To obtain a durable floor covering, it is necessary to prepare a high-quality base, which is most often a concrete screed. To ensure the strength of the screed, you need to use reinforcement, but not everyone can afford to lay expensive metal reinforcement.

Thanks to the development of technologies for the production of building materials, an original and effective replacement for metal mesh for reinforcing concrete foundations has emerged - light and cheap fiber fiber. Now, to organize a solid base for the finishing coating, you can use a fiber cement floor screed, the technology of which is simple and accessible to any home craftsman.

Fiber fiber is produced in the form of thin (approximately 20 microns in thickness, 6 to 20 mm long) rods made of various materials: polypropylene, metal, fiberglass and basalt. Reinforcing fibers are used not only to organize screeds, but also to strengthen plaster mixtures, to give greater strength to concrete products, and to tighten fractions in the road surface.

By following the technology for preparing cement-sand mortar with fiber, a material is obtained in which the binding fibers are evenly and multidirectionally distributed throughout the entire volume, which makes it possible to obtain unique strength characteristics of the finished product.

The different fiber lengths are determined by the purpose of the concrete mixture. So, for brickwork, 6 mm long fiber is added to the mortar, for pouring screed - 12 mm, and for concrete mortars intended for use in difficult conditions, fiber up to 20 mm long is used.

What is it and why is it needed

Fiber fiber, or simply fiber, is a reinforcing additive in various building mixtures and solutions. By adopting a chaotic arrangement inside the concrete, it improves its quality characteristics, such as abrasion, strength, etc. In addition, fiber-fiber concrete better resists bending and tensile loads. All this is very important for floor screed.

Fiber is very strong thin fibers ranging from 6 mm to 20 mm in length. The size of reinforcing additives affects the characteristics of concrete differently, so the following is used:

- 6 mm - in mortars for cladding and masonry;

- 12 mm - screeds and various monolithic concrete products;

- 18-20 mm - in structures operated in extreme conditions, for example, dams.

It is produced in the form of crumbly material from glass, metal, basalt and polypropylene. It begins to influence the screed already at the stage of mixing the solution - it actively influences future physical and chemical processes that will begin after pouring, in two directions at once.

1. A solution with reinforcing additives requires less water to completely mix. Consequently, during the hydration process, the screed will gain strength faster, and excess moisture will not actively evaporate, forming microvoids and a network of small cracks.

Illustration of fiber distribution inside concrete.

For information: in any solution there are voids. In a traditional mixture of cement and sand, they are filled with water; in a reinforced mixture, they are filled with fibers. Therefore, you need less water up to 20%.

2. By filling all voids after pouring, fiber fiber prevents the formation of microcracks in the first 5-7 hours of setting of the solution.

For information: at the initial stage of hydration, internal stresses appear in the pouring body due to micropores and different rates of hardening, which manifests itself in a network of cracks on the surface of any concrete product. The use of reinforcing fibers allows, firstly, to fill voids and, secondly, to evenly distribute moisture inside the concrete product, as a result of which the hardening process proceeds evenly, which reduces internal stresses to zero.

At the second stage of hydration, when ordinary concrete begins to shrink and cracks appear, the fiber fibers hold the screed in its original dimensions, as a result of which cracks do not form. If they do appear, then due to the multidirectional effect of the reinforcing fibers on the concrete surface, the resulting gaps between the cement particles are tightened.

Polypropylene fiber for screed

We have already talked about the main properties of polypropylene fiber for concrete reinforcement. We found out how fiber is useful for concrete and mortars, how it improves their qualities. But at the same time, let’s not forget that in addition to reducing the formation of microcracks, imparting flexibility and improving the intrinsic properties of the concrete composition, microfiber does not play a global role and does not replace real reinforcement.

Waterproofing impregnations and additives for concrete: how to make concrete waterproof

If you pour concrete on a rigid base, it will lie flat and dry without cracks (if the technology for preparing the solution is followed). It is useful to add microfiber as a safety net in cases where soft material (heat or sound insulation) is laid underneath.

It is good to use polypropylene fiber to make the surface abrasion resistant. It also helps make the surface smoother.

Advantages of use and disadvantages

The inclusion of fiber fiber in the cement-sand composition gives the screed significant advantages over the classic version of the mortar.

- In concrete, fiber acts as a reinforcing element, which increases its strength and elasticity. It can withstand increased loads from above, both dynamic (impacts, resonant vibrations) and static (high specific pressure per 1 m2), and from below (shrinkage of the house, rise of soil under the influence of severe frosts).

- The random arrangement of fibers, in contrast to traditional reinforcement methods, keeps concrete from delamination. This is facilitated by the property of fiber to evenly distribute moisture throughout the entire screed layer during hydration - explosive spalling of concrete due to uneven setting and hardening is reduced.

- The resistance of concrete to freeze/thaw cycles increases, as a result of which it can be used in areas with frequent temperature changes, where pure mixtures of cement and sand are not recommended.

- The service life of the floor increases.

- The use of fiber in a wet screed prevents its shrinkage. There are two reasons:

- reinforcing fibers do not allow microvoids to form in the solution;

- the amount of water for the setting process is reduced (the level of moisture in the solution directly affects its sediment upon drying).

- During the strengthening process, the fiber relieves internal stress in the screed layer.

High-quality fiber has no disadvantages. Problems can only arise with polypropylene fiber produced in violation of technology. Over time, it begins to release toxic substances that negatively affect the health of people living in the house or apartment. To avoid this, be sure to check the availability of a certificate for the building material you purchase.

Reviews

Concrete with added fiber is perfect for domestic construction needs. According to customer reviews, this material allows, in some way, to eliminate the use of reinforcement in screeds. But at the same time, many note that the quality of the product depends on the type of fiber used and the manufacturer.

Some use fiberglass to form screeds, while large companies build industrial floors that resist cracking.

Fiber fibers are an excellent opportunity to extend the life of floors by minimizing the thickness of the concrete layer.

To learn how to screed a floor with the addition of fiberglass, see the following video.

Types of fiber fiber and their characteristics

The industry produces several types of fibers with different physical properties and prices.

Fiberglass

Fiberglass is made from zirconium. It is a complex thread with a thickness of 8-10 microns from several very thin fibers. Has a length of up to 12 mm. The material is environmentally friendly, not subject to rotting and corrosion.

Mainly used for reinforcing gas and foam concrete, for finishing work (plastering walls), for the production of lightweight cladding slabs, decorative sculptural and architectural products, sound barriers, etc. Its peculiarity compared to other types of fiber is that when a reinforced mortar less than 3 cm thick sets, cracks and delamination do not form.

Fiber glass.

Fiberglass is also used for floor screeds, but not much, due to the lower strength of the screed compared to other types of fiber (the bending and tensile strength of concrete increases by 3-5 times, impact strength by 10-12 times). Its main purpose is plaster mixtures.

Due to the complexity of manufacturing and the high cost of the charge from which it is produced, glass fiber belongs to the middle price category (100-130 rubles / kg).

Attention: due to the high fragility of glass fiber, it cannot be used in masonry mortars and finished monolithic concrete products.

The optimal consumption per 1 m3 of solution is 900 g.

Steel fiber

Made from high-carbon wire with a diameter of 0.2-1.2 mm and a length of 5 mm-15 cm. Used in industrial construction and factory production of monolithic reinforced concrete structures, mainly for fortifications and hydraulic structures, bridge spans, airport buildings and runways .

Metal fiber.

In housing construction, it has found application in self-leveling and seamless floors. It is practically not used for screeds, since in thin-layer concrete (up to 4 cm) it promotes the formation of local gaps of 1-3 microns due to different expansion coefficients with temperature changes, which over time grow to microcracks.

Reinforcement with steel fiber allows:

- reduce labor intensity by 27%;

- reduce the total cost of products by 5-7%;

- increase bending strength by 2 times, tensile strength by 20 times.

The disadvantages include the high sound conductivity of the reinforcement elements, as a result of which the sound absorption coefficient of the screed is reduced. The cost of metal fiber is very low and amounts to 25-40 rubles. for 1 kilogram. Consumption per 1 m3 - 25-50 kg.

Basalt fiber

It is a short fiber with a thickness of 20-500 microns and a length of 1-150 mm, obtained by melting basalt rocks up to 1400 degrees. This is the best reinforcing material used in construction. Its use increases the strength of concrete:

- impact - 5 times (this indicator characterizes the fragility of concrete and is estimated by the amount of work that is necessary to destroy it);

- for bending - 3 times;

- for splitting - 2 times;

- compression and stretching - 1.5 times.

- frost resistance - 2 times.

In addition, the following are improved:

- water resistance - 1.5 times;

- abrasion resistance - up to 3 times.

As a rule, it is not used in floor screeds, although the price, compared to the widely used polypropylene fiber, is much lower (145-200 rubles/kg). Considering that its consumption per 1 m3 is slightly higher than that of polypropylene fiber, the final overpayment for basalt fiber for an apartment will be in the region of 1.0-1.5 thousand rubles. True, many of the positive qualities of basalt fiber are simply not needed there.

Basalt fiber.

When purchasing a screed, you need to focus on a consumption of 0.6-2.3 kg/m3.

Propylene fiber fiber

Modern reinforcing material made of granular high-modulus thermoplastic polymer. It is obtained by pressing a viscous mass of polypropylene through the finest holes (the technological process is called “extrusion”), followed by stretching along (structural modification). White fibers have a length from 6 mm to 2.0 cm, a diameter of 15-20 microns. It should be noted that the commercial fiber sizes in one package are conditional, which is determined by the technological process.

The use of polypropylene fiber in concrete improves its strength indicators slightly:

- for tension and compression - 0.6 times;

- for bending - coefficient 1.0.

Polypropylene fiber.

The advantages include increased sound insulation of reinforced concrete. In the ranking of reinforcing materials, synthetic fiber takes last place in all physical and chemical indicators without exception. However, for floor screeds and plastering work this is quite enough.

It is also not used in concrete products due to its short service life - the fibers age and lose strength. In the price segment it is in the high price category (220-240 rubles/kg). 600-900 g are consumed per 1 m3. For ease of calculation, it is produced in bags of 600 g, packed in bags of 10, 20 or 30 pieces.

Impact resistance

Fiber fiber provides the solution with the greatest resistance to impact and other mechanical damage. According to tests, fiber reinforced concrete is five times more impact resistant than conventional concrete.

Fiber fiber provides concrete with plasticity, which makes it less brittle and brittle. Such concrete is more resistant to impact due to the greater amount of energy that is absorbed during the tension of the fibers formed after cracks appear in the mortar.

Impact resistance allows fiber fiber to be used in heavy industry, in the construction of buildings in areas of high seismic activity, etc.

Calculation of fiber consumption

When calculating the amount of fiber for a floor screed, for some reason the opinion has been established that the quality characteristics of concrete are determined by the weight of the reinforcing material. This is an extremely erroneous opinion. Two factors influence:

- number of fibers per m3 of solution;

- quality characteristics of fiber for elasticity, stretching, etc.

Therefore, the higher the density and elasticity, the less reinforcing material is needed. The number of fibers has a greater influence on the process of crack formation on the surface of the screed - the more there are, the more effectively they are tightened during the hydration of concrete.

Based on the above, it should be clearly understood: the fiber consumption given in construction reference books applies only to polypropylene. In other species it is completely different.

A table of fiber consumption can be made per cubic meter of solution and per 1 m2 of screed, but only for 1 cm of the thickness of the fill (it is not difficult to continue the calculation yourself - the consumption rate per 1 m2 is multiplied by the area of the room and the height of the screed in cm).

When calculating the table, we proceeded from the optimal fiber consumption specifically for floor screed. In this case, we were guided by the results of studies of the influence of the amount of polypropylene fiber in 1 m3 of solution on the quality characteristics of concrete:

- 300 g - improves the plasticity (fluidity) of the solution, i.e. acts as a simple additive;

- 600 g - increases the strength of concrete, sufficient for screeding;

- 900 g - the maximum possible resistance to bending, stretching and compression is achieved.

Table: Optimal fiber consumption when pouring screed.

| Fiber consumption | Per 1 m3 of solution | Per 1 m2 area |

| Types of fiber in grams | ||

| Fiberglass | 900 | 9 |

| Metal fiber | 35000 | 350 |

| Basalt fiber | 1500 | 15 |

| Polypropylene fiber | 600 | 6 |

Based on the table above, you can calculate the average cost of fiber per 1 m2. Fiber fiber for floor screed, consumption per m2 in rubles:

- fiberglass - 1.08 rubles;

- metal fiber - 10.50 rubles;

- basalt fiber - 2.40 rubles;

- polypropylene fiber - 1.38 rub.

In terms of price factor, glass fiber is the leader, but the difficulties in its use, especially when stirring the solution, have made synthetic fiber fiber the most popular.

conclusions

Reinforcing the floor screed with fiber fiber is very convenient. Firstly, this allows you to qualitatively strengthen it. Secondly, it is much more convenient, since the fibers are distributed over the entire surface of the solution. What is most important: the cost of fiber fiber is several times less than welded steel mesh, and it is more convenient to work with. Fibers can be added in different proportions depending on the requirements for the screed; it is possible to carry out the filling work yourself. In addition, it is not difficult to do, the main thing is to go through all the stages. This will allow you to get a good, strong and durable floor that will cost “cheap and cheerful.”

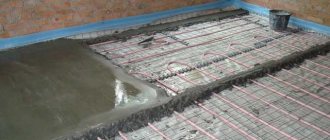

Materials, tools, equipment

Compared to the conventional process, semi-dry screed with fiber fiber looks more attractive - it is simpler. For work you will need to prepare the following materials:

- Portland cement M400 (M500);

- sand, preferably river sand, since quarry sand will have to be sifted and washed to remove clay;

- fiberglass;

- plasticizer, its replacement is liquid soap;

- damper tape;

- plastic film.

A master cannot do without some items, tools and equipment. You need to have on hand:

- painting strip (twine rubbed with chalk);

- guides - beacons;

- rule;

- construction pencil;

- roulette;

- level: hydraulic or laser (preferably the latter);

- concrete mixer;

- concrete shoes;

- large capacity for solution;

- trowel;

- trowel (trowel);

- bubble level;

- putty knife.

Purpose

Fiber fiber is a universal construction filler that is used only as additives.

The main purpose of fiber is to create durable concrete surfaces that can withstand certain types of loads. The substances can be used with several types of cement mixtures, including aerated concrete, foam concrete and sand concrete.

In domestic construction, fiber fibers can be added to the screed for the purpose of additional reinforcement. Some varieties are added to plasters. But technically, fiber does not produce results without a binding component, which is cement.