Updated: 02/19/2021 18:45:21

Expert: Konstantin Borisovich Polyakov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

A hydraulic accumulator is a container for storing water, which is equipped with a rubber membrane surrounded by compressed air. The design performs four functions at once: it provides water supply in case the central supply is turned off or the pump breaks down, it protects subsequent wiring and fittings from water hammer, reduces the frequency of pump operation, and maintains stable pressure in the system. Let's consider how to choose such a device and take a more detailed look at the advantages and disadvantages of the most popular models. This will help you make your choice and not regret the money spent.

What is it needed for

The main purpose of our device is to maintain optimal fluid pressure in the water supply. Such equipment protects the pumping station from frequent starts and premature wear of parts, which usually leads to burning of the regulator relay contacts. After turning off the power supply, a certain amount of water remains in the tank.

The main functions of the described device are:

- Extending pump life. The engine starts after the liquid supply in the tank is exhausted. The duration of operation of the device depends on the frequency of its starts. Installing a membrane tank allows you to increase the time between starts, which will extend the life of the pumping device;

- Maintaining pressure in the system according to the specified parameters. In the absence of a hydraulic accumulator, pressure drops occur during the simultaneous activation of several consumers, for example, a water tap and shower;

- The device allows you to save a certain supply of water during a power outage. This quality is especially valuable when operating an autonomous water supply in a private home.

Reliable manufacturers

Before choosing the volume of a hydraulic accumulator, you should familiarize yourself with reliable companies whose products will definitely not let you down. Among the companies that have gained trust: 1. Gilex. Engaged in the production of equipment adapted for operating conditions in Russia. The line includes tanks of almost any volume. There are models with a galvanized or stainless steel body. There are also models with a galvanized or plastic flange. If necessary, spare membranes can be purchased for the tanks. 2. Wester. A very well-known manufacturer of membrane tanks for heating and hydraulic accumulators for water supply. The membrane itself is made of butyl rubber, which is not subject to rotting. If the membrane is damaged, it is easily replaced.

If you want to choose a hydraulic accumulator, we will be happy to help you. Call us now!

Device

As we have already said, our device is divided into two parts by a pear. One of them collects liquid, the other collects compressed air. After filling the bulb, the water pressure will be balanced by air pressure, so the capsule liquid will not touch the metal walls of the tank. The membrane does not inflate to significant sizes through internal air pressure. A valve is installed on the body to regulate pressure.

Note! The supply pipes must be connected to the hydraulic accumulator in such a way that the device can be quickly disassembled for repairs without draining the water from the system.

In tanks with a volume of more than 100 liters, a special valve is provided, which serves to remove excess air released from the liquid. In smaller containers, a special tap is used for such purposes.

Differences between cheap and expensive hydraulic accumulators

Taking into account the operating conditions of the hydraulic accumulator - constant pressure and contact with water, more expensive models provide not only increased tightness and reliability of all components, but also environmental friendliness.

- a well is drilled to obtain drinking water. Therefore, the rubber cylinder of the hydraulic accumulator must be made of high-quality material that will not cause harmful substances to enter the water. Only if you plan to use water exclusively for technical purposes, you may not specify what exactly the cylinder or membrane is made of.

- the flange on the cylinder can be made of stainless steel or cheaper galvanized metal. Stainless steel will not only last much longer, but will not become a source of chemical compounds harmful to humans.

The rubber cylinder and flange are easily replaceable elements. Therefore, if you doubt the reliability of the information about the quality of the materials used in the accumulator, these parts can be replaced yourself.

Principle of operation

The device in question works as follows. A pumping station from a well supplies water to the membrane under a certain pressure. When the pressure reaches a threshold value, the pumping station is switched off.

During liquid consumption, the pressure drops, which causes it to turn on again. The efficiency of the device depends on the volume of the tank. As the tank size increases, the load on the pump decreases. The pressure switch can be set to a certain water supply by rotating special nuts.

During prolonged operation of the accumulator, the air present in the liquid accumulates in the membrane, filling the useful space that could be used for water. In this regard, it is recommended to carry out preventive actions, which include releasing accumulated gases. Such operations must be carried out at intervals of 1-3 months.

Reflex de 100

The development of German engineers is distinguished by impeccable build quality. The container is made of carbon steel, the only seam is very well welded. The tank is designed for systems with increased requirements for corrosion resistance. The metal is coated on the outside and inside with a protective and decorative layer based on epoxy resin. All units are designed to operate for 10 years. The recommended temperature of the pumped liquid is from 1 to 99 degrees.

The preset pressure is 4 bar, maximum values can reach 10 bar. The elastic membrane is made of synthetic butyl rubber and is highly durable. The design of the tank allows you to quickly replace the membrane. Vertical legs are provided for installation. A significant distance between the base and the fitting allows you to connect to the water supply in comfortable conditions.

Advantages:

- Low weight makes transportation and installation simple;

- Takes up little space in the caisson;

- Long membrane life;

- Manufacturer's warranty 2 years.

Flaws:

Pressure switch for hydraulic accumulator and how to adjust

The device in question is used to automatically regulate the operation of the pump. When adjusting the pressure switch, you need to pay attention to the following terms:

- Lower pressure is the pump starting parameters, the standard value is 1.5 Bar;

- The upper pressure parameters are used to expand the relay contacts and further turn off the pump. The values used here are 2.5-3 bar;

- The maximum permissible pressure should not exceed 5 bar.

After starting the station, water begins to accumulate in the membrane or bulb. Subsequently, the liquid will be pushed through pipes to consumers. After purchasing the necessary equipment, you need to check the water pressure. The devices in question have special pressure gauges, but experts say that such devices have significant measurement errors.

Note! To check pressure readings, it is recommended to use a car pressure gauge with a special scale.

Pressure switch

When checking the air pressure in the membrane tank, remove the protective cover and connect the pressure gauge to the nipple. It should be noted that as the pressure in the hydraulic tank decreases, the volume of pumped liquid increases.

To create the required liquid pressure, air must be pumped into the container until the pressure reaches 1.5 atmospheres. An increase in indicators leads to frequent starts and wear of the pump. Too little pressure will cause the rubber bulb to swell and fail.

When adjusting the relay, you need to remove the cover from the device, after which we will find a housing with two springs on which a large and small nut is screwed. Note that the first nut regulates the lower pressure level (let's denote it with the symbol P). The second, small nut is used to adjust the pressure difference (usually designated by the letter H). Work begins relative to the lower pressure, which is set on a large spring.

Hydraulic tank with pressure switch

After filling the hydraulic tank with compressed air, turn on the pump and monitor the position of the pressure gauge needle. If the readings exceed the upper limit, you will need to turn off the pump. The maximum pressure in the system is set after the needle stops on the pressure gauge.

Note! When making adjustments, you must follow the recommended operating parameters of the pumping station specified in the product instructions.

When setting the relay, it is advisable to maintain the difference between the upper and lower pressure limits within one or two atmospheres, which will ensure proper use of the pumping station. After pumping water and setting the upper threshold, the pump is turned off and the relay begins to be adjusted. To do this, rotate the small nut until the mechanism starts. Next, drain the water from the system until the pump starts. This usually occurs at a lower pressure threshold.

Important! Set the lower limit 0.1-0.3 atmospheres higher than the pressure in the accumulator. This will increase the life of the pear.

At the next stage of work, rotate the large nut to set the lower pressure. Next, turn on the pump and monitor the pressure gauge needle; it should rise to the upper level. At this point, the work on regulating the pressure switch can be considered completed.

Popular models

On today's market, there are many different models of hydraulic accumulators. However, among them there are the most popular devices for a private home.

| Name | Characteristics | Price |

| AQUABRIGHT GM-80 V | 80 liter tank made in Russia, operating pressure is 10 atmospheres, maximum temperature is 99 degrees | 3,500 rubles |

| Ultra-Pro vertical (Zilmet) | The tank with a volume of 100 liters has a reinforced membrane that can work with aggressive water compositions. Working pressure up to 10 atmospheres, maximum temperature – 99 degrees, vertical position. | 12,000 rubles |

| Hydraulic accumulator SPERONI AV 100 | The storage capacity is 100 liters, the maximum permissible pressure is 10 atmospheres, the maximum temperature is 99 degrees. This model is available in horizontal and vertical versions. The membrane is made of high-strength food grade rubber. | 14,400 rubles |

| Vertical hydraulic accumulator Gilex pl./fl. 100l. | Tank with a capacity of 100 liters and a working pressure of up to 9 atmospheres. It is characterized by high quality and durability at a low cost. Has a reliable membrane. The flange is made of plastic. | 5,400 rubles |

| Hydraulic accumulator VCF-36L, vertical | The tank is of small capacity, intended for use in conjunction with low-power pumps. Tank volume – 36 liters, operating pressure up to 8 atmospheres. Characterized by high quality material and durability. | 4,000 rubles |

This rating is indicative and based on popularity among consumers.

There are plenty to choose from on the market. At the same time, it is important to understand in advance what characteristics the accumulator should have. And the most important of them are volume, layout and built-in air release valve.

Previous articles Next articles

Related Posts

- 25.03.2017.

What is a hydraulic accumulator and how it works

- 25.03.2017.

Replacing the membrane in the hydraulic accumulator

- 25.03.2017.

Automation for pump with hydraulic accumulator and pressure switch

Automatic devices for regulating the operation of the pumping station make it possible to minimize human presence during system operation. In this case, it is necessary to correctly configure the relay to supply the required pressure to the system (we discussed these operations above).

Hydraulic accumulator in the water supply system

As experts note, the main reason for reducing the life expectancy of a pump is considered to be the so-called dry running, when the device operates without water. This phenomenon can occur during frequent power outages. Risk points with the possible occurrence of dry running are considered to be:

- Incorrect selection of operating parameters of the pump, which is used to pump water from a well or well, and especially during dry summers when the groundwater level drops;

- Water outlet from the storage tank. In this case, it is necessary to immediately turn off the pump.

To protect against the possibility of dry running, automation is used:

- A float switch is a relatively inexpensive device that is used for pumping liquid from wells or tanks. In practice, two main types of floats are used. The first type of automation stops the pump when the tank is completely filled, when the water reaches the level of the float and opens the contacts. In the second case, the device cable is connected to a break in the electrical wiring to power the pump. The pump stops when the liquid level drops below a critical level;

- A special pressure switch is set to turn off the pump by the manufacturer. The contacts of the device open when the pressure in the system drops to 0.4…0.6 bar. The pump is started manually after the cause of dry running has been eliminated.

What pressure should be in the accumulator and how to pump it up

As we have already said, the main purpose of the hydraulic accumulator is to reduce the number of pump starts, which will ultimately lead to an increase in its service life and protection of the system from water hammer. In order for the installed equipment to work correctly, you need to know what pressure should be in the hydraulic tank.

Important! It should be understood that the accumulator is pumped up when there is no water in the tank.

Pump connection

There are several formulas for calculating the pressure in the expansion tank. According to experts, these indicators should be less than the pressure parameters at which the pump starts. If the equipment operates in the range of 1.5...3 bar (as recommended by the manufacturer), then the accumulator will need to be pumped up to 1.3 bar, i.e. 0.2 bar less than the lower pressure of the relay.

Manufacturers usually supply equipment with an inflated expansion tank. The pressure in the container should be within 1.5 bar, but sometimes it drops. Before starting the pumping station for the first time, you need to check the air pressure with a special pressure gauge, if necessary, connect the car pump to the nipple and pump it up. You can also add pressure using a hand pump, periodically checking its parameters with a pressure gauge.

It is necessary to periodically inspect installed water supply equipment. The fact is that water always contains a certain supply of compressed air, the presence of which reduces the useful volume of the membrane. In tanks with a volume of 100 liters or more there are special valves to bleed off excess air; in smaller tanks such devices are not provided.

To remove excess air from the pear, carry out the following steps. Turn off the pump and drain all the liquid from the expansion tank by turning on one of the taps. We carry out similar work several times in a row, which will help remove excess air from the water supply system.

Is it possible to increase the volume of the hydraulic accumulator?

Incorrect hydraulic calculations, changes in water or electricity supply parameters may require an increase in the volume of an already installed hydraulic accumulator. This can be done quite simply - by installing one or several hydraulic tanks in addition to the main one. This is possible because the volumes of all hydraulic accumulators in the system are summed up. That is, two tanks with a volume of 50 liters are approximately equal in efficiency to one tank with a volume of 100 liters.

several hydraulic tanks in one water supply system

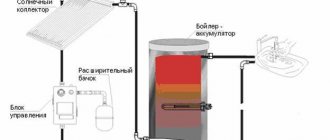

Scheme of water supply for a private house from a well with a hydraulic accumulator

If it is necessary to install an autonomous water supply in a private house, many owners of country real estate drill a well with a depth of 40 to 60 meters. The pumping station is located in a special pit near the well, which will increase the efficiency of its operation.

Hydraulic tank in a water supply scheme from a well

In most cases, the supply water pressure passes through a hydraulic accumulator, which helps balance the pressure in the system and protect the pipes from possible water hammer. Note that a certain supply of liquid is retained in the reservoir, which can be used after a power outage. Subsequently, water from the tank enters the system.

Note! As experts note, installing a hydraulic accumulator is not considered mandatory, but this device can improve the efficiency of the water supply system.

Vertical or horizontal?

From the point of view of the physical processes occurring in the accumulator, its vertical or horizontal orientation does not matter. Choose a vertical or horizontal form factor based on the convenience of placing the equipment in a house or caisson. According to statistics, horizontal hydraulic accumulators are more often chosen for pumping stations due to ease of mounting. For borehole pumps - vertical, as they take up less space when installed in a caisson.

hydraulic accumulator horizontal and vertical

Hydraulic accumulator and expansion tank - what is the difference

Expansion tank

In appearance, the two containers under consideration are similar to each other. An expansion tank is used in a heating system; its main purpose is to compensate for excess pressure that occurs as a result of expansion of the heated liquid. During operation of the boiler, the temperature of the coolant rises, which leads to its expansion and increase in volume.

According to experts, heating water by just 10 degrees increases its volume by 0.3%. That is, a 50 degree difference in the coolant temperature readings before and after heating will increase its volume by 1.5%. Liquid doesn't compress; it has to go somewhere. This is what an expansion tank is used for.

The hydraulic accumulator is considered one of the main devices of the plumbing system. The main tasks of this device are to accumulate water in the system and maintain the required pressure. The presence of an additional reservoir allows you to reduce the number of starts of the pumping station, which will contribute to the long-term operation of the power plant.

The next important function of the membrane tank is to protect the water supply from water hammer. As you know, water hammer most often occurs when a pumping station is started or shut down, as well as when taps are suddenly turned off. A rubber bulb or membrane in a container allows you to balance the excess pressure that occurs in the system.

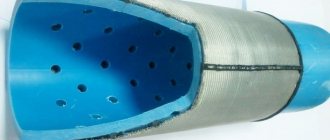

Vertical accumulator

Despite the fact that the expansion tank and the hydraulic accumulator are similar to each other, there are differences between them, and significant ones. The design of the hydraulic accumulator has a special membrane or bulb, which is used to compensate for pressure. The expansion tank also has a special partition that divides the container into two parts: the first is filled with water, the second with air. If oxygen and liquid come into contact in the heating expansion tank, then in the hydraulic accumulator the contact of these two substances is unacceptable.

Recommendations for use

In order for the water battery to last as long as possible, you must follow the rules of its operation and carry out maintenance on time. It is recommended to check monthly whether the relay settings have been lost and, if necessary, adjust them. At the same time, you need to inspect the device for external damage to the housing, leaks of seals and couplings.

The most common malfunction with hydraulic accumulators is a rupture of the rubber membrane. This can happen due to a sharp surge in pressure during injection, or due to wear and tear of the material from long-term use. Loss of membrane tightness will immediately affect the water pressure in the water supply network. It will drop sharply or begin to jump, either increasing or falling to almost zero.

A membrane rupture can only be confirmed by disassembling the tank body. At the same time, a new rubber partition is being installed between the internal battery compartments. The whole process looks like this step by step:

- The hydraulic accumulator is disconnected from the water supply system.

- The bolts securing the neck or the two halves of the tank (depending on the model) are unscrewed.

- The old membrane is removed and replaced with a whole one.

- The body is assembled in the reverse order, the bolts are tightened tightly.

- The device is reconnected to the water supply and put into operation.

- The relay is checked to see if the settings have been lost during the repair work.

This is a general repair principle; the specific nuances of replacing the membrane may vary for different modifications of the tank.

How to choose

Only a properly selected hydraulic tank will help you use your plumbing system correctly. In practice, two containers are used: membrane and hydraulic. The first reservoir contains a rubber capsule, which is inflated to a certain volume under water pressure.

The second part of the tank contains compressed air. During operation of the system, liquid is squeezed out due to compressed air. The second type of hydraulic accumulator is identical in principle; here the space between air and water is separated by a special elastic membrane.

Note! When selecting the device in question, preference should be given to the balloon version. In such a tank, the capsule does not come into contact with the metal walls of the container.

Variety of hydraulic accumulators

When choosing a device for an autonomous water supply, it is necessary to calculate the family’s water needs. During a power outage, there may be a varying amount of water in the device (the volume increases as the overall dimensions of the tank increase). When purchasing a hydraulic tank, pay attention to the following important details:

- Regardless of the volume of the tank, the bulb will only take up half of the tank. For an autonomous system used in a private home, a tank with a capacity of 80-100 liters is suitable. This volume is enough for continuous operation of a pumping station with a capacity of 30 l/hour. In this case, the device will turn on no more than 30 times per hour;

- Focus on maximum water consumption when all family members use it at the same time;

- A 100-liter hydraulic accumulator will allow you to maintain a sufficient supply of water after a power outage.

To ensure maximum efficiency of the device, it is located in close proximity to the well.

Hydraulic tank type

There are two types of such devices on the market:

- vertical;

- horizontal.

Horizontal tank

There are no fundamental differences in their work. The main difference is in the layout. Therefore, first of all, you need to focus on the convenience of placement in the room. After all, you need to take care not only of installation - in the future the container will need to be maintained, which means it must be easily accessible.

Another point is the release of accumulated air. In vertical type models, a special valve is provided, located at the top of the tank. And for horizontal ones, you will have to install an additional tap.

However, the main thing is to make sure that the chosen model generally has such an opportunity. After all, if the tank does not provide a special outlet for releasing air accumulated during the operation of the system, it can only be removed by completely draining all the water from the tank.

Gilex crab 50

The design feature of the model is that it can be mounted to the wall using brackets included in the kit. Weight of 10 kg and small dimensions allow installation without the assistance of assistants. The equipment is designed to operate in 5.5 bar systems. The model is not intended for hot water supply - the maximum water temperature should not exceed 35 degrees.

The 50-liter Gilex hydraulic accumulator is equipped with automatic equipment to control the pump, maintain the set pressure and water pre-filtration cartridges. The kit includes a built-in relay, a pressure gauge, a platform for monitoring the cartridge replacement time, a check valve and a ball valve.

Advantages:

- No adjustment of the pump or other equipment is required;

- Connection to the highway in any convenient place;

- Service life 10 years;

- Does not depend on the direction of water flow;

- Butyl rubber membrane.

Flaws:

- Volatility - automation requires electricity;

- Short electrical cable.