruments.

The material from which the flooring and walls are made also does not matter - there will be no damage or harm.

A palette of hundreds of colors and shades makes it possible to choose the appearance of the case to your liking. The texture can be a flat and smooth surface or an imitation of granite stone, marble, or wood.

A baseboard radiator will equalize the temperature in colder corner and end rooms; owners of cottages and country houses who want to create an elegant interior in their homes are interested in this technology. And in high-rise buildings, many people want to heat loggias and balconies, and this task is also easily solved using a similar heating scheme.

Wherever baseboard heating is used - in greenhouses and winter gardens, swimming pools and gyms, in museum buildings, concert halls, etc. Panoramic construction is in fashion, but you cannot install ordinary radiators along a wall that is solid glass.

A wide range of textures and shades of the warm baseboard body allows it to be used as a decorative element. In this case, it merged into a single whole with the door frames

Traditional heating also loses in rooms with high ceilings. No matter how much you heat them with radiators, warm air will still rush up to the ceiling, leaving the lower zone cool, and with the help of a thermal baseboard the situation can be easily corrected.

As for the price, the purchase and installation of heated baseboards is comparable to the cost of heated floors. Both will not be cheaper than installing a classic heating system with batteries.

Unfortunately, all energy-efficient devices cannot be called cheap, but the costs are worth it. In order not to overpay, you need to complete the system in advance - each of its elements has its own price. Only a specialist can do this correctly.

Classification of baseboard heating

Baseboard heating networks are classified into two types:

- electrical;

- aquatic.

The main elements of water baseboard heating are plastic, oxygen-permeable tubes, a distribution manifold, and baseboard batteries.

A baseboard heating system is installed in addition to the main heating of an individual house only when the coolant heats up by less than 85°C and the pressure in the central heating system does not exceed 3 atmospheres. Restrictions that should be taken into account when installing the system are imposed due to the possibility of water hammer.

When installing a water baseboard heating system, you must adhere to these instructions

- Copper ones should be preferred to ordinary PVC pipes;

- a heat exchanger is installed that takes heat from the main heating and is built into the system using special copper plates;

- thermostats can be installed on all batteries;

- a servo drive is installed on the distribution manifold;

- a pressure gauge, thermometer, and circulation pump are installed.

Water baseboard heating Electric baseboard heating is implemented according to a simpler scheme.

The main element of the system is a specific radiator unit with a heating element. A tubular electric heater is placed in the lower radiator tube, and the power cable runs in the upper one. This type of baseboard heating cannot be used in rooms with high air humidity. The system is powered from a standard 220 V outlet.

Heating system installation

Select the right radiator power. We advise you to take devices 10-20% more powerful than indicated in the table, this will provide a reserve for the winter cold.

There is nothing stopping you from installing baseboard heating yourself, no matter what the experts say - there is nothing complicated about it. And claims that good specialists will make the system more economical and efficient can also be questioned. The main thing is to correctly calculate the power of radiators based on the standard formula - for every 10 sq. m of living space requires 1 kW of heat .

Pipes for baseboard heating are laid under the floors, reaching the places where the initial sections of each of the circuits will be located (one or two circuits for each room, depending on the size). The installation of radiators is carried out in accordance with the instructions - first, a layer of thermal insulation is attached, on top of which the base of the decorative box is placed. Next, the tubes are laid and the radiators themselves (diffusers) are attached. At the last stage, the system is checked for leaks.

Electric convectors for baseboard heating systems are installed in a similar way. The use of protective devices for each circuit is considered a mandatory requirement. The wires must be laid in such a way as to avoid their damage - for this they can be stretched in plastic pipes laid in the floors.

Types of baseboard heating

Baseboard heating is divided into water and electric. Accordingly, water systems operate on the basis of gas or any other boilers. Electrical systems are built on the basis of baseboard electric convectors.

Water systems

Water heating systems are built on the basis of the radiators described above, made of non-ferrous metals. Hot coolant, prepared by a heating boiler or obtained from a central heating system, circulates through them.

Water baseboard heating can be used to heat rooms for any purpose - these can be halls, corridors, kitchens, children's rooms, living rooms, shopping areas and much more. In addition, it is well suited for use in rooms with panoramic glazing - baseboard radiators will prevent the penetration of cold and protect against the formation of condensation.

The “warm baseboard” heating system is recommended for installation in individual households. But its use with a centralized coolant supply can lead to an accident - baseboard heating does not tolerate water hammer. Some experts recommend using an intermediate heat exchanger, but in this case certain heat losses will be observed.

A water baseboard heating system consists of the following parts:

- Radiators - they are miniature convectors made of non-ferrous metal. They are the sources of heat for heating rooms;

- Protective boxes - they cover the radiators and pipes themselves;

- Pipes - in most cases, metal-plastic pipes are used here, as they are more resistant to pressure and high temperature.

The installation of a water baseboard heating system is carried out in such a way that it does not form a complete ring throughout the house - this would cause uneven heating. Therefore, the most common practice is to create separate directions for each room. To do this, distribution manifolds are installed in the heating system, to which coolant is supplied from the boiler.

The main advantage of using a distribution manifold is the ease of repair work in the event of an accident. It will also allow you to adjust the temperature in each direction separately.

Electrical systems

Electric baseboard heating is intended for use in buildings not connected to gas mains. It involves the use of small-sized convectors, powered from the mains. In their design, they are similar to water radiators, only instead of tubes with hot coolant, powerful heating elements are used here.

Electricity in our country is quite expensive, so using electric heating can lead to high costs. But in many cases it remains the only available heating method.

As in water systems, in electric heating it is desirable to use a circuit with several separate directions. That is, each room is powered by a separate electrical cable. A special electrical panel is installed in the building, in which circuit breakers are installed. From here the cables disperse throughout the rooms. If a room is not in use, it can be turned off, thereby saving energy.

Electric convectors work on the same principle as water ones - they produce heated air, which seems to “stick” to the walls and is sent upward. At the same time, cold air masses are sucked into the equipment and undergo the next heating stage. After some time, the room will become noticeably warmer.

The main advantages of electric baseboard heating over water systems:

- Increased reliability - the use of modern heating elements allows us to guarantee a service life of up to 20-25 years, while for water appliances this period is about 10 years;

- There is no coolant - which means there is no risk of flooding the neighbors;

- Easier installation - laying the cable is much easier than fiddling with pipes.

The main disadvantage of any electric heating is its gluttony in terms of electricity consumption - combined with electricity tariffs, the costs will be high.

Requirements for lining the heating pipeline under the baseboard

Finishing materials used to decorate components of heating systems must have the following properties:

- low flammability;

- sufficient thermal stability - the ability to maintain geometry and elegance when exposed to heat;

- low thermal expansion rate;

- hydrophobicity – resistance to moisture (during routine care and emergency leaks);

- resistance to chemical-based substances (household chemicals);

- safety – absence of harmful emissions and aromas under the influence of temperature;

- ease of installation and daily maintenance;

- resistance to mechanical influences - when rearranging furniture, etc.;

- elegance.

All of the above also applies to plinths for hiding heating pipes.

Installing baseboard heating - a detailed guide

When calculating the efficiency of baseboard heating, as for other systems, the standard indicator is 100 W of thermal energy per square meter of room area.

When using the system as additional heating, to calculate the power of the heating devices, simply multiply the area of the room by the standard indicator. And if this system is the main one, then another 20-25% of power must be added to the result obtained. Step-by-step installation is carried out as follows:

- The collector is being installed;

- The pipeline route is marked;

- The required length is measured from the collector to the radiator connection point. Two sections are cut plus 20 cm for connection. The tube is inserted into a protective casing and covered with protective tape.

- Installation of supply and coolant pipes to the radiator connection points is being carried out. The ends of the pipe are fixed in the floor or walls;

- The floor is poured with concrete or the laying channels in the walls are sealed;

- The screed is poured, the underlay and the finished floor with coating are installed;

- Thermal insulation tape is laid around the entire perimeter;

- After this, an aluminum profile is installed and screwed to the floor;

- An aluminum frame profile is installed along the entire perimeter, holders and brackets are installed every 40-45 cm;

- The tubes with plates are installed on the brackets;

- Connecting corrugations and couplings are installed, connections are made to the supply and return pipelines;

- All elements are fixed on brackets;

- A connection is made to the manifold, a pressure test is carried out and then a test fire is carried out;

- After eliminating the leak, a decorative casing is installed.

As you can see, installation of the system is in many ways similar to laying a heated floor pipeline, with the only difference being that the installation of external baseboard panels is also done here.

Interior design without flaws

Hiding pipes and electrical wiring is not difficult if the owner initially built the building himself. Engineers incorporate these conditions into the architectural design. The builders are equipping special channels where communications will be installed in the future. But if the building was erected a long time ago, the heating system is installed and functions perfectly, there is no point in changing it. Sometimes it happens that the construction features do not allow pipes to be laid on the floor or in wall channels.

double click - edit image

There is a solution. The special design of the skirting boards allows electrical wiring and other communications to be laid in their internal cavity. Two pipes of the heating system - supply and return lines - fit perfectly there.

Installation of warm baseboard

For installation you will need tools: adjustable wrenches in a set, a drill with an impact function (or a hammer drill), a hammer, wire cutters, pliers, scissors (to cut plastic). A baseboard heating system can be quickly installed if the connection points are prepared in advance.

Even before purchasing the necessary equipment, you need to plan what power the heating elements need and how to place them around the perimeter of the room.

Assembling a water heating system

Stage 1. We measure the distance from the point where the distribution manifold will be located to the location of the baseboard. We cut two lengths of the protective pipe and two with an allowance of 20 cm for the connecting pipe. We insert the connector into the protective one, and seal the ends with adhesive tape to protect it from dirt.

Installation of a water baseboard heating system: red - main flow, blue - return. The return flow pipe must be located higherStage 2. We pull the pipes along the floor without tension so that if extensions are necessary, one or more can be laid nearby. We fix it with mounting tapes, cover it with a protective solution, protecting it from damage, and place it in the right place on the wall 6 cm above the floor and 10-15 cm from the edge of the wall or corner, fix it with cement.

Stage 3. After laying the finished floor, we continue work. We glue an insulating strip along the entire length. We stretch the aluminum edge (also along the entire length of the heating), covering the junction of the wall and the floor. Screw it or secure it with adhesive tape or silicone.

Stage 4. We lay a special profile along the top line, put holders on it at a distance of 15 cm from the corners and every 40 cm along the wall.

Stage 5. To connect heating pipes and heating elements, we use couplings with nuts, bushings and gaskets, in the corners - 90º corner rotary tubes, in the ends - 180º end rotary tubes and plugs. We connect the thermal sections with adapters.

When connecting the heating module, you need to remove 2-3 lamellas from the edge and put connecting nuts, crimping parts, and rubber gaskets on the tubes

Stage 6

We carefully press the connected heating sections into the holders. We put on decorative panels (attach with screws or snap on) and decorative corner elements. We connect the system to the manifold, fill with water, test at operating and maximum pressure

Like all collector systems, the heating baseboard requires a circulation pump to stimulate the movement of the coolant. Without a pump, it is difficult for heated water to circulate along an extended circuit. However, the use of technical devices affects the overall cost of the system.

The plinth will work if all technological operations were performed without violations. If there is a leak, the problematic connections must be tightened with a wrench. The coolant is supplied through the collector by a circulation pump from the boiler or from a general (centralized) heating system.

Electric heating system assembly

For a warm baseboard, a separate circuit breaker must be made in the electrical panel. Its power is determined by the number of heating modules.

Stage 1. We supply power to the distribution box, which should be near the location of the system at a height of 4-6 cm from the floor.

Installation of an electric heating system: most often, the electric system is used where it is possible to supply the required power, or in small rooms as additional heating

Stage 2. Apply insulating tape to the wall.

Stage 3. We install the lower aluminum profile (edge) and the upper one, onto which we attach holders at the same distance as for the water system - 15 cm from the corners and in increments of 40 cm along the wall. We install a remote thermostat. It should be located at a height of about 1.5 m opposite the system modules and at a distance of at least 2 meters from them.

Stage 4. We insert electric heating elements (heating elements) into the lower pipe of the heating module, fix the modules in the holders so that they do not touch the wall.

The electrical contacts of the heating elements have a thread, two nuts, a retaining ring on a spring, and a heat-shrinkable tube for additional insulation. The modules are connected in parallel using a heat-resistant power cable coated with silicone and heat-resistant up to 180°C.

Stage 5. We close the system with a plastic box from above.

To connect heating modules, a 3-core cable is used: brown wire - phase, blue - zero, green (yellow) - ground. The cable must be grounded

It is best to entrust the connection of the installed heating system to the power supply to an electrical specialist. He will check the reliability of the insulation with measuring instruments, supply electricity and adjust the thermostats.

Preparation for installation

First of all, you need to prepare a set of tools for work:

- A hammer drill or a drill suitable for perforating;

- Hammer;

- Wire cutters;

- Pliers;

- Plastic scissors.

In order for baseboard heating to be installed quickly and efficiently, you need to prepare all connection points in advance. To simplify the work, it is worth creating a system design in advance, selecting suitable heating devices and how to place them in the rooms.

Interior use

With the help of baseboard heating you can realize original design ideas. Slim and attractive heaters look great with the overall design of the room. This device can be combined with any furniture set, appliances, antique items and modern elements. The warm baseboard box can be made in various colors, so it is easy to match it to any interior. The surface of the material can be flat and smooth. For classic styles, choose options with a stone or wood texture.

The plinth can be easily matched to any interior

Assembly and installation of the heating module

Connecting the heating module

- Before installation, it is necessary to measure the distance for connecting them to each other and the wiring. Using a hacksaw, we cut the module into the required parts. We remove the excess slats from the edge of the module with pliers.

- We install a heating element (tubular electric heater) in the lower tube.

- We lay a special (heat-resistant) three-core connecting cable into the upper tube. We cut the cable so that there are ends sufficient for electrical connections, approximately 15 cm.

Assembling an electrical circuit.

- We assemble a system for connecting to the electrical network. We use a single-phase electrical circuit with three conductors: phase, ground, 0. The silicone cable has 3 conductors with a cross-section of 1.5 mm². The connection of tens is carried out according to a parallel circuit. We supply the grounding and the tip of the contact group with a crimp clamp (insulating tape). To connect to the wires, we attach terminals with PVC cuffs: a flat piece is for grounding, and a round terminal is used for the phase.

- We install the heating module into the brackets. Then we insert a plastic wedge between the bracket and the module, ensuring rigid fixation of the heating module. We cut off the protruding part of the wedge with a mounting knife.

- We connect the corresponding contacts of the ten to the phase and neutral wire using a lock washer and a nut with a thread diameter of m4.

- We close the contacts with a coupling, which we heat evenly with a hairdryer. This will ensure tight connections and electrical safety.

How to choose?

Having decided to become the proud owner of a baseboard heater, you need to remember several important recommendations from experts.

- Such heating systems are not intended for individual use, especially in large areas. They are only an effective addition to the central heating system.

- Be sure to take into account the area of the room, and based on this indicator, choose the power of the baseboard heater itself. If calculations are made incorrectly at this stage, the efficiency of such additional heating may be zero.

- Be sure to take into account the power of the convector. It is necessary to choose those heater models that have a thermoregulation sensor.

If we talk about what type of warm baseboard to choose, then everything rather depends on material capabilities and personal preferences.

However, it should still be remembered that infrared baseboard heaters are the most modern and safe, while water systems can be left on for a long time even without human presence.

Electric models are the simplest and most inexpensive.

What systems are used today for heating rooms?

Objects for various purposes must be warm. This is necessary for normal human life. Not only in residential, but also in office, warehouse, industrial, and public premises, various types of heating systems are installed for this purpose.

Heating battery in the interior

Heating can be:

- air;

- water;

- electrical;

- stove.

Classification of the main types of heating systems

A set of equipment usually consists of several main components:

- heat generator;

- heating devices (radiators, heaters, convectors, etc.);

- communication systems (it includes electrical cables, pipelines, air ducts, etc.).

Centralized networks or your own equipment (for example, a boiler) can be used as a source of coolant.

Heating scheme with electric boiler

The most common types of space heating today are air and water.

Prices for Ballu convectors

Convectors Ballu

Air heating

In this case, the air is heated directly.

Air heating at home

Such heating can be organized in different ways:

- using natural or forced circulation of air masses;

- through suspended or floor-mounted equipment;

- direct-flow, recirculation or combined heat exchange.

Air systems can be installed both in private buildings and at large facilities.

Such equipment can be used in private homes

Air heating is a complex structure consisting of a heat source (they can operate on different types of fuel), an air duct network, fans, air distributors, filters, regulators and automation.

pros

- The heating of air masses and the creation of comfortable conditions for living occur within a short period of time.

- System efficiency and efficiency are at a high level.

- It is possible, in addition to the main task, to arrange air conditioning and ventilation of rooms.

- There is no need to use water (or other liquids) as a coolant (hydraulic systems often become a source of problems).

- When using suspended equipment layouts, it is possible to save usable space.

- You can install air heating with your own hands.

Minuses

- Calculating the parameters of system components is not so easy.

- To ensure a normal level of humidity in the room, it is necessary to additionally install devices for humidifying air masses.

- It is often not possible to modernize the system.

- The equipment may be noisy when operating.

Air heating of industrial facilities

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

Despite some disadvantages of this method, it is considered quite competitive in comparison with the more traditional - water method. And if earlier air heating was more often used in industrial facilities, today many private property owners are inclined to install such systems in their houses and apartments.

Prices for Volcano water fan heaters

Volcano water fan heaters

Water heating

The method of heating the surrounding space by transferring heat from its source through a water system is one of the most popular. Liquid is still the most common coolant. The equipment includes a heating unit, a main network, heating devices, and devices for controlling heat transfer. Pipeline routing can be top, bottom, horizontal, vertical or combined , while communications can sneak in in a hidden way (hidden behind the cladding) or be in plain sight. Constant and variable hydraulic modes, natural and artificial fluid circulation are used. Systems can be one-, two-, three-, four-pipe, manifold or combined.

One- and two-pipe systems

Today, water-heated floors are also increasingly being installed (in autonomous structures).

pros

- Low cost of equipment.

- Possibility of temperature control.

- The use of pipelines with a smaller diameter (when compared with air or steam analogues).

- No noise during system operation.

Minuses

- Due to the inertia of the system, heating and cooling do not occur as quickly.

- The uninterrupted operation of the heat source must be monitored.

- It is better not to leave operating equipment unattended. In this regard, in winter, if there is a need to leave the house for a long period of time, the water has to be drained.

- Installing water heating is not so easy.

- After draining the water, air pockets may form. Metal elements of the system are subject to corrosion.

Recently, underfloor heating has become increasingly popular.

Water heated floor

Using this method, it is possible to create a comfortable microclimate without installing heating devices. In addition, the entire system is hidden from view. In this case, the pipeline network is filled with a concrete screed, on which the floor covering is laid. The coolant (liquid) circulates through the pipes and heats the floor, which becomes the heating device.

Expert opinion

Masalsky A.V.

Editor of the “floor screed” category on the Pol-exp.com portal. Engineering systems specialist.

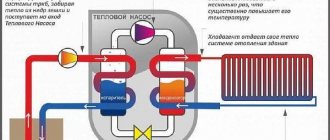

However, it should be noted that radiators, convectors, and heated floors, among other things, have a common drawback: when they operate, the walls of the room remain cold . And by heating them, you can not only improve the performance characteristics of the walls. A heated wall itself becomes a source of heat.

Example of a house with water heating

The warm baseboard system that appeared not so long ago could be called “warm walls,” because it is they who ultimately become the source of heat. It must be emphasized that it is much more comfortable for a person to be in a room with warm walls and fresh air than in a room whose walls are cold and the air in it is overheated.

Today, more and more owners of apartments and houses use warm baseboards, which can be water or electric, to heat their rooms.

Warm baseboards have become increasingly popular in recent years.

Tips for use

It is best to turn on baseboard heating in the off-season or during periods of severe cold. Using any type of it as an independent source of heating is allowed only in small rooms at a temperature outside the window not lower than -15 degrees Celsius. Otherwise, there will be practically no heating effect, and the energy consumption will be enormous.

Before each turn on, be sure to check the integrity of the entire system.

After the off-season period, it is necessary to disassemble the baseboard heater, carry out a visual inspection , and, if necessary, replace damaged parts.

It is not recommended to leave such a heating system of any type turned on unattended for a long period of time, even if there is a thermostat.

And yet, if any problems are detected in the operation of the baseboard heater, it is best to call a specialist rather than try to solve the problem yourself.

The following video provides an overview of the Megador electric baseboard heater, which allows you to save energy by heating the wall and reducing heat loss.

Some installation tips

- Before installing the heater, you need to stick class B1 insulating tape on the wall. It will become additional fire protection.

- Fasteners for electric skirting boards are installed in increments of forty centimeters.

Skirting board connections are made using heat-resistant cable - All cables and connections used must have a high temperature resistance class - at least B1.

Advantages and disadvantages

An electric heating system based on “warm baseboard” technology has both a large number of obvious advantages and some compromise nuances.

Pros:

- As opposed to conventional heating using radiator batteries, new heating systems do not operate by convection, that is, they do not create sharp air currents with different temperatures and drafts, and therefore do not drive a cloud of dust microparticles around the room.

- The technology ensures exceptional uniformity of heating, which eliminates the formation of fungi and mold on individual walls or areas thereof due to dampness.

- Simplicity not only in operation, but also in installation, unlike the same heated floors.

- Such a system does not lose efficiency even in rooms with large windows and high ceilings, because the higher they are, the greater the area of the walls through which heat is transferred to surrounding objects, which means that the room will still warm up evenly.

- Instant influence on the microclimate even with small changes in settings, its balance, providing the optimal amount of oxygen and air humidity for health.

- The versatility of the design allows such a system to fit into any interior without additional decoration, which, however, is also possible even in the form of painting such a baseboard.

- The modular design allows you to easily replace any failed elements without dismantling the entire system.

- Electric skirting boards are cheaper to purchase and easier to install, unlike their liquid counterpart.

Minuses:

- Installing such a system will not be a big problem even for a non-professional, but doing it with the greatest uniformity of heat transfer to ensure maximum efficiency of its operation is difficult for a beginner. Therefore, it is recommended to entrust this work to specialists, of whom there are still few in our country.

- The operation of warm baseboards is only effective if they fit tightly to the walls, which in turn can damage their finishing made from wallpaper or other materials.

- Just as with conventional radiators, it makes no sense to install such equipment, for example, behind a cabinet, wall or something similar, since it is this furniture that will heat up, and not the air in the room.

- Contrary to the stated efficiency, the most powerful electric skirting board systems have quite significant energy consumption and quite high costs during the cold season when operating in forced mode.

- Despite the variety of decorating materials for such devices, their use, as a rule, significantly reduces the heating efficiency.

Results

Like everything new, the plinth system has many critics and theorists. Their main thesis: “It’s stupid to heat walls and then heat the air. It’s better to heat the air directly, and then start heating the walls.” The point of view is clear. This is what is used for convector heating. But the result and its shortcomings are known to everyone. And for the efficiency of heating the walls, an experiment was carried out: in one room the air was +12 oC, and the walls were heated to +37 oC. And people sweated in it. In another, the air was heated to +40 oC, and the walls were cooled to +12 oC, and people were freezing.