Greenhouses with geothermal heating are an original method of using energy from renewable sources and the elementary laws of physics. The scope of application of this alternative type of energy is quite extensive, but most often it is used for heating livestock farms, poultry farms and greenhouses. The use of natural heat sources makes it possible to obtain significant savings and, consequently, reduce the cost of agricultural products. Calculations of a geothermal heating system for each object are made individually.

Geothermal heating and its benefits

The purpose of the greenhouse heating system is to provide temperatures sufficient for growing crops and ripening their fruits. To maintain the required temperature inside the greenhouse, the greenhouse effect alone will not be enough in winter, but the use of traditional heating systems leads to a significant increase in the cost of the production process. Contrary to the popular belief that new methods of alternative energy saving are something akin to a perpetual motion machine, geothermal heating systems actually work to save money and have a number of undeniable advantages:

- working completely autonomously, they do not require energy supplies and are completely independent of changes in their cost,

- operation of geothermal systems is a low-cost procedure,

- systems do not require expensive maintenance, approvals, periodic repairs,

- subject to high-quality implementation, the service life of the geothermal heating system will be at least 50 years,

- the system allows you to ensure the desired temperature inside the greenhouse throughout the year,

- with a balanced soft microclimate in the heated space, the system produces uniform ventilation and regulates the level of humidity.

Glass, polycarbonate or film?

The choice of heating method is also influenced by the material from which the greenhouse itself is made. Thus, in film structures, heat sources are used with greater caution. Because this material is very easy to damage. And they are usually not used year-round, but only in the off-season for earlier planting or germination of seedlings.

More often, greenhouses are made of glass or polycarbonate. Polycarbonate is a cellular translucent polymer that can withstand heavy mechanical loads.

Thanks to its structure, it maintains indoor temperature much better than glass, plastic or other similar materials. It also compares favorably with glass in terms of price.

Glass is the most permeable to sunlight, and therefore to the accumulation of natural heat. But for use throughout the calendar year, it is necessary to install double-glazed windows, which is quite expensive.

Geothermal heating - how it works

The functioning of geothermal heating systems is possible due to the stable temperature of the soil at certain depths. In winter, it can be 5-7 degrees C, in summer - 10 - 12. These indicators are quite enough to ensure the basic temperature in greenhouses; due to solar radiation and the presence of the greenhouse effect, in winter the air temperature in the greenhouse increases several times.

In the summer heat, the system works to normalize the microclimate by lowering the temperature to 23-27 degrees. In principle, this temperature is optimal for growing almost all types of vegetable crops. Thanks to air exchange, the soil accumulates heat during the day, and at night it releases it and heats the greenhouse, which helps equalize day and night temperatures.

Geothermal greenhouses turn out to be effective even in northern conditions; of course, in harsh cold climates, additional heating will be required, but the costs for it will be quite acceptable.

Of course, building a greenhouse with geothermal heating is not an easy task; the first problem is the extraction of a huge volume of soil - after all, the installation of underground communications will be required at great depths. However, the cost of building materials will be significantly lower than the estimated costs of gas or electricity used in traditionally equipped greenhouses, and the efficient operation of the geothermal system will quickly compensate for all financial costs.

Recommendations for use

The most efficient operation of the heat pump is ensured in rooms where the air temperature is from 14 degrees Celsius. Whenever possible, you should prefer the vertical layout of the contours to the horizontal, because it is the most effective of all. Judging by the reviews, geothermal heating in its pure form is irrational; it warms up the water for too long, therefore in many cases such a system plays a purely auxiliary role. To achieve the highest performance, you should focus on the maximum permissible intensity of heat resource involvement and the calculated well flow rates.

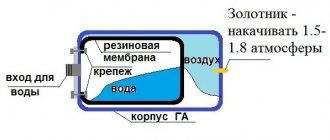

If there is not dry rock below, but hot water, this is an almost optimal situation. Then there is an opportunity to save money and get the maximum benefit. But we must remember that if you plan to simultaneously use hot underground springs for water supply, the water in them must meet standard sanitary requirements. When chemical analysis shows the presence of aggressive components, it is advisable to organize two autonomous circuits in which the liquid is not mixed, but only heat is exchanged. Compressors from either refrigerators or air conditioners are mounted on the walls.

If the wiring in the house is rather weak, it is worth using a couple of compressors to reduce the starting current due to series connection. When installing capacitors, you should take care of the movement of freon in them from the top to the bottom, and not vice versa. In order for the collector to work stably and heat the room, its area (for a private house measuring 100 sq. m) should be 200-250 m2. A horizontal heating scheme should not be used if you plan to subsequently plant a garden or vegetable garden. You can even use a regular well pump to complete the system.

Heating system design

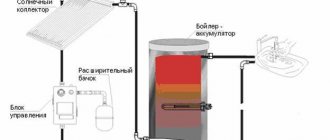

At its core, the design of a geothermal heating system is quite simple. It consists of two contours located under the soil layer and on the surface. With the help of the first, thermal energy is collected, i.e. it is a heat exchanger. Its installation is carried out either in non-freezing reservoirs at an appropriate depth or in the ground, below its freezing point.

The secondary circuit pipes are filled with water or water with the addition of an appropriate amount of antifreeze. The energy collected by the coolant is supplied to a heat pump equipped with two heat exchangers; geothermal heating works precisely from the energy obtained in this way.

There is also an option when a well is drilled to a depth of about 100 m for geothermal heating; this option is much more effective, but drilling to such a depth is very expensive.

Expenses

When manufacturing a 9 kW heat pump, you will have to spend:

- for condenser products and materials: $163;

- for evaporator: $206;

- for a used compressor and freon: about $50.

If you have automation, the total cost of a homemade heat pump will be approximately $500.

A polypropylene pipe PN10 with a diameter of 50 mm for the external circuit will cost 193 rubles. per linear meter.

Did you know that you can heat your house completely free of charge using the heat of the earth? Geothermal heating: principle of operation, advantages and disadvantages of technology.

We will discuss the operating principle of a heat pump for heating a house in this article.

Planning

First, it should be noted that an existing greenhouse cannot be equipped with effective geothermal convection. This is difficult to accomplish from the technical side, but even in the case of modernization, the efficiency obtained from it will be significantly lower than what can be obtained with the correct implementation of design work for the construction of a new facility.

Secondly, to obtain an economic effect, geothermal systems should be designed in year-round greenhouses, and their minimum area should not be less than 50 square meters. m, increasing the area will improve efficiency. The site for the construction of the facility and its dimensions should be determined before the start of design work.

Determining the location for construction is of no small importance; the dimensions of the site should significantly exceed the area of the future greenhouse. There should not be any buildings or trees growing on the site. When planning a greenhouse with a length and width exceeding 14 m, the dimensions of the sides of the pit should be increased by 3.5 m. If the length of the sides is less than 14 m, you will need a pit, the dimensions of the sides of which will exceed the sides of the structure by about a third.

You can dig a pit with your own hands, but you can use equipment in the process. The following materials should be prepared:

- clean river sand,

- small crushed stone,

- rubble brick,

- polystyrene boards,

- 110 mm pipes and joint connections to them.

It is difficult to name the exact amount of costs; approximately, geothermal heating costs about 120 - 140 dollars per square meter. m of finished heated structure. The density of underground communications will be inversely proportional to the average temperature indicators of a particular climate zone.

Construction of a foundation for a greenhouse

A do-it-yourself winter greenhouse can be made like a thermos, for which you need to raise the base. A strip structure can serve as a foundation, which should be deepened 50 cm into the ground. But the width of the tape can be about 40 cm. It is preferable to choose warm days for pouring the foundation. Initially, a trench is prepared, the width of which will be slightly larger than this indicator characteristic of the future foundation. The bottom of the trench must be carefully leveled, as well as the walls. Next, you can begin arranging the substrate, which will consist of sand. On top of the latter you can pour gravel. All resulting layers must be thoroughly compacted. To make it easier to compact the sand, you can use the method of pouring water on it. Next, you can begin installing the formwork and preparing the cement mortar. Although a polycarbonate winter greenhouse will be lightweight, it is preferable to strengthen its foundation. For this purpose, reinforcement must be used. There is no need to perform any special bandaging of the reinforcement, since the foundation will be small. There will not be a strong load on its surface. After pouring the foundation, it must be left for at least a week. If work is carried out in hot weather, you need to moisten the surface of the base with water. After the foundation is ready, a waterproofing layer can be laid on its surface, which especially applies to places that will be adjacent to the base.

Geothermal heating installation

The main characteristic of a functioning heating system is the number of calories of thermal energy that it produces. Since there is no regulatory framework for geothermal heating systems, when carrying out detailed calculations it is recommended to use the provisions of SNiP relating to the design and installation of general-purpose climate systems.

Effective operation of the system can be ensured by air ducts whose placement density will be no less than 2.7 m per 1 sq. m. m, in cold climates underground communications are placed more densely.

conclusions

- Geothermal heating remains expensive for Russian consumers and is widely used only in developed countries. At the same time, the technology underlying such heating is very promising.

- Improving and reducing the cost of heat production technology should become the main factor in the spread of this heating method in our country.

Carrying out calculations

To perform a system calculation, it is necessary to take into account the basic parameters:

- at a depth exceeding 15-20 m in central Russia, the temperature is maintained at +8-+100C;

- for vertical structures, it is customary to take in calculations the resulting power value of 50 W per 1 m of height, and more accurate values depend on the degree of moisture in the rock, the presence of groundwater, etc.;

- dry rock gives 20-25 W/m;

- moistened clay or sandstone 45-55 W/m;

- hard granite rocks will provide up to 85 W/m;

- the presence of groundwater gives up to 110 W/m.

Where to start installing geothermal heating equipment

The work will take from 2 to 4 weeks to complete. The most labor-intensive stage will be excavation; the best option is to hire special equipment, namely an excavator. Installation of communications is not particularly difficult; you can handle it on your own.

Depending on the climate and the depth of soil freezing, the depth of the pit is calculated; for areas of the middle zone, a depth of 3 - 3.5 m will be sufficient. If the climate is warmer, then the pit can be made shallower. The top fertile layer of soil is carefully removed and preserved, and the clay layers are removed. The shape of the pit can be rectangular or trapezoidal; its walls do not need to be secured.

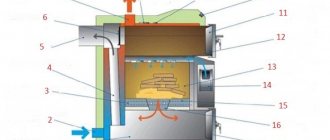

At a depth greater than 0.7 m, the pit slopes should be insulated with polystyrene foam boards. The bottom of the pit is covered with crushed stone (15 cm), then a layer of sand, about 30 cm thick, is compacted. Next, the internal contour of each of the walls of the future structure is beaten with a cord and its longitudinal axis is determined.

For laying air ducts, PVC plumbing pipes with a diameter of 110 mm are used. The pipes are laid in accordance with the marked route. It is recommended to lay the pipes in a “snake” pattern; with this option, the pipeline is divided into sections 1.5 - 2 m wide. The distance of the pipeline from the walls of the pit should be from 0.3 to 0.5 m. Each of the air ducts should have a tee connection in the center with three bells. At the next stage, the central branch from this connection is brought up, focusing on the longitudinal axis of the greenhouse.

After the construction of the greenhouse, the central branch of the air duct is increased, and the ends of the pipes should be 30-35 cm below the roof level. The side branches of the segments are also brought up, the distance between them and the walls of the greenhouse should be at least 0.2 m. The central and side branches are muffled using plastic plugs or polyethylene membranes. The vertical sections of the system are fixed by backfilling their base. Branches extending to the surface must be strictly vertical.

Having completed installation of the system, the pit is backfilled to the level at which the upper limit of the heat-insulating slabs is located - 70 cm from the ground level. The area of the pit that will be outside the inside of the greenhouse is covered with a layer of polystyrene foam and covered with a layer of soil until it rises to the soil level.

The walls of the resulting pit are secured using panel formwork, then insulated with polystyrene foam boards. The depression formed inside the greenhouse is filled with chernozem, not reaching the ground level by about 35-40 cm.

principle of organizing the air exchange process

The normal functioning of the system, in principle, does not require the organization of forced air exchange. To avoid sudden temperature changes and improve operating parameters, it is possible to install a homemade exhaust fan and filter device. If a forced air exchange system is installed, it will also filter the air. You can make the system yourself using a fairly simple diagram.

installation of mosquito net

To protect the system from various insects, a mosquito net is installed, the mesh size can be from 02 to 0.4 mm, the net is pulled onto a hoop and glued into the case in which the fan is placed.

how to deal with condensation

Since the temperature indicators of the soil and air can differ significantly, it can be assumed that condensation will form in the pipeline. To prevent this phenomenon, holes with a diameter of 5 mm are drilled in the pipes, up to 15 pieces per linear meter. When laying pipes, the holes should be positioned downwards. To adjust air humidity, water in an amount of 3-5 liters can be added to the segments.

If heating is carried out according to the principle of air convection, then caring for it will only consist of cleaning the mosquito nets. Greenhouses heated in this way are a profitable option for obtaining optimal temperature indicators through the use of autonomous climate control equipment.

Installation

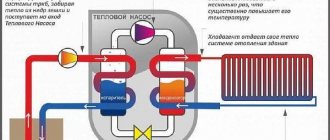

There are several ways to save a minimum of space for installing heat pumps:

- operation of underground probes. To do this, you will need to run a special circuit filled with antifreeze into a deep well;

- exploitation of warm groundwater. To do this, you will need to drill a fairly deep well. Groundwater is driven through a heat exchanger, previously pumped out by a pump;

- laying special umbrellas in a horizontal position below the level of winter glaciation at the bottom of the reservoir.

Construction of industrial greenhouses: heating and lighting

Heating an industrial greenhouse always becomes a pressing problem during the cold season. Each owner of a greenhouse complex is looking for his own way out of this situation. Some solve the problem with the help of anthracite coal, some are satisfied with the air heating system, others are introducing small and large Russian and global heating technologies of the new generation.

Lighting in large structures is no less important. Especially if the greenhouse “works” even in winter

For lighting equipment, new LED lamps and fixtures are installed, starting to turn them on as soon as the seeds germinate. Don't forget about the irrigation system.

Irrigation systems are:

- Drip;

- Autonomous;

- Ordinary;

- Air.

Ventilation also plays an important role. Recently, taking into account 2021, an automatic ventilation system with the installation of curtains has been actively used. You just need to set the sensors correctly, and the circuits will do everything for you.

Let's sum it up

Don't be intimidated by the impressive scope of work. Experience shows that from the zero cycle to the installation of filters it takes about 3 weeks, which, taking into account the half-century operation of the system, is simply insignificant. Such schemes are widely used in regions with a frosty climate, among the leaders is Greenland, whose vast territory is always hidden under a layer of snow. Remember that once you spend 3 weeks, you will not devote another minute to the system. For correct operation, no external influences are required; it is enough to only occasionally clean clogged mosquito nets.